Instruction Sheet

© 2014 TE Connectivity Ltd. family of companies

All Rights Reserved

*Trademark

TE Connectivity, TE connectivity (logo), and TE (logo) are trademarks. Other logos, product and/or Company names may be trademarks of their respective owners.

1of 4

TOOLING ASSISTANCE CENTER

1-800-722-1111

PRODUCT INFORMATION

1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.te.com LOC B

408-32033

PRO-CRIMPER* III Hand

Crimping Tool Assembly 2161732-1

with Die Assembly 2161717-1 09 JAN 14 Rev B

PROPER USE GUIDELINES

Cumulative Trauma Disorders can result from the prolonged use of manually powered hand tools. Hand tools are intended for occasional use

and low volume applications. A wide selection of powered application equipment for extended-use, production operations is available.

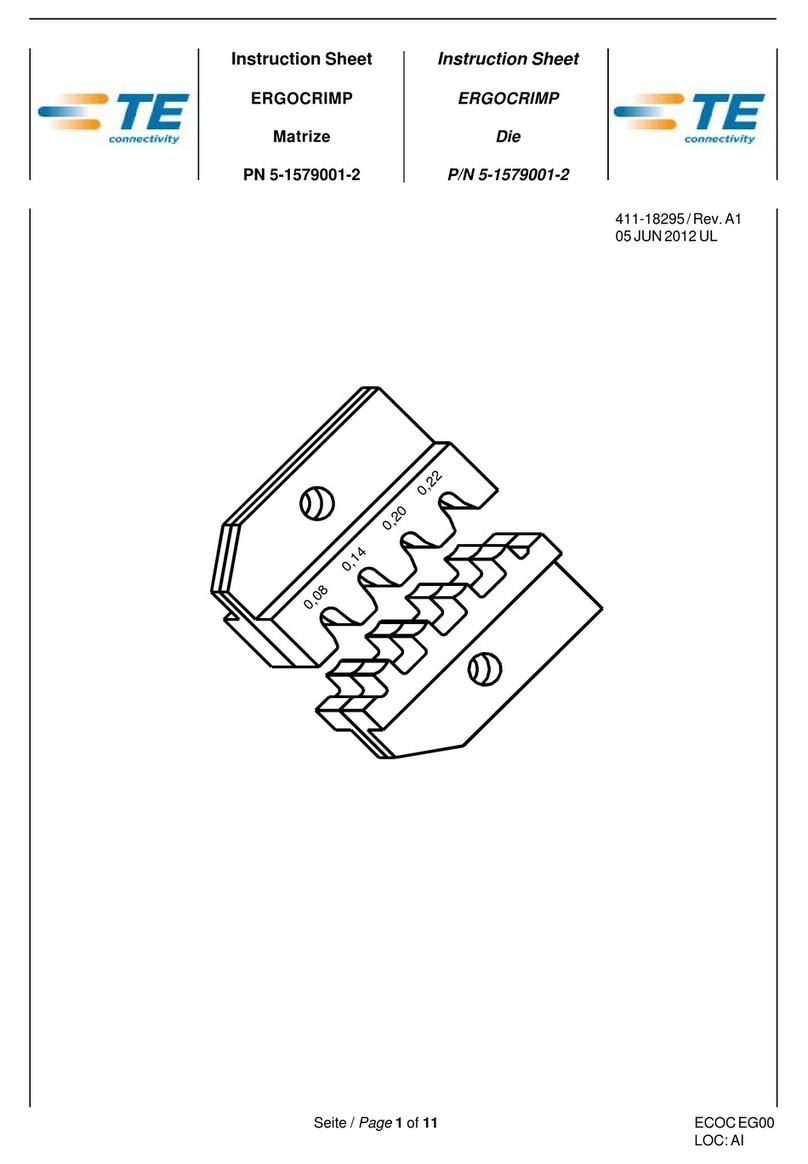

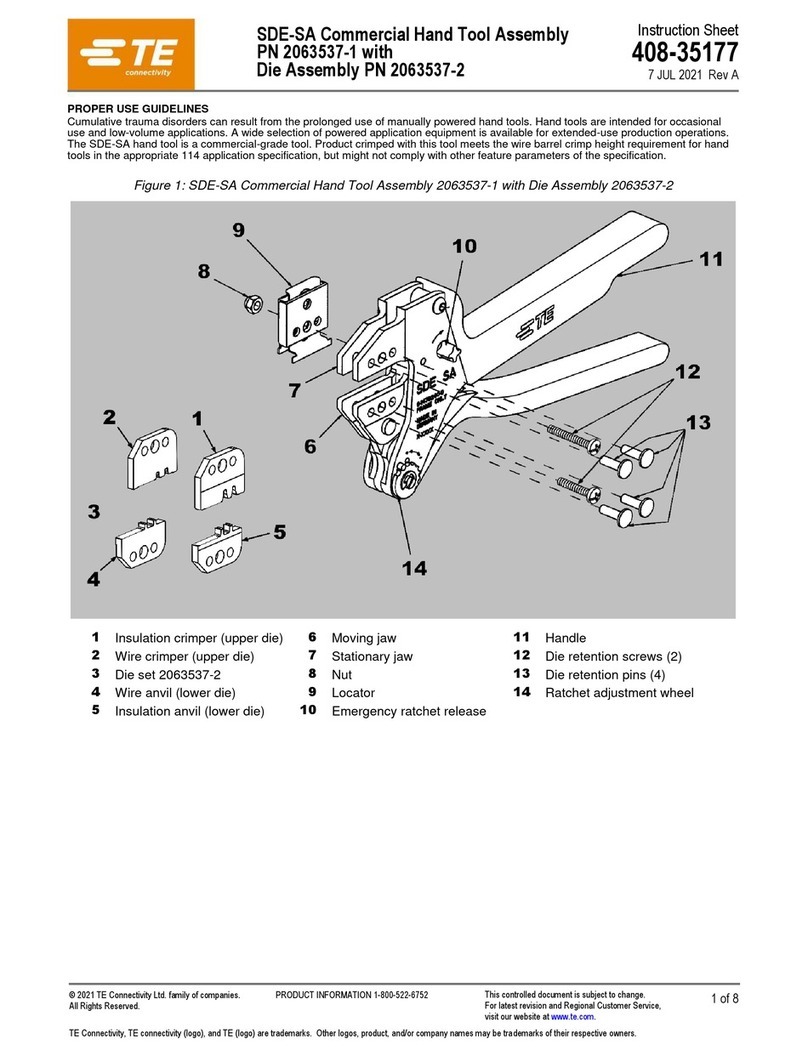

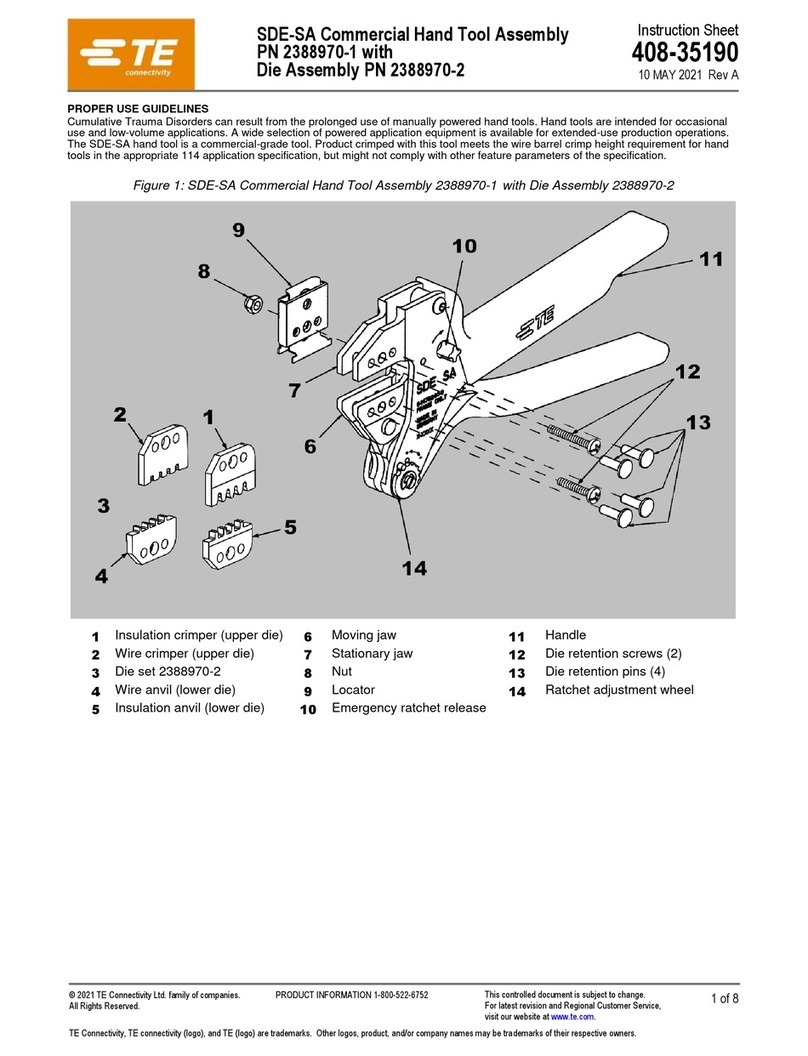

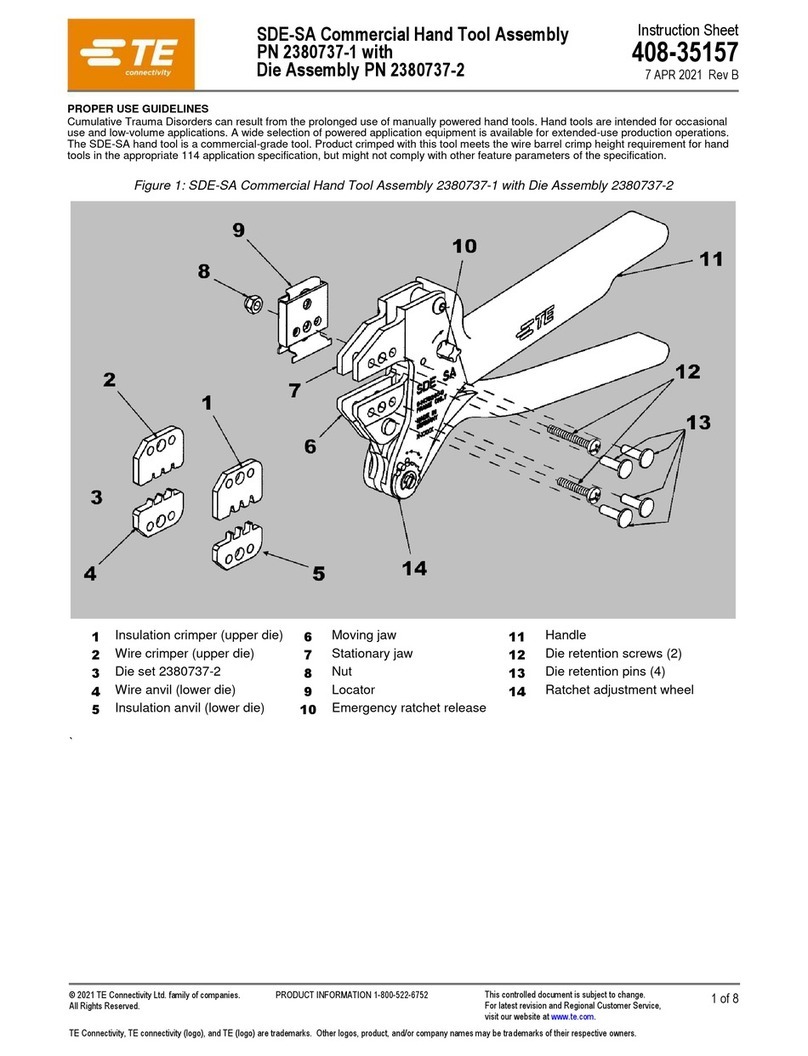

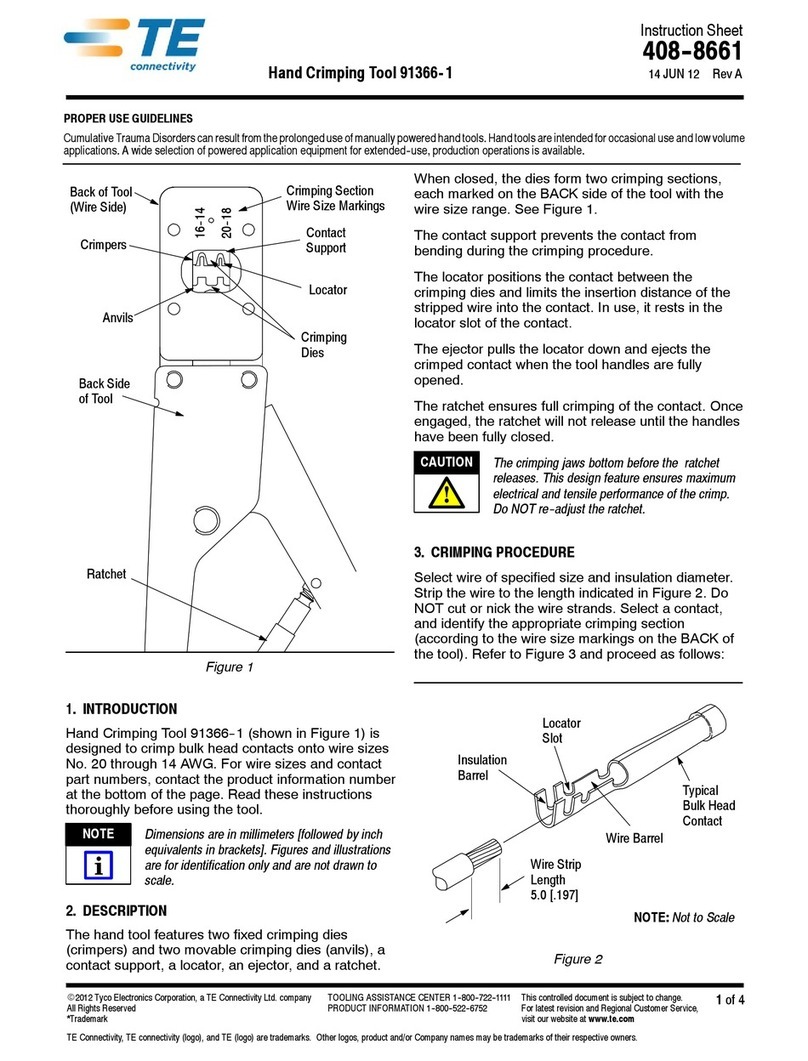

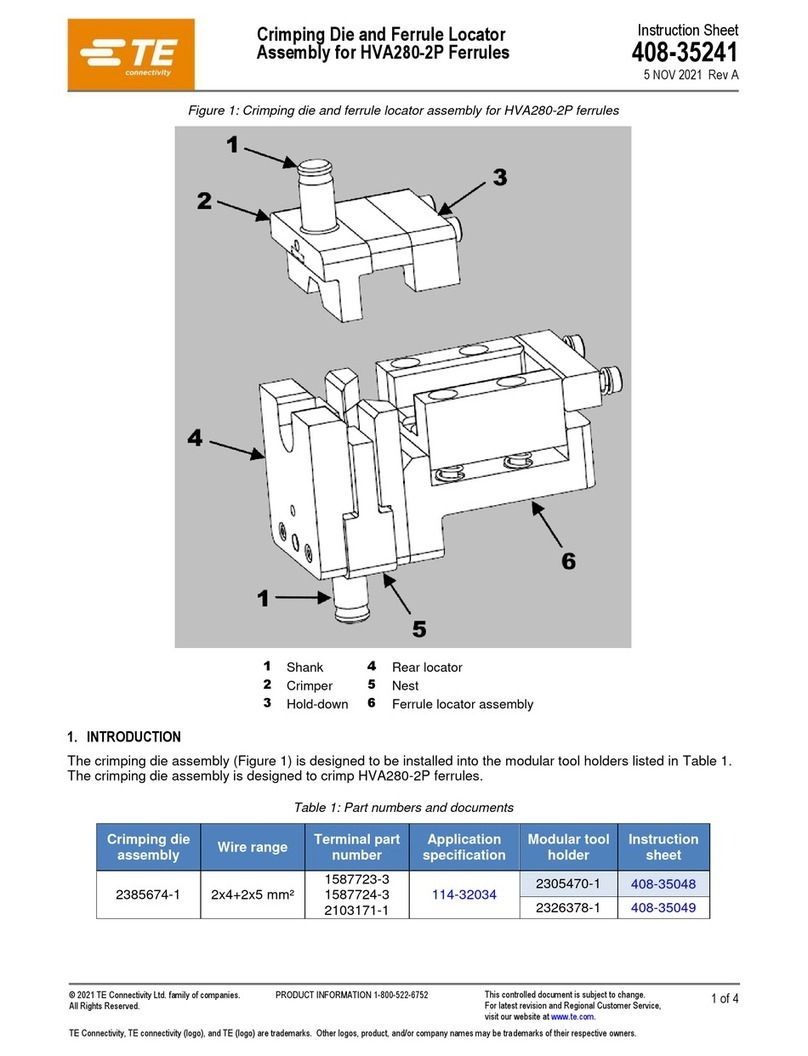

Figure 1

1. INTRODUCTION

This instruction sheet provides application and

maintenance procedures for PRO-CRIMPER III Hand

Tool Assembly 2161732-1 and crimping die assembly

2161717-1. See Figure 1. The hand tool consists of

the die assembly and PRO-CRIMPER III Hand Tool

Frame Assembly 354940-1 (refer to Instruction Sheet

408-9930 for use and maintenance on the hand tool

frame). The die assembly can be purchased

separately, or purchased with the hand tool.

For information on connector part numbers and

connector assembly procedures, refer to the

appropriate instruction sheet packaged with the

connector.

Dimensions in this instruction sheet are in metric

units [with U.S. customary units in brackets].

Figures and illustrations are for reference only and

are not drawn to scale.

Read these instructions and all referenced materials

thoroughly before using the die and tool assembly.

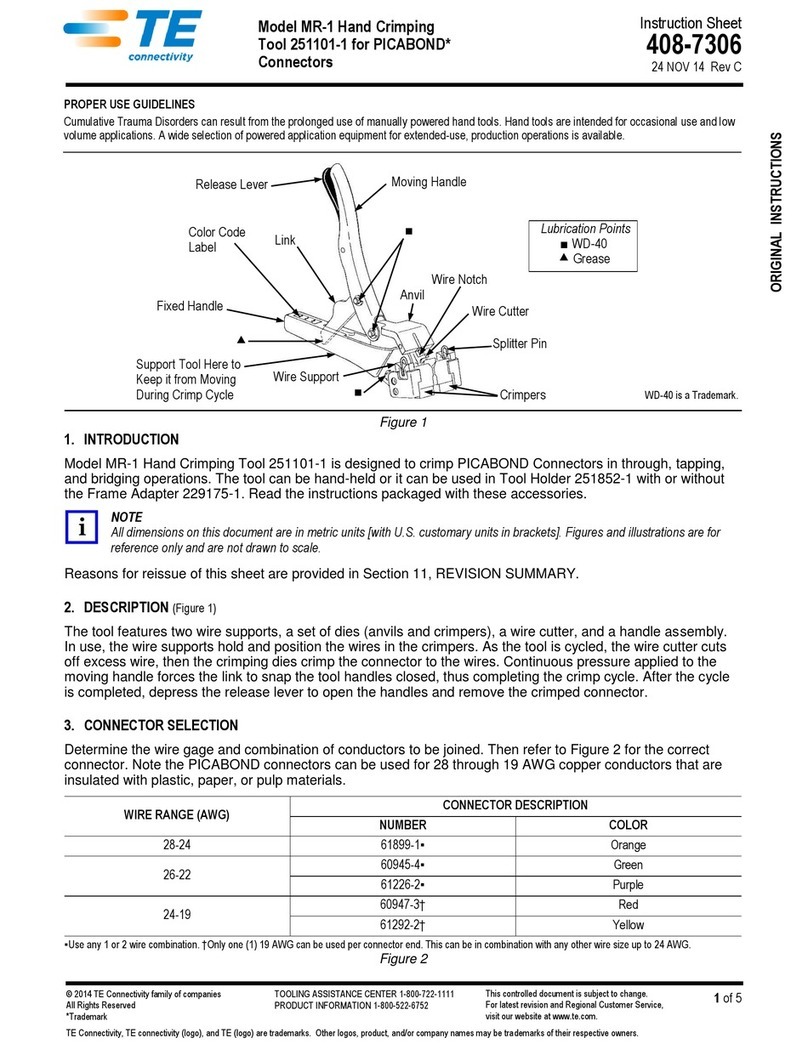

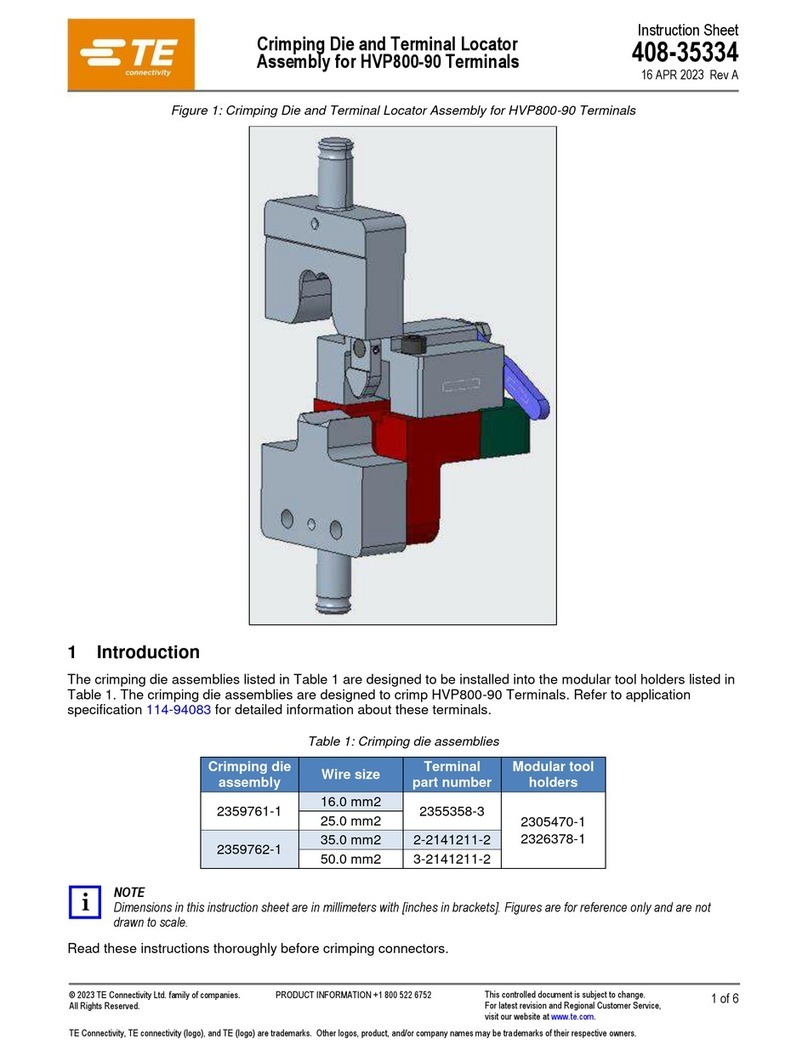

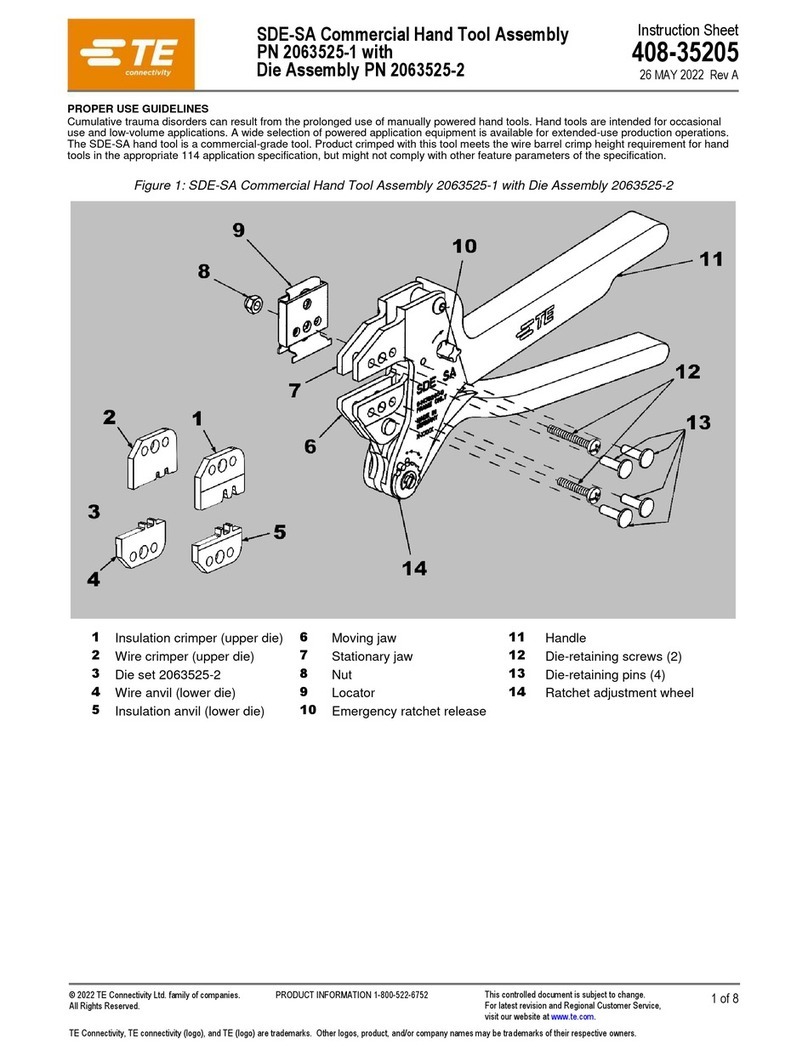

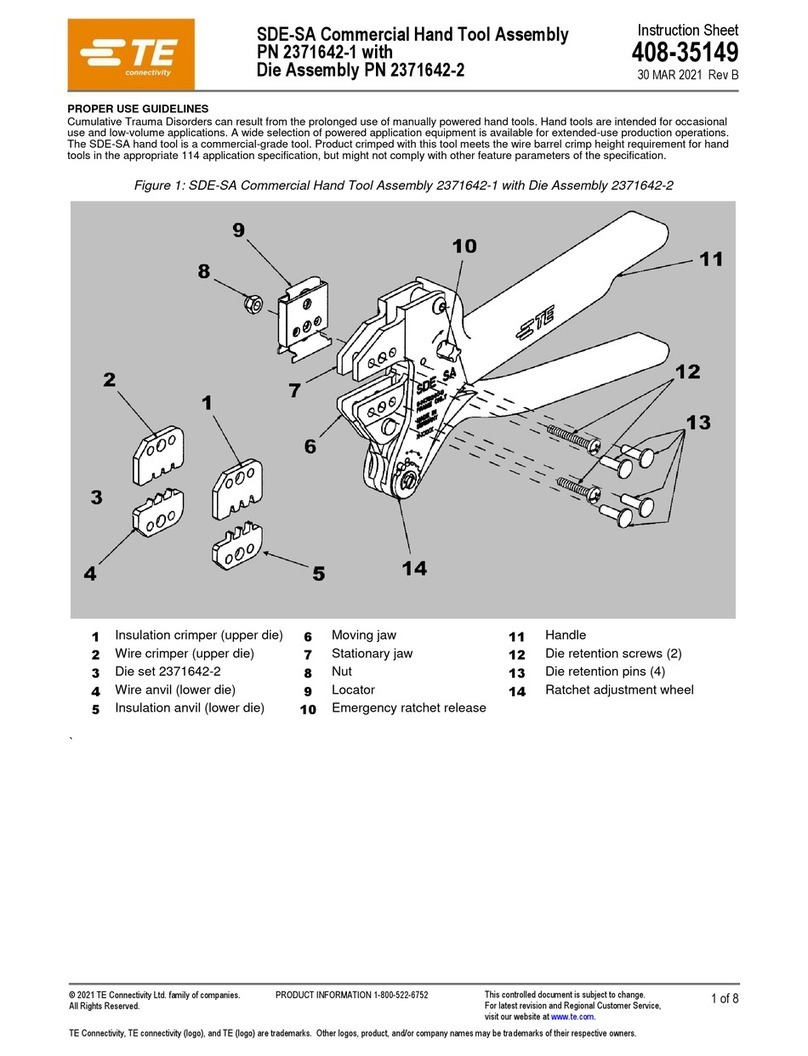

2. DESCRIPTION (See Figure 2)

The die assembly features an anvil die and a crimper

die. When closed, the dies produce three crimping

chambers that crimp the ferrule of the connector. Each

die is held in the tool jaws with a single die-retaining

screw.

3. DIE INSTALLATION (Figure 2)

1. Close the tool handles until the ratchet releases;

then allow the tool handles to open FULLY.

2. Install anvil die in the moving jaw of the hand tool.

Align the die with the retaining screw hole; then

secure die with the button head cap screw. Do NOT

fully tighten.

3. Install crimper die in the stationary jaw of the

hand tool. Slowly close the tool handles, allowing

the die to align itself with the upper die. When dies

are properly aligned, securely tighten both screws.

PRO-CRIMPERIII

Frame Assembly

354940-1

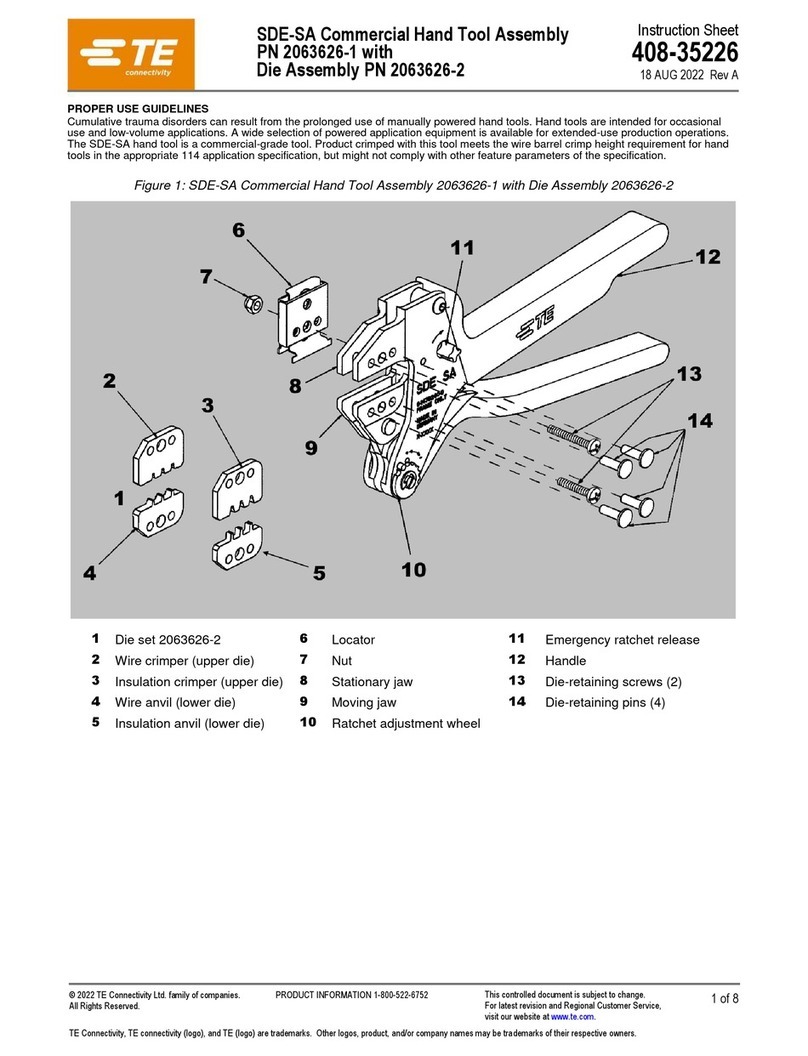

The PRO-CRIMPER III Hand Crimping Tool is a “Commercial” grade tool and is designed

primarily for field installation, repair, maintenance work, or prototyping in industrial,

commercial, or institutional applications. Product crimped with this tool will meet the crimp

height requirement for handtools in the appropriate ApplicationSpecification (114-series),

but may not comply with other feature parameters of the specification.

TE Connectivity offers a variety of tools to satisfy your performance requirements.

For additional information, contact the Tooling Assistance Center at 1-800-722-1111.

Crimper Die

(Stationary)

Anvil Die

(Movable)

CrimpingDie

Assembly

2161717-1

Die

Retaining

Screws

ORIGINAL INSTRUCTIONS