8. PREPARATION OF THE TRACTOR

For good visibility down both sides of the machine when

working and reversing, the tractor should be fitted with

mirrors.

The PTO power required to drive the Tomahawk is

typically about 60KW (80HP) for the 1005 and 67.5 KW

(90HP) for the 1010. However, the suitability of any

particular tractor will depend upon, a) the distance over

which the straw is to be spread, b) the type of bale to be

spread, and c) whether the machine is to be used to

transport bales along the road.

The machine is designed to use the standard 540 rpm

PTO shaft.

The hydraulic valve block requires a double acting spool

valve or a single acting valve with an unrestricted return.

Whichever is used, the hydraulic supply must be

independent of the 3-point linkage.

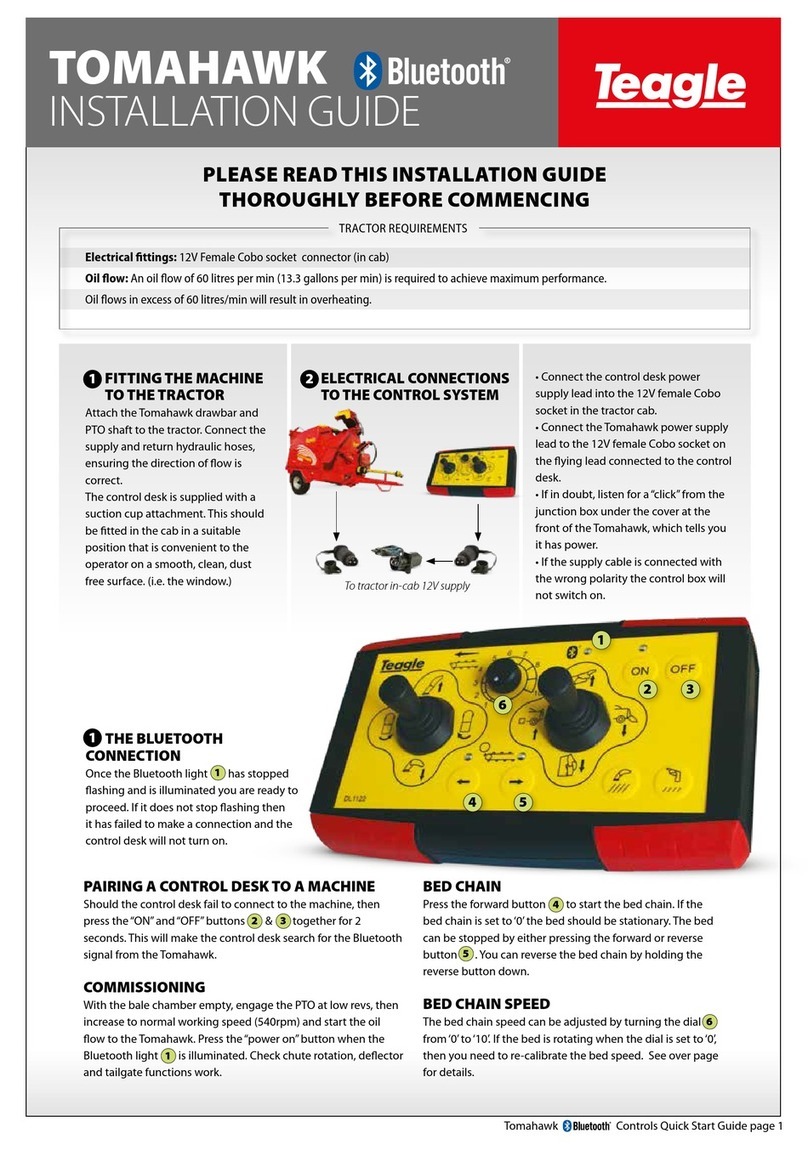

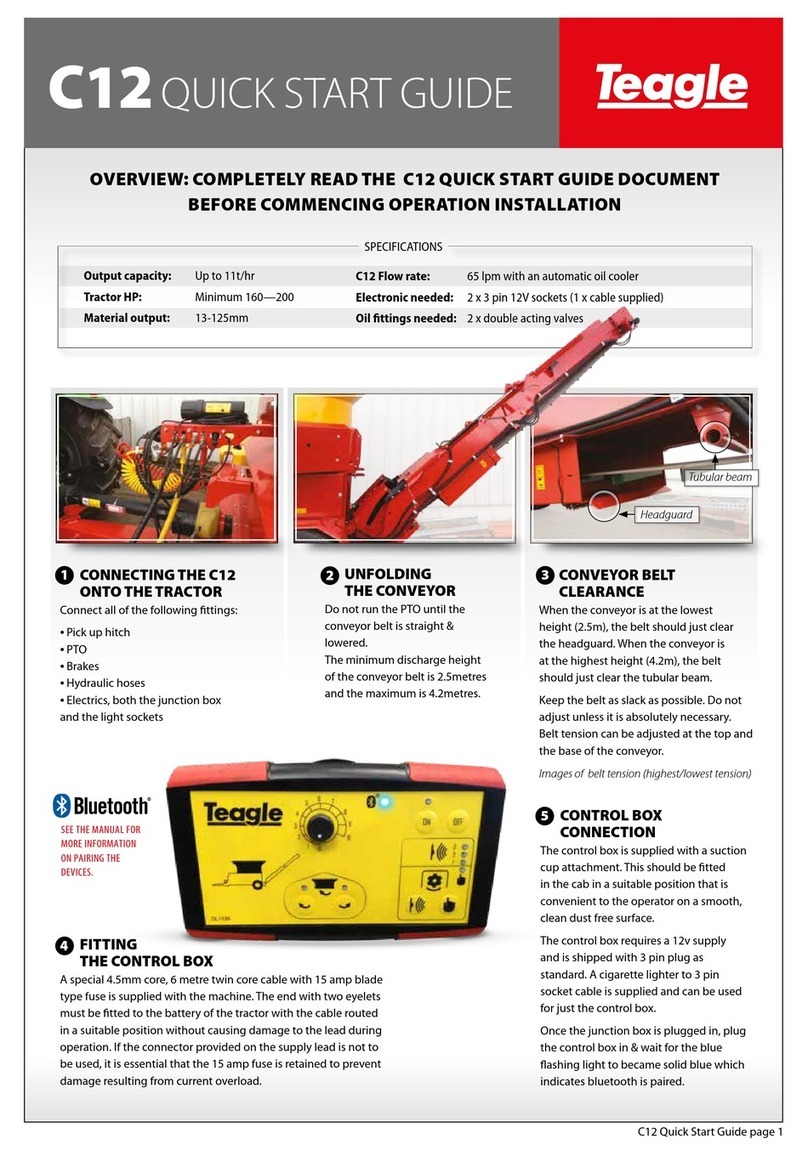

The control box mounting bracket should be fitted inside

the cab so that the controls are conveniently situated for

the operator. It should be remembered that structural

members of the cab must not be drilled or welded.

The electric control supply cable should be connected

the tractor’s auxiliary 3 pin socket. Should a socket not

be available then the control box must be wired directly

to the battery. Remove the connector plug to reveal the

brown and blue wires, brown is positive, blue is

negative. Wire directly to the battery with a suitable lead

and insulated connectors.

If the supply cable is connected to the battery with

the wrong polarity the control desk will not power

up.

If the fuse should blow this will be indicated by the red

LED illuminating.

Under no circumstances remove the fuse holder or

use fuses with a higher rating than 7.5amps.

Warranty will be invalidated

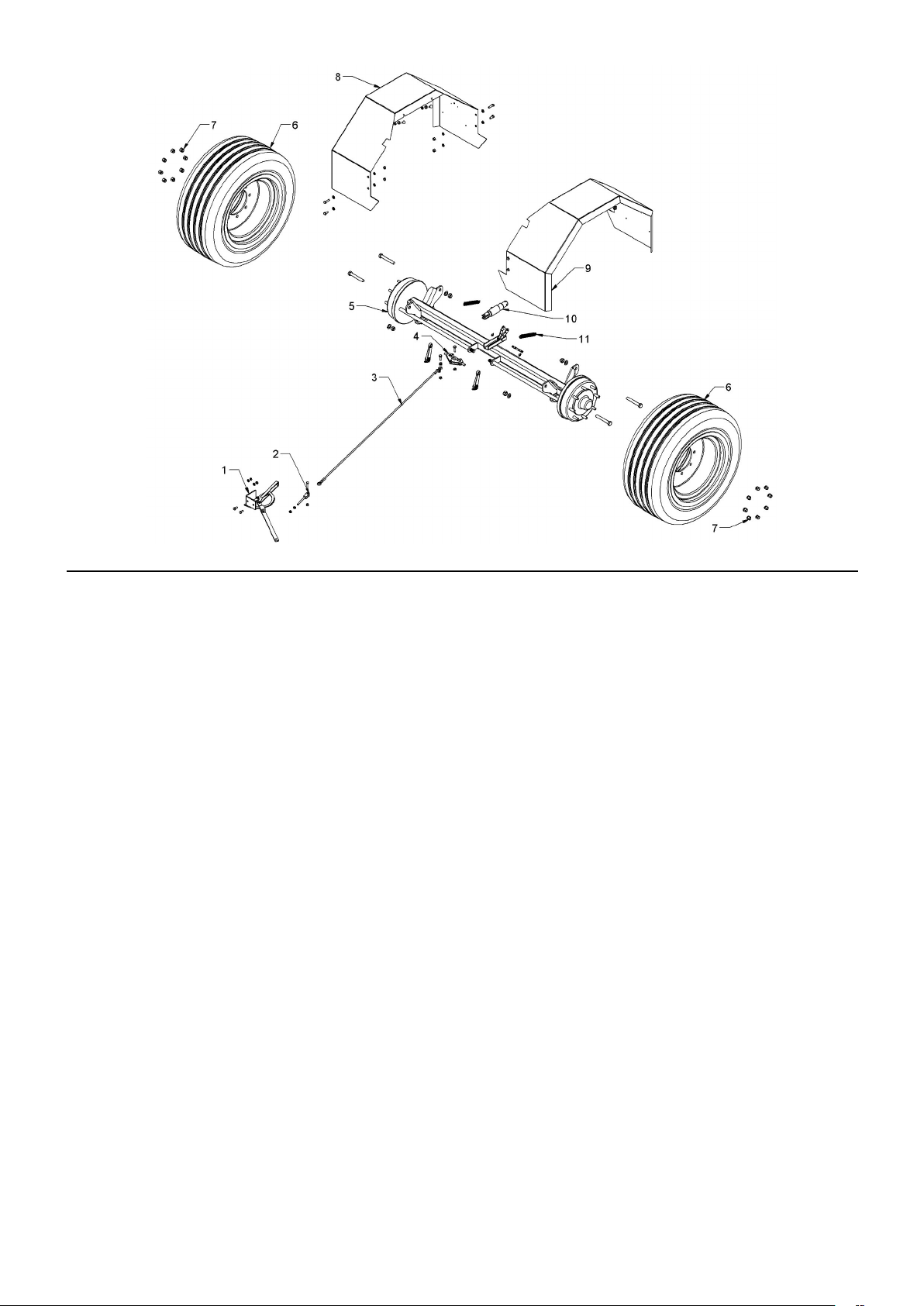

9. FITTING THE MACHINE ONTO THE TRACTOR

Check that the lower links are at a height such that

they do not foul the PTO shaft when the tractor is

turning. If they are not used regularly, it is

recommended that they be removed. Hitch the machine

to the tractor via the drawbar without the PTO shaft

fitted. Release the parking brake on the left hand side of

the machine by pulling forwards and then allow to swing

rearwards. Park the tractor and machine securely on

level ground and remove the key.

It is essential to get the relationship between the

tractor PTO shaft and the gearbox input shaft

correct to give a satisfactory PTO shaft life. The correct

geometry exists when the machine is horizontal.

If the machine is shredding whilst turning on a

regular basis it is recommended that a PTO shaft

with a wide angle, constant velocity joint be fitted. A

shaft of this type can be obtained from the manufacturer.

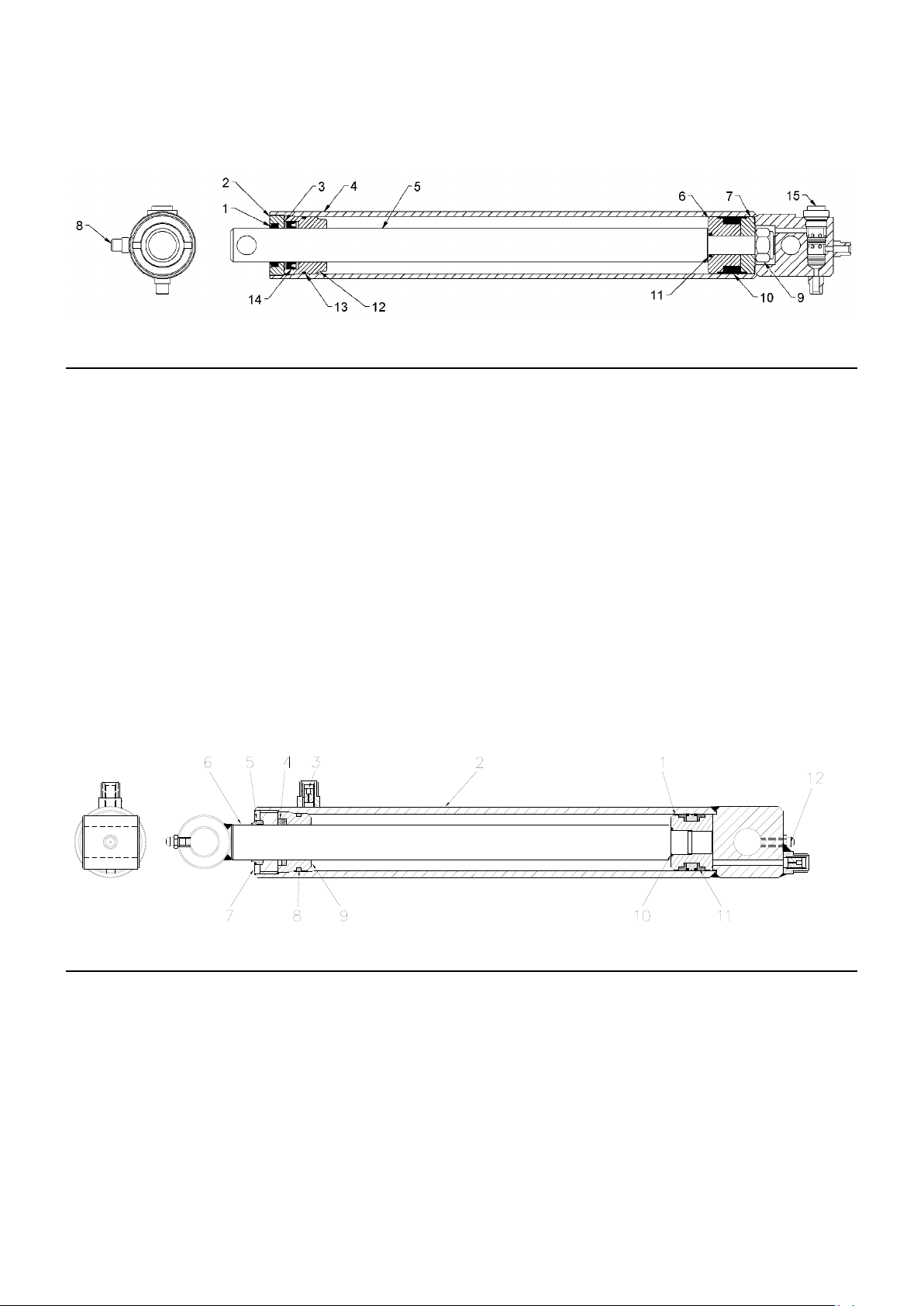

The PTO shaft will require cutting to length to suit the

tractor to remove the risk of bottoming resulting in

catastrophic failure of the machine gearbox.

Proceed as follows:

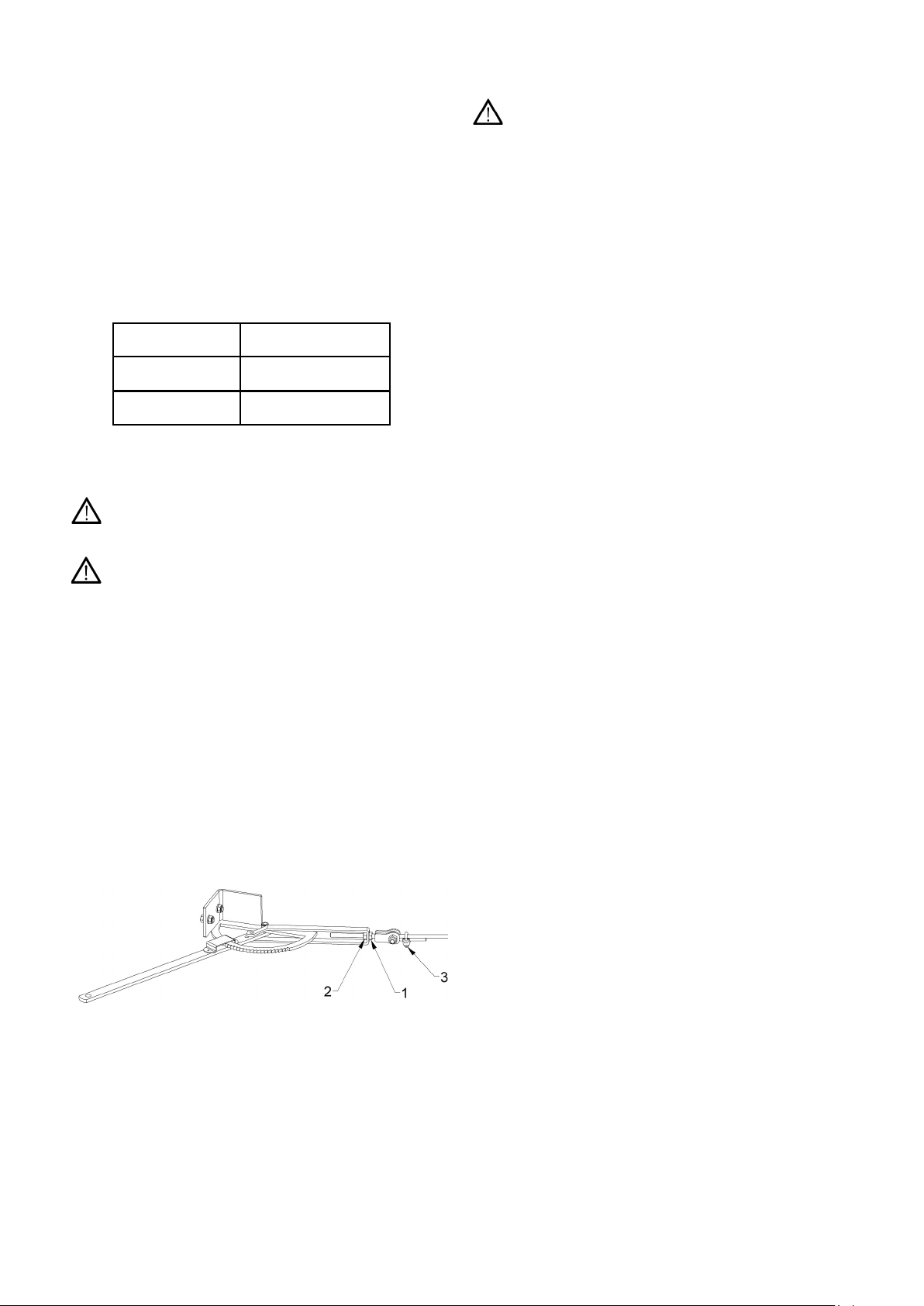

1.) Measure the distance between the annular groove

on the tractor output shaft to the annular groove on the

machine input shaft.

2.) Measure approximately the distance between the

retaining balls of each sliding yoke at either end of the

PTO shaft with it fully collapsed.

3.) Subtract the second measurement from the first and

now subtract this value from 150mm (6”). The answer is

the amount to be removed from each half of the PTO

shaft.

4.) Separate the 2 halves of the PTO shaft and remove

the necessary amount from each half guard and each

half tube. Remove the guards to facilitate cutting if

required.

5.) Fit the slip clutch side of the PTO shaft to the

machine and the other end to the tractor, the PTO shaft

should now have the required 150mm (6”) travel before

bottoming. This should be indicated by the length of

black PTO guard showing.

6.) Gradually turn the tractor until maximum turning lock

is achieved checking that the PTO shaft does not come

to within 100 mm (4 inches) of bottoming.

7.) Drive the tractor and machine over any significant

undulating ground conditions checking that the PTO

shaft does not come to within 100 mm (4 inches) of

bottoming.

Connect the hydraulic hoses into the spool valve of the

tractor. It is important that the supply hose to the valve

is connected to the pressure port of the tractor, this hose

is marked with red tape around the hose. Attach the

brake hose to the tractor brake coupling

Once the control box has been positioned, route the

machine cable into the cab making sure it is kept away

from the rear wheel and any pinch points between the

PTO shaft and link arms. Where possible, route into

the cab through cable entry points on the tractor,

allowing the rear window to be kept closed during use.

Plug the cable connector into the socket on the box

and lock by the clamp provided.

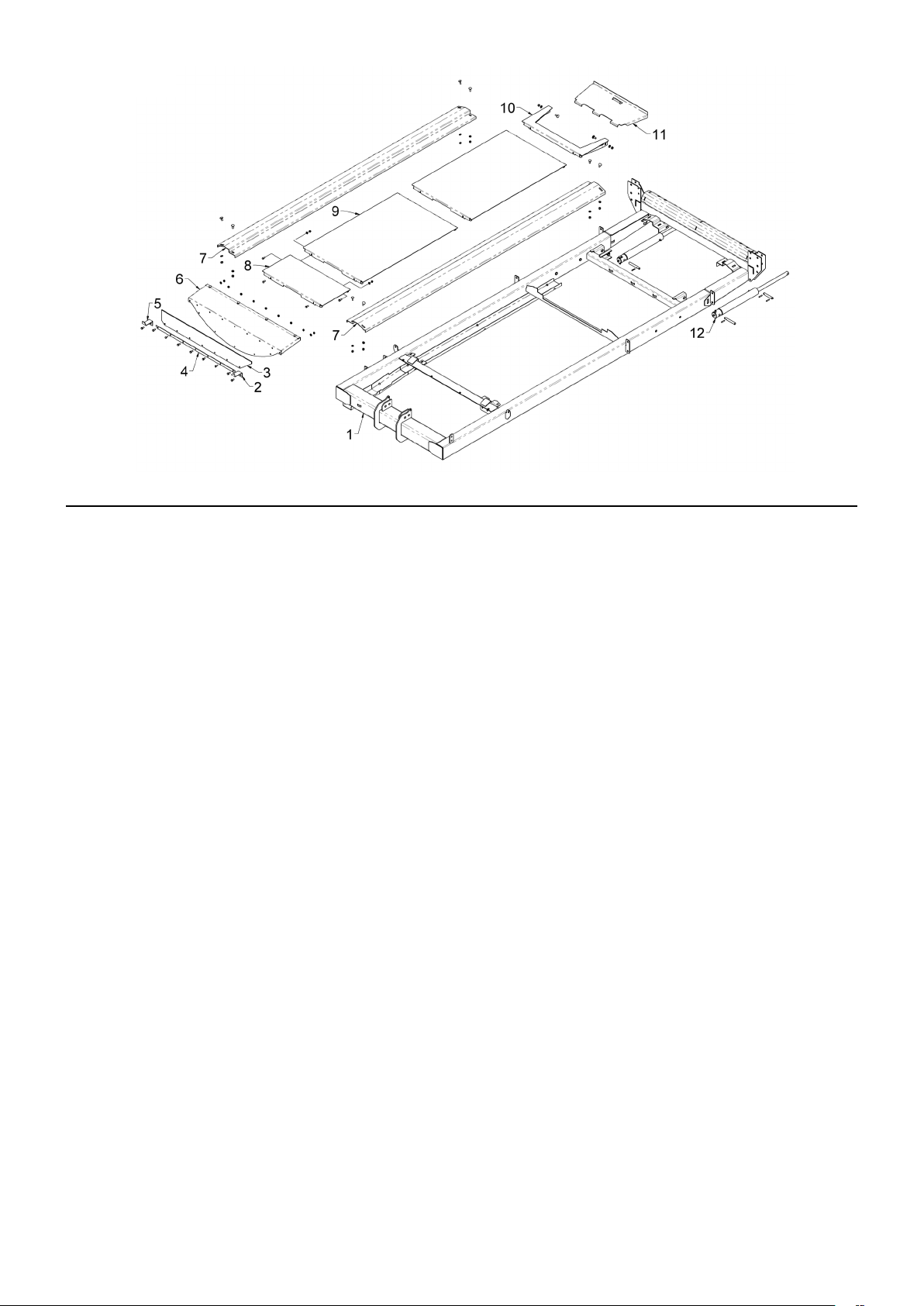

Ensure the functions of the control box are

completely understood before proceeding to use

the machine. In particular the bed chain is actuated in

the forward direction by pushing the forward direction

button and stopped by pressing the button again.

Reverse of the bed chain can only be actuated by

holding the reverse button.

10. OPERATING INSTRUCTIONS - LOADING

10.1 General

The strings or net should be removed from the

bale as it is being loaded into the machine. The

Tomahawk will shred some string but some will

tend to wrap around the crossbeaters. Putting twine or

netwrap through the machine is not recommended as it

will be eventually spread on the land and polluting

subsequent crops.

When removing string or netwrap from bales never

climb into the bale chamber or onto the tailgate

behind a bale unless the PTO has been disengaged, the

engine has been stopped, the key removed and the

machine come to rest.

5