Tomahawk Controls Quick Start Guide page 1

1

2 3

4 5

6

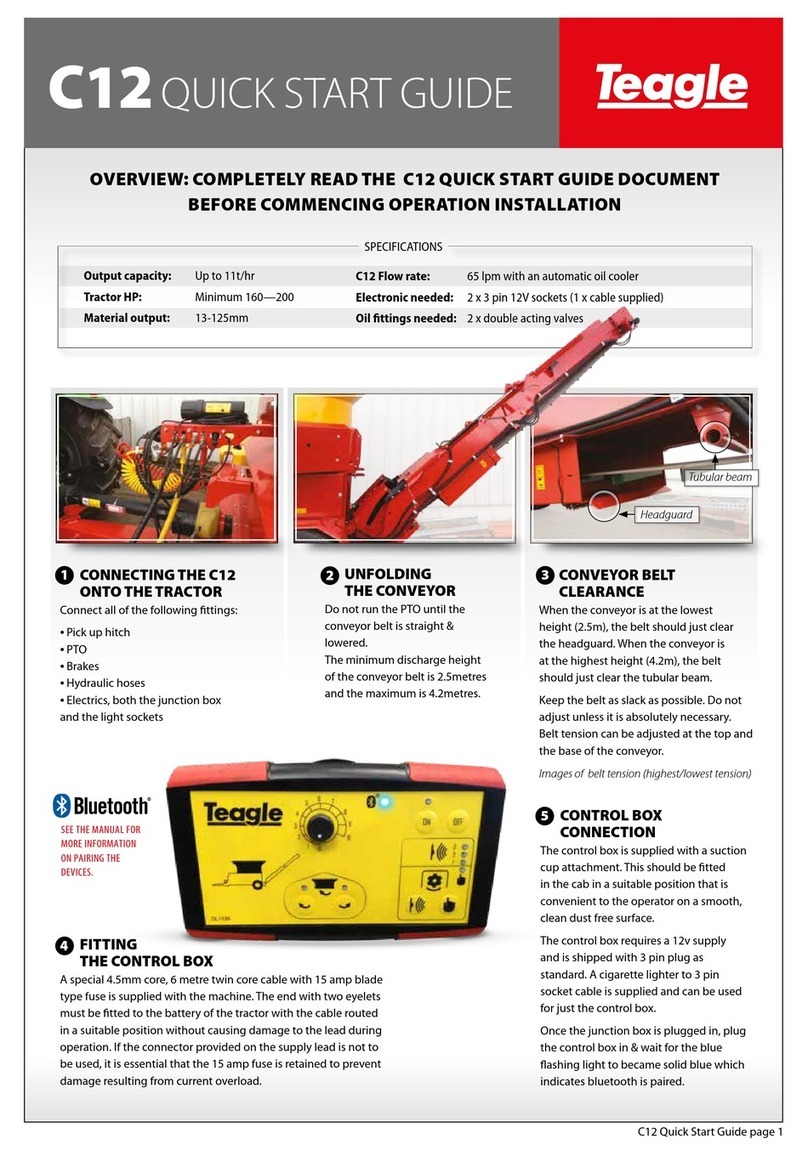

Electrical ttings: 12V Female Cobo socket connector (in cab)

Oil ow: An oil ow of 60 litres per min (13.3 gallons per min) is required to achieve maximum performance.

Oil ows in excess of 60 litres/min will result in overheating.

TRACTOR REQUIREMENTS

PLEASE READ THIS INSTALLATION GUIDE

THOROUGHLY BEFORE COMMENCING

FITTING THE MACHINE

TO THE TRACTOR

Attach the Tomahawk drawbar and

PTO shaft to the tractor. Connect the

supply and return hydraulic hoses,

ensuring the direction of ow is

correct.

The control desk is supplied with a

suction cup attachment. This should

be tted in the cab in a suitable

position that is convenient to the

operator on a smooth, clean, dust

free surface. (i.e. the window.)

ELECTRICAL CONNECTIONS

TO THE CONTROL SYSTEM

To tractor in-cab 12V supply

THE BLUETOOTH

CONNECTION

Once the Bluetooth light has stopped

ashing and is illuminated you are ready to

proceed. If it does not stop ashing then

it has failed to make a connection and the

control desk will not turn on.

PAIRING A CONTROL DESK TO A MACHINE

Should the control desk fail to connect to the machine, then

press the “ON”and“OFF”buttons & together for 2

seconds. This will make the control desk search for the Bluetooth

signal from the Tomahawk.

COMMISSIONING

With the bale chamber empty, engage the PTO at low revs, then

increase to normal working speed (540rpm) and start the oil

ow to the Tomahawk. Press the“power on” button when the

Bluetooth light is illuminated. Check chute rotation, deector

and tailgate functions work.

TOMAHAWK

INSTALLATION GUIDE

1

BED CHAIN

Press the forward button to start the bed chain. If the

bed chain is set to ‘0’ the bed should be stationary. The bed

can be stopped by either pressing the forward or reverse

button . You can reverse the bed chain by holding the

reverse button down.

BED CHAIN SPEED

The bed chain speed can be adjusted by turning the dial

from ‘0’ to ‘10’. If the bed is rotating when the dial is set to ‘0’,

then you need to re-calibrate the bed speed. See over page

for details.

2 3

4

5

6

1

• Connect the control desk power

supply lead into the 12V female Cobo

socket in the tractor cab.

• Connect the Tomahawk power supply

lead to the 12V female Cobo socket on

the ying lead connected to the control

desk.

• If in doubt, listen for a“click” from the

junction box under the cover at the

front of the Tomahawk, which tells you

it has power.

• If the supply cable is connected with

the wrong polarity the control box will

not switch on.

1 2

1