TE Connectivity 90382- 2 User manual

Other TE Connectivity Crimping Tools manuals

TE Connectivity

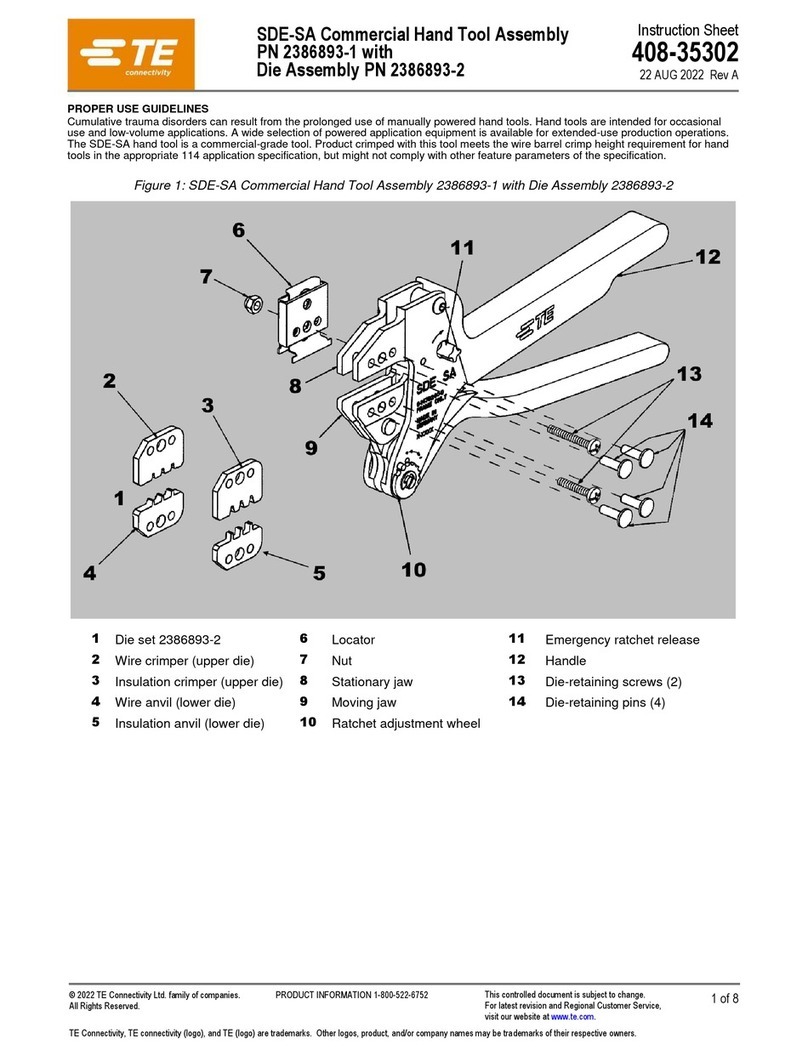

TE Connectivity 2386893-1 User manual

TE Connectivity

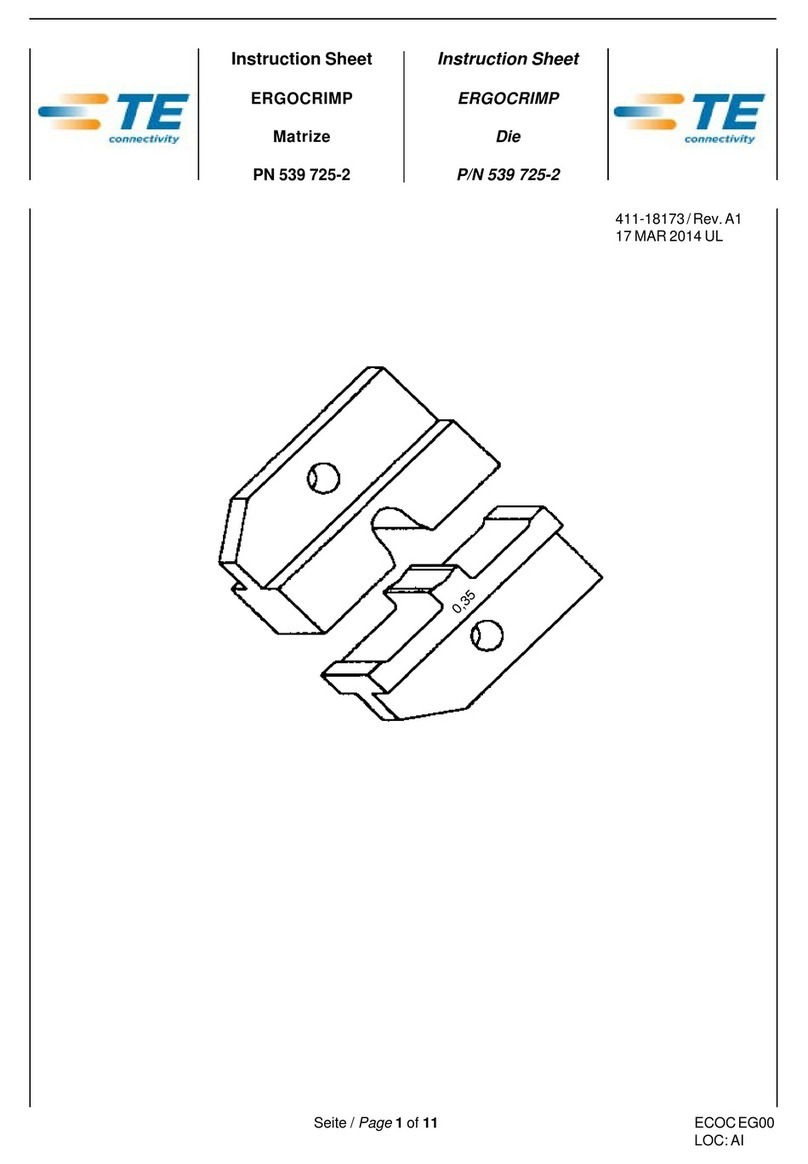

TE Connectivity ERGOCRIMP 539 725-2 User manual

TE Connectivity

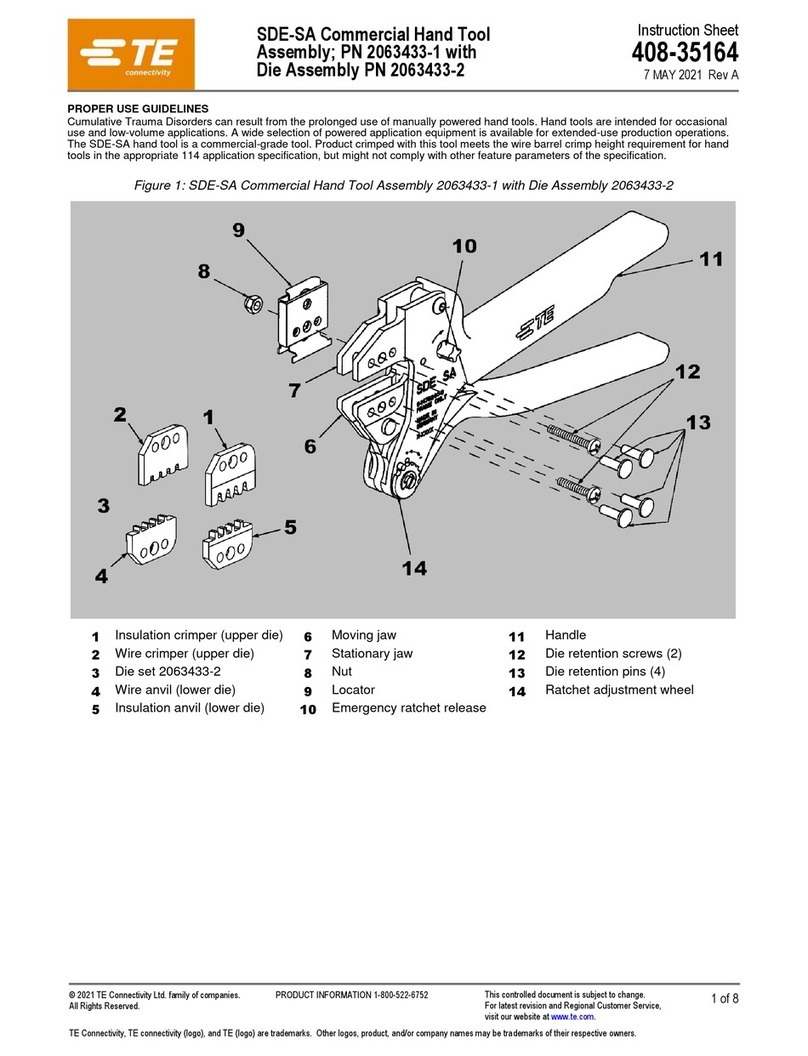

TE Connectivity 2063433-1 User manual

TE Connectivity

TE Connectivity FFC-MQS User manual

TE Connectivity

TE Connectivity 220015 Series User manual

TE Connectivity

TE Connectivity 58422-1 User manual

TE Connectivity

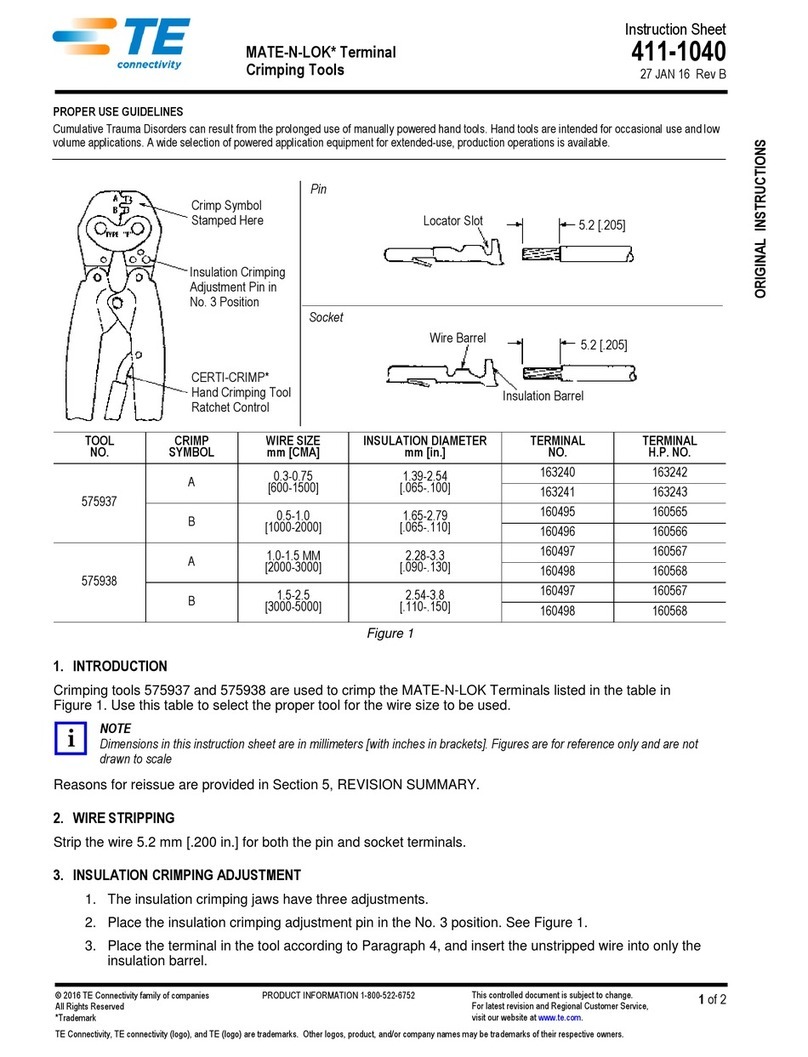

TE Connectivity 575937 User manual

TE Connectivity

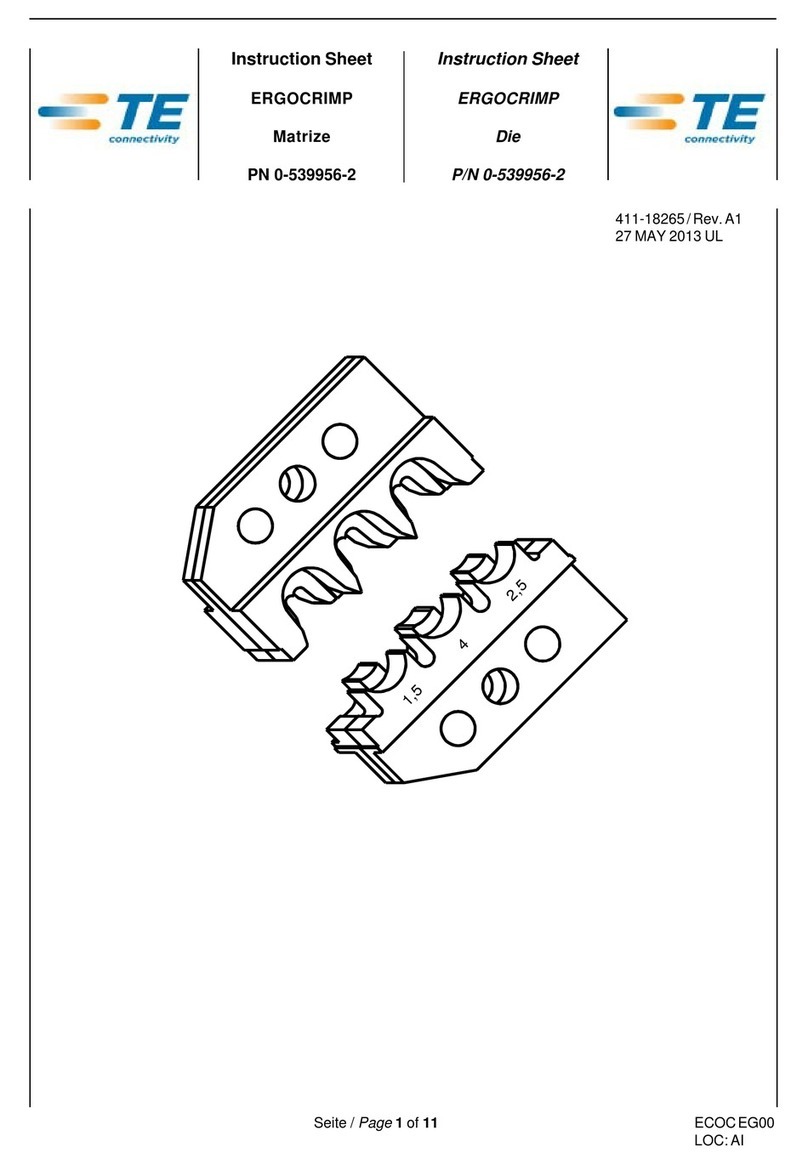

TE Connectivity ERGOCRIMP 0-539956-2 User manual

TE Connectivity

TE Connectivity AMP 3K Reference guide

TE Connectivity

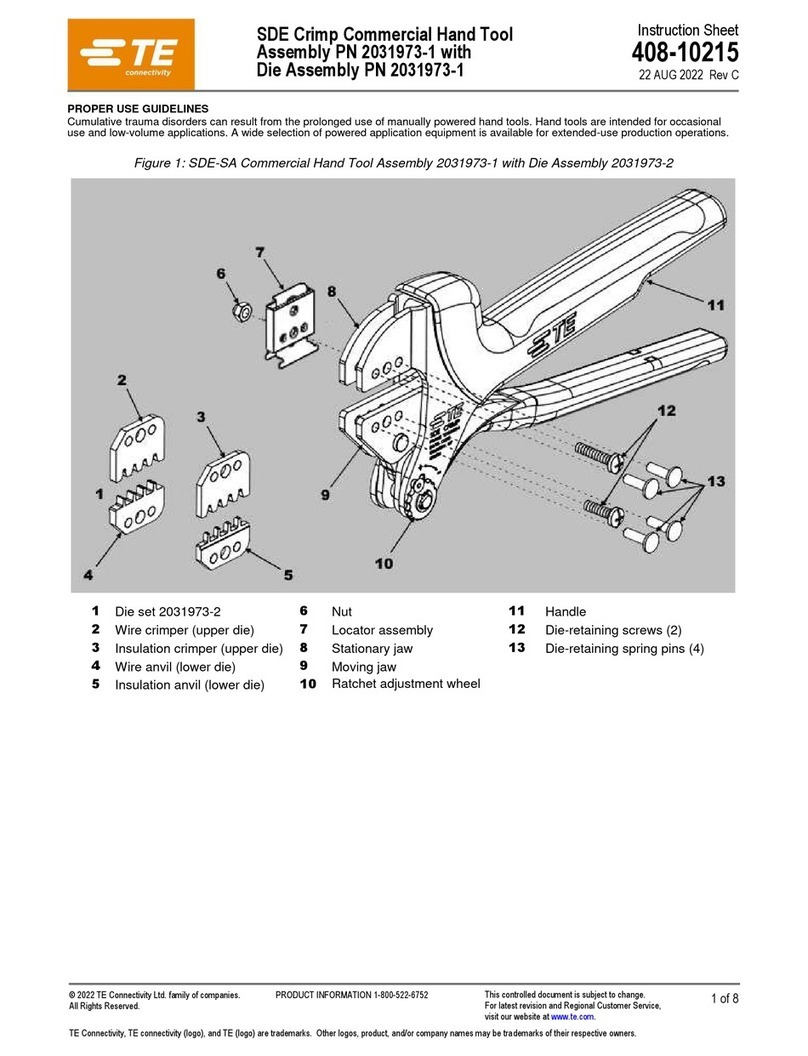

TE Connectivity 2031973-1 User manual

TE Connectivity

TE Connectivity 2386892-1 User manual

TE Connectivity

TE Connectivity 528008-4 User manual

TE Connectivity

TE Connectivity 2063574-1 User manual

TE Connectivity

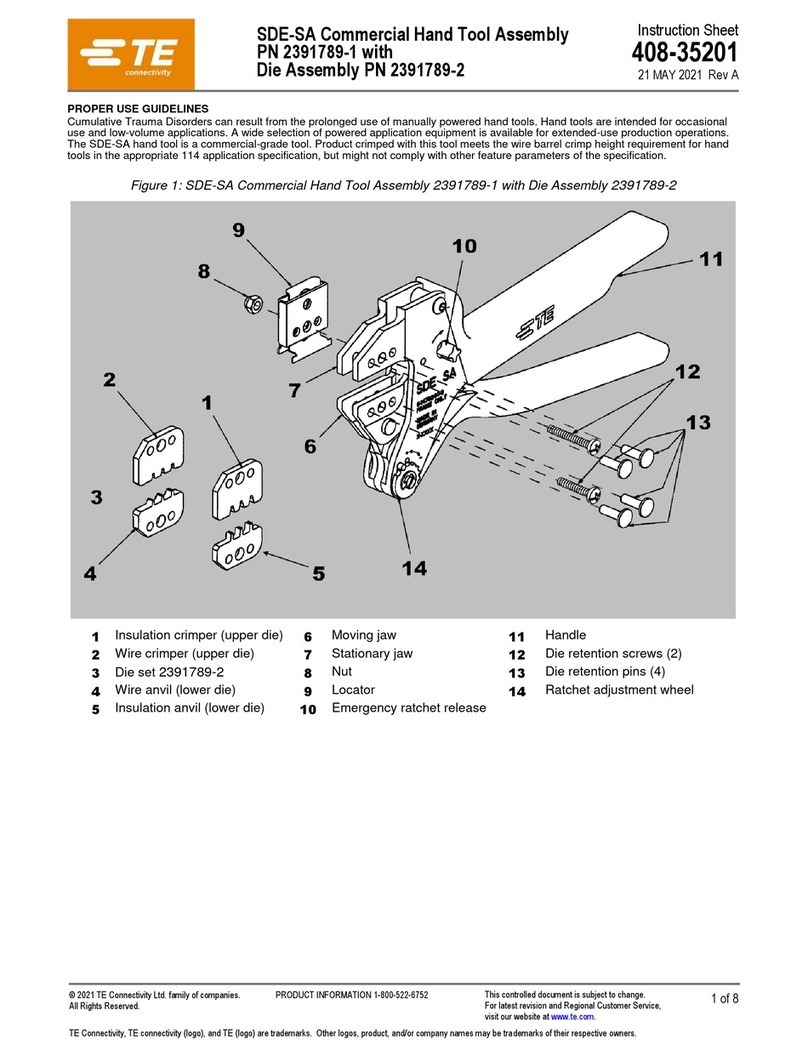

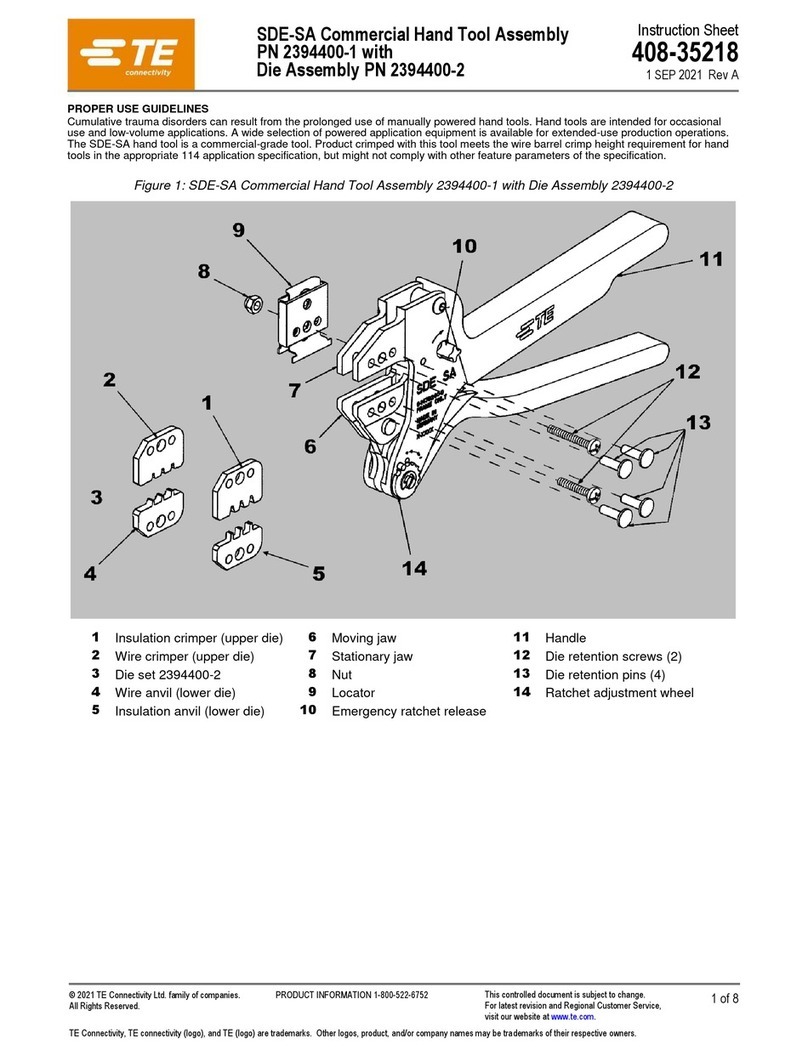

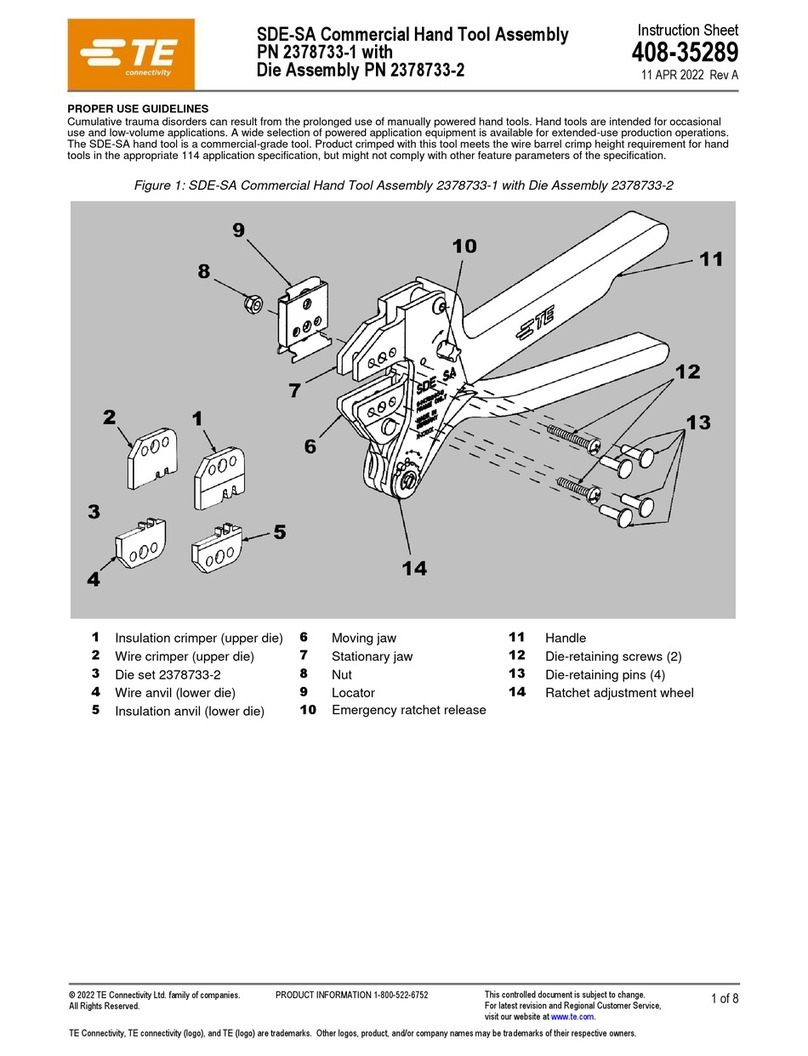

TE Connectivity SDE-SA User manual

TE Connectivity

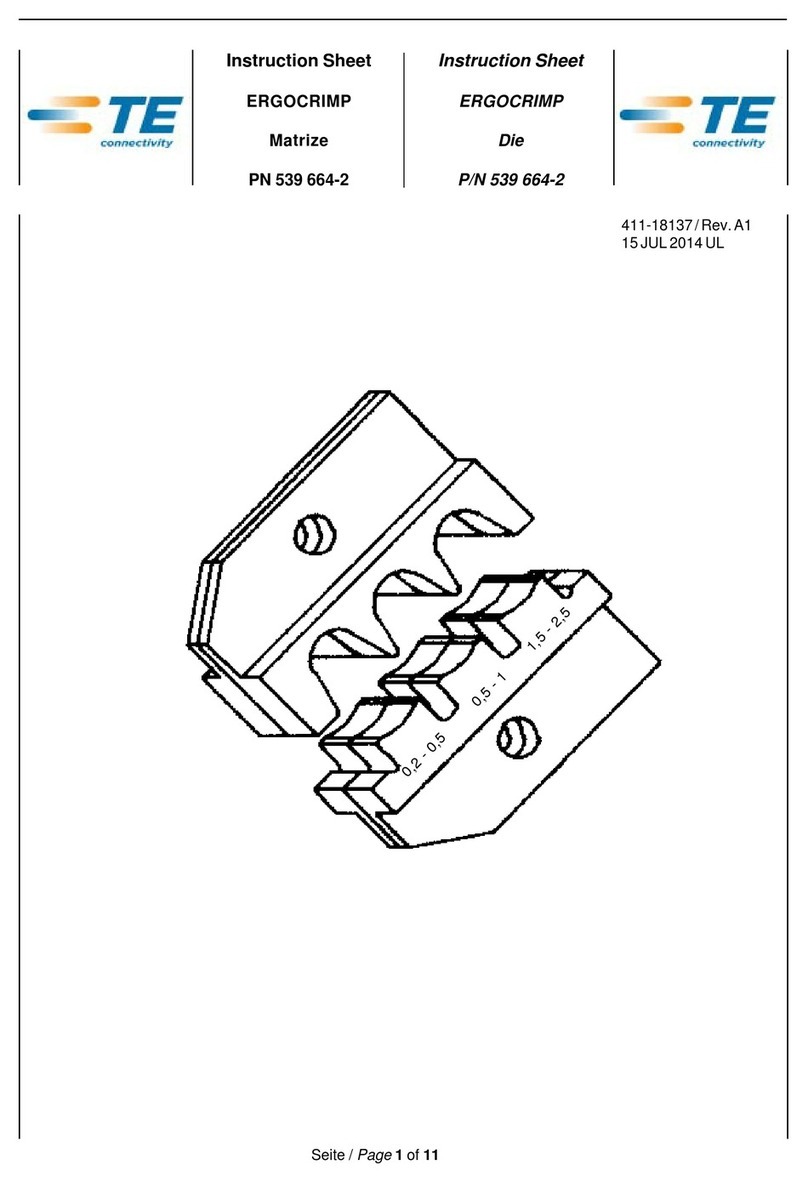

TE Connectivity ERGOCRIMP 539 664-2 User manual

TE Connectivity

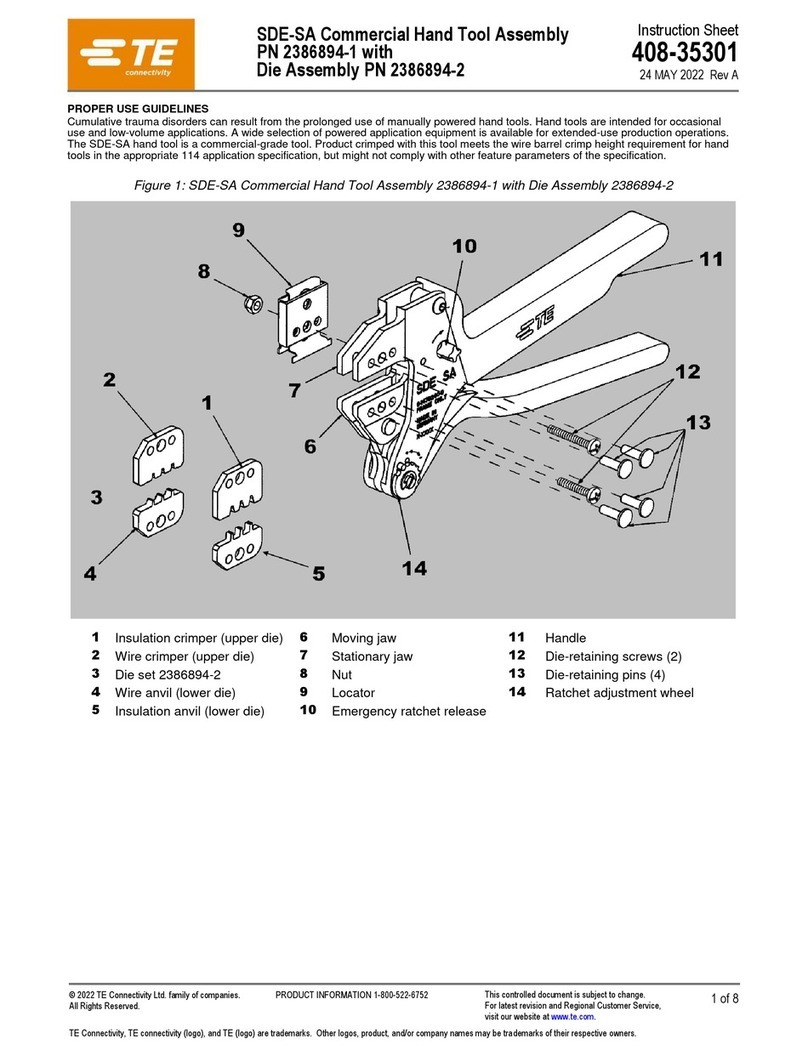

TE Connectivity 2386894-1 User manual

TE Connectivity

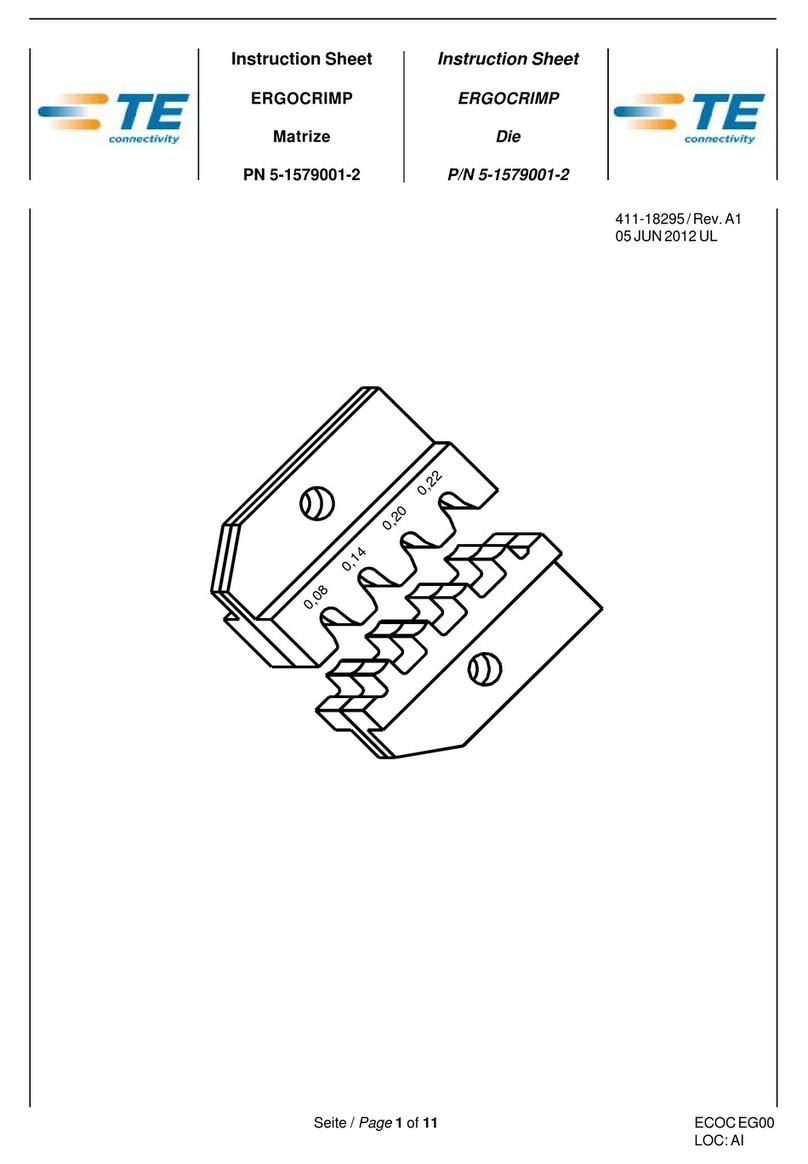

TE Connectivity ERGOCRIMP 5-1579001-2 User manual

TE Connectivity

TE Connectivity 825508-5 User manual

TE Connectivity

TE Connectivity SDE-SA User manual

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

molex

molex 207129 Series Specification sheet

molex

molex 207129 Series Specification sheet