408-4251

2of 4

Rev F

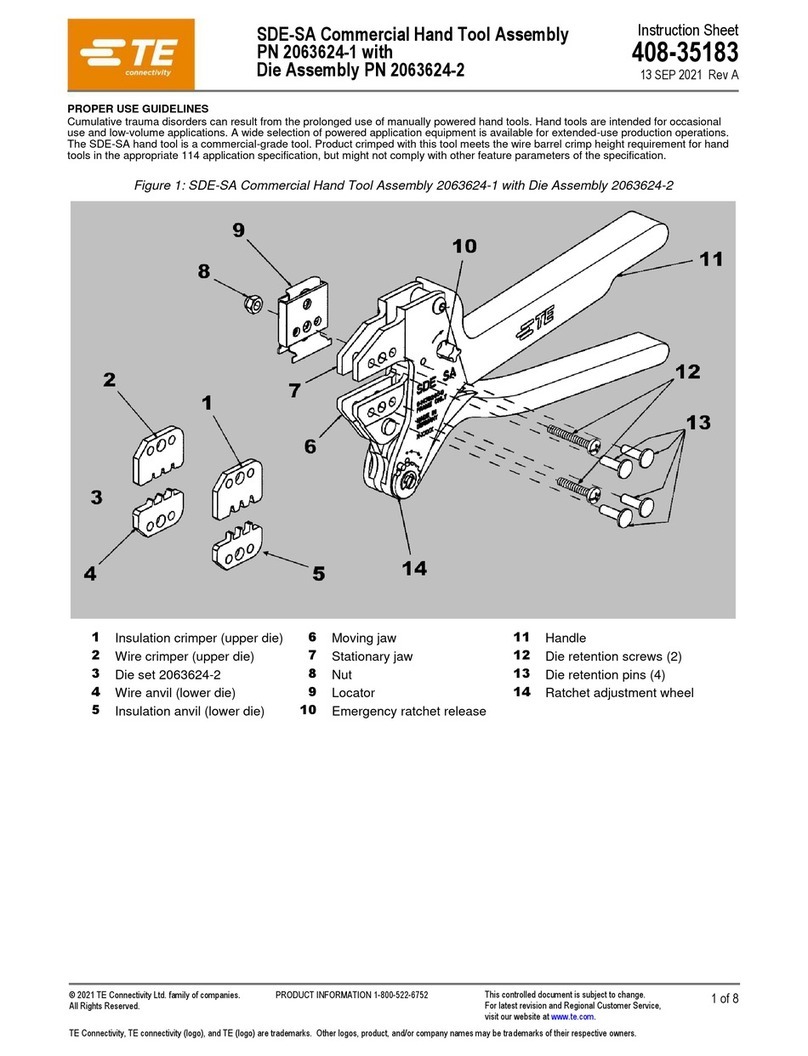

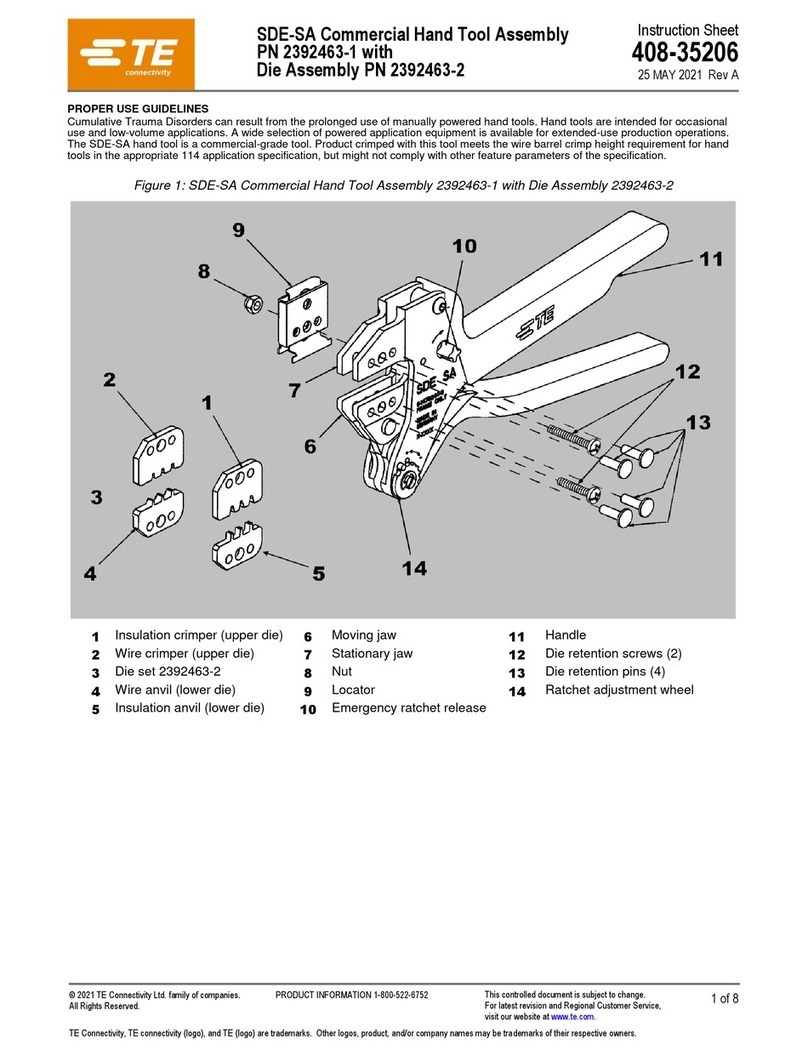

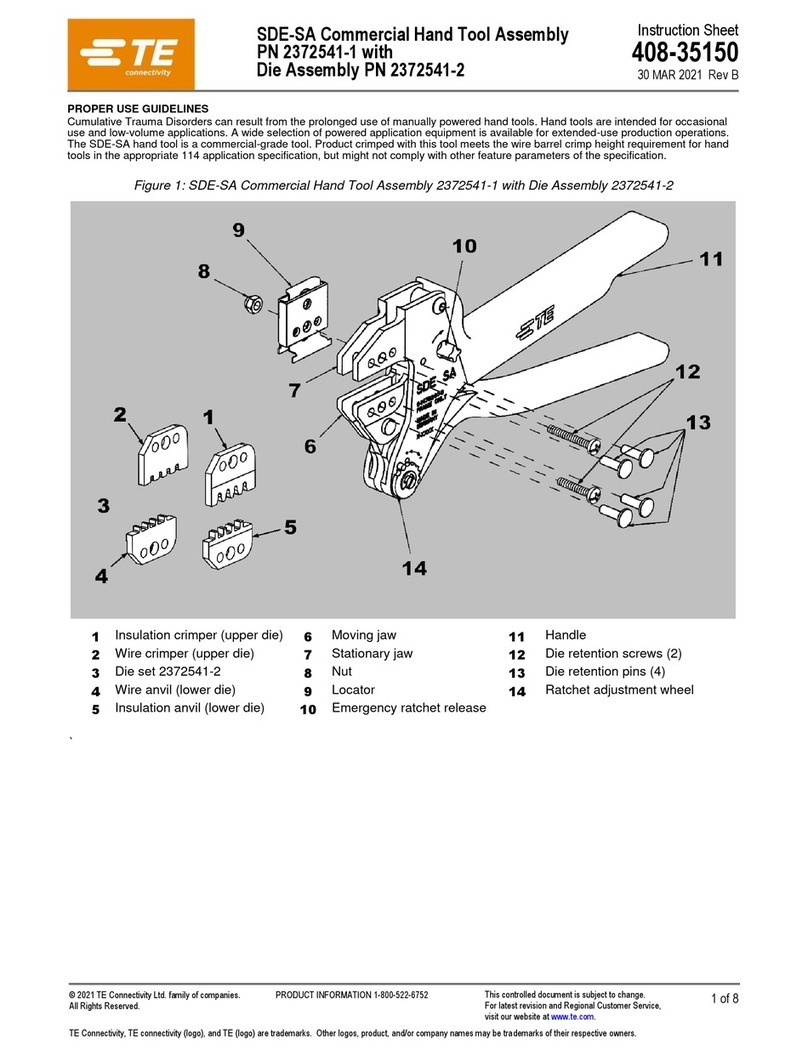

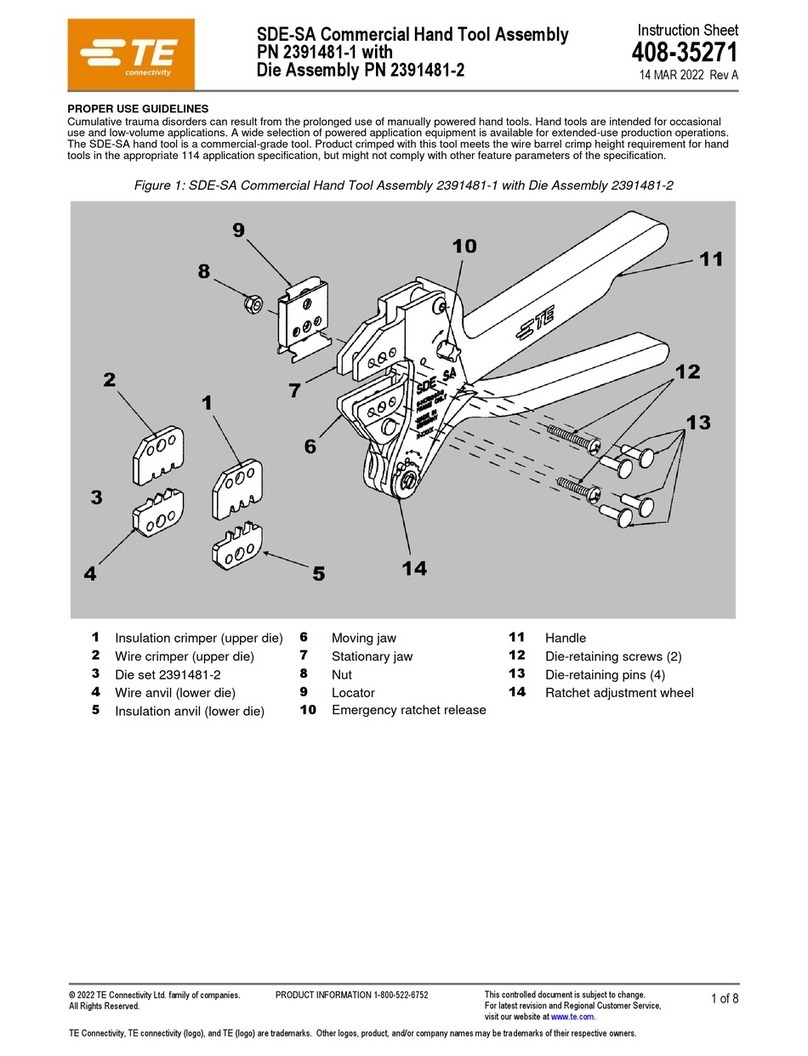

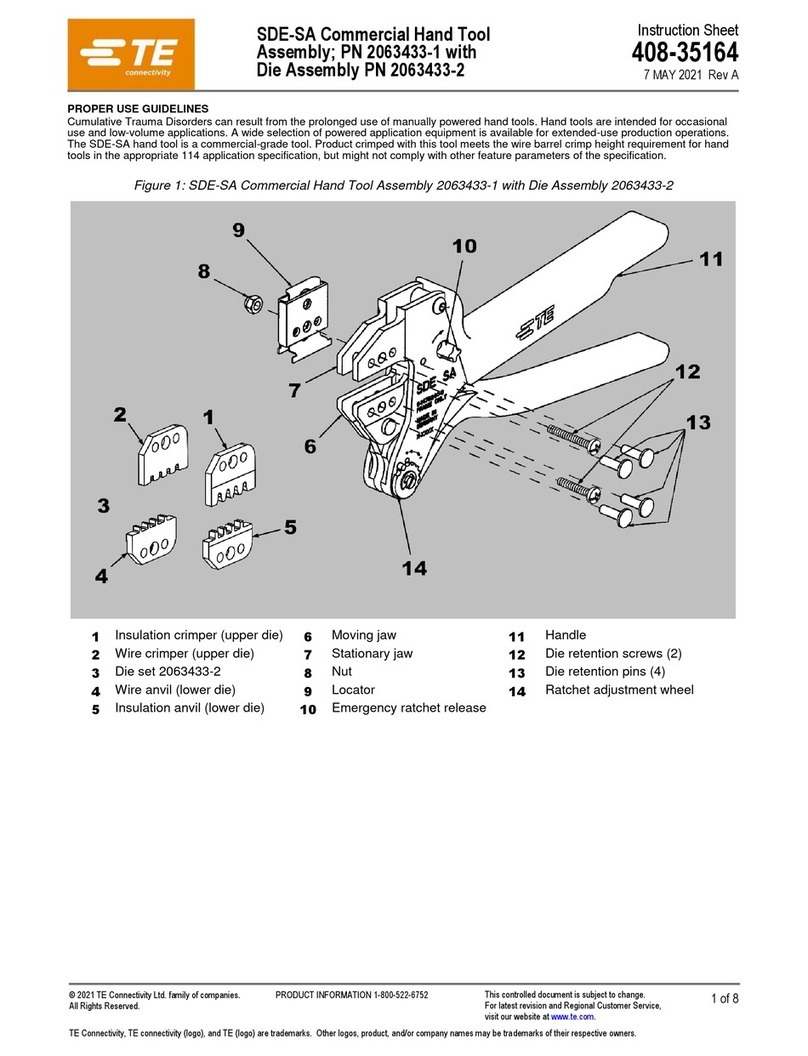

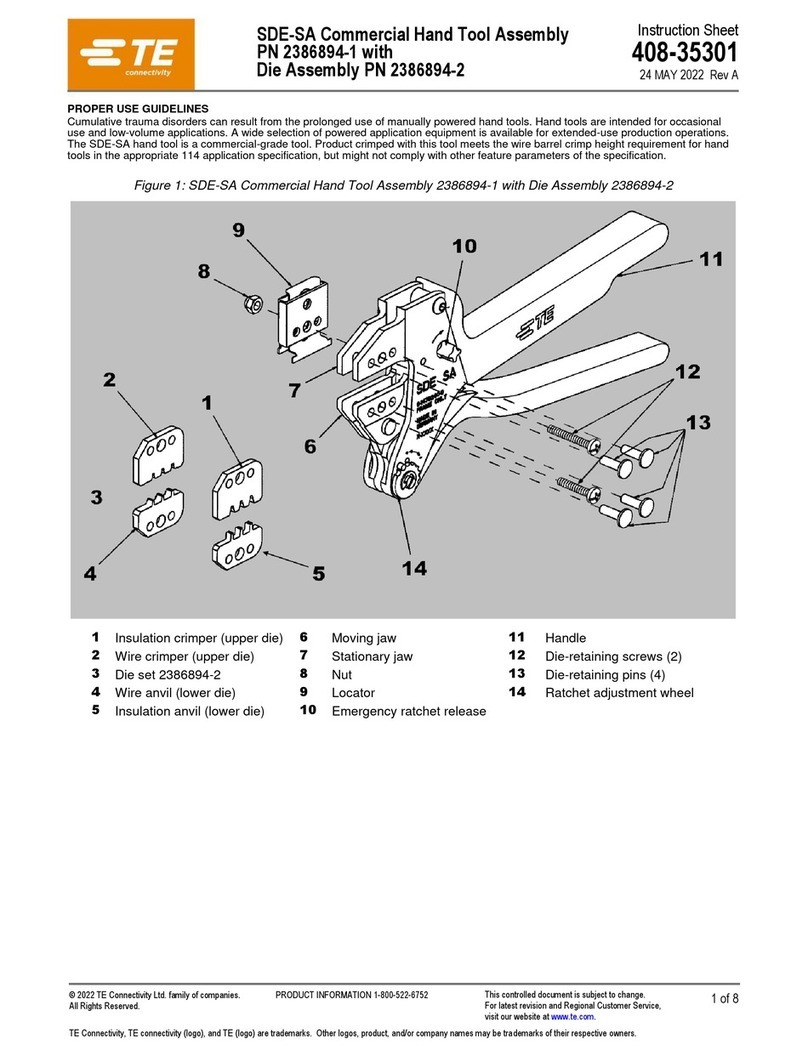

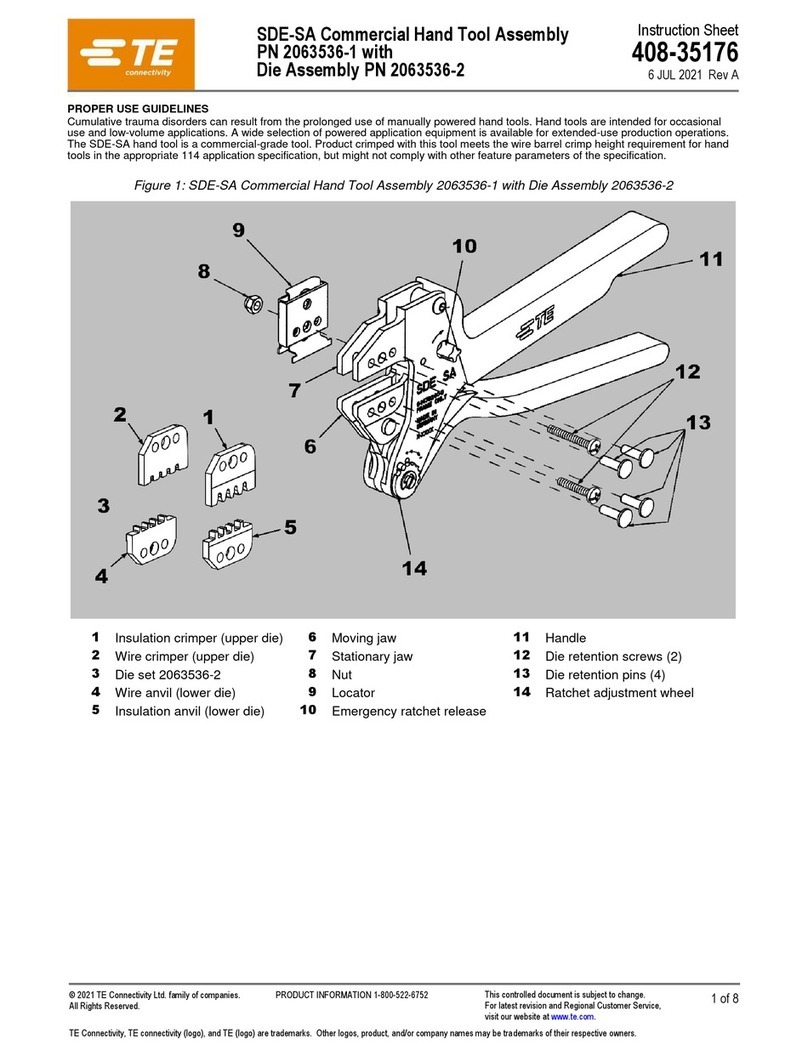

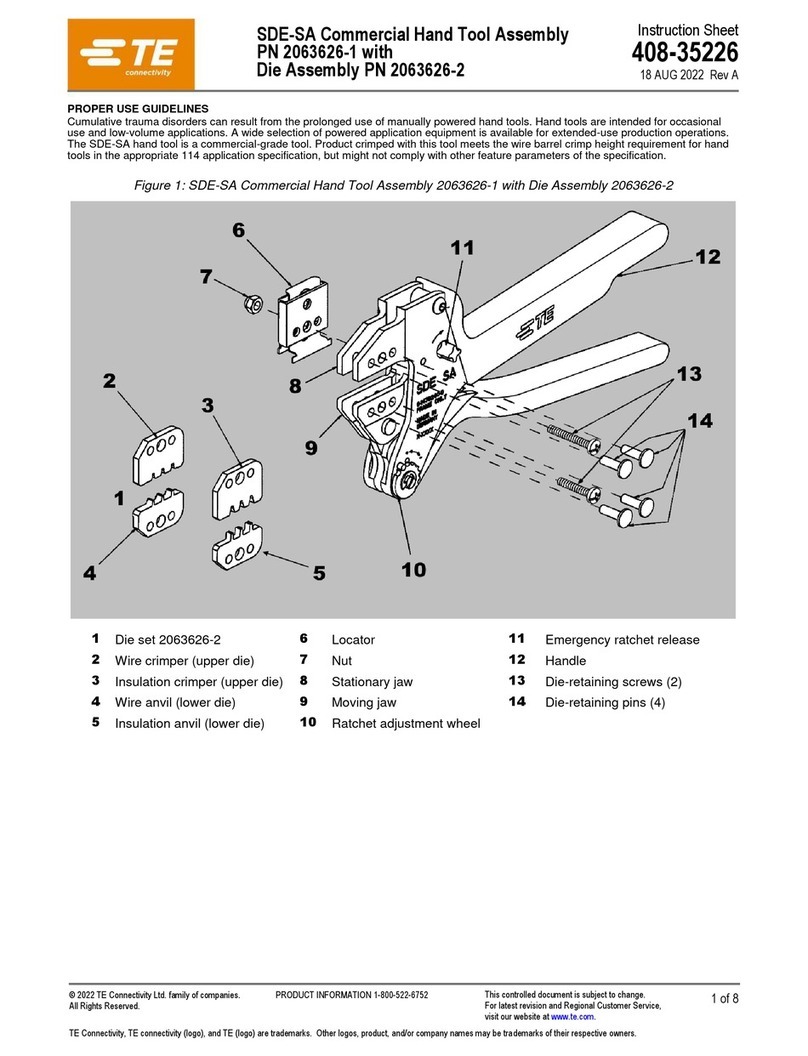

3. INSTALLATION AND REMOVAL OF DIE ASSEMBLY

1. Close the tool handles until the ratchet releases,

then allow the handles to open fully.

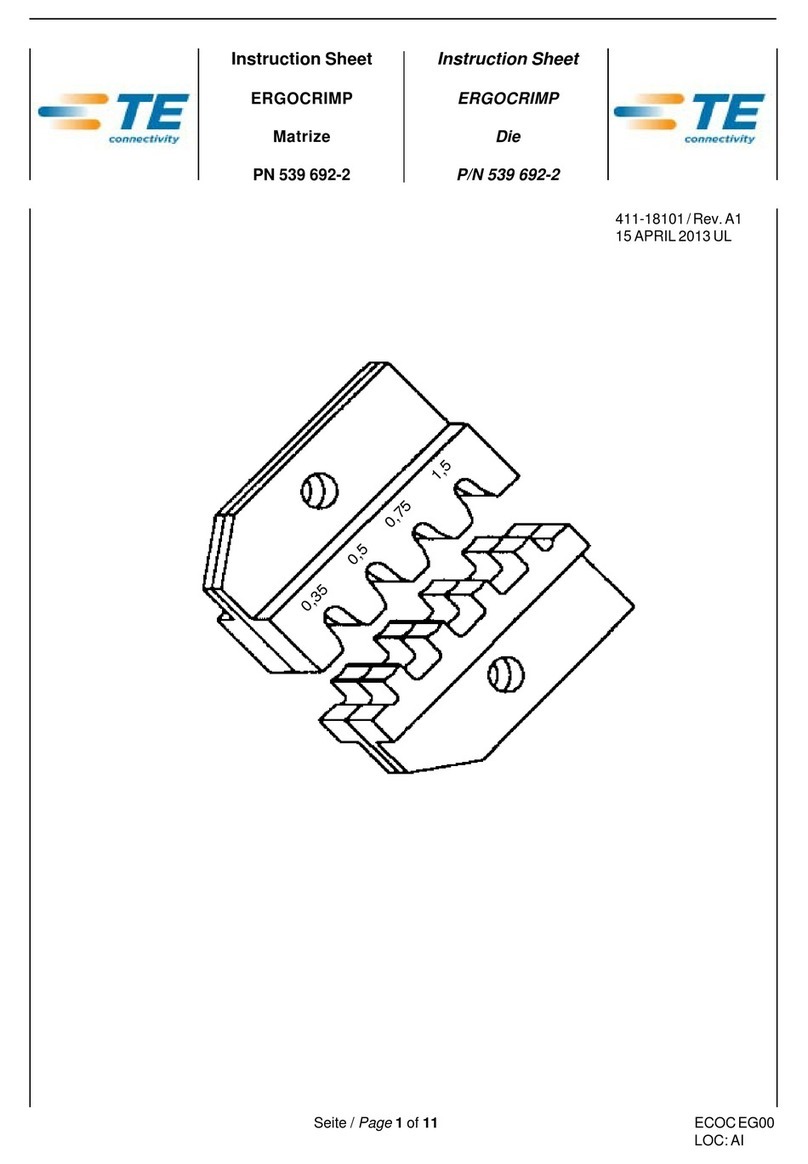

2. Insert the dies into the tool jaws as shown in

Figure 2, and align the retaining holes in each die

with the associated hole in the tool.

3. Thread, but do not tighten, the die retaining

screws into the holes.

4. Carefully close the tool handles, making sure that

the dies align properly.

5. Tighten the die retaining screws using the

appropriate screwdriver.

6. To disassemble, close the tool handles until the

ratchet releases, remove the two die retaining

screws, and slide the dies out of the tool jaws.

Figure 2

4. CRIMPING PROCEDURE

Refer to Figure 1, and select a spare wire cap for the

insulation diameter of the wire being used. Then

proceed as follows:

1. Close the tool handles until the ratchet releases,

then allow the handles to open FULLY.

2. Identify the color code of the spare wire cap, and

insert the spare wire cap into the crimping chamber

with the same color code. Make sure that the spare

wire cap is fully inserted.

3. Begin closing the tool handles until the spare wire

cap is held firmly in place. DO NOT deform the cap.

4. Insert the unstripped wire completely into the

spare wire cap. When bottoming the wire in a

moisture-resistant spare wire cap, greater insertion

force must be exerted on the wire to displace the

inhibitor in the spare wire cap.

5. Close the tool handles until the ratchet releases.

6. Allow the tool handles to open FULLY, and turn

the spare wire cap and wire one quarter of a turn

while pulling lightly on the wire until the spare wire

cap is free from the crimping chamber.

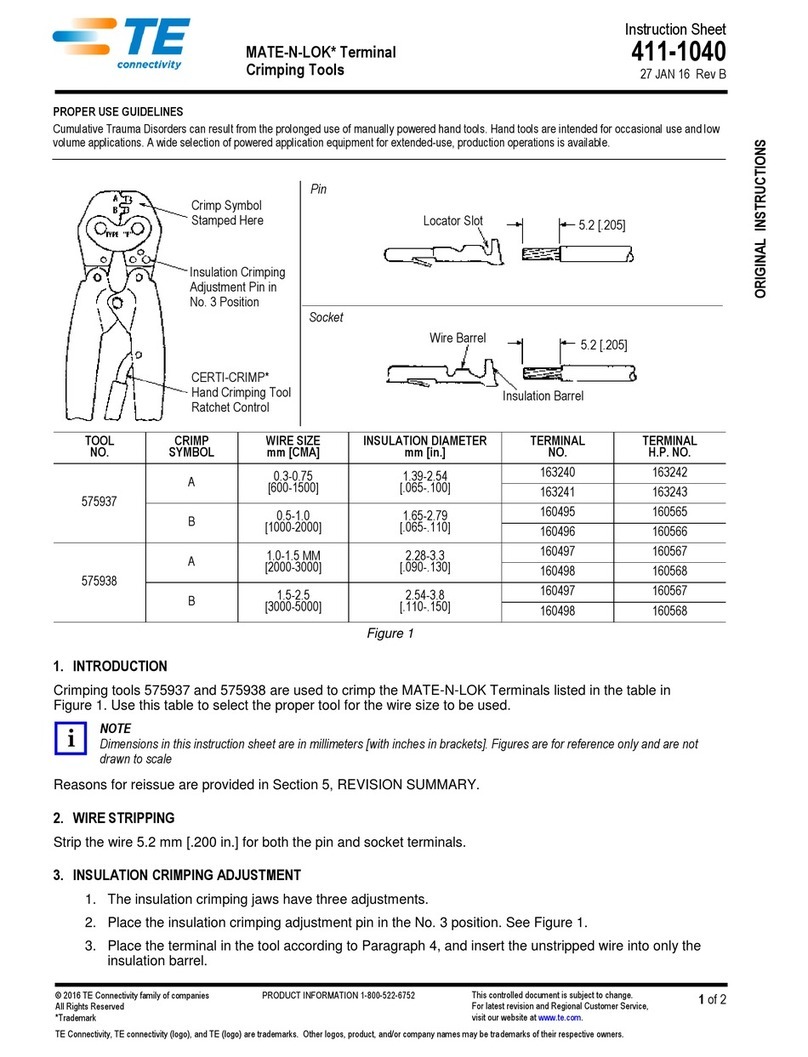

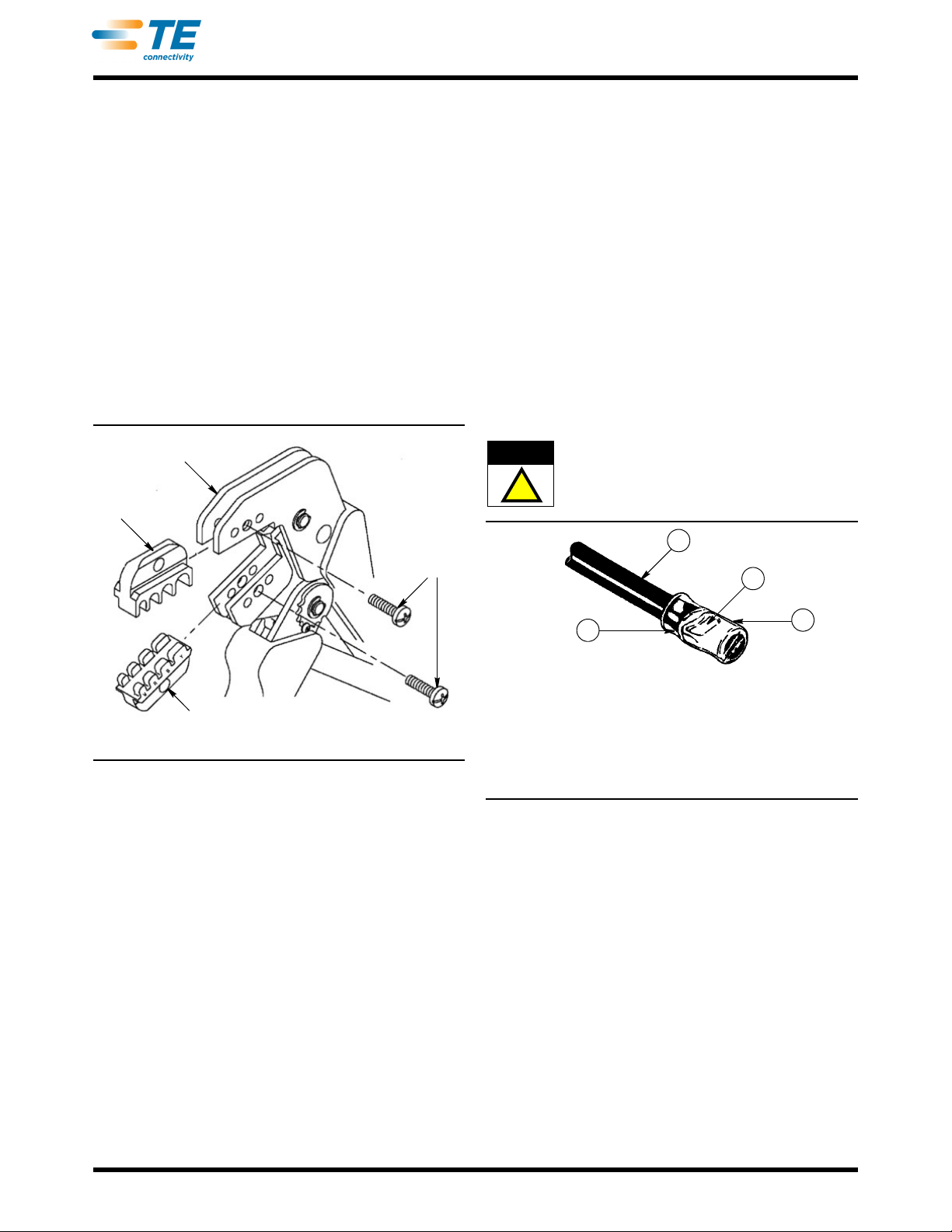

7. Refer to Figure 3, and inspect the crimped spare

wire cap for the following:

— The crimp should be near the center of the insert

in the spare wire cap, and the wire should be

bottomed in the spare wire cap.

— Double check that the correct spare wire cap was

used for the wire insulation diameter, and make

sure that the correct crimping chamber was used.

If the spare wire cap fails inspection, cut the wire

from the spare wire cap, then apply a new spare

wire cap to the wire by carefully following the

crimping procedure.

DO NOT use defective or damaged products.

Figure 3

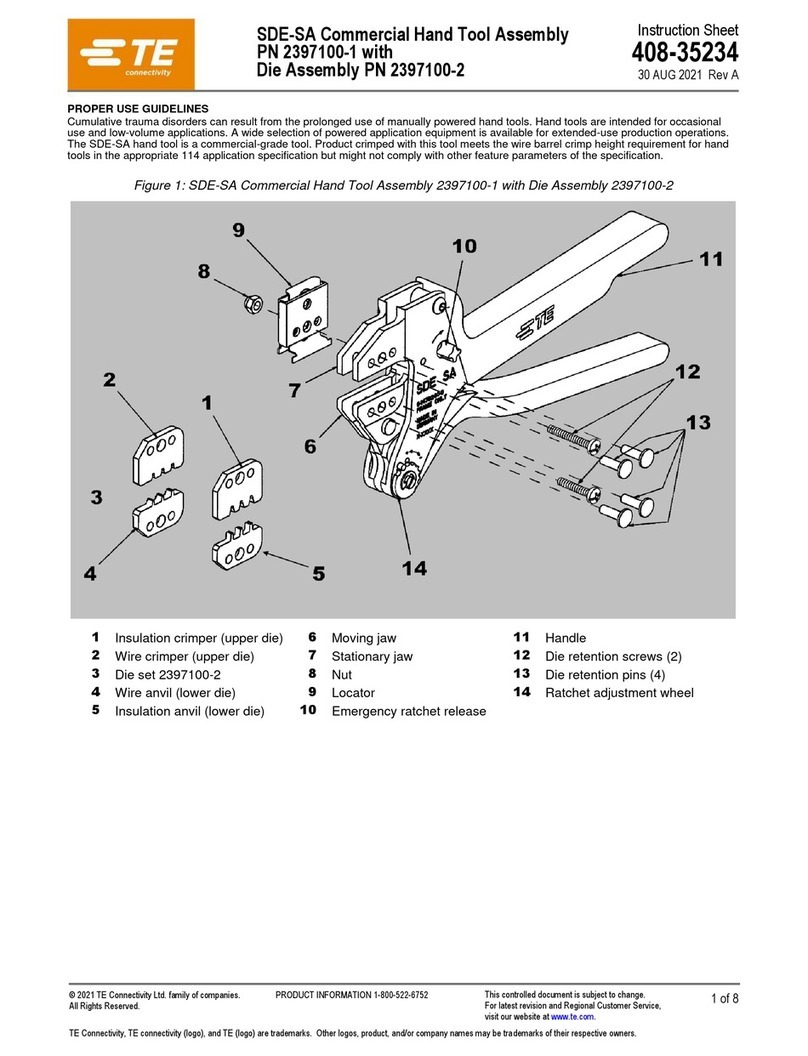

5. RATCHET ADJUSTMENT

The tool ratchet mechanism features an adjustment

wheel with numbered settings. The adjustment wheel

controls the amount of handle pressure exerted on the

jaws during crimping. If the crimp is not acceptable,

adjust the ratchet as follows:

1. Remove the lockscrew from the ratchet

adjustment wheel. Refer to Figure 4.

2. Using a screwdriver, adjust the ratchet wheel

from the front of the tool.

3. Observe the ratchet adjustment wheel. If a tighter

crimp is required, rotate the adjustment wheel

counterclockwise to a higher-numbered setting. If a

looser crimp is required, rotate the adjustment

wheel clockwise to a lower-numbered setting.

Indenter

Die

Anvil

Die

Die

Retaining

Screws

Jaws

1

2

3

1 Crimp near center of insert; spare wire cap was fully

bottomed in closed dies.

2 Correct wire insulation diameter for spare wire cap was used.

3 Wire bottomed in spare wire cap.

4 Spare wire cap insulation color matches die crimping

chamber marking.

4