Pregis Easypack coiler-lite User manual

Operating Manual (EN)

52-OM216-1

English

Easypack®

2

www.pregis.com 52-OM216-1

Safety Information

Description and Purpose of Machine

Specification and Maintenance

Set Up

Controls

Pre-start checks

Operation

Paper Jam

Troubleshooting

EC Declaration of Conformity

3

4

5

6

8

10

11

13

14

15

Contents

3

www.pregis.com 52-OM216-1

Always switch off the machine from the mains supply before

freeing paper jams, lifting the top cover or cleaning.

• Never damage or remove factory installed safety stickers. If a safety sticker is

lost, damaged, or becomes illegible, report this condition to a supervisor and

obtain a replacement sticker from Pregis.

• When moving the Coiler ensure that the power lead and the flying lead con-

necting the Coiler to the Packmaster™ pro are disconnected.

• Keep the work area clean and uncluttered. Walkways and access/egress routes

should always be free of packing material and debris to prevent a slipping or

tripping hazard.

• Ensure that all covers, guards and other safety devices are in place. NEVER

disable a safety device for any reason.

• Never leave the equipment unattended while operating. Turn the machine off if

you must leave the work area.

• Keep body parts and clothing away from moving components.

• DO NOT operate equipment if you are under the influence of alcohol, drugs

or medications that can make you less alert or affect your judgment.

The machine can be stopped at any time by pressing the red (0) switch. This cuts all

supply to the control panel and motors.

THIS MACHINE MUST BE EARTHED

The wires in the mains cable are coloured as such:

GREEN/YELLOW

BLUE

BROWN

EARTH

NEUTRAL

LIVE

• It is important that this machine is installed, maintained and used

correctly to avoid the risk of injury.

• This machine contains dangerous voltages and rotating mechanical parts.

• Use the machine only for the purposes described in the Operating Manual.

• This machine is to be used only by trained personnel.

• The machine is to be serviced or repaired only by Pregis.

Safety Information

•The machine uses a 120/230V(±10%), 50/60Hz, single-phase AC supply.

•To protect against electrical shock, do not immerse the plug or mains cable in

water or spray with liquids.

•Unplug from the electrical supply when not in use.

•Do not operate this machine with a damaged mains cable or plug.

•To disconnect from electrical supply, grip the plug - do not pull on the mains

cable.

4

www.pregis.com 52-OM216-1

The Pregis Coiler-lite produces large quantities of paper coil cushions when used in con-

junction with the Pregis Packmaster™ pro. Paper coil cushions provide light, strong pack-

aging options which mould to the shape of the items to be protected and are manufac-

tured using 100% recycled materials.

Paper coils can be made using 52/90gsm and 70gsm white or brown paper. The coils can be

produced at sizes ranging from 30cm to 70cm diameter. All of our paper is 100% recycled,

100% recyclable and 100% biodegradable.

These coils can be produced quickly either for immediate use or to store for later use. The

Coiler is simple to use providing a hands-free repeat option which allows production to con-

tinue. Advanced safety features ensure safe operation at all times.

The Machine is of rugged design and construction and is quickly wiped over for cleaning

purposes.

The Machine is designed to meet EC safety standards and requires connection only to a

suitable electrical supply.

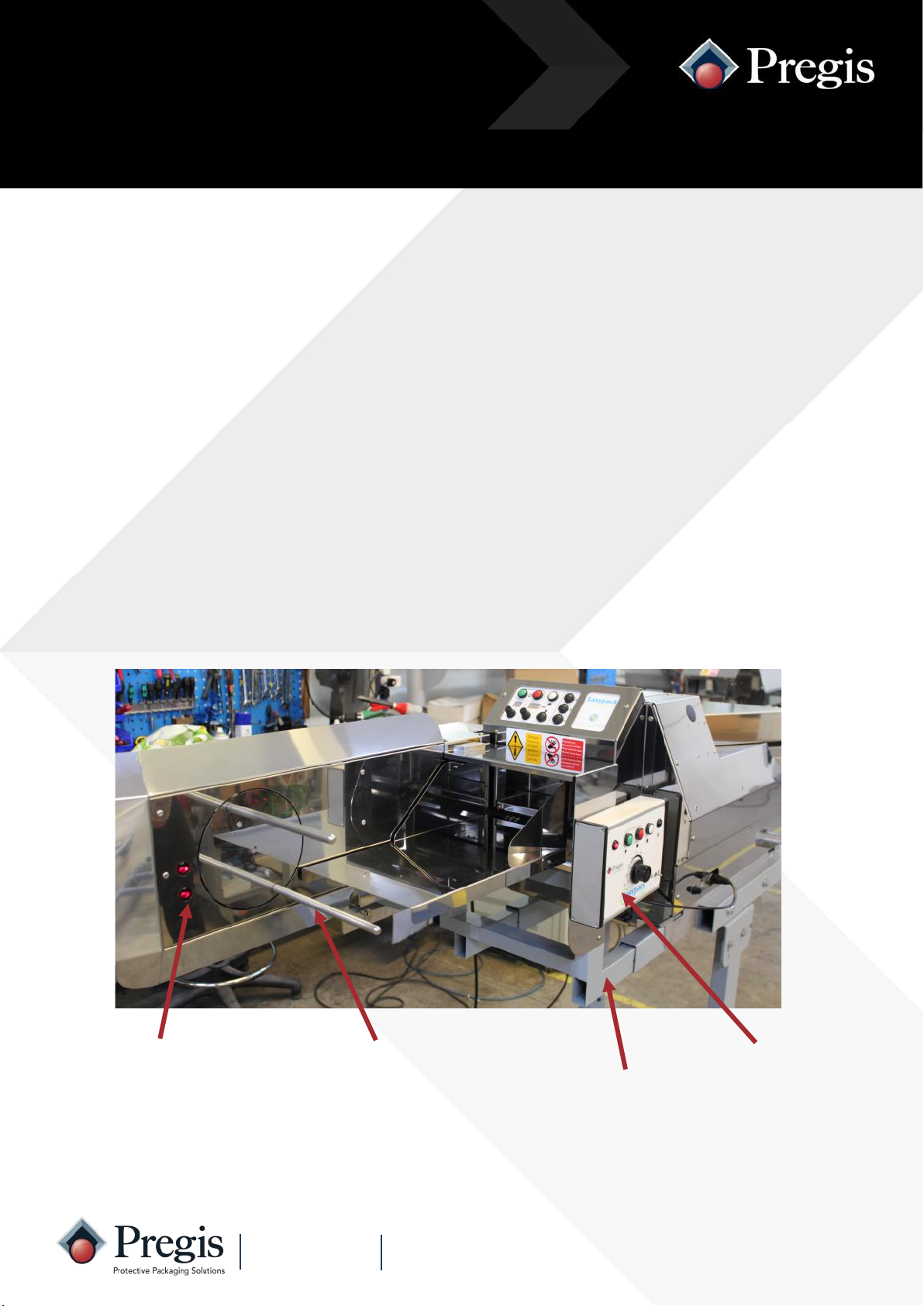

Tine (part of the

winding head)

Description and Purpose of Machine

Coiler-lite

Control

Console

Sensors

Holding arms

5

www.pregis.com 52-OM216-1

Specification

Maintenance

Specification and Maintenance

Machine Weight (Coiler-lite only) 30 kg

Machine dimensions (mm)

With/ without Packmaster™ pro

(L) 1910 / 1510

(W) 840 / 520

(H) 885—1285 / 510

Coil diameter From 300mm – 700mm (approx.)

Coil depth 200mm Nominal

Average output speed 26 m/min (Automatically matched to

Packmaster™ Pro)

Ideal usage On demand

Supply 120V/230V AC, 50/60 Hz

Max power input 350W

Compatible with all Packmaster™ Pro paper grades. Single ply or twin

-ply grades from 70gsm to 52/90gsm. White and brown paper options

• Always unplug the Machine before clearing a jam or cleaning the

Machine.

• Activity around the machine should not put the mains supply cable and

foot switch line in danger of sustaining damage or being a trip hazard.

• If in doubt, unplug the Machine and contact your local Pregis office.

• Do not allow water or other liquids to drip on or into the Machine.

• If the Machine fails to operate, check the Troubleshooting Guide.

• Clean the Coiler using a lint free cloth.

• Clean the paper contact surfaces with a silicone based furnish polish

• Ensure the two sensors (just to the left of the winding head) are free of

dust (TAKE CARE - THESE ARE FRAGILE)

• If the Machine still fails to operate after checking against the Guide,

contact Pregis.

• There are no user serviceable parts inside the Machine.

• Refer to the ‘Troubleshooting’ Guide for operational issues.

6

www.pregis.com 52-OM216-1

Set Up

1. Using a hoist, lift and align the

Packmaster™ Pro to its frame.

2. Remove the existing bolts on

either side and replace with M12 x

110mm bolts.

4. Secure with nuts and tighten.

3. Align additional holding bars to the

newly added bolts.

Setting up the Packmaster™ Pro for the Coiler-lite

5. The machine should look like this.

The Coiler-lite, Packmaster™ Pro and the frame arrive detached from each other and will

require assembly. NOTE: This should be done only by Pregis engineers.

7

www.pregis.com 52-OM216-1

Set Up

1. Two people to lift the Coiler-lite

and align with the front of the

Packmaster™ Pro.

2. Align and connect the holding arms

from the Coiler-lite into the newly

added holding arms of the

Packmaster™ Pro.

4. Once all four bolts are in, tighten and

secure.

3. With one person navigating the

Coiler-lite for alignment, loosely

screw in the bolts to hold into place.

Attaching the Coiler-lite to the Packmaster™ Pro

NOTE: This should be done only by Pregis.

8

www.pregis.com 52-OM216-1

Controls

Location of controls

Mains Power Switch Switch illuminates when switched on.

Control box Refer to the next page for an explanation of the Control Console

functions.

Coiler-lite Control Console

Packmaster Pro

Control Console

Power switch on reverse

side of Coiler-lite

9

www.pregis.com 52-OM216-1

Controls

Control console functions

‘Stop’

Button

‘Home’

Button

‘Start’

Button

Power

Indicator

Coil

Indicator

Tail switch

position

Coil size

control

Power Indicator Illuminates when the Coiler-lite is switched on

Start Button Press the green ‘Start’ button to start the Coiler-lite.

Stop Button Press the red ‘Stop’ button to prematurely stop the Coiler-lite mid-cycle.

Home Button Resets the Coiler-lite, if an error has occurred.

Coil Indicator Illuminates whilst making a coil and flashes when the coil is completed and

requires removal.

Coil Size Control Selects the required coil size. The coil size will vary with different grades of

paper.

Tail Position

Switch

This selects the position of the ‘tail’ of the coil.

Switch to left (normal position) - coil is completed with the tail in the bottom

position which keeps the tail in position until the coil is removed.

Switch to the right - coil is completed with the tail in the top position allowing

10

www.pregis.com 52-OM216-1

Pre-start checks

1. Plug in the 5WAY XLR plug as shown.

2. Plug in mains and switch ON the

Packmaster™ Pro and check switch

is illuminated.

3. Plug in mains and switch ON

the Coiler-lite and check switch

is illuminated.

4. Ensure the sensor lights, control console light and dots on the

Packmaster Pro console are displayed.

11

www.pregis.com 52-OM216-1

Operation

1. Press the green ‘Start’ button on the

Packmaster™ Pro.

3. Press the green ‘Start’ button on the

Coiler-lite. 4. A ‘loading’ pack will be generated

automatically; remove this from the

Coiler-lite.

Load the Packmaster™ Pro with paper in accordance to the Packmaster™ Pro manual.

2. Press the blue ‘Feed’ button on the

Packmaster™ Pro.

5. Select the required coil size using

the Coil Size Selection Knob.

NOTE: The coil size will vary with

different grades of paper.

12

www.pregis.com 52-OM216-1

Operation

1. Select the tail position using Tail

Position Switch.

3. Switch to the right: Coil is completed

with the tail in the top position allow-

ing access for manual taping of the

coil end.

4. When the coil is complete and wound

to the selected tail position, the Coil

Indicator will start to flash denoting

operator action is required to remove

the coil.

Once the coil is removed, the Coil Indi-

cator will extinguish, and the Coiler-lite

is ready for the next coil to be produced.

2. Switch to left (normal position): Coil

is completed with the tail in the bot-

tom position which keeps the tail in

position until the coil is removed.

Coil production can be stopped at any point during the winding process by pressing the Red

‘Stop’ button. This will immediately stop the pack being produced by the Packmaster™ pro

and will result in a smaller incomplete coil.

This may place the Coiler-lite into a temporary ‘fault’ mode and the Coil Indicator will start

to flash denoting operator action is required to remove the coil. To exit the ‘fault’ mode

remove the coil and press the White ‘Home’ Button once. The Coil Indicator extinguishes

and the machine is ready to run again.

13

www.pregis.com 52-OM216-1

Paper jam

1. If there is a paper jam, turn ma-

chine OFF, and unscrew the ‘T’ han-

dles.

3. Carefully remove the jammed paper 4. Once paper jam has been cleared,

lower and secure the top gear and

operate as normal.

2. Lift the top gear to reveal the

jammed paper.

14

www.pregis.com 52-OM216-1

Troubleshooting

If the above information does not clear the fault, contact

Pregis for further assistance on 00800 888 888 44.

Please have the serial number of the machine available.

This can be found on the back of the machine, on the far

left.

Fault Check

Machine will not produce a

coil even though the Blue In-

dicator Light is not flashing

• Machine needs to be reset

• Press the Home button

Power indicator not lit on

mains switch of machine

• Machine is connected to the mains

supply

• Mains supply is switched on

• Fuse in machine is okay

• Fuse in mains plug is okay

Machine will not switch on

(control panel)

• Power indicator is lit

Troubleshooting

15

www.pregis.com 52-OM216-1

EC Declaration of Conformity

EC Declaration of Conformity

We declare that the following machinery complies with the essential

health and safety requirements of the Machinery Directive 2006/42/EC,

the Low Voltage Directive (LVD) 2014/35/EC and the Electromagnetic

Compatibility Directive 2014/30/EC.

Manufacturer: Pregis Ltd

Address:

Unit 1, The Io Centre, Whittle Way,

Arlington Business Park, Stevenage,

Hertfordshire, SG1 2BD, England

Description of Product: Coiler-lite

Model No. & Serial No. : 52

The following transposed harmonized European Standards have been

used:

EN 12100: 2010 Safety of Machinery - Basic concepts, general

principles for design.

EN 13857: 2008

Safety of Machinery - Safety distances to prevent

hazard zones being reached by upper and lower

limbs.

EN 60204-1: 2006 Safety of Machinery - Electrical equipment of

machines - General requirements.

EN 61000: 2007 (part 6-1) Generic standards - Immunity for

light-industrial environments.

EN 61000: 2007 (part 6-3) Generic standards -Emission standard for

light-industrial environments.

Jason Cox

Operations Director

13/10/2020

Signed on behalf of the manufacturer

Table of contents

Other Pregis Packaging Equipment manuals

Pregis

Pregis packmaster pro 383 User manual

Pregis

Pregis Easypack Coiler User manual

Pregis

Pregis SHARP MAX-PRO User manual

Pregis

Pregis SHARP MAX 1143 User manual

Pregis

Pregis EASYPACK QUANTUM Series User manual

Pregis

Pregis AirSpeed SMART Installation and operating manual

Pregis

Pregis SHARP MAX PRO 18 User manual

Pregis

Pregis SHARP SX GO User manual

Pregis

Pregis Quantum Pro 4068969 User manual

Pregis

Pregis Easypack Quantum XT User manual