tbs electronics ATP1-120 User manual

www.trianglebiomedical.com

INNOVATIONS FOR SCIENCE™

TRIANGLE BIOMEDICAL SCIENCES, INC.

3014 CROASDAILE DRIVE • DURHAM, NC 27705-2507 • USA • 919.384.9393 • FAX 919.384.9595 • E-MAIL: [email protected]

ATPTissue Processor

Catalog # ATP1-120, ATP1-220

Operations Manual

Version 5.3, May 2006

Be certain to read this manual thoroughly

before proceeding with unpacking and installation.

ii

WELCOME

Thank you for selecting the ATPAutomated Tissue

Processor. This instrumentwas carefully designed to be easy

to use, safe to operate and capable of producing consistent,

quality results. The embedded Personal Computer affords

you the flexibility and reproducibility required by the modern

laboratory. The built-in software safety features protect you

(the operator) while its internal electronic sensors protect the

instrument’s critical components. The ability to optimize each

step of every program will allow you to create programs that

yield excellent reproducible results consistently.

The employees of TBS thank you for your support. Feel free

to call TBS customer service at 919-384-9393 or e-mail us

TBS Corporate Headquarters

Phone: 919-384-9393

Fax: 919-384-9595

E-mail: [email protected]

Web: http://www.trianglebiomedical.com

Product Service Department

Phone: 919-384-9393

E-mail: [email protected]

iii

TABLE OF CONTENTS

INTRODUCTION.....................................................................................................1

CHAPTER 1 –GENERAL INFORMATION..............................................................2

1.1 –Regulatory Compliance..................................................................................2

1.2 –Patents, Trademarks and Specifications........................................................2

1.3 –Symbols and Conventions..............................................................................3

1.4 –Abbreviations and Units of Measure...............................................................4

1.5 –Safety Precautions .........................................................................................5

CHAPTER2–UNPACKING,PACKINGANDTRANSPORTING.........................................7

2.1 –Unpacking.......................................................................................................7

2.2 –Packaging and/or Preparation for Transport ..................................................8

2.3 –Transportation ................................................................................................8

CHAPTER3–INTRODUCTIONTOTHEATPPROCESSOR..........................................9

3.1 –General Features............................................................................................9

3.2 –Front View ....................................................................................................10

3.3 –Rear Panel & Floppy Drive...........................................................................11

Floppy Drive.......................................................................................................11

CHAPTER 4 –REAGENTS...................................................................................12

4.1 –Compatible Reagents...................................................................................12

4.2 –Incompatible Reagents.................................................................................13

CHAPTER5–INSTALLATIONANDOPERATIONALQUALIFICATION.................................14

CHAPTER 6 –PREPARATION FOR OPERATION...............................................16

6.1 –Filling Reagent Bottles .................................................................................16

6.2 –Filling Paraffin Bottles...................................................................................17

6.3 –Installing Charcoal Bottles............................................................................18

CHAPTER 7 –FIRST RUN PROGRAMMING.......................................................19

7.1 –Introduction...................................................................................................19

7.2 –Language......................................................................................................19

7.3 –Main Menu....................................................................................................20

7.4 –Reagent Labels ............................................................................................21

7.5 –Program Label..............................................................................................22

iv

7.6 –Hour and Date..............................................................................................23

7.7 –Purge Reagents Limits Setting.....................................................................23

7.8 –CCW (Paraffin Oven) Temperature Setting..................................................24

7.9 –Charcoal Filter Limit Setting.........................................................................24

7.10 –WPC (Wax Purification Cycle) ...................................................................25

Activation / Deactivation........................................................................................25

7.10.1 –Manual Start of the WPC.........................................................................26

7.11 –RMS Activation...........................................................................................26

CHAPTER 8 –PROGRAMMING PROCESSES....................................................27

8.1 –Programming Processes...............................................................................27

Reagent .............................................................................................................28

Time...................................................................................................................28

Temp..................................................................................................................28

P/V .....................................................................................................................28

Agit.....................................................................................................................29

8.2 –Process # 13: Reversed ...............................................................................29

CHAPTER 9 –REAGENT MANAGEMENT SYSTEM (RMS)................................30

9.1 –Introduction...................................................................................................30

9.2 –Choosing the RMS Mode..............................................................................31

9.2.1 –RMS Single Mode Description and Example.............................................32

9.2.2 –RMS Group Mode Description and Example.............................................33

Example Group Mode Sequence.......................................................................34

9.3 –RMS –Programming Reagents Definition....................................................36

Single Mode.......................................................................................................36

Group Mode.......................................................................................................36

9.4 –RMS –Programming Limits Definition..........................................................37

Single Mode.......................................................................................................37

Group Mode.......................................................................................................37

9.5 –RMS –Counters Total Reset........................................................................38

RMS –Single Counter Reset.............................................................................38

9.6 –RMS On / Off................................................................................................39

9.7 –Printing Menu ...............................................................................................39

CHAPTER 10 –NORMAL OPERATION ...............................................................41

10.1 –Loading Samples into the Basket...............................................................41

10.2 –Checks and Procedures before Operating.................................................41

v

10.3 –Selecting a Program...................................................................................42

10.4 –Setting the Program Completion Time/Date...............................................43

Setting Delay......................................................................................................44

Programming Completion Times........................................................................44

Midweek holidays...............................................................................................45

Starting from step other than the first.................................................................45

Runtime Test Aborting Run................................................................................45

10.5 –Starting a Procedure...................................................................................46

10.6 –Interrupting the Process .............................................................................47

10.7 –Opening the Retort During a Program........................................................48

10.8 –Process Completion....................................................................................48

10.9 –Cleaning the Retort (Purge Cycle)..............................................................49

CHAPTER 11 –ALARMS......................................................................................51

11.1 –Managing Alarms........................................................................................51

Non-Blocking Alarms..........................................................................................51

Blocking Alarms .................................................................................................51

11.2 –Non-Blocking Alarms..................................................................................52

1 -BLACK OUT..................................................................................................52

2 -RETORT T°LOW .........................................................................................53

3 -SHORT DRAIN.............................................................................................53

4 -P/V TIMEOUT...............................................................................................53

5 -FULL FILL P .................................................................................................53

6 -FULL FILL S .................................................................................................53

7 -FILE NOT FOUND........................................................................................54

8 -LONG DRAIN................................................................................................54

9 -T° WAX LOW................................................................................................54

11.3 –Blocking Alarms..........................................................................................54

11 -FILL NO VACUUM......................................................................................54

12 -FILL TIME OUT ..........................................................................................55

13 -OVER FILL S..............................................................................................55

14 -OVER T°RETORT .....................................................................................55

15 -TSC OUT....................................................................................................55

16 -SHORT FILL...............................................................................................55

17 -VR OUT ......................................................................................................55

18 -FILE NOT FOUND......................................................................................56

19 -RETORT T° LOW .......................................................................................56

20 -WAX T° LOW..............................................................................................56

21 -OVER T° WAX............................................................................................56

22 -TSW OUT ...................................................................................................56

23 -PRESSURE N.R.........................................................................................56

24 -DRAIN NO PRESS .....................................................................................57

vi

25 -DRAIN TIME OUT.......................................................................................57

26 -RET. NOT EMPTY......................................................................................57

27 -OVER FILL P..............................................................................................57

30 -COM ERROR [FRAME]..............................................................................57

31 -COM ERROR [PARITY]..............................................................................57

32 -COM ERROR [OVERRUN].........................................................................58

33 -COM ERROR [TIMEOUT] ..........................................................................58

39 -COM ERROR [LINE OR PORT DOWN].....................................................58

40 -ELODEV LACK...........................................................................................58

50 -OVER PRESSURE.....................................................................................58

51 -OVER VACUUM .........................................................................................59

52 –PS BREAK –HIGH ....................................................................................59

53 –PS BREAK –LOW.....................................................................................59

11.4 –Alarms Historical Archive............................................................................59

11.5 –Instrument Reset ........................................................................................60

CHAPTER 12 –SERVICE MENU..........................................................................61

12.1 –End User Service Tests..............................................................................61

Vacuum test.......................................................................................................61

Pressure Test.....................................................................................................62

Retort Heating....................................................................................................62

Runtime Test......................................................................................................62

Edit Setup...........................................................................................................62

Reset Flag..........................................................................................................62

Alarms Reset......................................................................................................62

12.2 –Service Menu Abbreviation List..................................................................63

12.3 –Service Assistance.....................................................................................63

CHAPTER 13 –SAFETY FEATURES...................................................................64

13.1 –Protection against Overheating..................................................................64

13.2 –Protection against Excess Pressure...........................................................64

CHAPTER 14 –INSTRUMENT MAINTENANCE ..................................................65

14.1 –Daily Maintenance......................................................................................65

14.2 –Monthly Maintenance .................................................................................65

14.3 –Paraffin Wax Purification Cycle..................................................................65

14.4 –Charcoal Filters Replacement....................................................................66

14.5 –Retort Lid Gasket Replacement..................................................................66

14.6 –Fuse Replacement......................................................................................67

CHAPTER 15 –ACCESSORIES...........................................................................68

15.1 –Printer.........................................................................................................68

vii

15.2 –Remote Alarm and Auto-dialer ...................................................................69

APPENDIX 1 –ACCESSORIES AND SPARE PARTS..........................................70

APPENDIX 2 –ATP™ TECHNICAL DATA SHEET...............................................71

APPENDIX 3 –ATP™ FEATURES.......................................................................72

APPENDIX 4 –ATP™ PROGRAM MENU FLOW.................................................73

CONTACT INFORMATION ...................................................................................74

1

INTRODUCTION

Thank you for purchasing an ATP. The instrument was designed by experienced

engineers with the input of service and laboratory technicians.The number one

priority was to produce the most dependable tissue processor on the market. After

getting to know your instrument, we trust that you will agree. As always, TBS®

sincerely welcomes your suggestions for any improvements.

2

CHAPTER 1–GENERAL INFORMATION

Before using the instrument, please make certain that you carefully read this manual.

Pay particular attention to the precautions that must be taken for user and product

safety.

The ATPis an automatic tissue processor for laboratory use. It should only be

used for routine processing of histological tissue samples.

To avoid potential instrument damage, do not use different reagents from those

specified in Chapter 4.

The instrument should only be operated by qualified technicians.

The warranty applies only if the instrument is used in the correct manner and in

accordance with the information and advice provided herein. The manufacturer

declines all responsibility for possible damages to persons and/or objects due to

improper or inexperienced use of the instrument.

1.1 –REGULATORY COMPLIANCE

SAFETY / QUALITY STANDARDS

The ATP™has been tested by a registered independent body to rigorous

international quality and safety standards, and has been found to be in compliance

with the following regulations/specifications:

UL 61010A

CSA 1010-1

CE EN/IEC EN61010-1, Safety

EN61000-3-2, Harmonic Distortion

EN55011, Emissions

EN61326, Immunity

EN61000-3-3, Voltage Fluctuation/Flicker

1.2 –PATENTS,TRADEMARKS AND SPECIFICATIONS

Prices and specifications are current at time of publication; however, they are subject

to change without notification. Please contact our North Carolina office or one of our

distributors for current prices and availability. ATPand Innovations for Science

are trademarks and TBS is a registered trademark of Triangle Biomedical

Sciences, Inc., Durham, NC U.S.A.The ATP has certain features that are covered

3

under Patent # US 6,780,380 B2.

1.3 –SYMBOLS AND CONVENTIONS

Do not use free flame near the instrument

No smoking near the instrument

Recyclable

High voltage

Important safety notice

Important operation information

4

1.4 –ABBREVIATIONS AND UNITS OF MEASURE

ABBREVIATIONS

A/D Analog/Digital Converter

CCW Paraffin Wax Heating Chamber

CdP Retort (Processing Chamber)

MdC Control Module

MV Main Valve

PMP Air Pump

PNV Ambient Valve

PV1 Pressure Valve

SdO Overfill Sensor

SdP Rotating Valve Position Sensor

SGR Reagents Management System

VR Rotating Valve

VT Vapor Trap

VV1 Vacuum Valve

WPC Paraffin Wax Purification Cycle

Retort Processing chamber

UNITS OF MEASURE

Bar Pressure unit of measure

mBar Millibar; 1000 mBar = 1 Bar

WPower unit of measure; Watt

ΩResistance unit of measure; Ohm

ACurrent unit of measure; Ampere

VVoltage unit of measure; Volt

5

1.5 –SAFETY PRECAUTIONS

Carefully follow the installation instructions:

•Severe damage can result if the instrument is connected to a power supply

different from that stated in the manual and on the identification tag at the rear

of the instrument.

The instrument must NEVER be used without being connected to an

appropriate ground. If damages due to transport occur, DO NOT use

and DO NOT connect the instrument to a power source. Contact TBS

technical service.

•This instrument has been designed to work 24 hours a day; for this reason

and for operative precautions, the power switch is placed at the rear of the

instrument, on the right-hand side at approximately the same height as the

screen in the front.

•Always make certain to correctly engage the reagent bottles.

NEVER use ACETONE, BENZENE, or TRICHLOROETHANE.

•Fixatives with mercury salts, acetic or picric acid may corrode metal. We

strongly advise against their use.

•DO NOT open the Retort lid when the instrument is working without having

previously followed the instructions contained in this manual.

•Use specific precautions in handling flammable reagents such as ethanol.

•Use specific precautions in handling liquid paraffin waxes as they can cause

burns.

•The emptying and filling of reagent bottles must only be done by qualified

personnel.

6

•Due to the presence of flammable substances inside reagent bottles, it is

recommended to:

Avoid smoking near the instrument.

Avoid using open flames near the instrument (e.g. Bunsen burner).

•DO NOT wear clothes that are prone to create electrostatic charges while

handling reagents (wool, synthetic fibers, etc.).

•Contaminated reagent waste must be disposed of in accordance with all

applicable laws and ordinances.

•Access to the instrument’s internal components is reserved only to those

specialists trained in the service of the instrument.

Always disconnect the processor from the electrical source before

accessing the electronics.

•Only original spare parts sold by the manufacturer or by authorized dealers

are recommended for the instrument.

BEFORE replacing fuses, disconnect the instrument from the power

source.

DO NOT extract bottles, replace reagents or do other maintenance

operations when the instrument is operating.

7

CHAPTER2–UNPACKING,PACKINGANDTRANSPORTING

Before moving or transporting the instrument, it is essential to carefully read this

chapter, paying particular attention to the instrument setup instructions.

The warranty is invalid if the instrument is improperly operated. Be certain to follow

the instructions and recommendations provided by this manual. The manufacturer is

not responsible for damages resulting from improper operation or handling of the

instrument. If the crate is damaged, inform the driver and get written

acknowledgment of the damage on the delivery truck or you may forfeit any rights for

damage recovery.

Pay particular attention to the outside of the shipping container. In the event of

concealed damage, save all shipping crates and packing material. DO NOT unpack

the instrument if damage is apparent. Immediately notify the carrier of any damage

and contact the shipper to initiate any claims.

2.1 –UNPACKING

The proper steps to be taken for unpacking are:

1) Open the rear of the box.

2) Remove the screws securing the top.

3) Remove screws and nails securing the wooden sides to the base of the box.

4) Lift the side walls out of the way.

5) Raise the instrument to the vertical position as you move it off of the wooden

pallet.

6) Remove the plastic layers that wrap the instrument.

7) Remove the nylon bag that contains the instrument.

8) Carefully check the external condition of the instrument. In the event of

concealed damage, DO NOT plug in the instrument. Immediately notify the

carrier and promptly contact the seller.

9) For the setup of the instrument, see the specific chapter in this manual.

10) Save the box and internal packaging for future shipment.

8

2.2 –PACKAGING AND/OR PREPARATION FOR TRANSPORT

To transport the instrument, perform the following steps:

1) Remove all reagents (paraffin included) from their bottles.

2) Remove and close, with the proper threaded cap, the charcoal filter bottles.

3) Transport the charcoal filter bottles separately from the instrument, wrapped

and securely closed in a protective nylon bag.

4) If the original box has been saved, follow the unpacking instructions in the

reverse order, using all the interior packaging to avoid serious damage to the

instrument during shipping.

5) Using the original box or another box adapted to carry the instrument

horizontally, lay the carton on its back after having properly wrapped and

packaged the instrument with care.

2.3 –TRANSPORTATION

Before shipping, please keep in mind that:

1) The instrument is very fragile.

2) The instrument is composed of electronic parts.

3) Contact with water and/or any other liquid is to be avoided; please ensure that

the internal plastic protection bag that wraps the instrument is utilized.

4) Transporting and storing temperature(s) must be between -10°C +50°C.

5) Using the original box, the instrument must always be transported

horizontally.

6) Transporting the instrument vertically could result in significant damage as its

center of gravity is quite high.

9

CHAPTER3–INTRODUCTIONTOTHEATPPROCESSOR

3.1 –GENERAL FEATURES

•The ATPtissue processor recycles the air utilized to move the reagents to

and from the Retort. Two effective charcoal filters on the external air-intake

reduce the exhaust fumes to acceptable levels.

•The control devices (hardware and software) are based on up-to-date

processing control technologies. A 9.5” backlit LCD touch screen display

makes the instrument easy and efficient to use.

•Up to 12 different programs can be permanently stored and can be easily

modified. A13th program is a special “REVERSED” program that is used to de-

process samples where further procedures are required.

•During a run, every step and action is displayed on the screen, such as current

step and function (emptying, filling, etc.), Retort and paraffin heating chamber

temperatures, Retort pressure, completion time and date.

•In the event of blackouts, the computer saves all the data necessary to restart

the process exactly where it was interrupted. If the interruption happens during

the paraffin stages, particular precautions are taken to guarantee melting of

the paraffin before any paraffin filling or emptying steps begin.

•The ATPhas 2 stainless steel baskets of identical dimensions. Each of the

baskets can hold from 125 cassettes (using the appropriate spring organizers)

up to 150 cassettes (without using spring organizers). The processing

capacity therefore varies from 250 cassettes (with organizers) up to 300

cassettes (without organizers).

Spring separators are recommended when processing medium to large tissue

samples to allow for good fluid exchange. Separators also impede the opening

of the cassettes when processing a small number of samples.

10

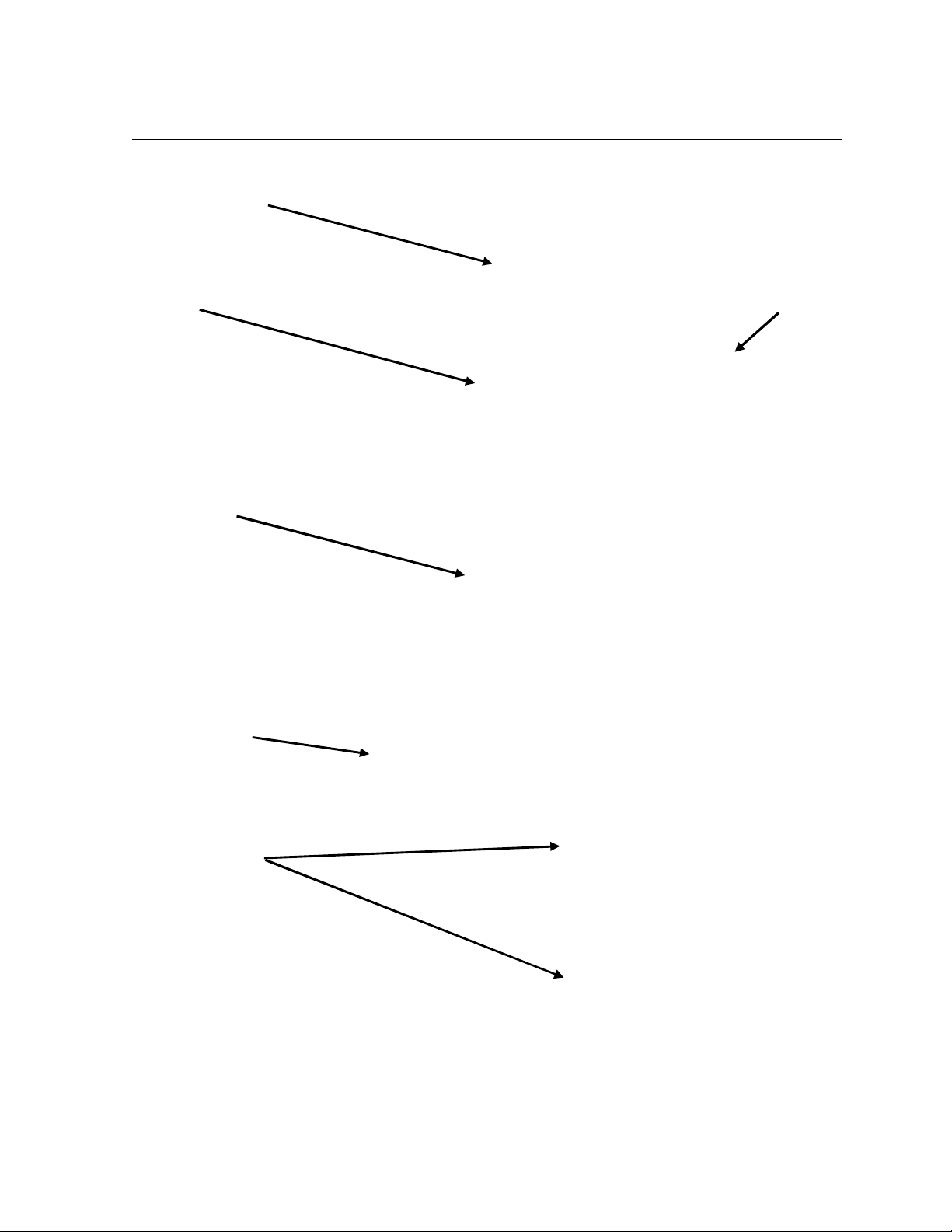

3.2 –FRONT VIEW

Tilting color touch

screen

Retort

Heated paraffin

chamber

(5 bottles)

Reagent bottle

chamber

Charcoal filter

bottles

Floppy

drive

11

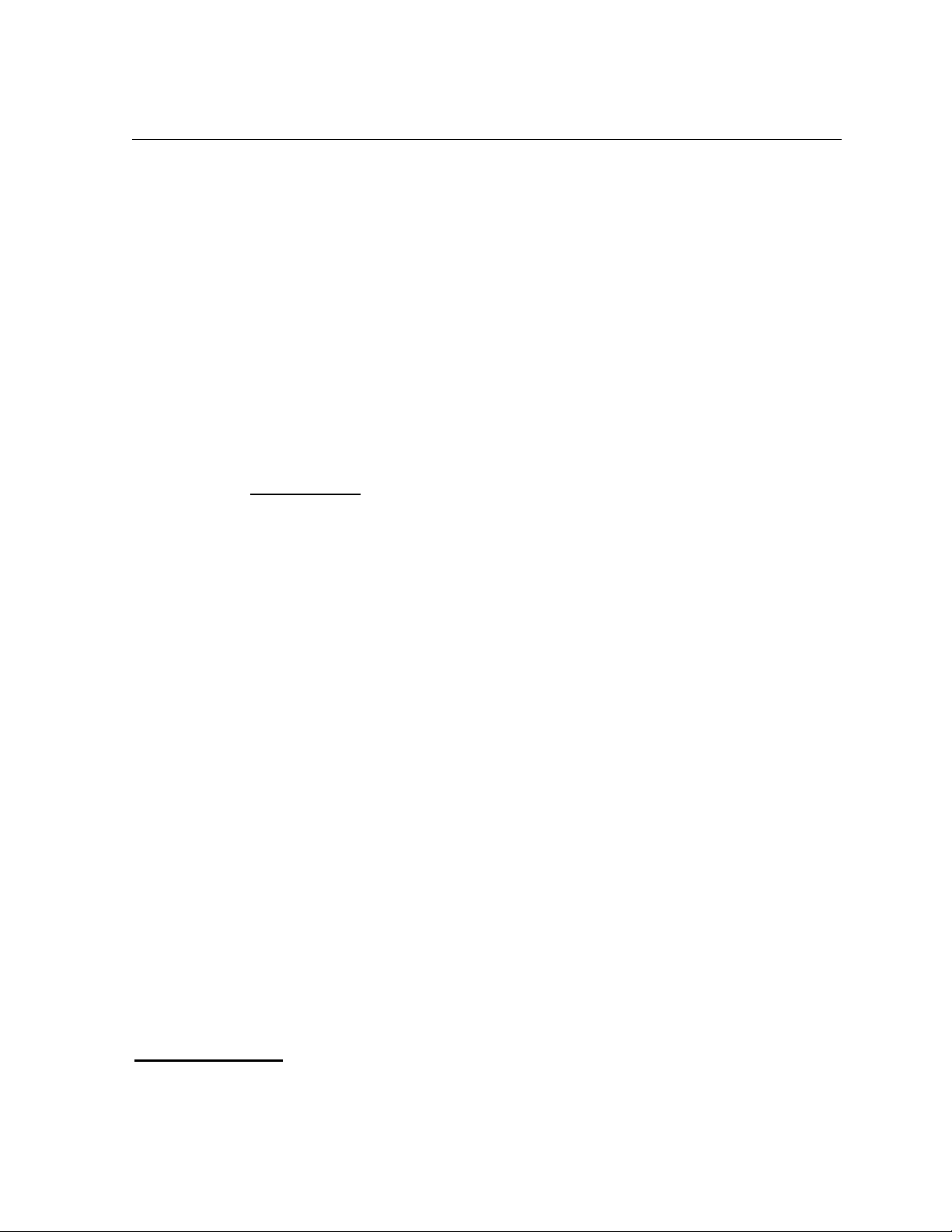

3.3 –REAR PANEL &FLOPPY DRIVE

On the rear panel of the control module there are:

A= On/Off main switch

B= Main power connection module

C= Fuse holder (2 x 10A fuses)

D = Keyboard Connector (for use by service technicians)

E= Remote Alarm socket:

No alarm = pins 1-2 closed, pins 1-3 open

Alarm = pins 1-2 open, pins 1-3 closed

Please note:The socket at “E” is a low voltage connection (maximum

48V, 6A) isolated from the rest of the instrument. An Auto Dialer or

other external alarm notification device can be connected here. The

device must output less than 48V, 6A or it will damage the alarm

relays.

F = RS-232 serial port

G= Reset button

Floppy Drive

The 3.5” floppy drive on the side of the ATP™ is only used by service technicians to

update the software.

A

F

G

B

C

D

E

C

1

2

3

12

CHAPTER 4–REAGENTS

4.1 –COMPATIBLE REAGENTS

The following reagents can be utilized in the ATPwithout any risk of damage:

•Water

•Formalin

•Ethyl alcohol (pure or denatured)

•Methyl alcohol

•Isopropanol

•Butanol

•Xylene

•Toluene

•Paraffin Wax

The following materials are used in the construction of the ATP. Reagents other

than those listed above can be utilized in the instrument if they DO NOT damage the

materials listed:

ØStainless steel Rotating valve, Retort and lid

ØTeflon Rotating valve, air pump

ØKynarflex Reagent pipes

ØViton Membranes

ØGlass Vapor trap

ØHDPE Paraffin and reagent bottles

ØNylon Connectors

ØTygon Air pipes

ØNickel-plated brass Air connectors, solenoid valves

The manufacturer is NOT responsible for damages due to the use of reagents NOT

listed here.

13

4.2 –INCOMPATIBLE REAGENTS

Below is a short list of well-known reagents that CAN DAMAGE the instrument. This

list is NOT complete. Before using reagents not explicitly noted in this manual,

please contact TBS®technical service for assistance.

ØAcetic Acid ØEthyl ether ØPicric acid

ØAcetone ØFlemmings Strong ØRossman’s fluid

ØAmyl acetate ØGendre fluid ØTetrahydrofuran

ØBenzene ØHelly’s fluid ØTrichloroacetic acid

ØBouin’s fixatives ØLittle’s alcoholic lead ØTrichloroethane

ØCarnoy’s fluid ØOlmacher fluid ØWeigirt lodine

ØCarnoy-Lebrum fluid ØOsmic acid ØZambini’s PAF

ØCedarwood oil ØParaformaldeide ØZenkers

ØChloroform ØPerfix

ØDioxane ØPetroleum ether

The manufacturer is NOT responsible for damages due to the use of the above

stated reagents.

WARNING: DO NOT use Acetone, Benzene or Trichloroethane. We

also advise against the use of fixatives containing mercury salts, acetic

or picric acid as they may corrode the metal components of the

instrument and shorten a component’s useful life.

This manual suits for next models

1

Table of contents

Other tbs electronics Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Benchmark Scientific

Benchmark Scientific Bioclave Operation manual

Steril-Aire

Steril-Aire DE 422 Panel Installation and operation instruction

Buchi

Buchi Lyovapor L-300 Guide for installation

Klein Tools

Klein Tools TI220 instruction manual

Biomeme

Biomeme Franklin three9 instructions

Thermo Scientific

Thermo Scientific iCAP 6000 Series Preinstallation manual