INDEX

1. INTRODUCTION .............................................................................................5

1.1. Vacuum packers models......................................................................................... 5

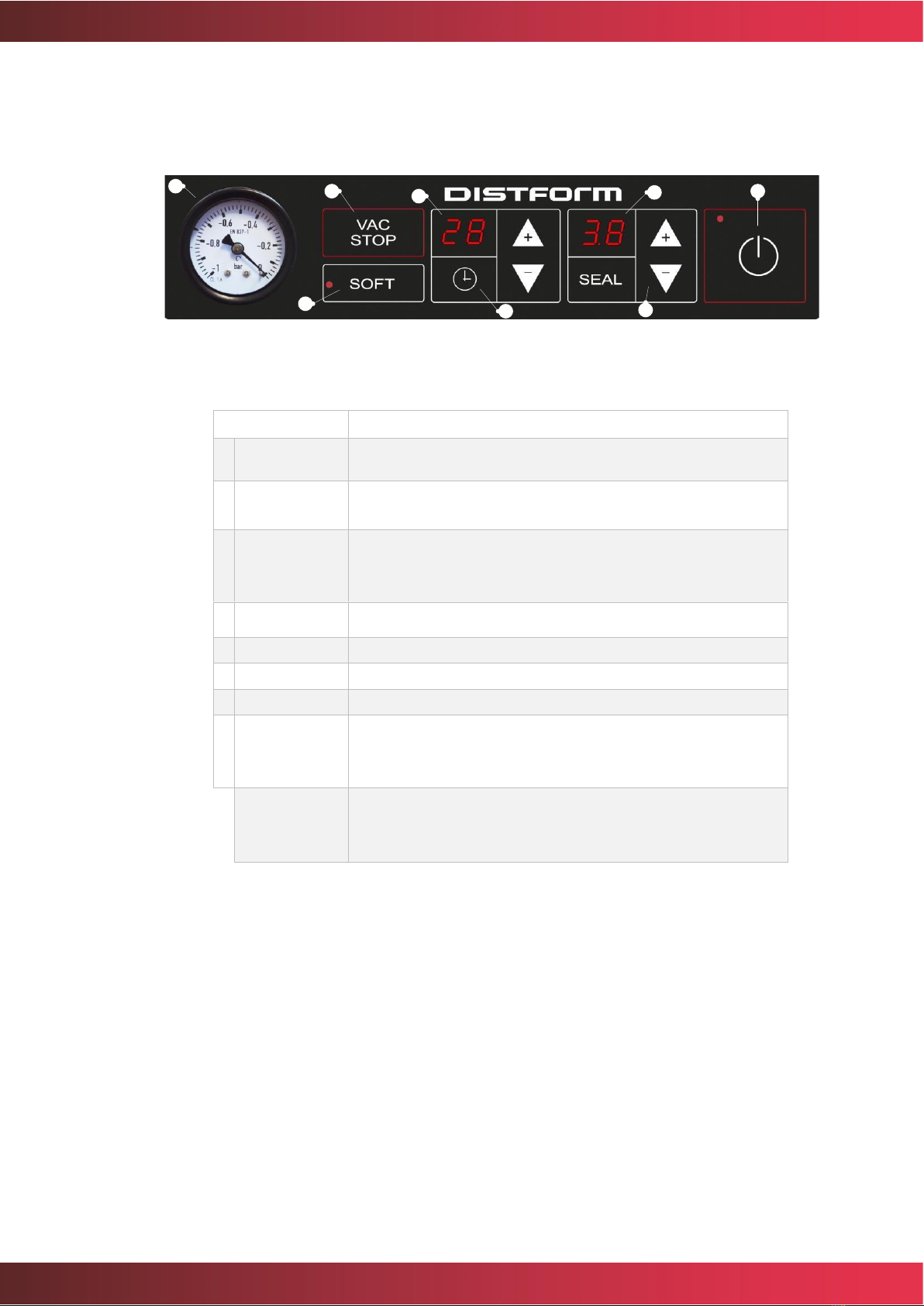

1.2. Keyboard (sensor).................................................................................................... 6

1.3. Keyboard (time)........................................................................................................ 8

1.4. Methodology............................................................................................................ 8

2. OPERATION ...................................................................................................9

2.1. Sensor models.......................................................................................................... 9

2.2. Time models............................................................................................................. 9

3. SOLUTION TO COMMON PROBLEMS ..........................................................11

3.1. Common problems ............................................................................................... 11

3.2. Automatic errors detection (only in sensor models).......................................... 11

3.2.1. Error E01....................................................................................................... 12

3.2.2. Error E02....................................................................................................... 12

3.2.3. Error E03....................................................................................................... 14

3.2.4. Error E04....................................................................................................... 15

3.2.5. Error E05....................................................................................................... 15

3.3. Vacuum pump ........................................................................................................ 16

4. DISASSEMBLE TO GET SERVICE ACCESS......................................................17

4.1. Frontal disassembly ............................................................................................... 17

4.2. Rear disassembly ................................................................................................... 20

4.3. Lid disassembly...................................................................................................... 21

4.4. Tub disassembly .................................................................................................... 22

5. TROUBLESHOOTING ....................................................................................24

5.1. Chech the power supplies .................................................................................... 24

5.1.1. Old model .................................................................................................... 24

5.1.2. Current model ............................................................................................. 26

5.2. Modo de test .......................................................................................................... 26

5.2.1. Electromechanical elements test............................................................... 27

5.2.2. Keyboard test............................................................................................... 30

5.2.3. Lid switch test............................................................................................... 31

5.2.4. Vacuum sensor test (sensor models only ) ............................................... 32

5.2.5. Internal memory test (sensor models only) .............................................. 32

6. BREAKDOWN REPAIRS ................................................................................33

6.1. Replacing lid switch ............................................................................................... 33