409-32023

Rev B

1.4. Smart Applicator Direct Integration Kit

The direct integration kit consists of cabling, which connects the smart applicator to the Komax leadmaker. This

kit is typically used when no servo feed applicators are used. This kit allows direct reading of data from

mechanical-feed and/or pneumatic-feed applicators.

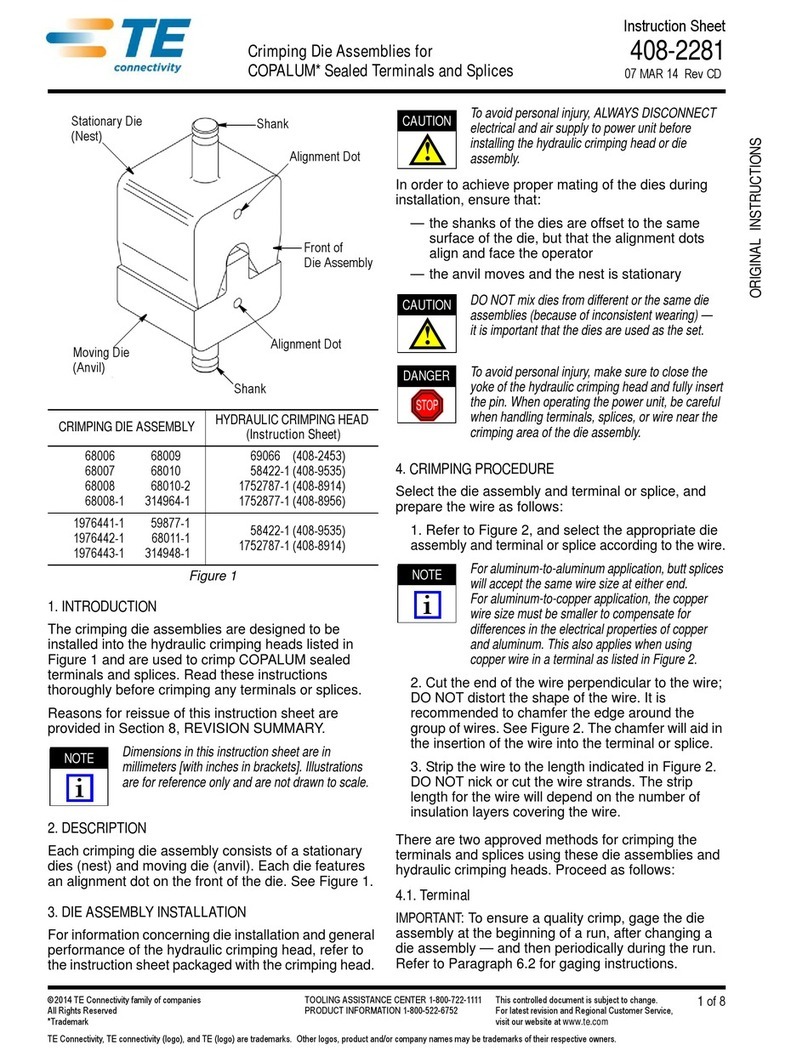

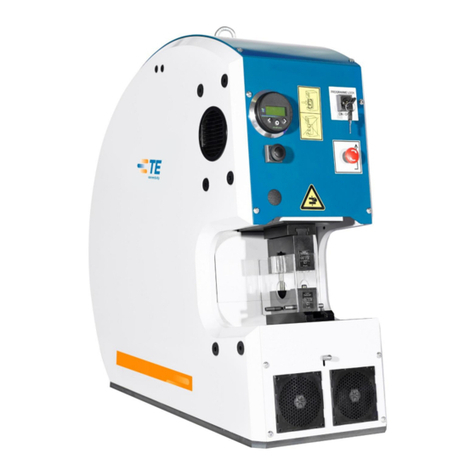

The system III precision controller (shown in Figure 2) is responsible for controlling the feeder assembly and

displaying the applicator information through a series of controller navigation and feeder control keys. A

description of the key operation is provided in Paragraph 3.1.

2. RECEIVING INSPECTION AND INSTALLATION

NOTE

Refer to assembly drawing 2161650 or 2161655 located in the print pack. These drawings contain installation information, part

numbers for components and assemblies, application information, and optional components that may be ordered separately

as required. When received, the kit should be checked against the assembly drawing to verify that it is correct for the

application, complete, and not damaged. Contact the Tooling Assistance Center at 1-800-722-1111 with any questions or to

report any problems.

2.1. Receiving

Each kit is thoroughly inspected during and after assembly. Prior to packaging and shipping, a final series of

tests and inspections is made to ensure proper functioning of the kit. The following inspection should be

performed as a safeguard against potential problems generated in transit:

1. In a well-lighted area, carefully uncrate the kit, and inspect each component as it is removed from the

crate.

2. Thoroughly inspect each component for evidence of damage that may have occurred in transit. If any

of the components are damaged, file a claim against the carrier and notify TE immediately.

Keep this manual and all drawings with the kit for the benefit of operation and maintenance personnel.

The controller and feeder should be inspected at regularly scheduled intervals, depending on care, degree of

operator skill, and environmental conditions.

2.2. Hardware Installation

NOTE

Hardware installation consists of installing the machine integration kit, precision controller integration kit(s), and/or direct

integration kit(s).

Installation of Machine Installation Kit

Refer to drawing 2651651 from the machine documentation package. This drawing contains hole cut-outs

and installation instructions for the machine installation kit. This kit must be installed before the hardware

and software can be integrated.

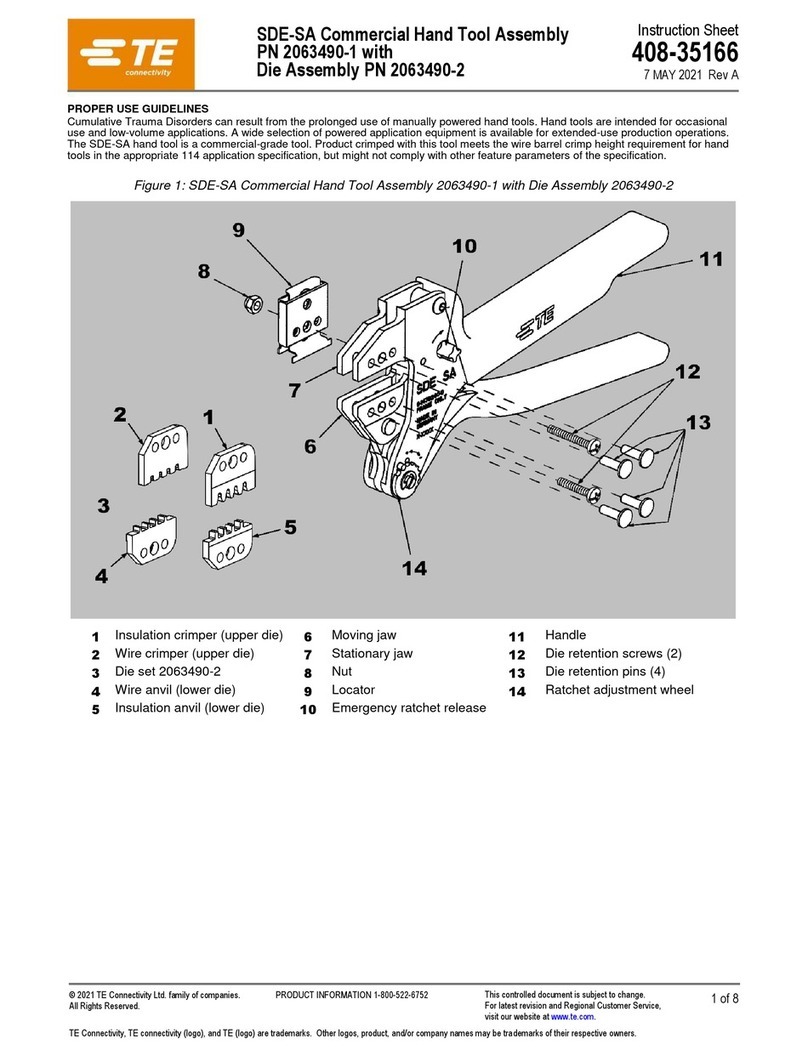

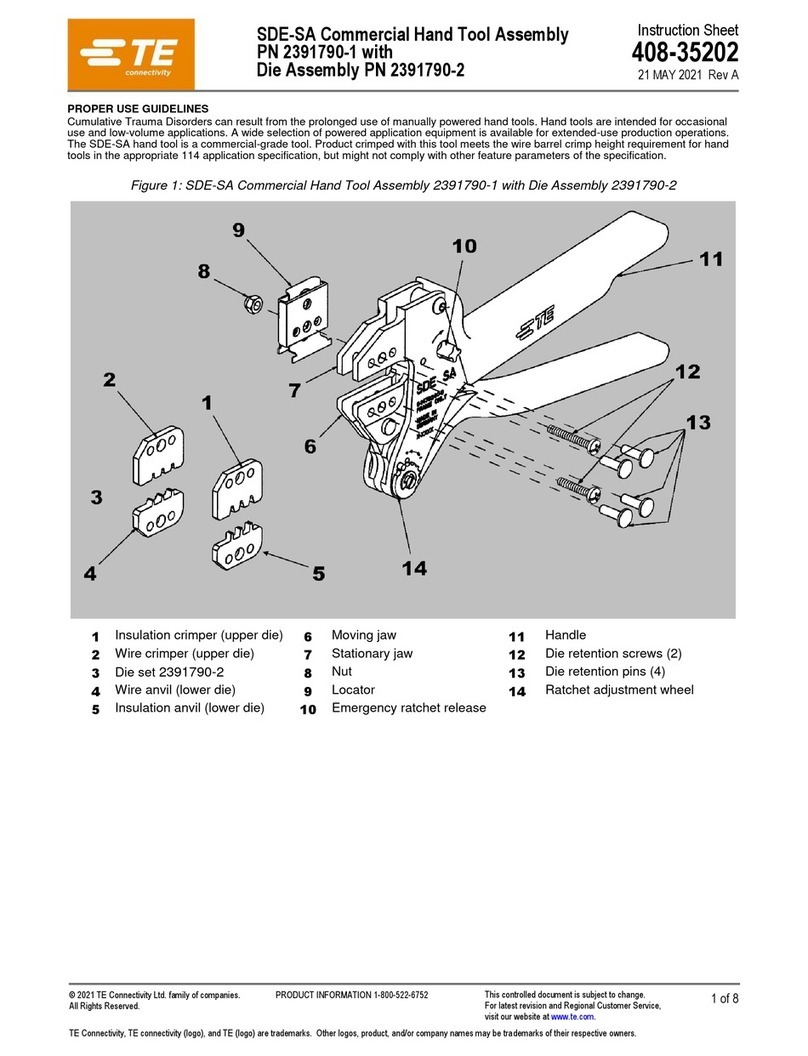

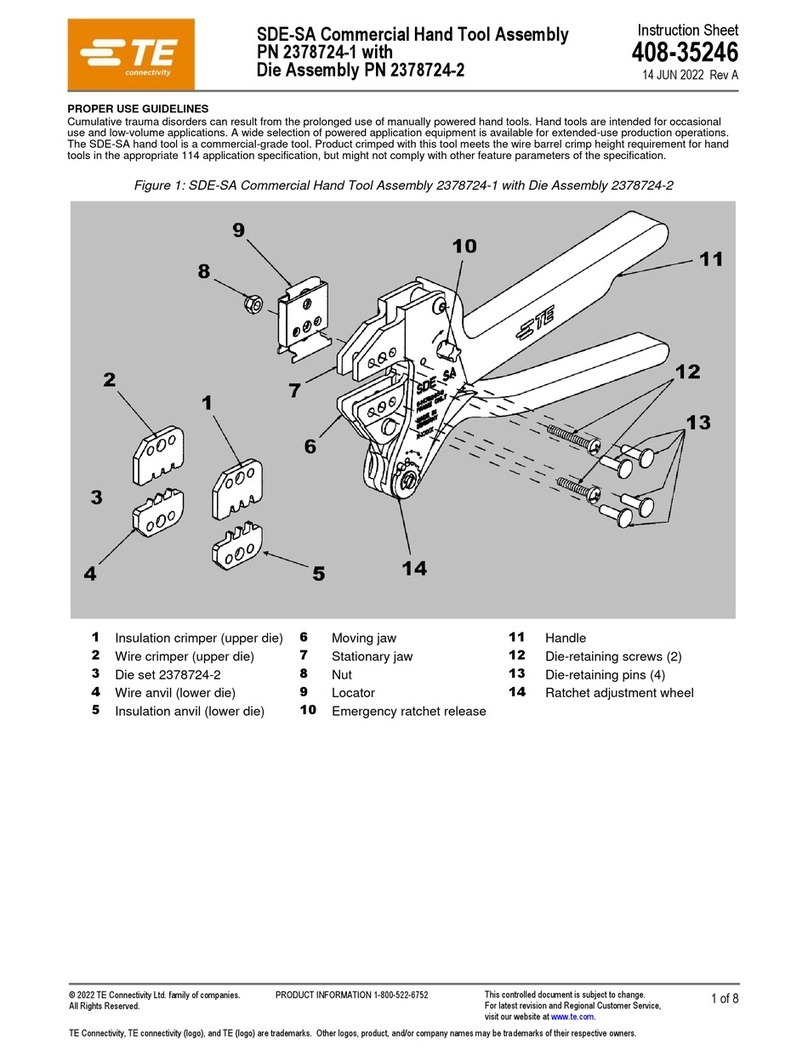

Installation of Machine Integration Kit with Precision Controller Integration Kit onto Komax Leadmaker

1. Remove the side covers (see Figure 3) from the existing terminating unit, and install modified side

cover 2-509805-3. Refer to drawing 2161650. See Figure 4.

NOTE

The side covers wrap around the terminator. Be careful not to damage the communication cable that is connected to the

panel. This cable must be unplugged, then reconnected when installing the modified side cover.

2. Install the adapter plate, feeder holder, cable cradle, and ball lock pins. Refer to Figure 4.

3. Install the system III precision controller onto the side of the terminator.

a. Route the power cable and the communication cable along the side of the terminator and through

the height adjustment mechanism.

b. Route the cable along the back side of the terminator. See Figure 4 and Figure 5.

Downloaded From Oneyac.com