TE Connectivity STRATO-THERM 314935-1 User manual

Other TE Connectivity Crimping Tools manuals

TE Connectivity

TE Connectivity PRO-CRIMPER III User manual

TE Connectivity

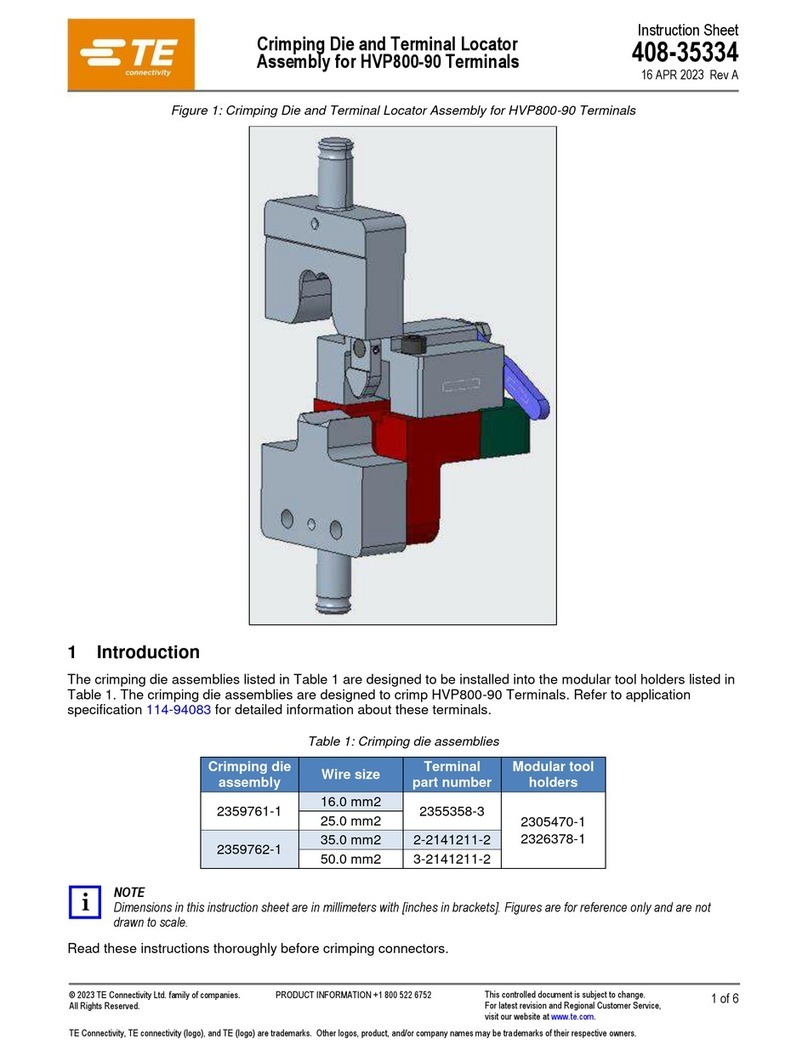

TE Connectivity 2359761-1 User manual

TE Connectivity

TE Connectivity PRO-CRIMPER III User manual

TE Connectivity

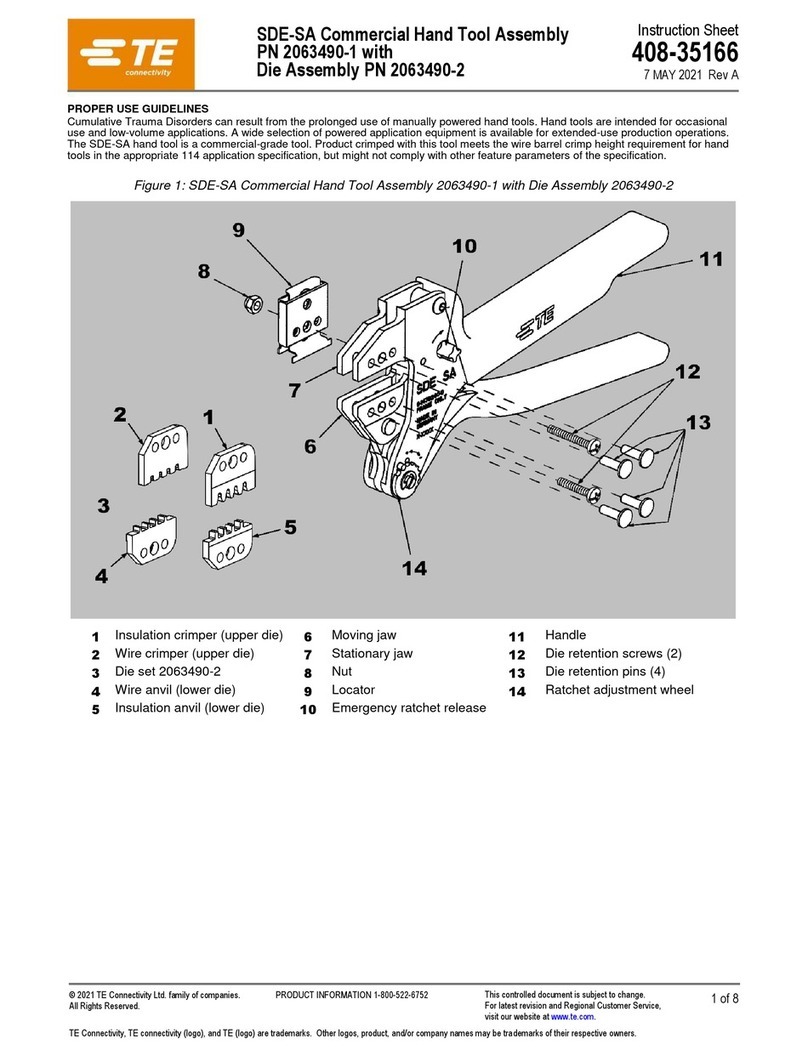

TE Connectivity 2063490-1 User manual

TE Connectivity

TE Connectivity 2161651 Series Reference guide

TE Connectivity

TE Connectivity MQS 3-1579014-9 User manual

TE Connectivity

TE Connectivity AT-65 User manual

TE Connectivity

TE Connectivity 2392637-1 User manual

TE Connectivity

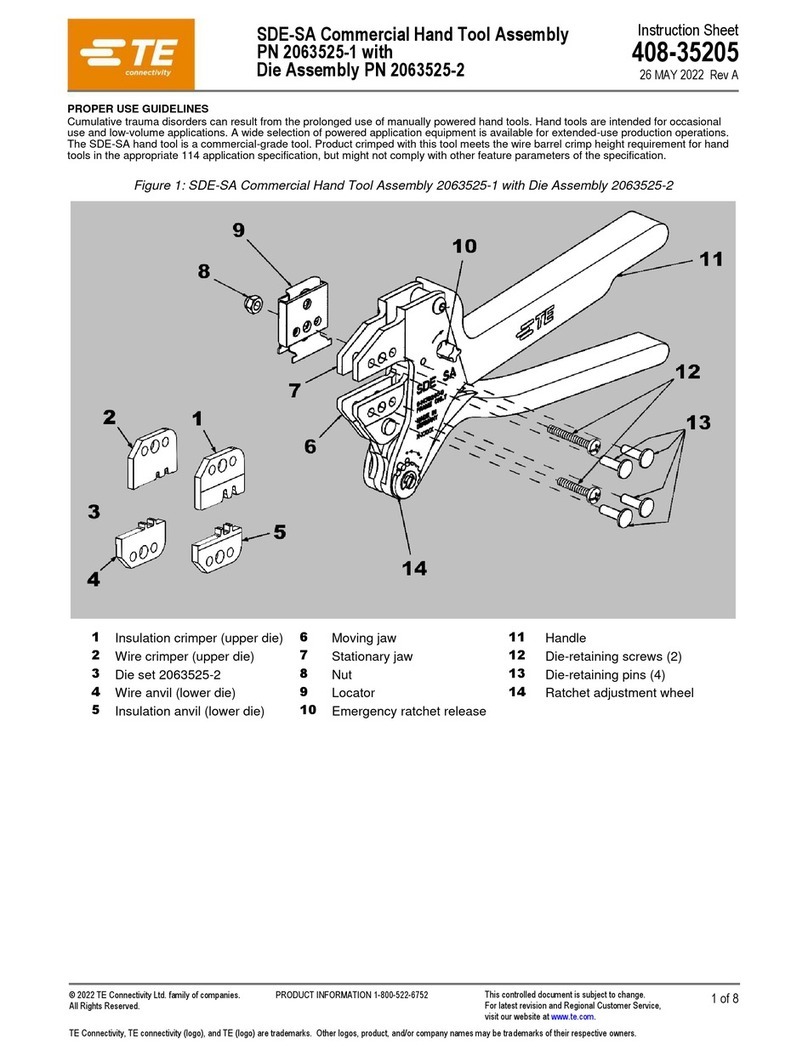

TE Connectivity 2063525-1 User manual

TE Connectivity

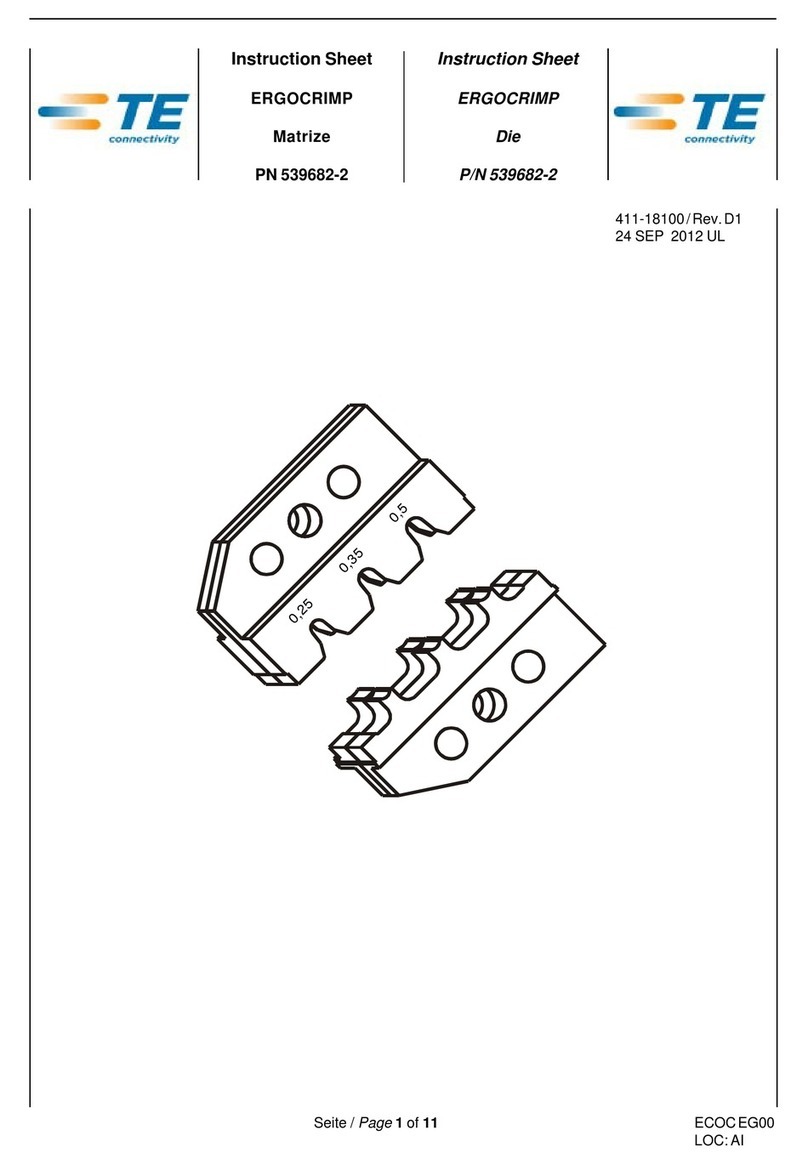

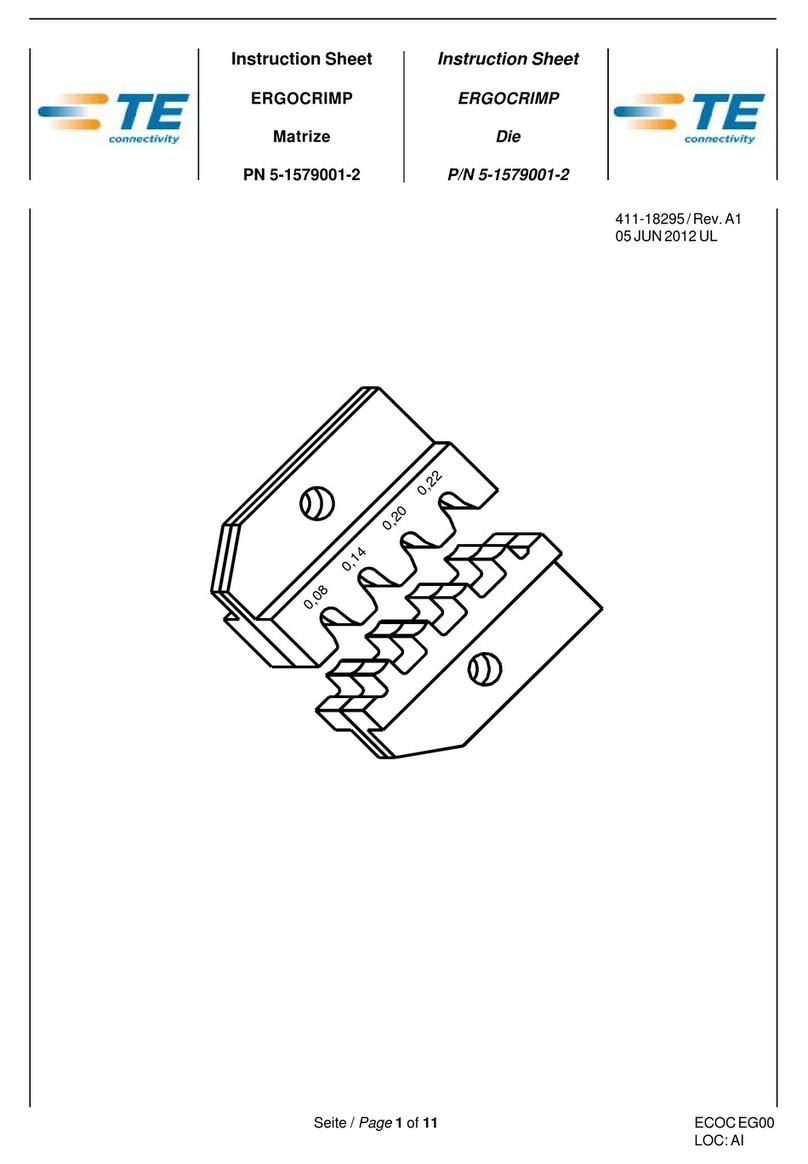

TE Connectivity ERGOCRIMP 5-1579001-2 User manual

TE Connectivity

TE Connectivity 46754-2 User manual

TE Connectivity

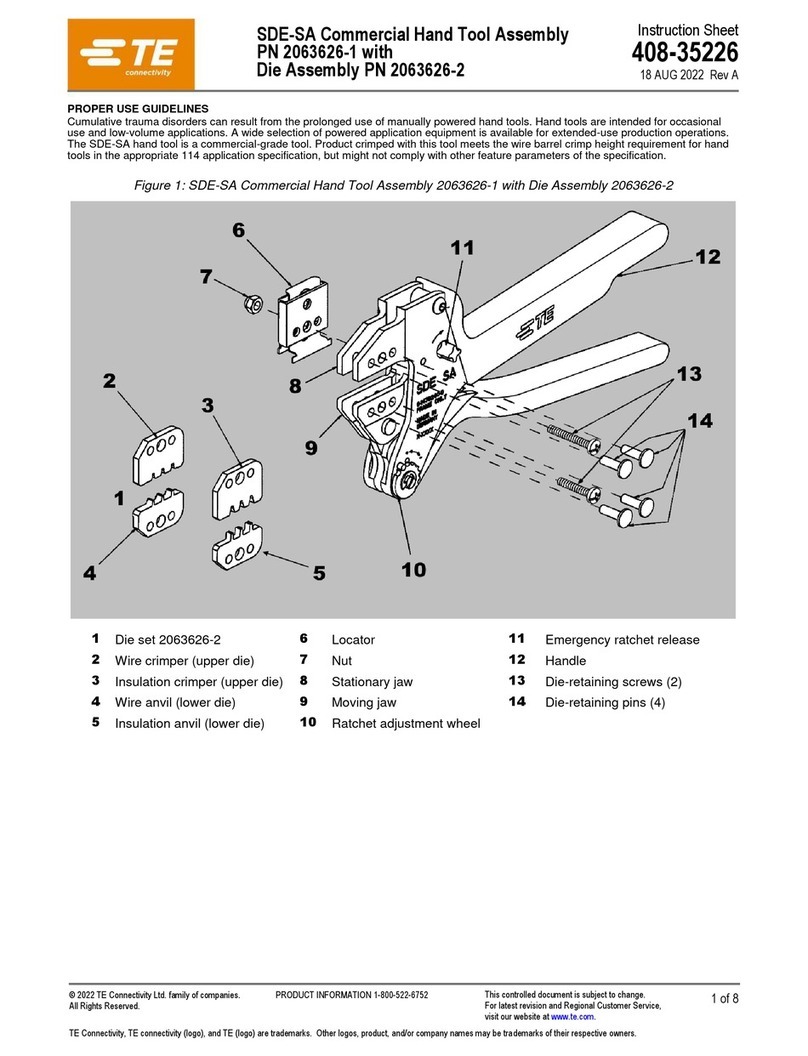

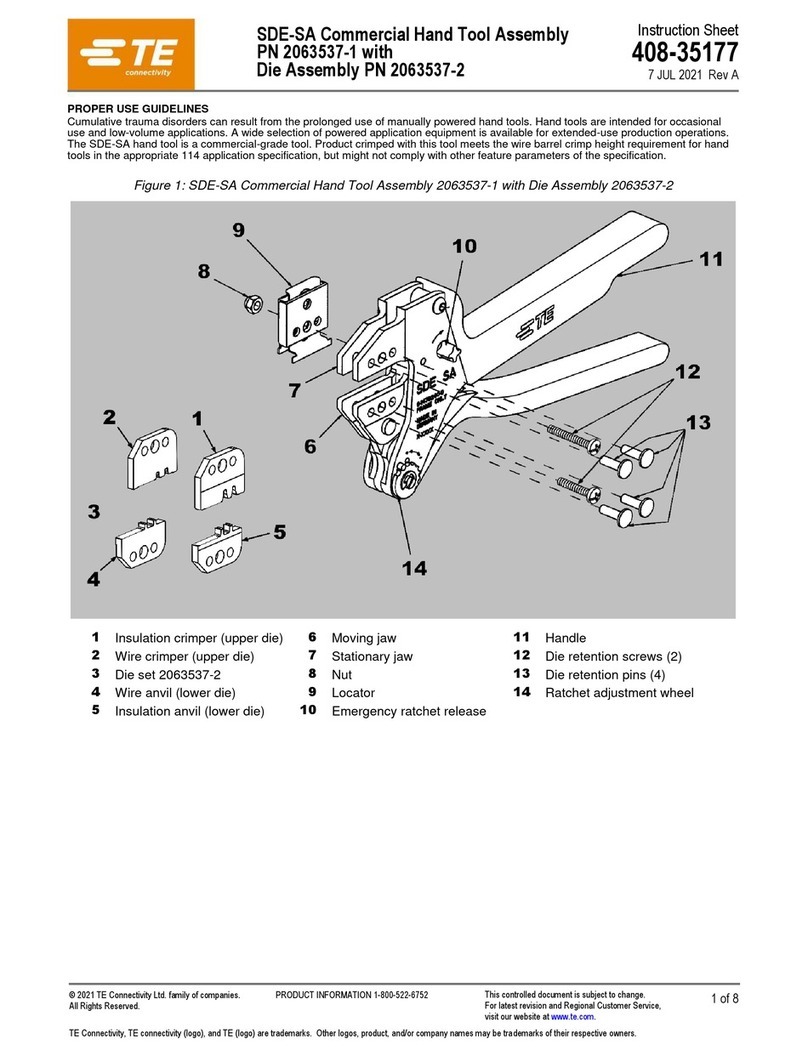

TE Connectivity SDE-SA PN 2063626-1 User manual

TE Connectivity

TE Connectivity AMP 3K Reference guide

TE Connectivity

TE Connectivity 2390275-1 User manual

TE Connectivity

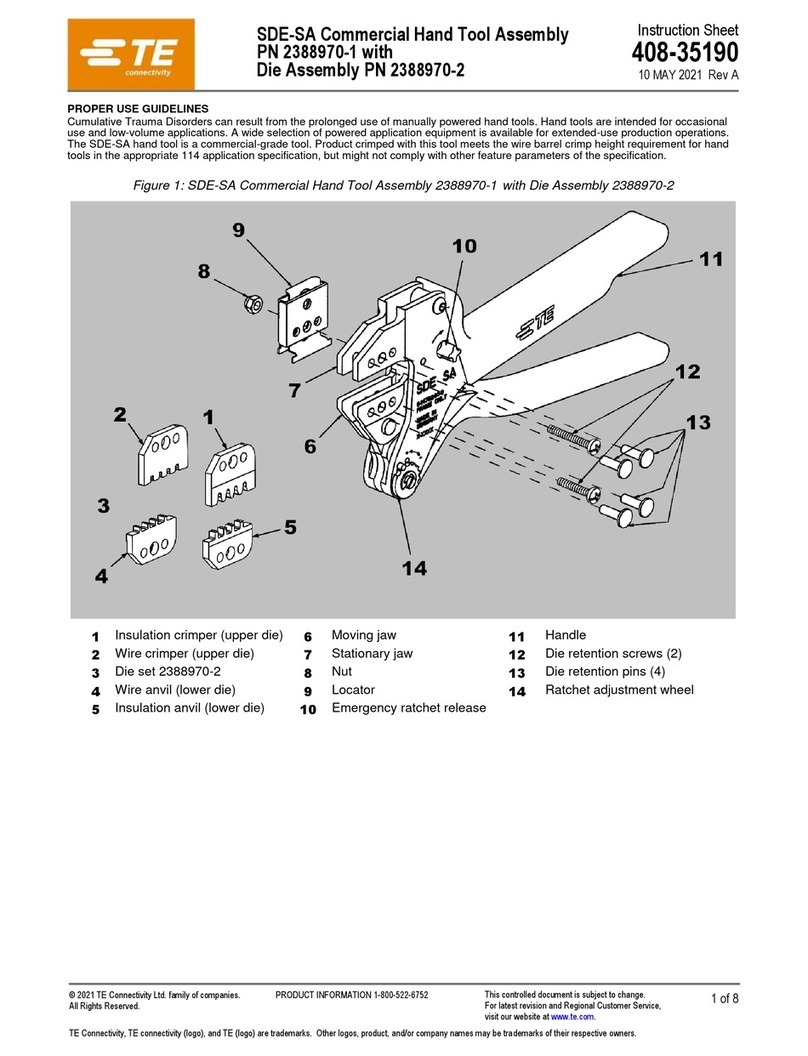

TE Connectivity SDE-SA User manual

TE Connectivity

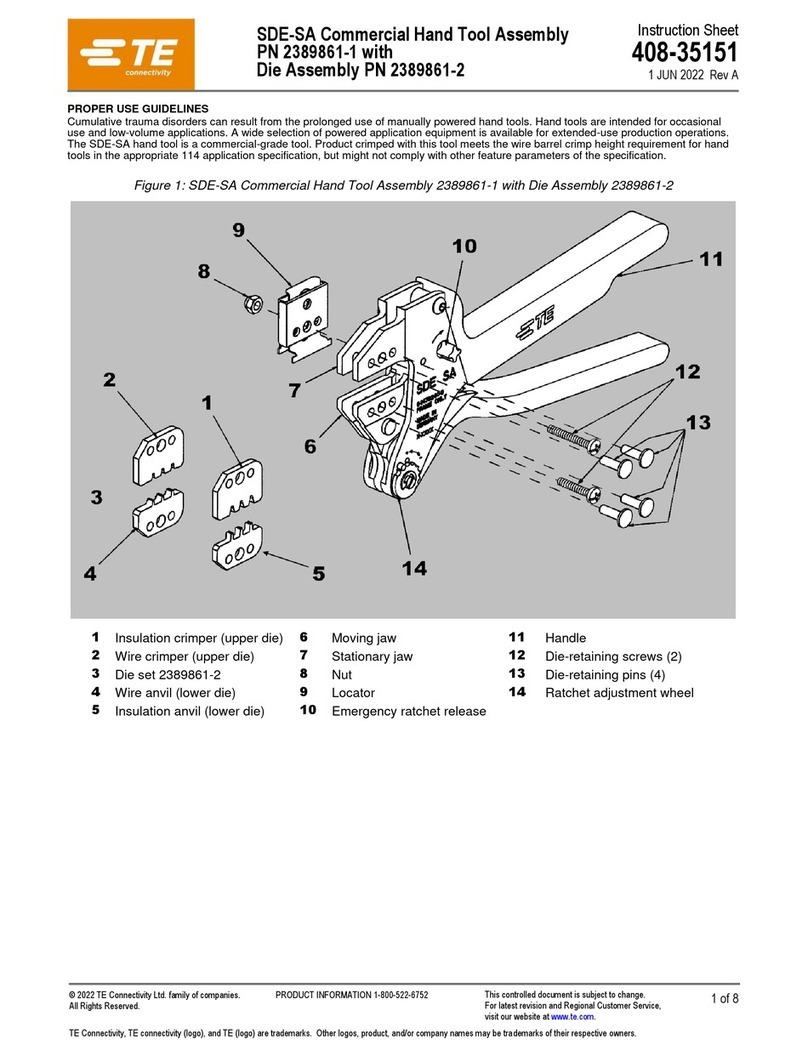

TE Connectivity SDE-SA 2379968-1 User manual

TE Connectivity

TE Connectivity PRO-CRIMPER III User manual

TE Connectivity

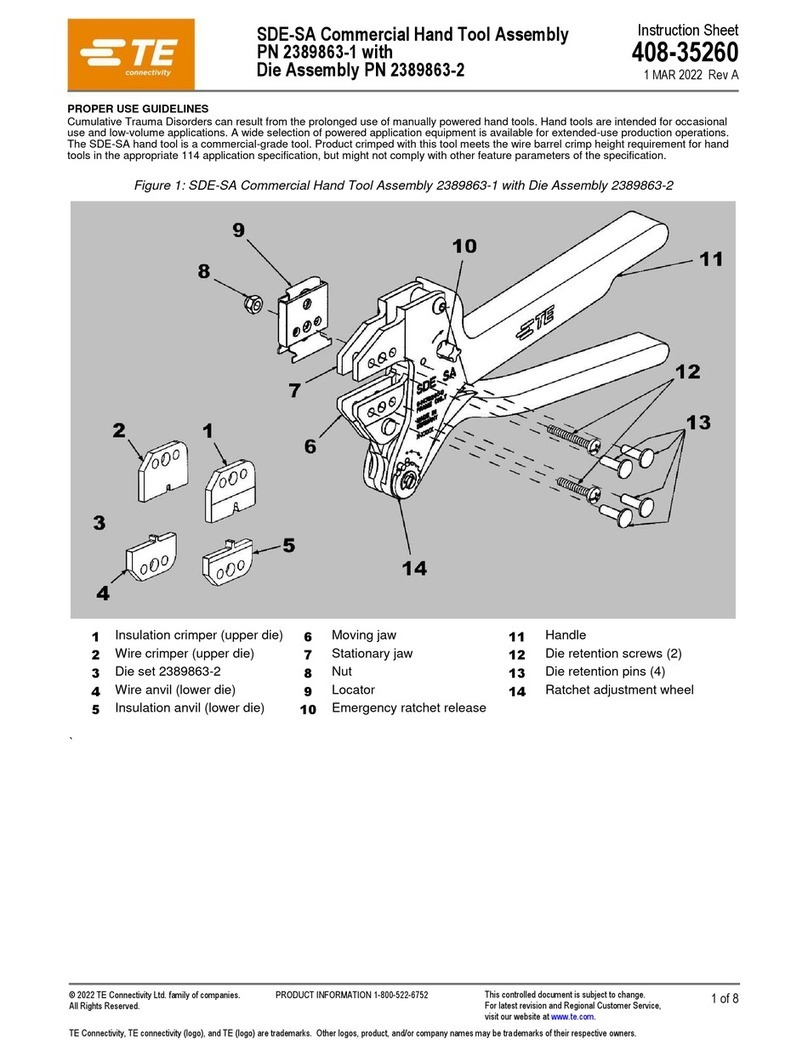

TE Connectivity SDE-SA 2389861-1 User manual

TE Connectivity

TE Connectivity SDE-SA User manual

TE Connectivity

TE Connectivity SDE-SA User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

molex

molex 207129 Series Specification sheet

molex

molex 207129 Series Specification sheet