408-6610

3of 4

Rev E

Specialprecautionsmustbetakenwheninsertinga

wireintoacontactcrimpedinthecrimpingchamber

marked “24-20/30-26”. The full length of the

stripped wire must rest on the bottom of the wire

barrel. For information concerning this “crush

crimp” technique, refer to Instruction Sheet

408-7497.

6. Holding the wire in place, squeeze the tool

handles until ratchet releases, then remove the

crimped contact.

Damagedcontacts mustnot beused.If adamaged

product is evident, it should be cut from the wire

andreplacedwithanewone.DONOTre-terminate

contacts.

4. MAINTENANCE AND INSPECTION

It is recommended that a maintenance and inspection

program be performed periodically to ensure

dependable and uniform terminations. Though

recommendations call for at least one inspection a

month, frequency of inspection depends on:

— care, amount of use, and handling of the hand

tool

— presence of abnormal amounts of dust and dirt

— degree of operator skill

— your own established standards

The tool is inspected beforebeing shipped; however, it

is recommended that the tool be inspected

immediately upon arrival at your facility to ensure that

the tool has not been damaged during shipment.

4.1. Daily Maintenance

1. The hand tool should be immersed (handles

partially closed) in a reliable commercial degreasing

compound to remove accumulated dirt, grease, and

foreign matter. When degreasing compound is not

available, the tool may be wiped clean with a soft,

lint-free cloth. DO NOT use hard or abrasive objects

that could damage the tool.

2. Make certain that the retaining pins are in place

and that they are secured with retaining rings.

DO NOT remove the retaining pins as permanent

damage to the tool could result.

3. All pins, pivot points, and bearing surfaces should

be protected with a THIN coat of any good SAE 20

motor oil. DO NOT oil excessively.

When the tool is not in use, keep handles closed to

prevent objects from becoming lodged in the dies.

Store the tool in a clean, dry area.

SAE is a trademark.

4.2. Periodic Inspection

At least one inspection a month is recommended and

the inspection frequency should be based on the

amount of use, ambient working conditions, operator

training and skill, and company established standards.

A. Lubrication

Keep all pins, pivot points, and bearing surfaces

lubricated with SAE 20 motor oil as follows:

•Tool used in daily production-lubricate daily

•Tool used daily (occasionally)-lubricate weekly

•Tool used weekly-lubricate monthly

Wipe excess oil from the tool, particularly from the

crimping area. Oil transferred from the crimping area

onto certain terminations may affect the electrical

characteristics of an application.

B. Visual Inspection

1. Close the tool handles until the ratchet releases

and then allow them to open freely. If they do not

open quickly and fully, return the tool for evaluation

and repair. See Section 5, REPLACEMENT AND

REPAIR.

2. Inspect the head assembly for worn, cracked, or

broken areas. If damage is evident, return the tool

for evaluation and repair. See Section 5,

REPLACEMENT AND REPAIR.

C. Crimp Height Inspection

This inspection incorporates the use of a crimp height

comparator (micrometer with a modified anvil) as

shown in Figure 4. Detailed information on obtaining

and using a crimp height comparator can be found in

Instruction Sheet 408-7424.

Proceed as follows:

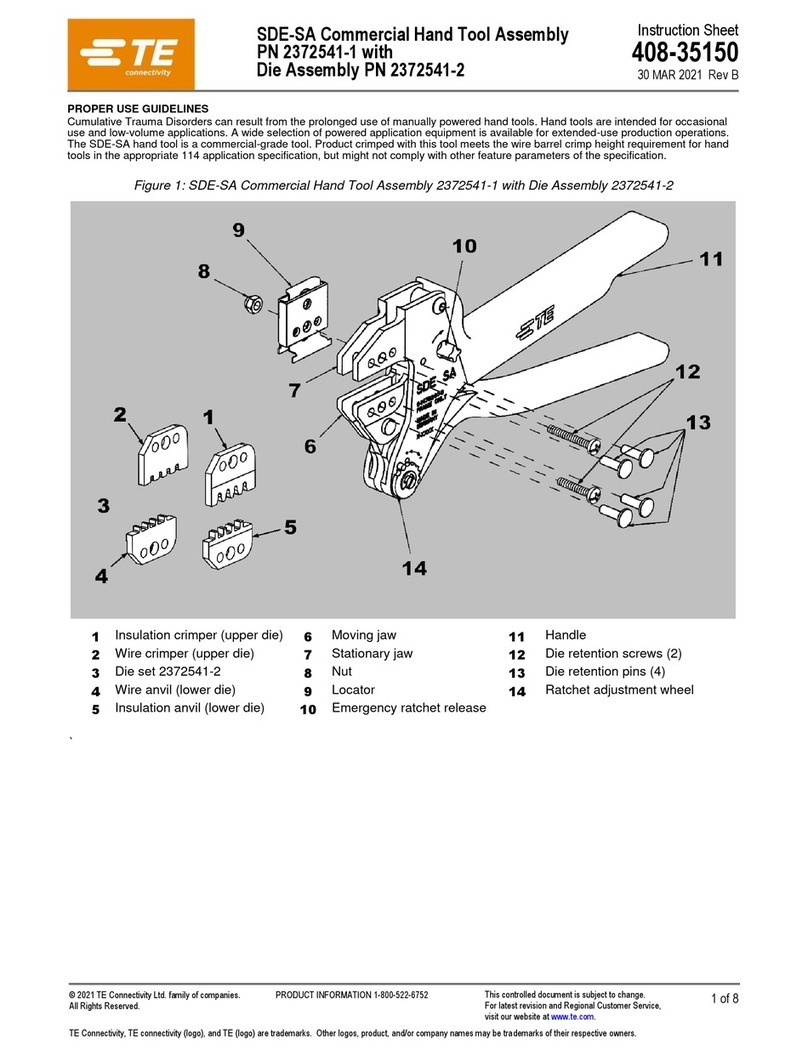

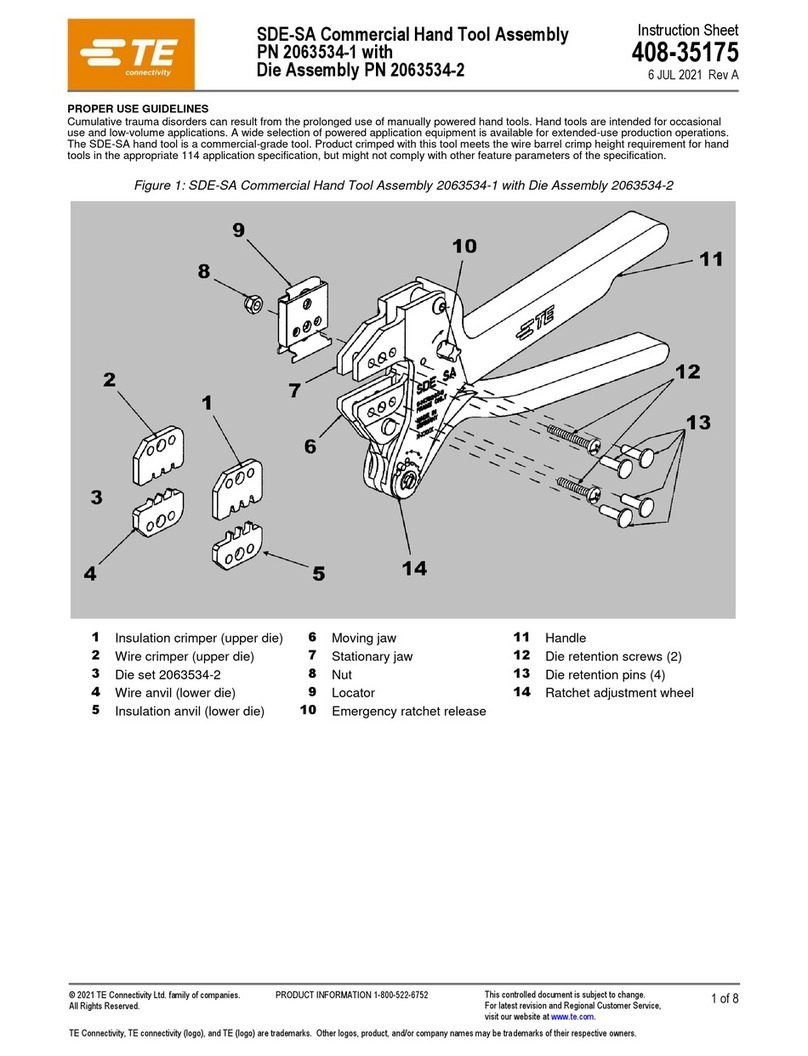

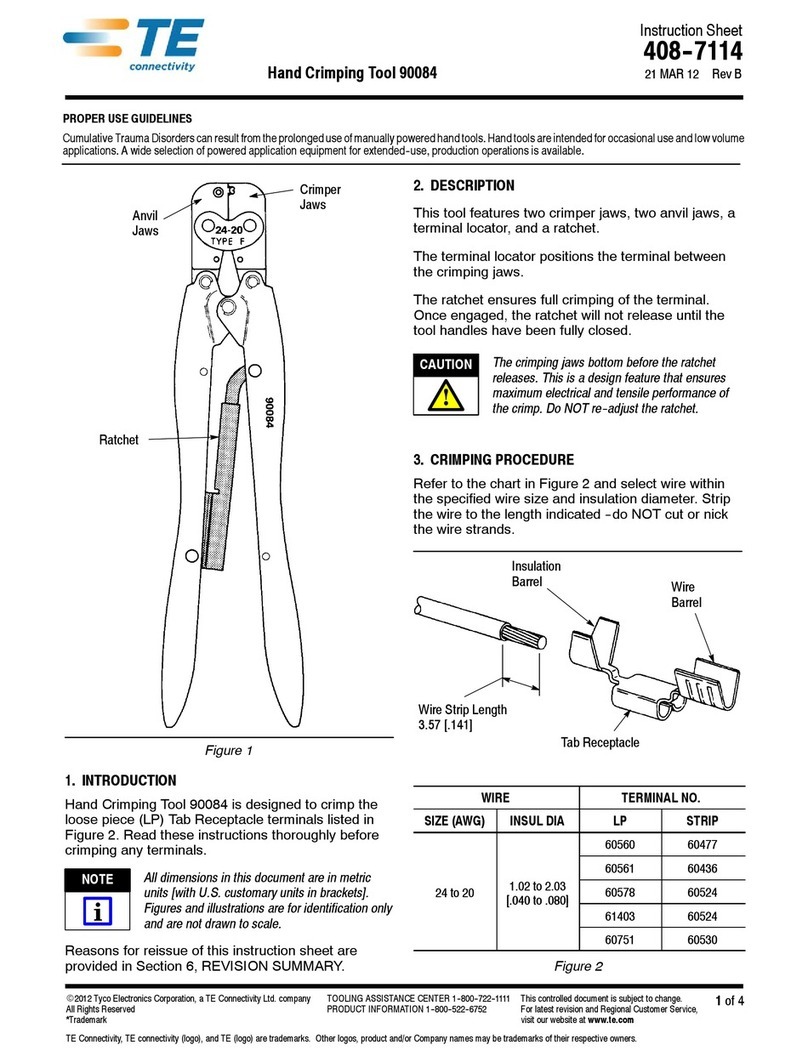

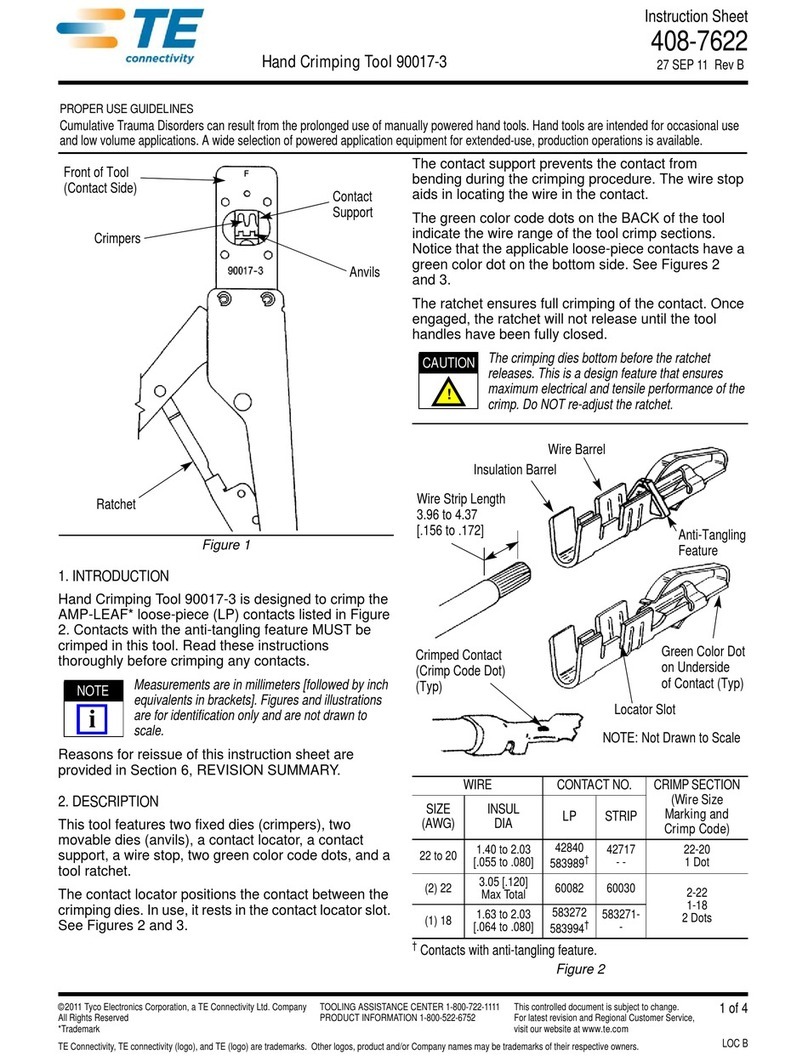

1. Determine the maximum wire size, and select the

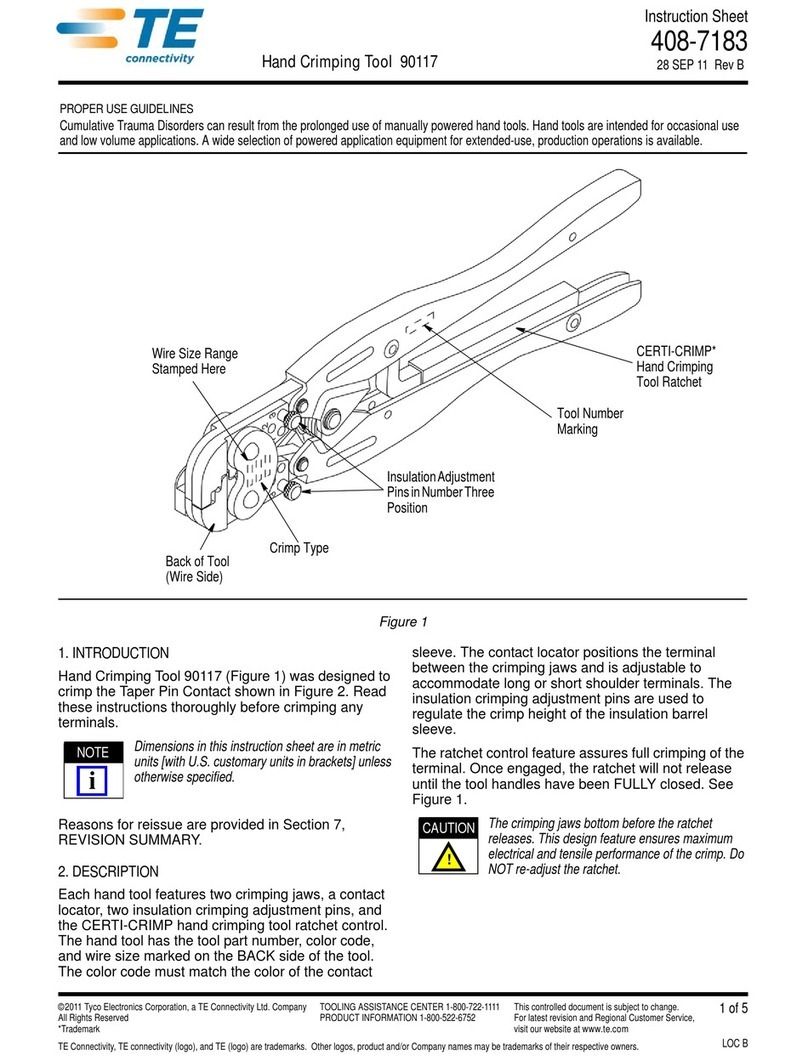

applicable contact for the tool (see Figure 1).

2. Refer to Section 3, CRIMPING PROCEDURE,

and crimp the contact accordingly.

3. Using the crimp height comparator, measure the

wire barrel crimp height as shown in Figure 4.

If the crimp height conforms to the dimensions shown

in Figure 4, the tool is considered dimensionally

correct. If not, return the tool for evaluation and repair

(see Section 5, REPLACEMENT AND REPAIR).