6

OPERATION

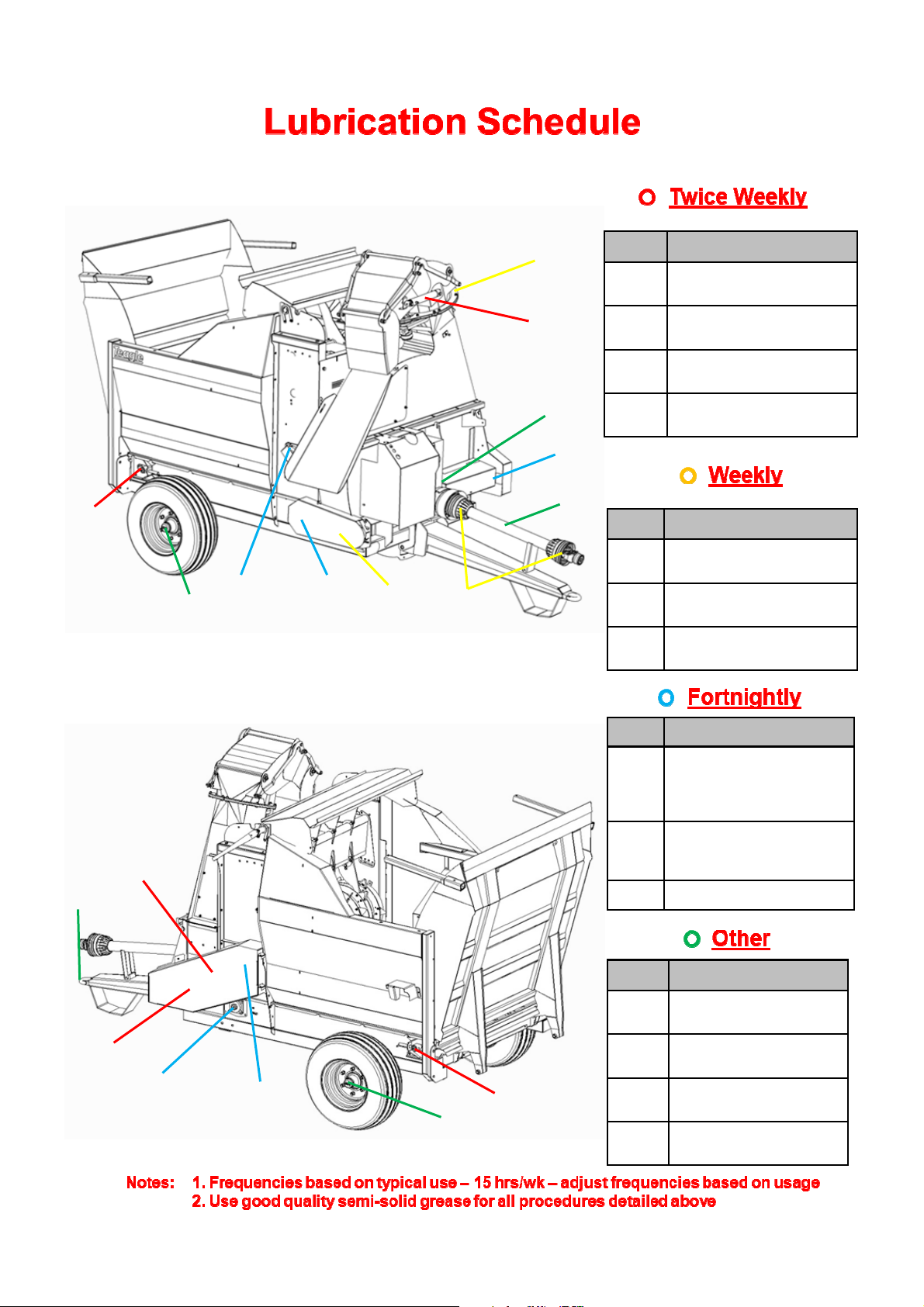

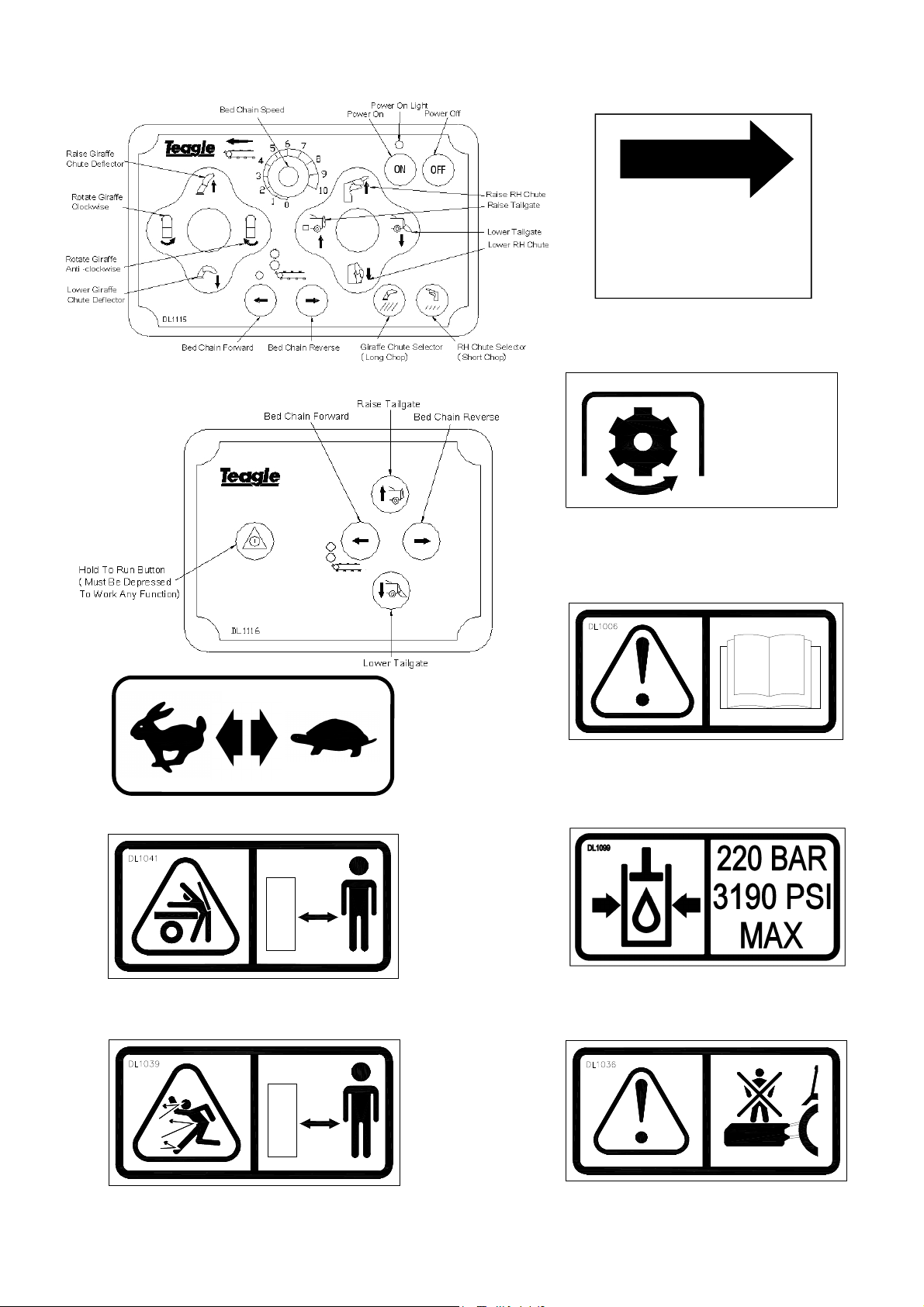

The machine is fitted with a 2-speed Gearbox. For

blockage free operation it is important that the

correct gearbox speed is selected for the material

being shredded.

The gearbox has a neutral position, make sure the

required gear has been properly selected. If operated in

neutral, material will enter the Rotor Housing possibly

resulting in a blockage. Make sure all material is

removed before restarting the rotor.

For shredding straw and other dry materials either rotor

speed may be used. For maximum throw distance the

handle should be moved towards the position marked by

the Hare to give a 1:1 ratio.

For shredding silage and other wet materials it is

recommended that the slow rotor speed is used as long

throw distances are not usually required and wastage is

reduced. To set the slow rotor speed the gearbox handle

should be moved to the position marked by the Tortoise

to give a 1.85:1 ratio.

To achieve maximum throw distance, operate the

tractor engine at PTO speed. For reduced throw

distances operate the tractor at reduced engine

speeds, as per Table 1. Very slow rotor speeds may

cause blockages.

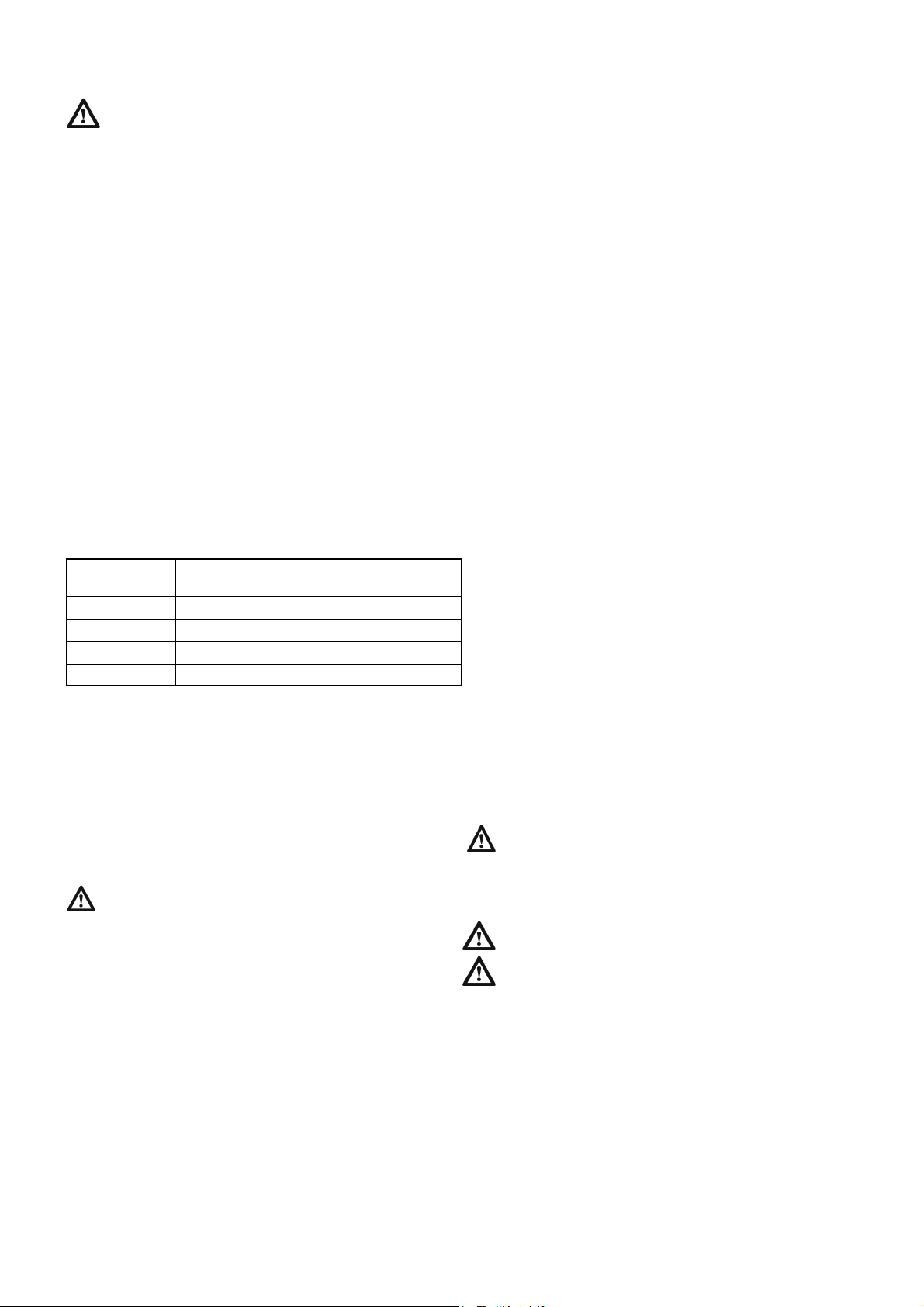

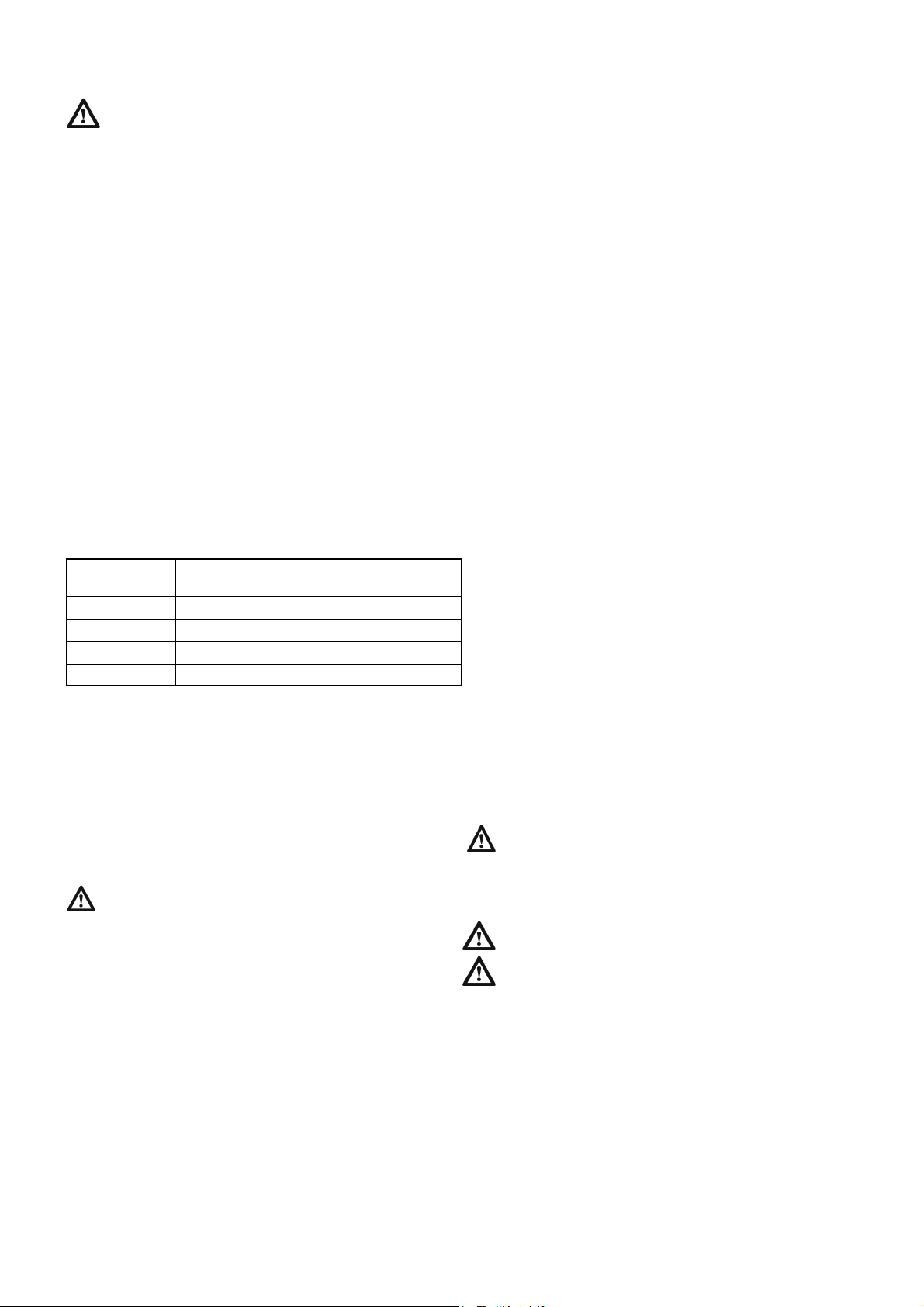

Table 1. Gearbox & PTO settings - right hand chute.

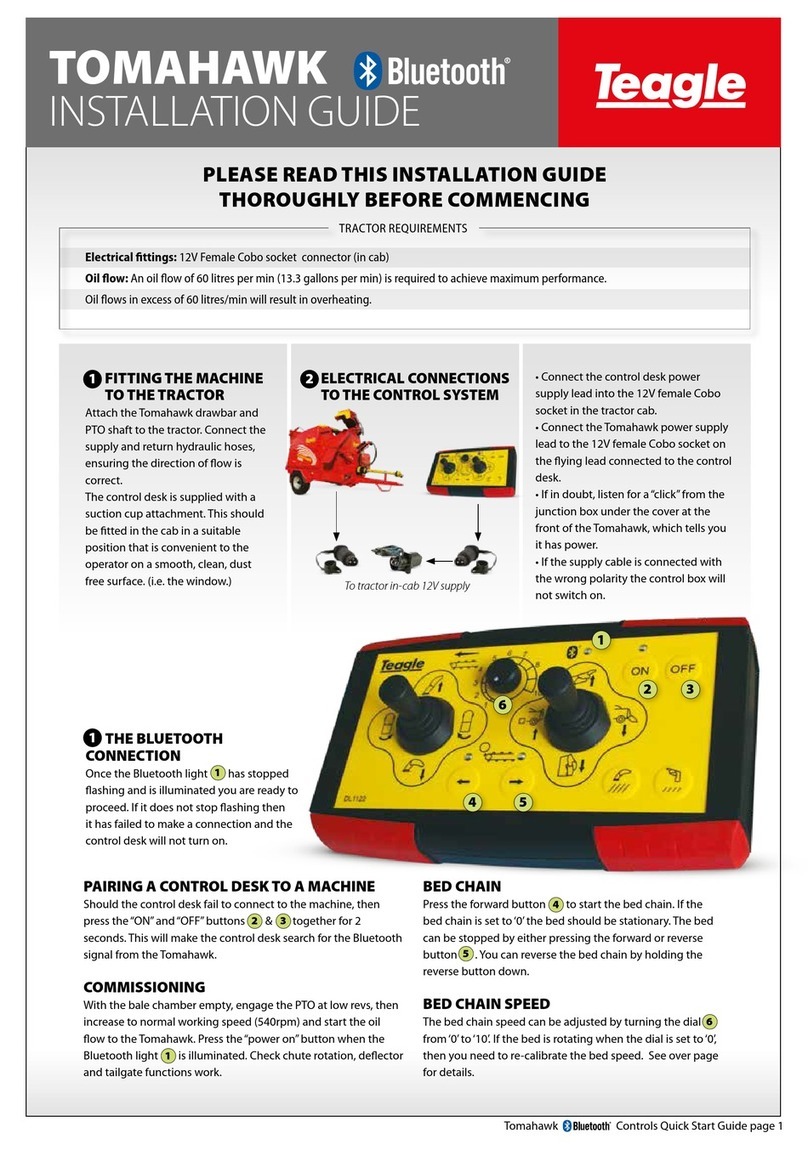

The valve block includes a flow control valve to vary the

rotational speed of the bed chain. A rotational speed of

the Bed Chain speed indicator of approximately 15 rpm

is required for the shredding of rectangular bales and

dispensing clamp silage. For round bales, indicator

speeds of up to 30 rpm may be used to improve the

feed rate.

DUAL CHOP OPERATION

Dual Chop machines can not chop Silage.

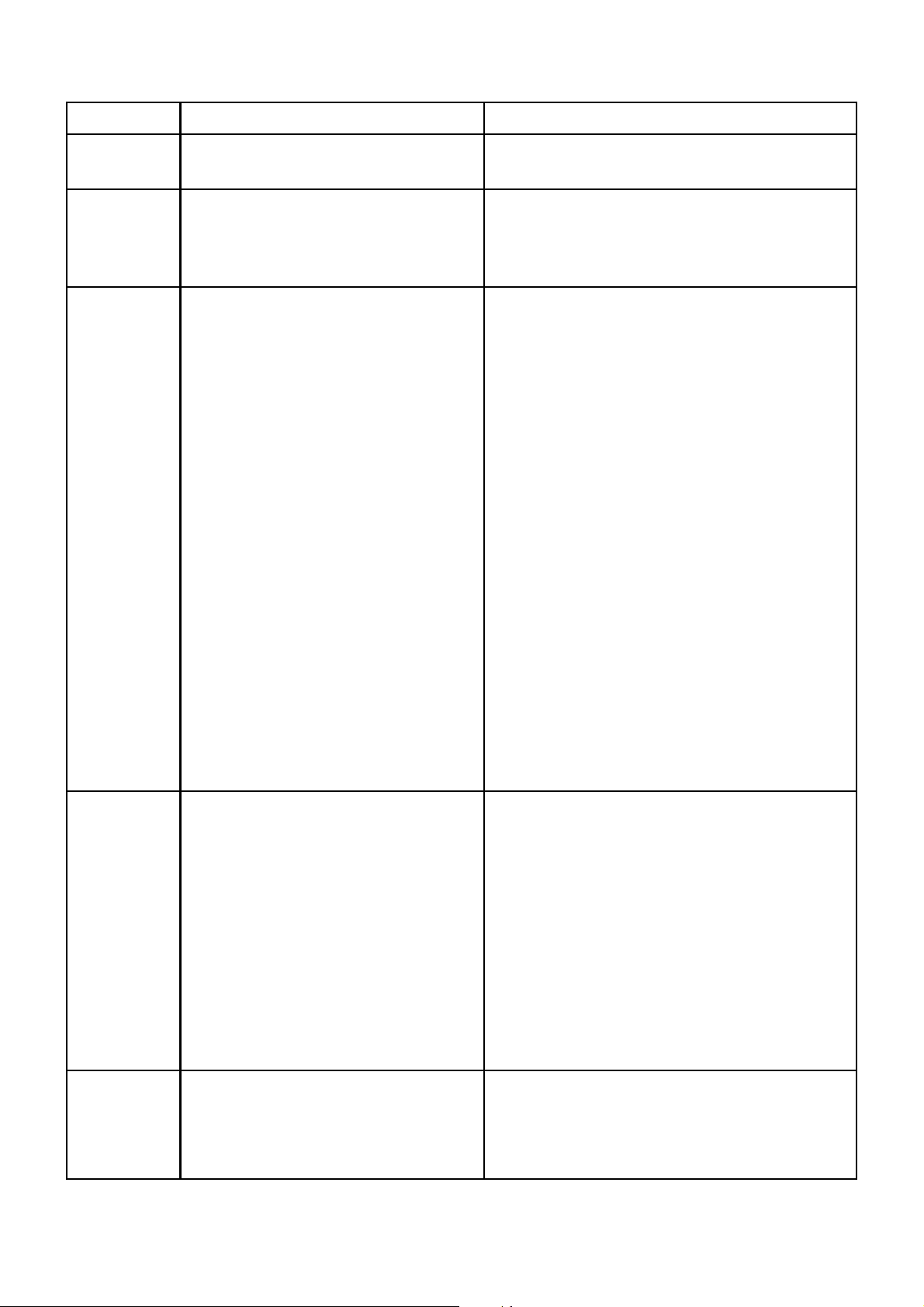

The Sliding Blade Carrier is controlled through the

hydraulic spool valve. Slots located on the front of the

machine indicate the engaged / disengaged positions of

the Sliding Blade Carrier, yellow for disengaged.

When a long chop length is desired raise the Blade

Carrier disengaging the blades.

When a fine chop length is desired lower the Blade

Carrier to engage the blades against the Crossbeater.

Before lowering the Blade Carrier, stop the Bed Chain

and wait for the material to stop flowing into the Rotor.

BALE RESTRAINT BEAM

The Bale Restraint Beam is factory set in the most

desirable position. If problems occur with excessive

breaking of Shear Bolts, it may be advisable to adjust

the Bale Restraint Beam backwards by one hole.

SWIVEL CHUTE

The Swivel Chute rotates through 270 degrees and can

be operated in any position.

To deliver silage close to the machine position the

Chute so that material is passed onto the Feed

Passage Slide. The position of the Slide can be

adjusted as desired.

Alternatively the material feed direction can be

controlled by the Chute. It may be necessary to rotate

the Chute fully to deliver material alongside the

drawbar.

In transport, rotate the Chute to the right hand side of

the machine aligning the indicators on the Chute and

Top Housing. Fully lower the Deflector to keep the

width and height of the machine to a minimum.

BED CHAIN OPERATION

The Bed Chain is operated by pressing forward button to

move forwards, pressing forward button to stop, and

pressing and holding reverse button to reverse. It is not

necessary to stop the Bed Chain before pressing the

reverse button as this will automatically cancel the

forward direction before engaging reverse.

COMMENCING OPERATION

LOADING THE MACHINE

The strings or net should be removed from the bale as it

is being loaded into the machine. The Tomahawk will

shred some string but some will tend to wrap around the

Crossbeater. Putting twine or netwrap through the

machine is not recommended as it will eventually be

spread on the land, polluting future crops.

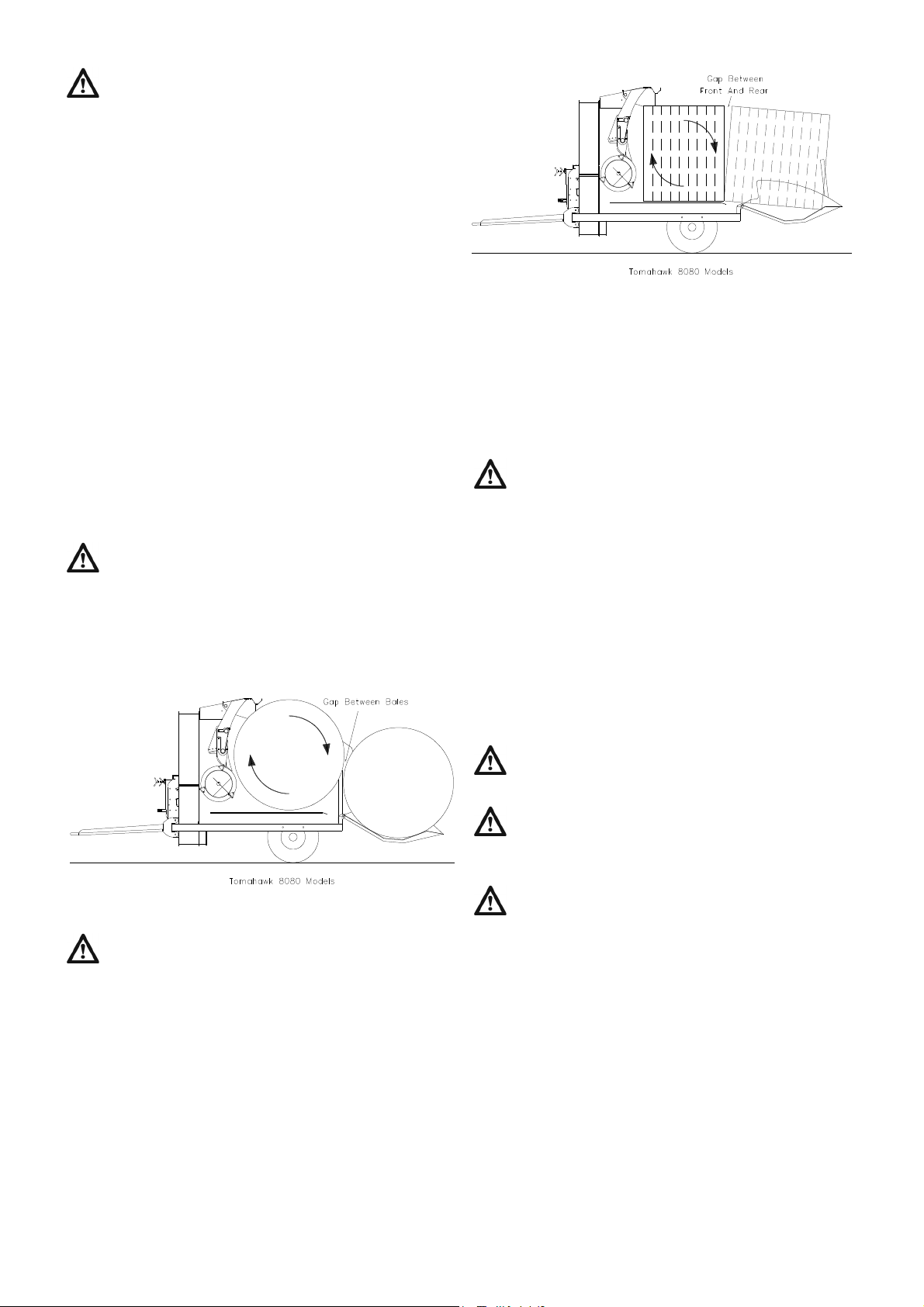

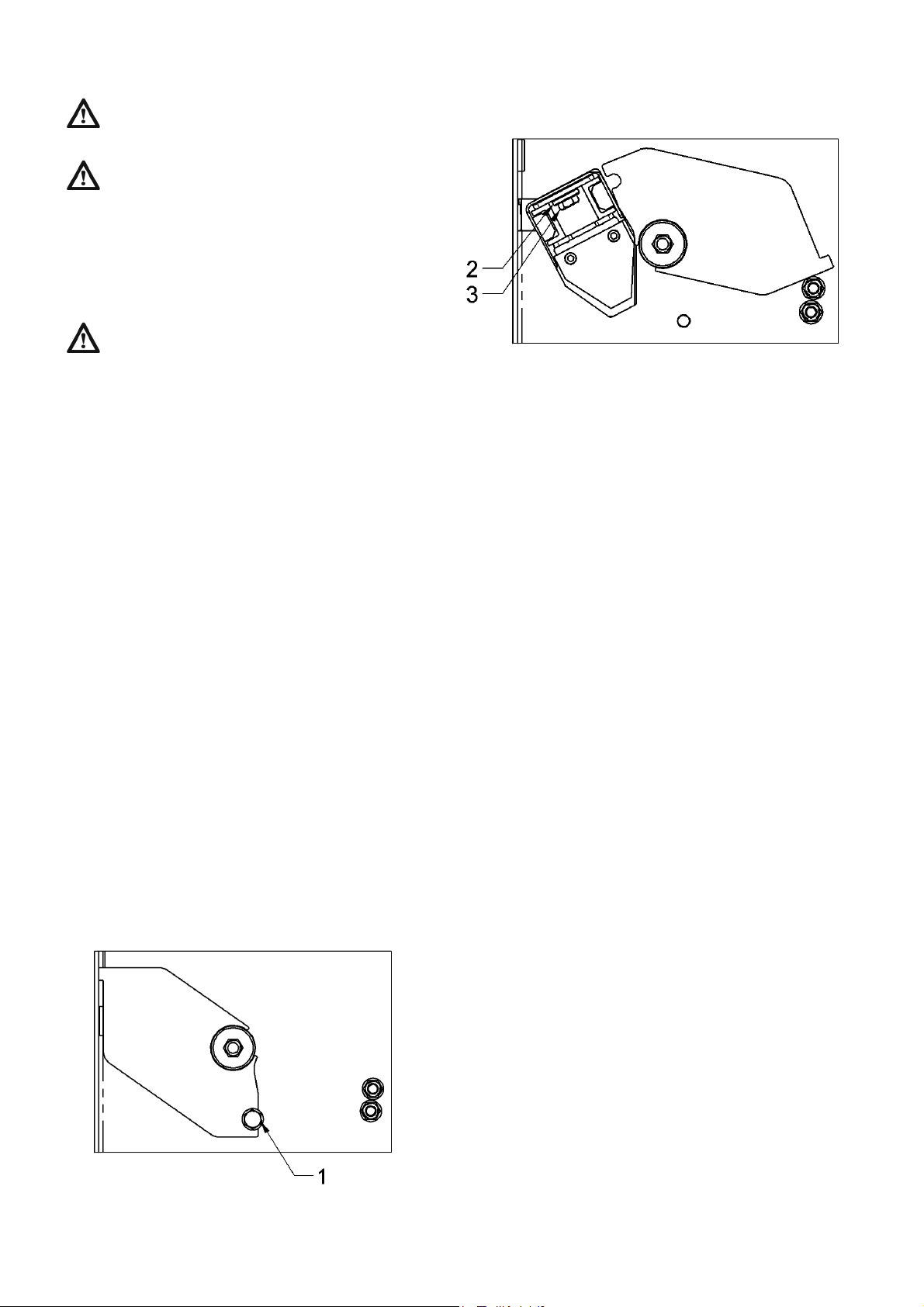

Bales can be loaded into the machine in two ways, by

using a loader or by self-loading using the machine

Tailgate. If a loader is used, simply load the bale into

the Bale Chamber so that it is fully inserted. Ensure the

bale is not rammed against the crossbeater. With

square bales it is recommended that the bales are laid

on their side to aid string removal.

When loading the machine, avoid running the Bed

Chain without the rotors turning. If there is a large

amount of material still in the Bale Chamber it will be

placed into the Rotor Housing causing the Rotor to jam

at start up.

Do not stand above the machine on a stack of bales

or in a barn to load the machine manually.

When removing string or netwrap from bales never

climb into the bale chamber or onto the tailgate

behind a bale unless, the PTO has been disengaged,

the engine has been stopped, the key removed from the

ignition and the machine has come to rest.

The Tailgate is designed to load bales into the Bale

Chamber of the machine. For large rectangular bales

place the bale on the ground with one end against a

solid object. For easy removal of the strings place the

bale on its side so that the strings are not in contact with

the ground. Reverse the machine with the Tailgate

lowered until the bale slides up the Tailgate and into the

Bale Chamber. Raise the Tailgate until it is in a

horizontal position and engage the Bed Chain to move

the bale fully onto the Tailgate.

Material Distance

Spread

Gearbox

Speed

PTO Speed

Straw Maximum High 540

Straw Close High 300

Baled Silage Close Low 540

Clamp Silage Close Low 300