SAFETY

In addition to the standard safety guidelines listed at the

eginning of this hand ook, the following special safety

items apply to the Telehawk.

1 The machine shall e operated y one person

only.

2NEVER put your hands inside the delivery

chutes. In the event of a lockage clear it

using the Blockage Removal Tool provided,

located on the front of the lower housing. First,

disengage the hydraulic pump, lower the machine to

the ground, apply the hand rake, stop the engine,

remove the key, and wait for the rotor to come to

rest.

3 NEVER enter the ale cham er unless the

machine has een lowered to the ground, the

engine has een stopped with key removed

from the ignition, and the machine has come to rest

(see note 2 a ove).

4 NEVER insert anything inside the chute or

ale cham er while the machine is running.

5 DANGER. When entering or leaving the ale

cham er take care, the floor surface may e

slippery.

6Beware of overhead power lines when the swivel

chute deflector is fully raised. Contact with power

lines could result in the operator receiving a severe

electric shock.

7Do not clim onto the top edges of the ale cham er

whilst the machine is in use.

8Do not allow anyone to ride on the machine.

9Do not allow persons or animals to stand in front of

the outlet chutes whilst the machine is running.

10 Do not lower the machine if any person or animal is

standing in the loading area in front of the machine,

always ensure good forward visi ility when lowering

the machine.

11 Never put your hand over a hydraulic leak. Oil under

pressure may enter the lood stream.

12 The spreading of dusty or mouldy material can

create dust which may have adverse health effects.

Operator exposure to such conditions should e

avoided where possi le. When circumstances

prevent this, either use a loader with a suita le

forced air ca filtration system or an adequate

respirator. Respirators must comply with the relevant

Standard and e approved y the Safety

Inspectorate. Disposa le filtering face piece

respirators to EN149 or half mask respirators to

EN140 fitted with filters to EN 143 are likely to e

adequate.

13 Before disconnecting the hydraulic hoses always

lower the machine onto the ground for safety

reasons and to avoid residual pressure in the hoses.

14 Care must e taken when handling large ales, as

they have sufficient weight and density to cause

serious injury. Large ales should e handled with

appropriate machinery either directly into the

Telehawk or into a position where they can e self

loaded. Do not manually load ales from the stack

a ove the machine, so as to prevent the risks of

falling into the machine and collapse of the stack of

ales.

15 Caution after prolonged intensive use of the machine,

the oil temperature will have risen causing the hoses

and fittings to e hot.

LEFT AND RIGHT HAND

In this Hand ook and Parts List, the terms Left and

Right Hand apply to the machine when viewed from the

drivers seat of the loader.

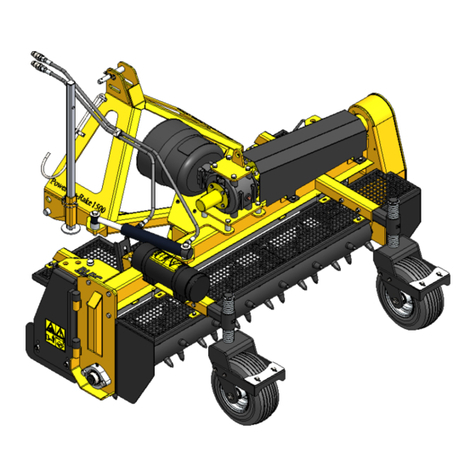

USE OF THE TELEHAWK

The machine is designed to spread only dry straw ales.

The machine must never e run with the chute

components removed. Unapproved chute modifications

should not e carried out as Safety Regulations may e

infringed.

USE ON THE PUBLIC HIGHWAY

If the machine is attached to the front of the loader

it is not recommended that the loader is driven on a

pu lic highway.

If the machine is to e transported along the pu lic

highway (any road where the pu lic have access)

ehind the loader, it may e necessary to fit lights to

comply with local road traffic legislation, as the machine

is likely to o scure the loader rear light units.

Suita le lighting kits are availa le from your local

supplier or may e o tained y contacting Teagle

Machinery.

Failure to comply with road traffic legislation may lead to

prosecution y local law enforcement agencies and

could also result in a road traffic accident.

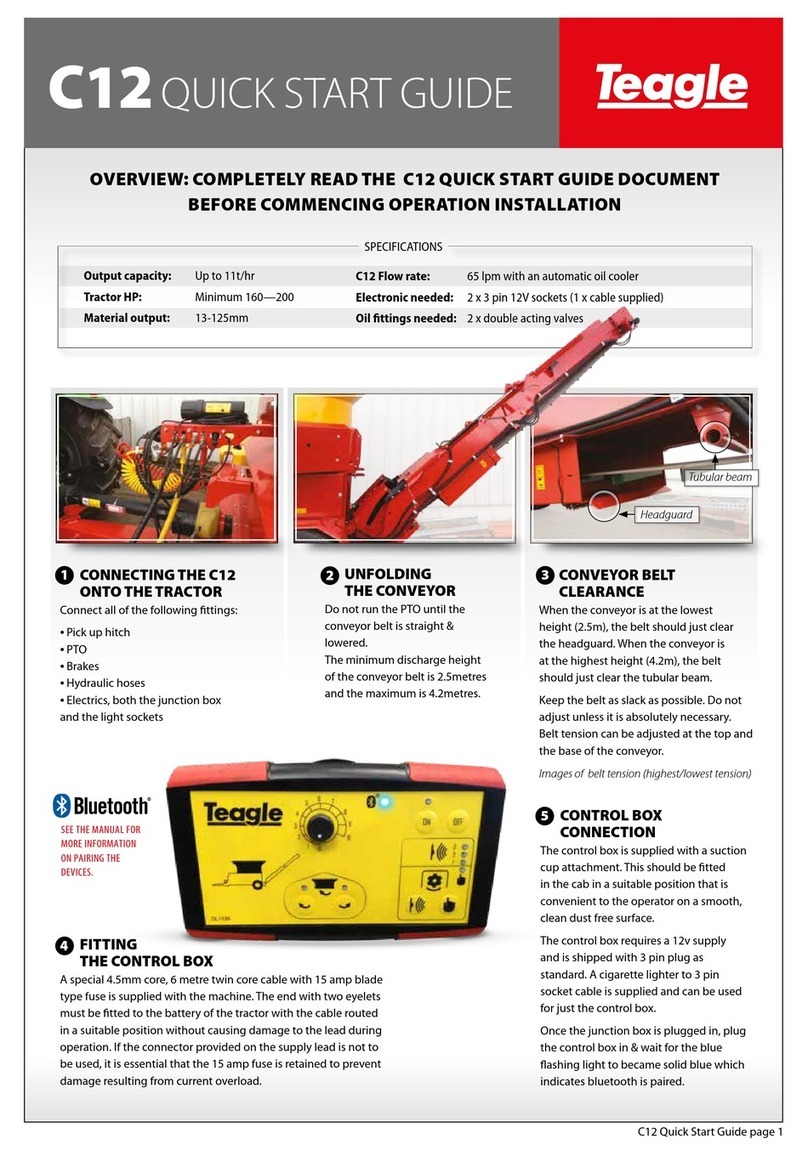

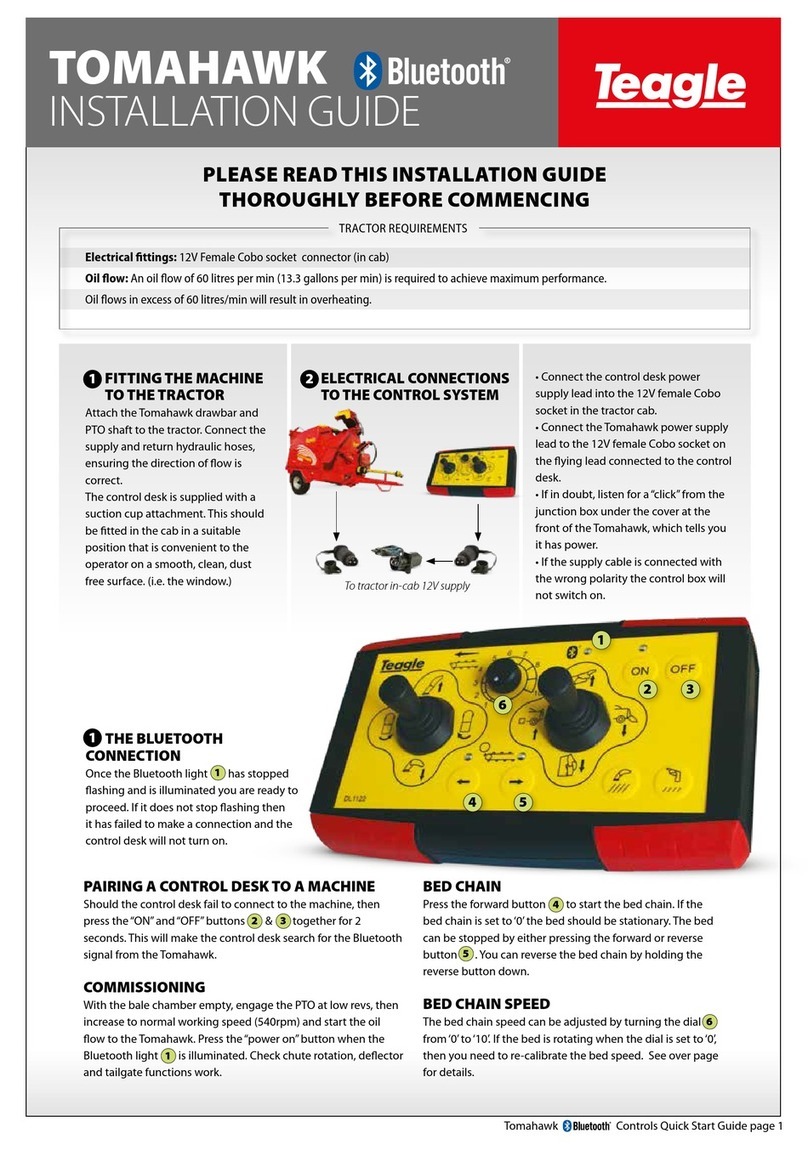

LOADER SPECIFICATIONS

Lifting capacity: Minimum of 2.6 tonnes.

Oil flow: Minimum oil flow of 60 litres per min (13.3

gallons per min). Maximum oil flow of 120 litres per min

(26.6 gallons per min).

Oil pressure: Minimum of 160 ar (2320 psi). Maximum

of 270 ar 3915psi @ 80 °C (176 °F)

Return line pressure: Maximum 20 ar (290psi).

The hydraulic system requires a single acting valve with

an unrestricted return. We recommend fitting an internal

Ø3/4” return line direct to tank. Operating the machine

without a free flow return will result in higher than

recommended ack pressures causing failure of seals in

oth the valve and motors.

Oil fittings: We recommend using flat face hydraulic oil

fittings with a minimum 24.5mm orifice to allow enough

oil to flow freely. Smaller fittings like 1/2” agricultural

fittings will work ut can restrict flow causing ack

pressure resulting in heat generation.

However, the suita ility of any particular loader will

depend upon,

a) the size and weight of the ale to e spread.

) the extent to which the oom is to e extended.

4