2

TDK-Lambda

LS 25-150 Series

INSTRUCTION MANUAL

3. Explanation of Functions and Precautions

3-1. Input Voltage Range

Input voltage range is single phase 88 ~ 264VAC (47 ~ 63Hz) or 125 ~ 373VDC for LS25 ~ LS100.

For LS150, selectable switch 115/230VAC will decide the input voltage range as mentioned in the table below.

Input voltage which is out of specification, may damage the unit. For cases where conformance to various

safety specs(UL,CSA,EN) are required, input voltage range will be 100~240VAC (50/60Hz ).

Note : LS series able to withstand Input Surge of 300VAC for 5 seconds.

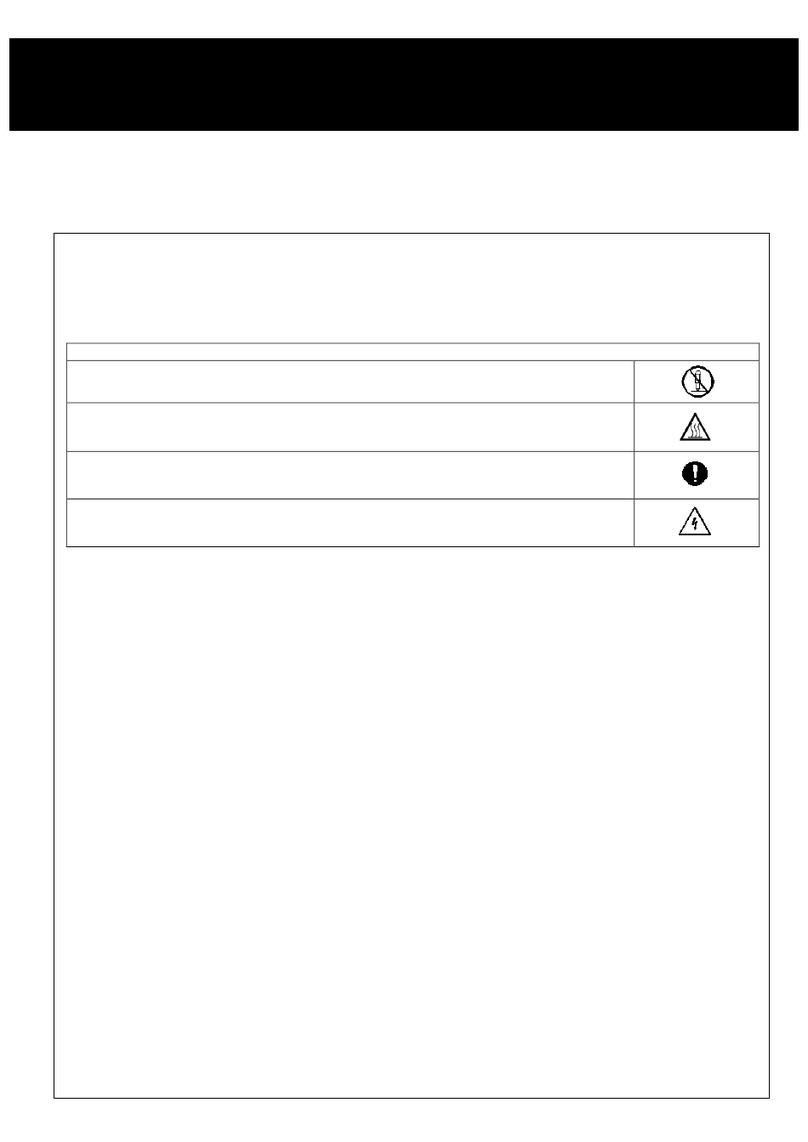

LS150 – Selectable voltage range

Selected Range Applicable Input Voltage Range in VAC Applicable Input Voltage Range in VDC

115 88 ~ 132 NA

230 176 ~ 264 248 ~ 373

3-2. Output Voltage Range

V.ADJ trimmer is for output voltage adjustment within the range of specifications. Turning the trimmer clockwise will

increase the output voltage. Note over voltage protection ( OVP ) function may trigger if the output voltage is increased

excessively.

3-3. Inrush Current

Power Thermistor is built in to protect the circuit from high Inrush Current. Please select suitable input switch and fuse

rating in case of re-input the power at high temperature.

3-4. Over Voltage Protection (OVP)

The OVP function will shutdown the output except for LS25. The input need to be removed for a few minutes, and then

re-input for recovery of the output. OVP setting is fixed and cannot be adjusted externally.

Note : For LS25, OVP function will cause the output into ”hiccup” mode and damage the unit.

3-5. Over Current Protection (OCP)

OCP function operates when the output current exceeds OCP specifications. The output will automatically recover when

the overload condition is removed. Do not operate overload or dead short conditions for more than 30 seconds, which

could result in damage or insulation failure.

3-6. Output Ripple & Noise

Ripple & noise are measured at 20MHz by using a 300mm twisted pair of load wires terminated with a 0.1uF film ca-

pacitor & 47uF electrolytic capacitor. When load lines are longer, ripple becomes larger. The output ripple cannot be

measured accurately if the probe ground lead of oscilloscope is too long. At low temperature, large ripple & noise may

also be observed due to large ESR of the internal Electrolytic Capacitors especially at -25degC. Output voltage rise may

not be smooth during initial turn on at low temperature.