C12 Quick Start Guide page 1

Output capacity: Up to 11t/hr

Tractor HP: Minimum 160—200

Material output: 13-125mm

C12 QUICK START GUIDE

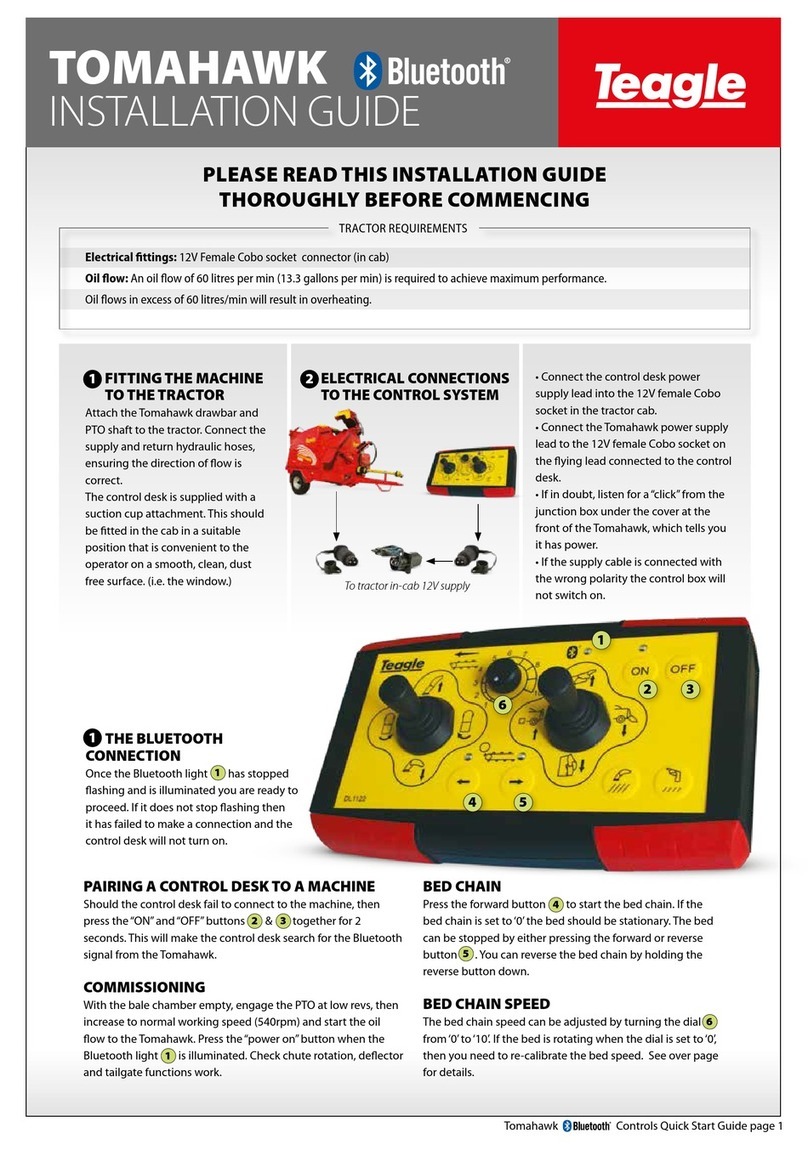

CONNECTING THE C12

ONTO THE TRACTOR

Connect all of the following ttings:

• Pick up hitch

• PTO

• Brakes

• Hydraulic hoses

• Electrics, both the junction box

and the light sockets

FITTING

THE CONTROL BOX

A special 4.5mm core, 6 metre twin core cable with 15 amp blade

type fuse is supplied with the machine. The end with two eyelets

must be tted to the battery of the tractor with the cable routed

in a suitable position without causing damage to the lead during

operation. If the connector provided on the supply lead is not to

be used, it is essential that the 15 amp fuse is retained to prevent

damage resulting from current overload.

SPECIFICATIONS

CONVEYOR BELT

CLEARANCE

When the conveyor is at the lowest

height (2.5m), the belt should just clear

the headguard. When the conveyor is

at the highest height (4.2m), the belt

should just clear the tubular beam.

Keep the belt as slack as possible. Do not

adjust unless it is absolutely necessary.

Belt tension can be adjusted at the top and

the base of the conveyor.

Images of belt tension (highest/lowest tension)

UNFOLDING

THE CONVEYOR

Do not run the PTO until the

conveyor belt is straight &

lowered.

The minimum discharge height

of the conveyor belt is 2.5metres

and the maximum is 4.2metres.

C12 Flow rate: 65 lpm with an automatic oil cooler

Electronic needed: 2 x 3 pin 12V sockets (1 x cable supplied)

Oil ttings needed: 2 x double acting valves

1

OVERVIEW: COMPLETELY READ THE C12 QUICK START GUIDE DOCUMENT

BEFORE COMMENCING OPERATION INSTALLATION

23

4

SEE THE MANUAL FOR

MORE INFORMATION

ON PAIRING THE

DEVICES.

Tubular beam

Headguard

CONTROL BOX

CONNECTION

The control box is supplied with a suction

cup attachment. This should be tted

in the cab in a suitable position that is

convenient to the operator on a smooth,

clean dust free surface.

The control box requires a 12v supply

and is shipped with 3 pin plug as

standard. A cigarette lighter to 3 pin

socket cable is supplied and can be used

for just the control box.

Once the junction box is plugged in, plug

the control box in & wait for the blue

ashing light to became solid blue which

indicates bluetooth is paired.

5