TE Connectivity PRO-CRIMPER III User manual

Other TE Connectivity Crimping Tools manuals

TE Connectivity

TE Connectivity PRO-CRIMPER III User manual

TE Connectivity

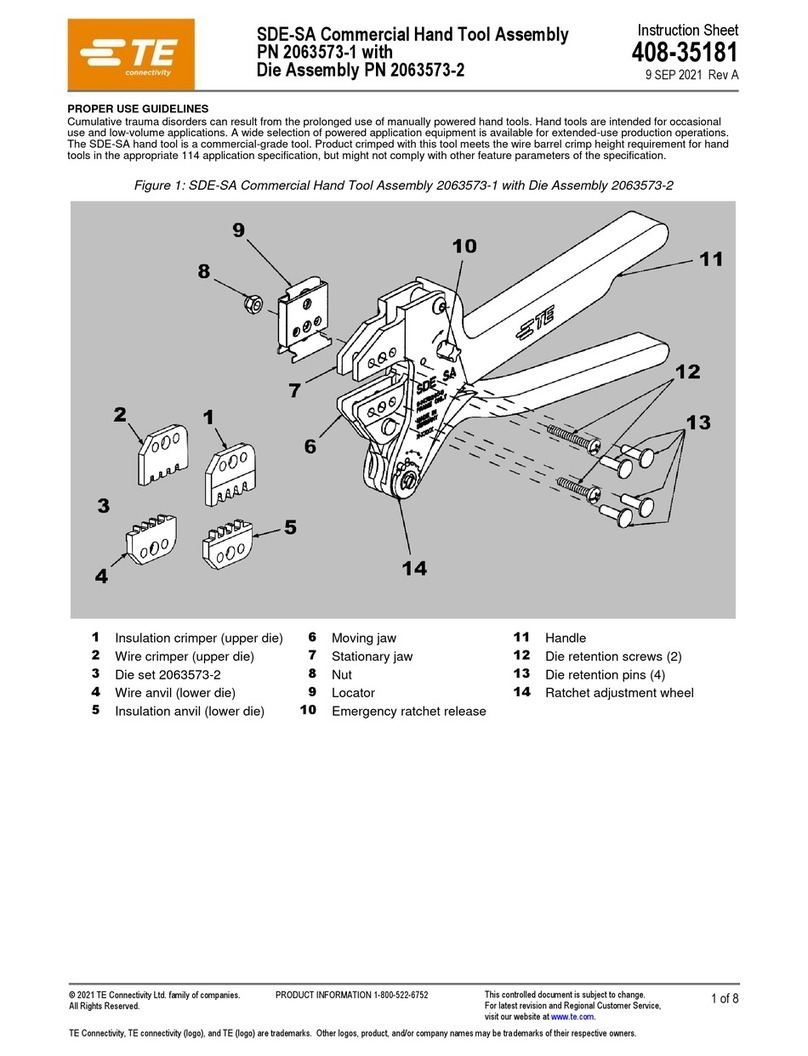

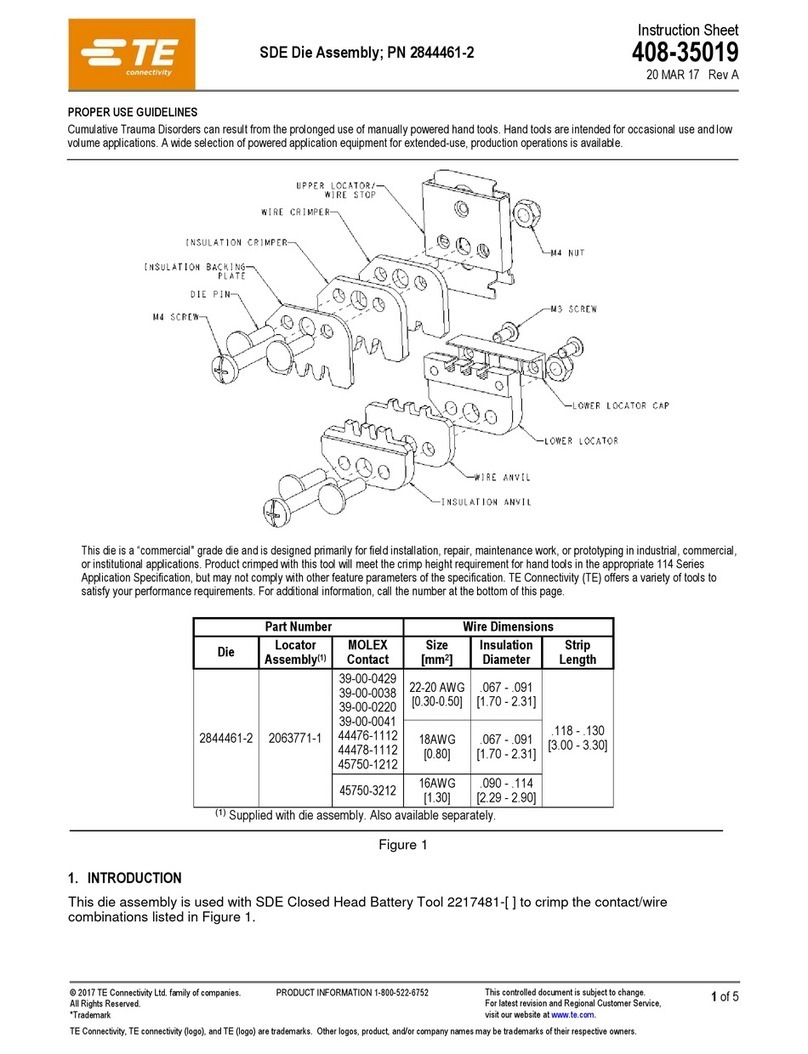

TE Connectivity 2844461-2 User manual

TE Connectivity

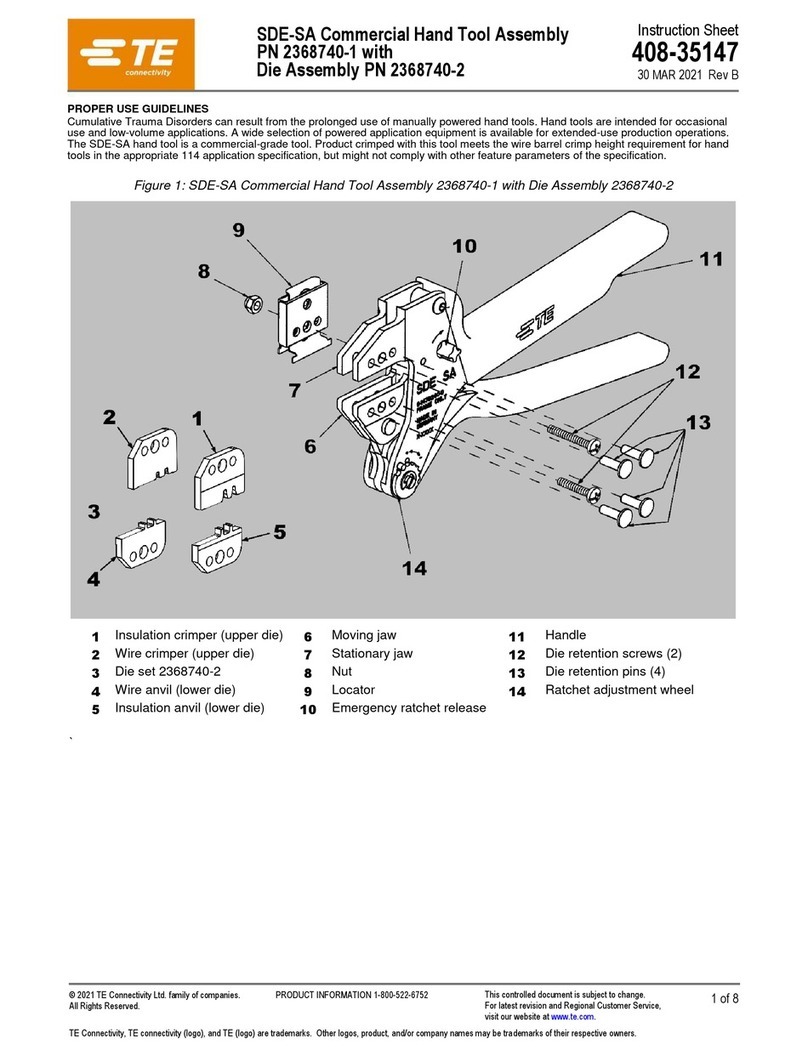

TE Connectivity 2368740-1 User manual

TE Connectivity

TE Connectivity 2393700-1 User manual

TE Connectivity

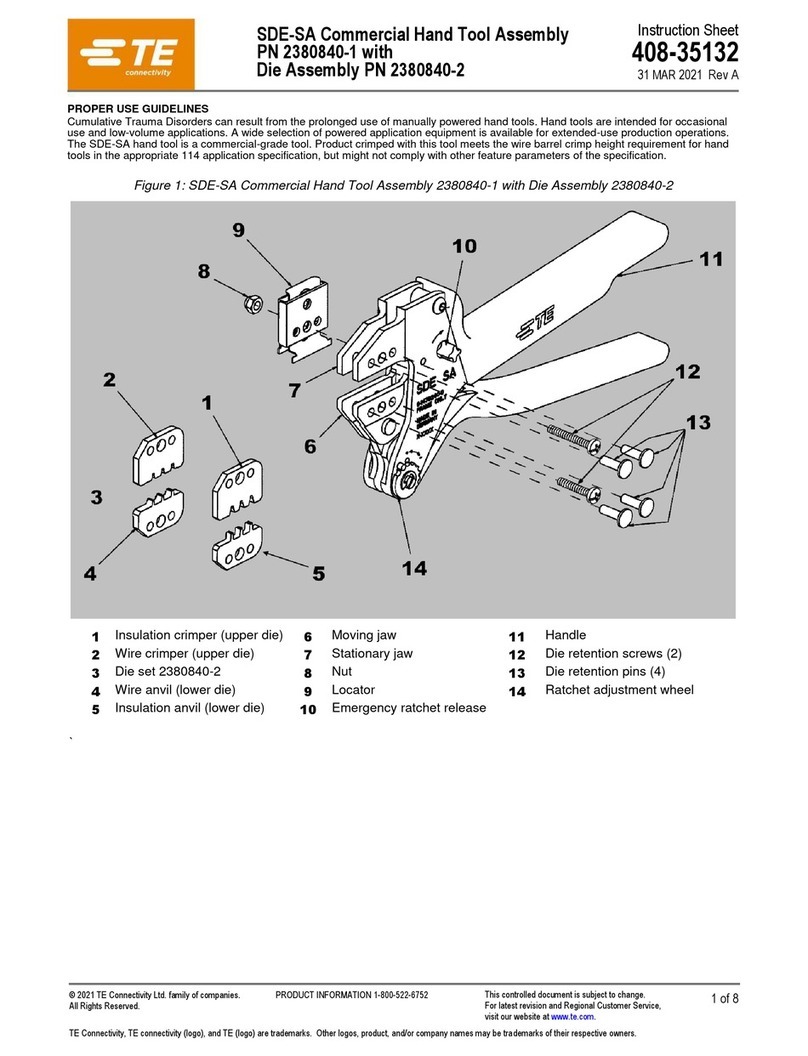

TE Connectivity 2380840-1 User manual

TE Connectivity

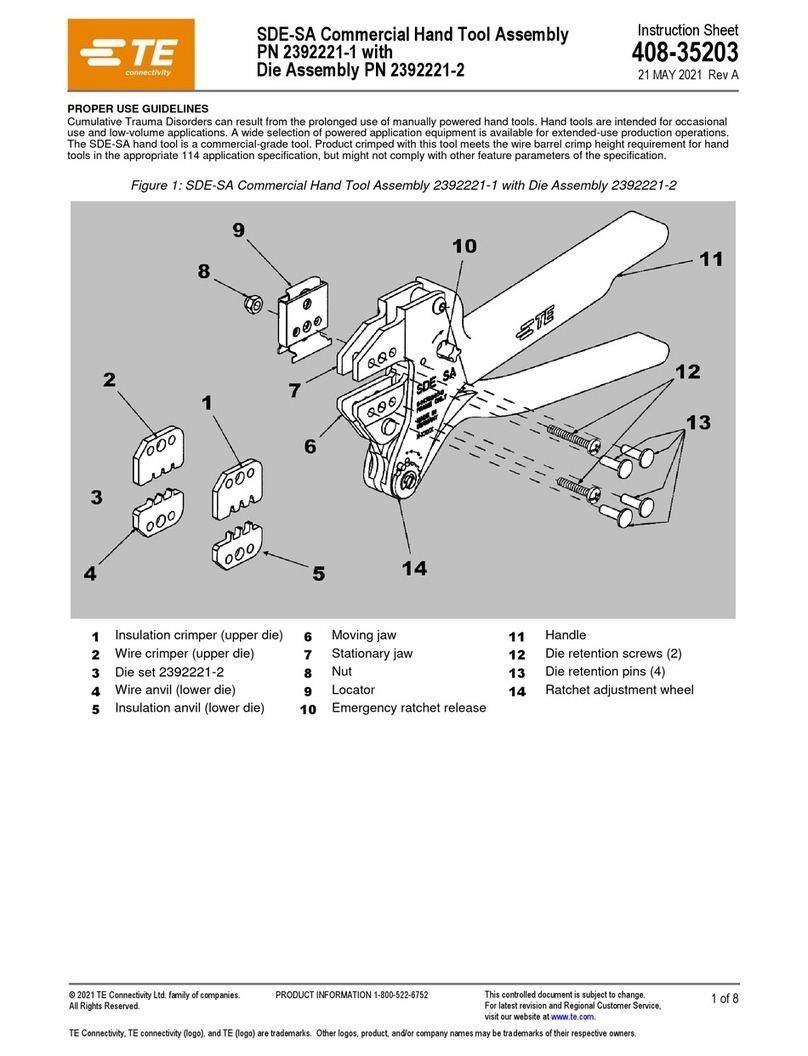

TE Connectivity 2392221-1 User manual

TE Connectivity

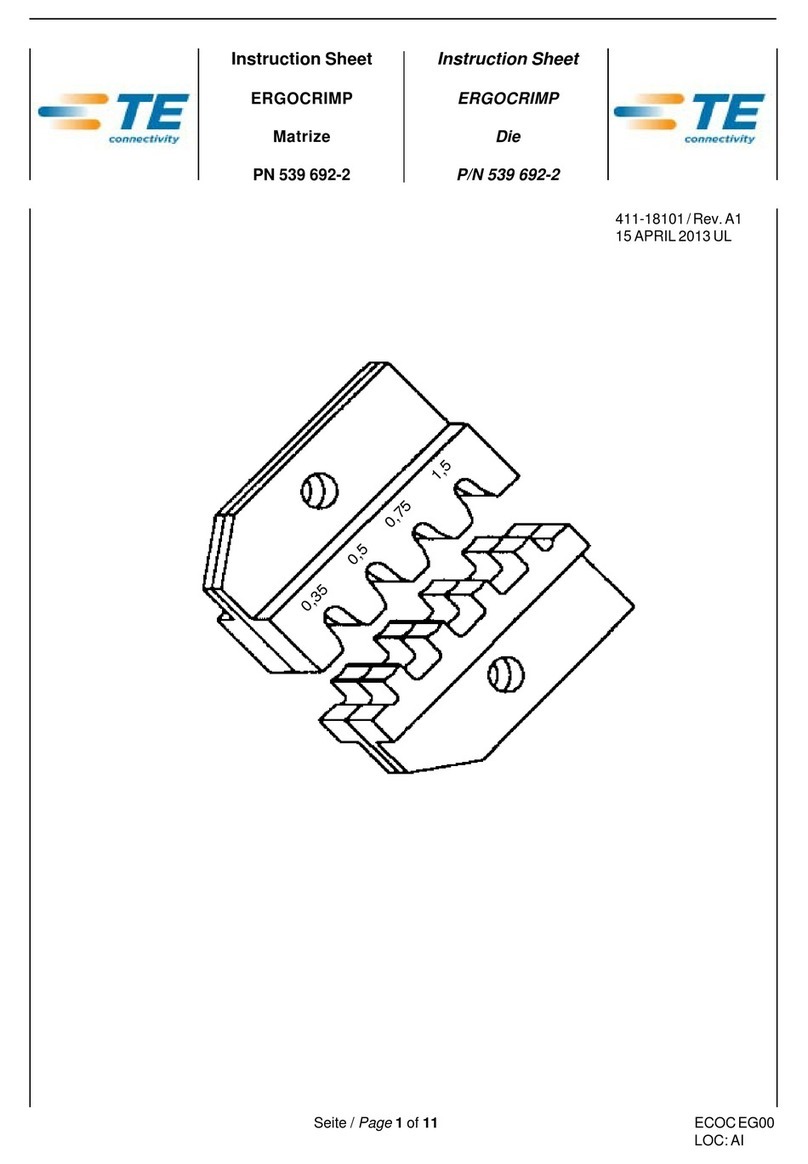

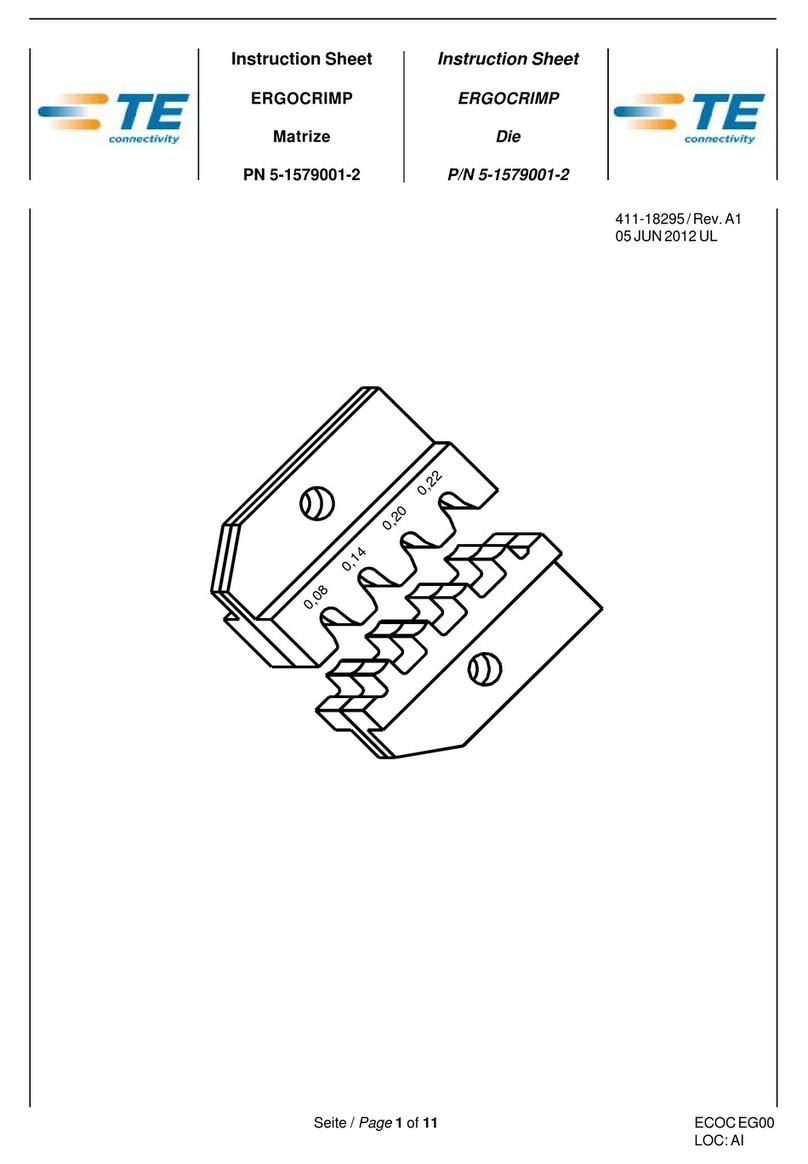

TE Connectivity ERGOCRIMP 5-1579001-2 User manual

TE Connectivity

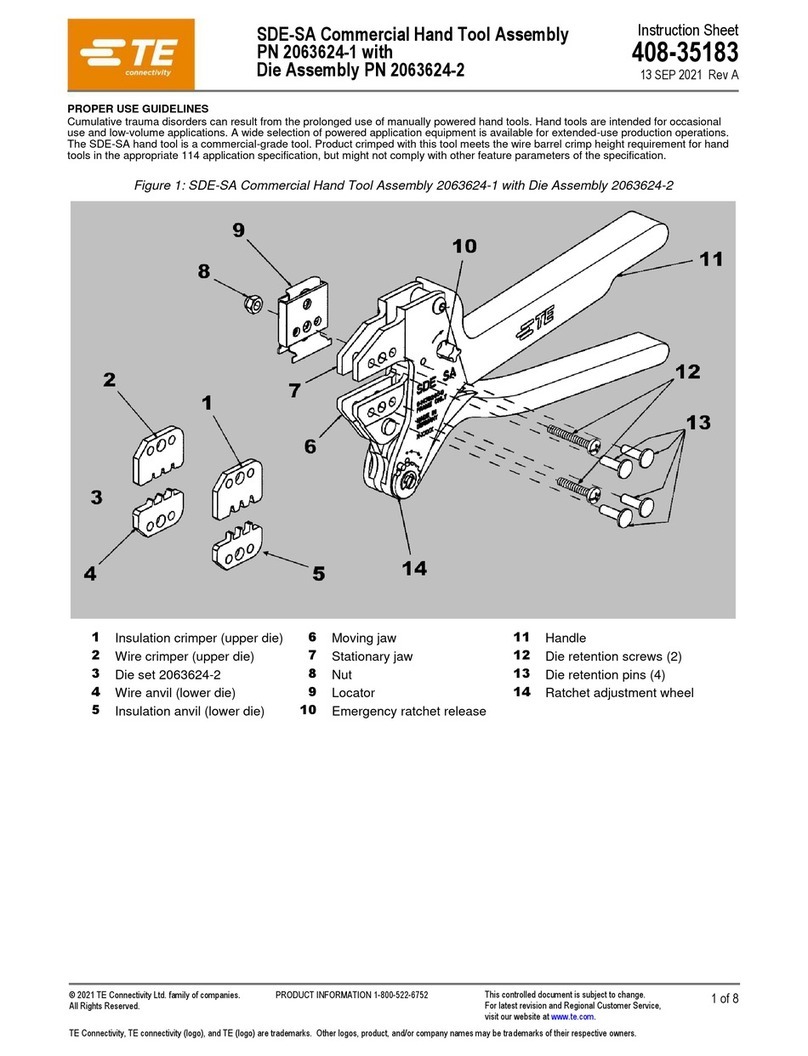

TE Connectivity 2063624-1 User manual

TE Connectivity

TE Connectivity Positive Lock A User manual

TE Connectivity

TE Connectivity 220189 Series User manual

TE Connectivity

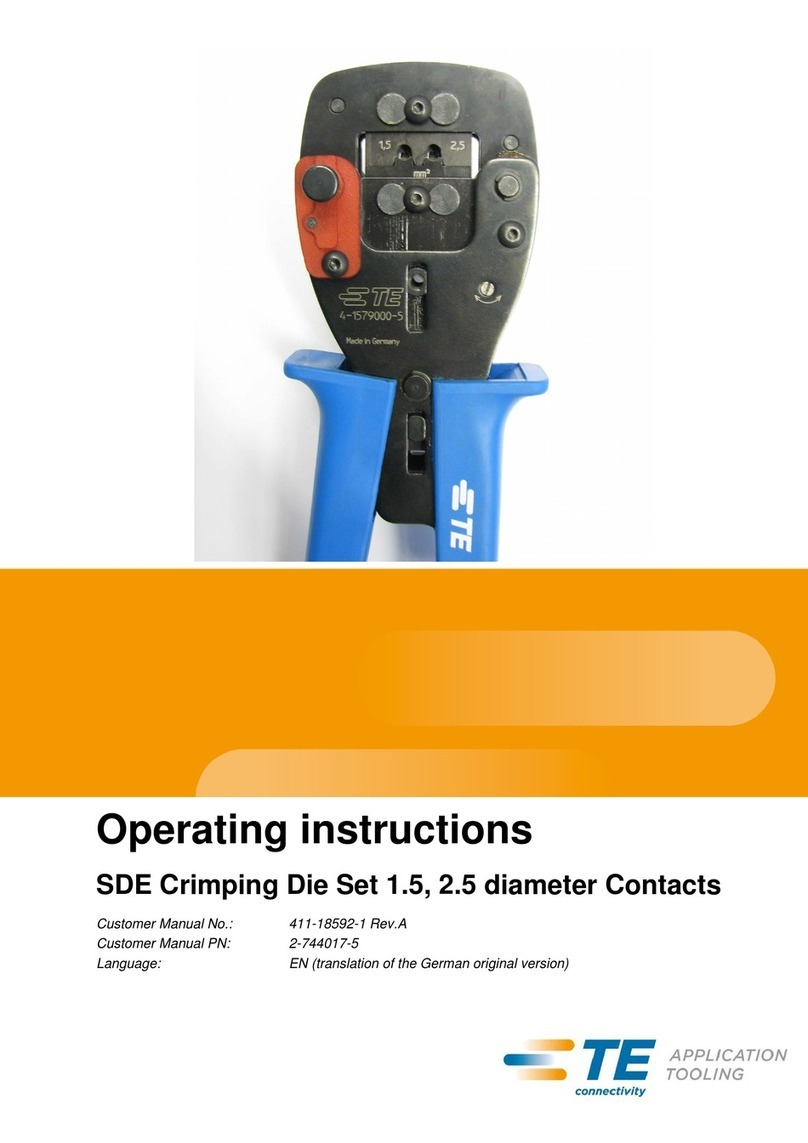

TE Connectivity SDE User manual

TE Connectivity

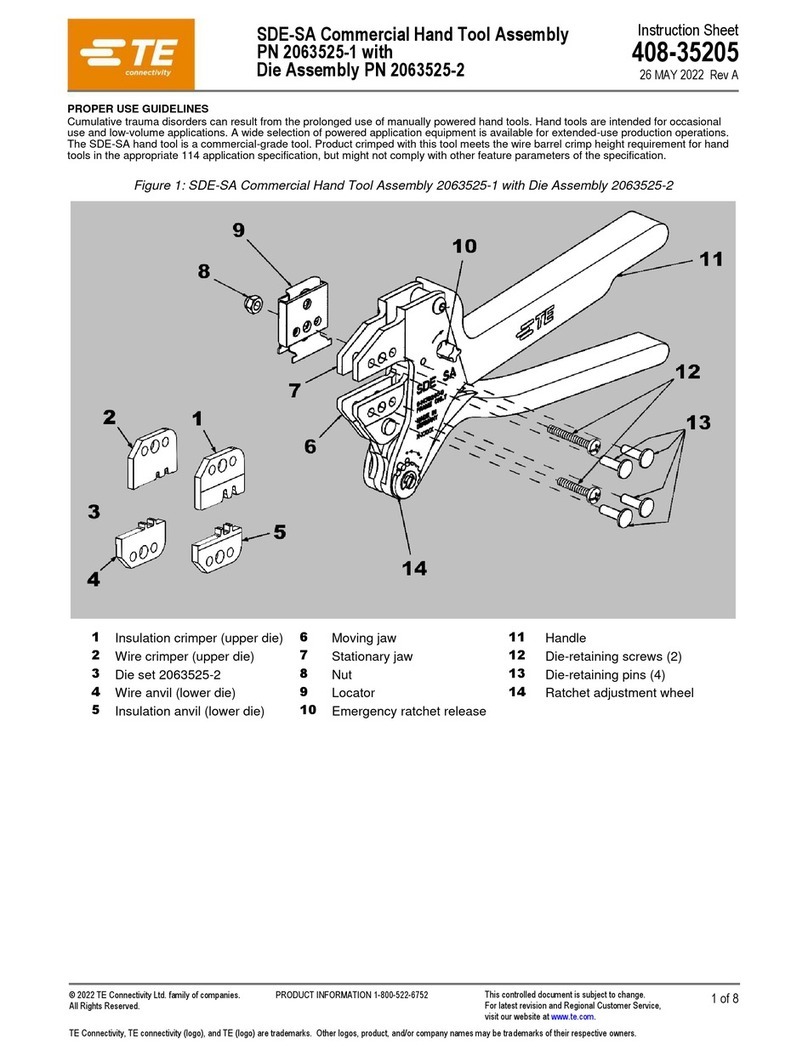

TE Connectivity 2063525-1 User manual

TE Connectivity

TE Connectivity PRO-CRIMPER III 58521-1 User manual

TE Connectivity

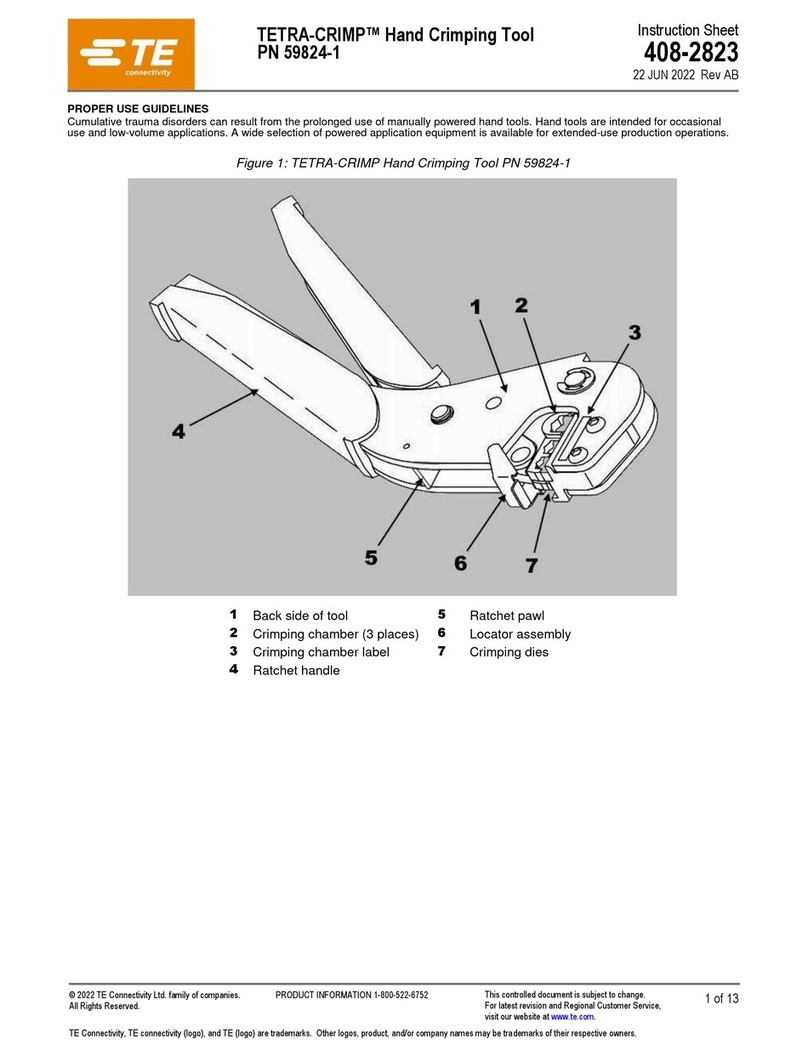

TE Connectivity TETRA-CRIMP 59824-1 User manual

TE Connectivity

TE Connectivity PRO-CRIMPER III User manual

TE Connectivity

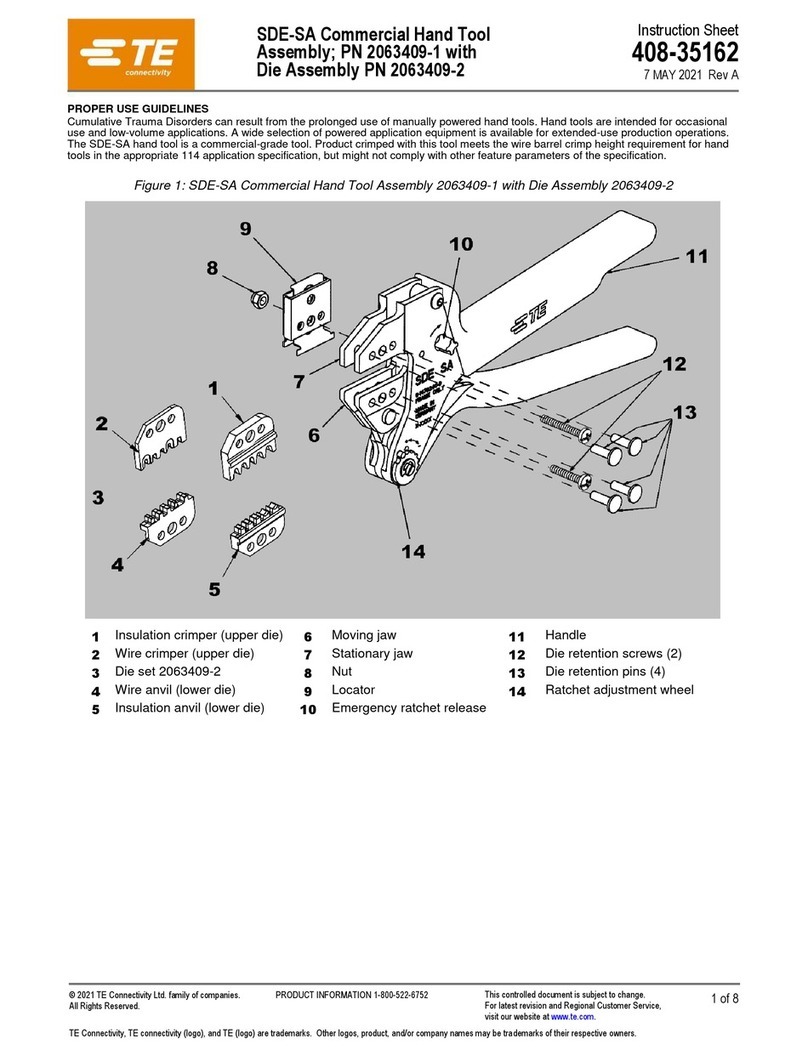

TE Connectivity 2063409-1 User manual

TE Connectivity

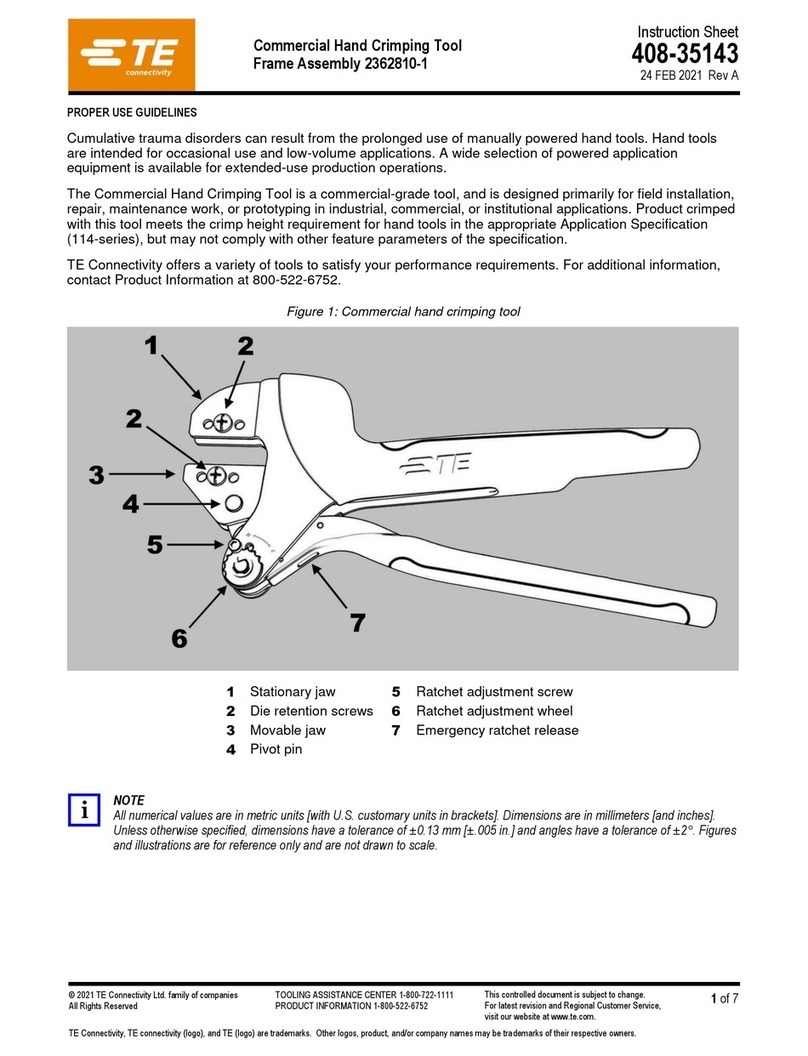

TE Connectivity 2362810-1 User manual

TE Connectivity

TE Connectivity PRO-CRIMPER III User manual

TE Connectivity

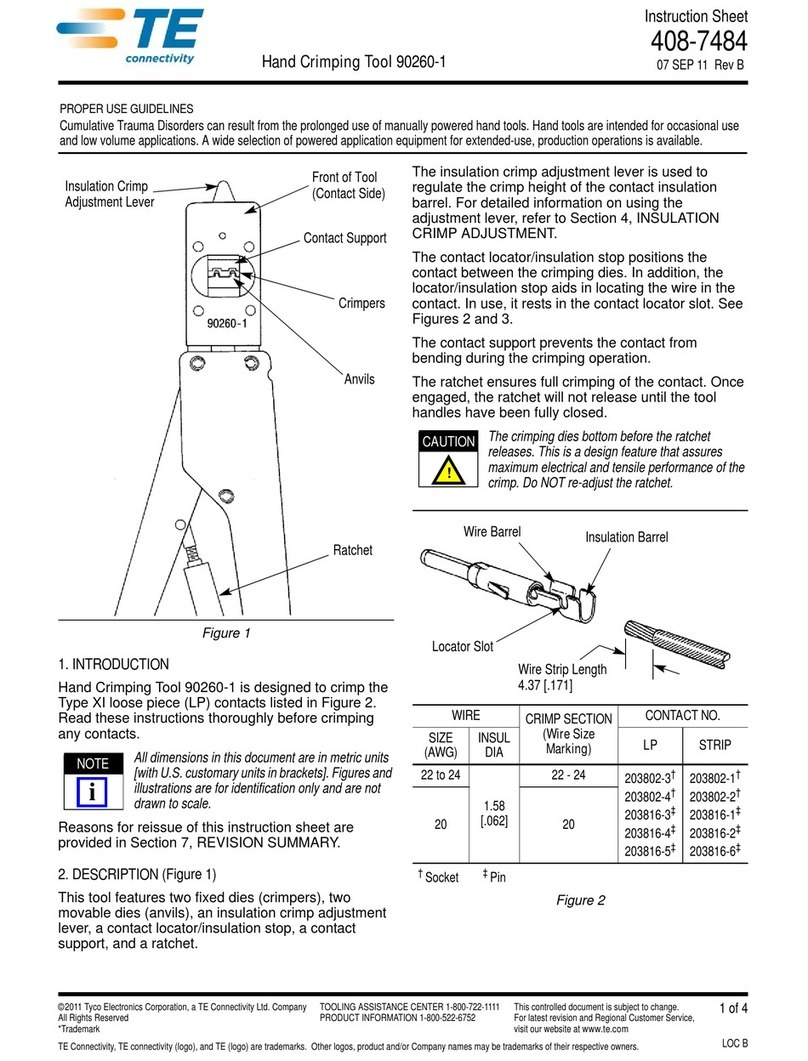

TE Connectivity 90260-1 User manual

TE Connectivity

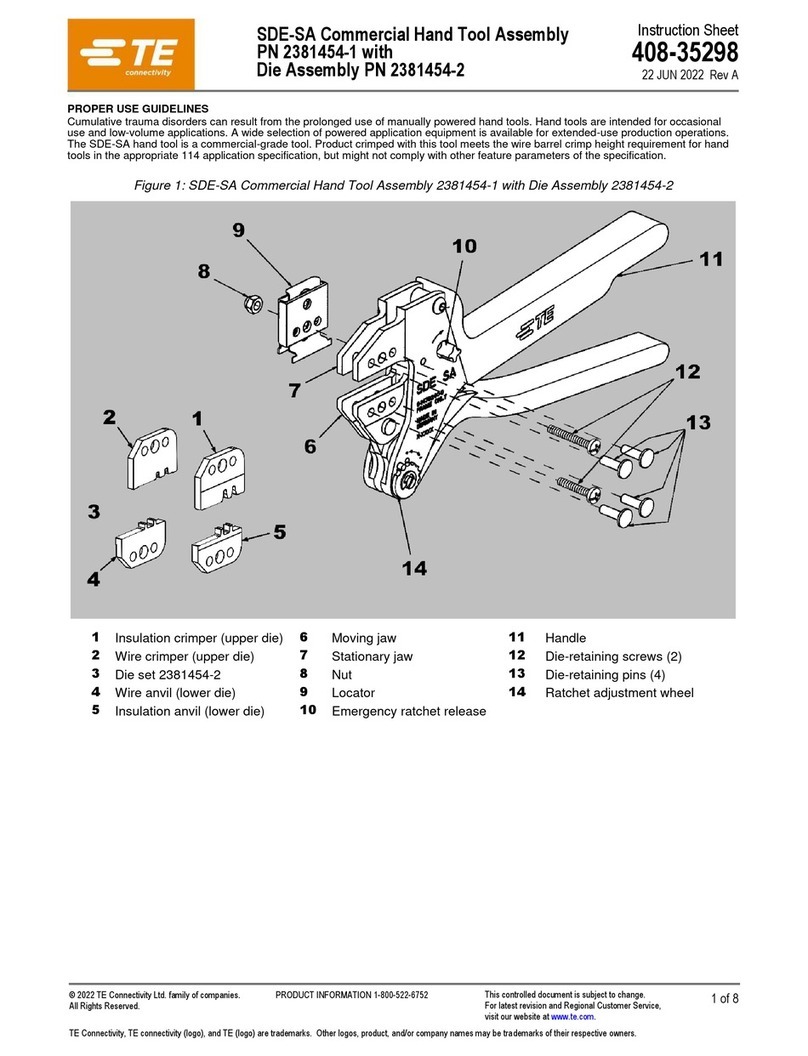

TE Connectivity 2381454-1 Instruction Manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

molex

molex 207129 Series Specification sheet

molex

molex 207129 Series Specification sheet