EO18-11006A

TABLE OF CONTENTS

Page

1. UNPACKING ..............................................................................................................1- 1

1.1 Procedure........................................................................................................................1- 1

1.2 Checks.............................................................................................................................1- 1

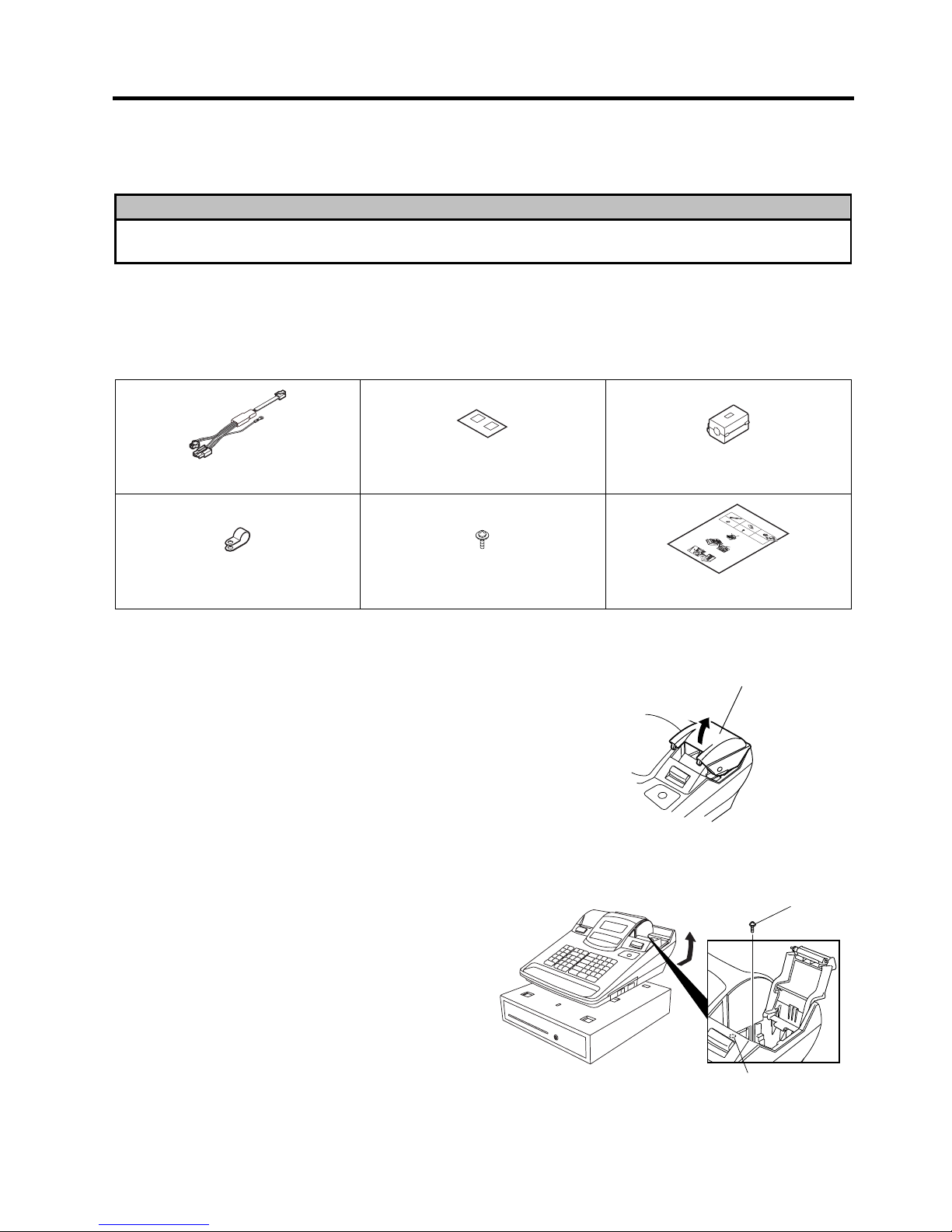

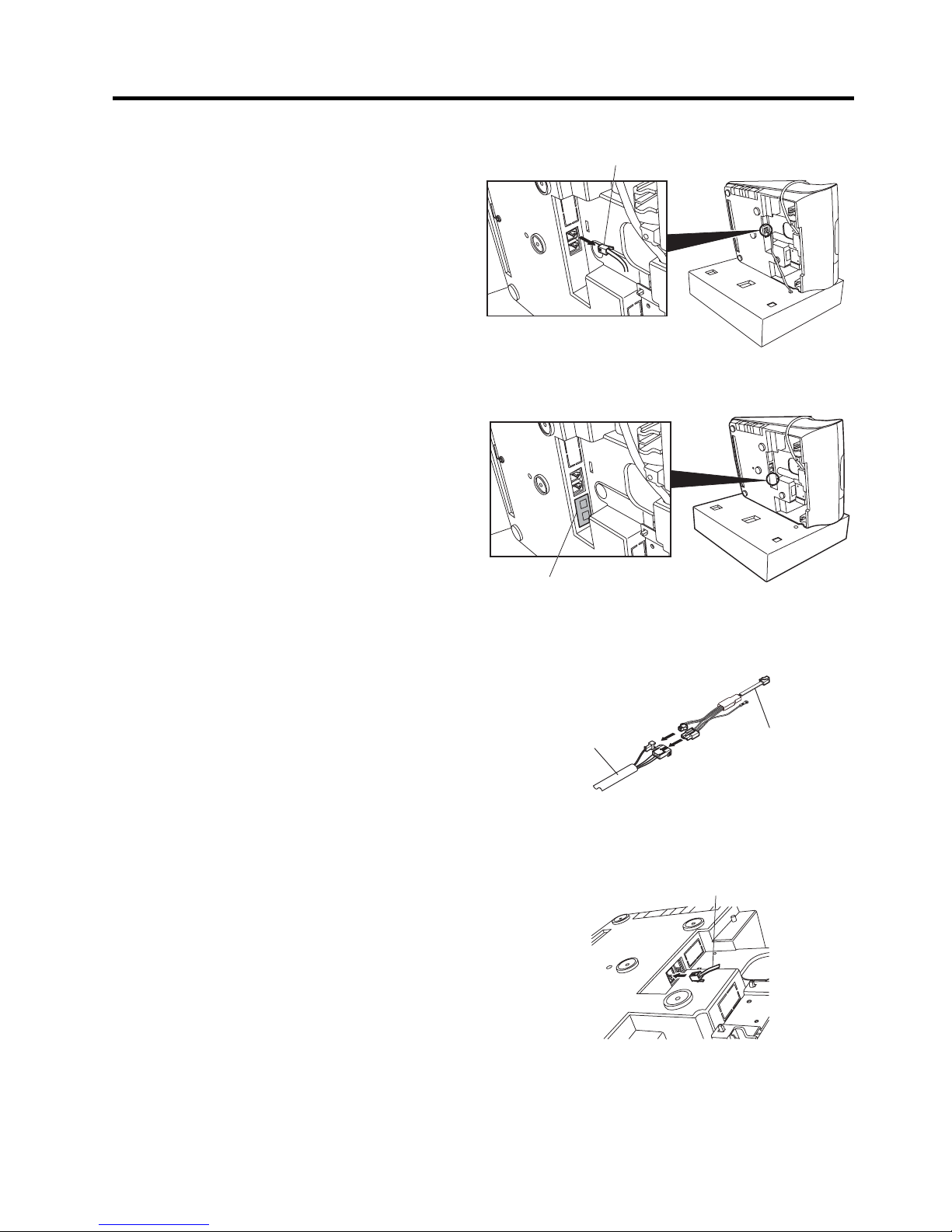

2. INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT................................2- 1

2.1 KRDC-600-QM-R (for QP model only) ............................................................................2- 1

3. DIAGNOSTIC TEST OPERATION.............................................................................3- 1

3.1 Diagnostic Test Operation List ........................................................................................3- 1

3.2 Print Test (“H” & All Characters)......................................................................................3- 2

3.3 Display Test.....................................................................................................................3- 3

3.4 ROM Test........................................................................................................................3- 4

3.5 RAM Test.........................................................................................................................3- 5

3.6 Print Test (“H”-consecutive).............................................................................................3- 6

3.7 RS-232C Loop Back Test................................................................................................3- 7

3.8 USB Test.........................................................................................................................3- 8

3.9 Keyboard Test.................................................................................................................3- 9

3.10 Drawer Open Test ..........................................................................................................3-10

3.11 Thermal Printer Test.......................................................................................................3-11

3.12 LCD Test ........................................................................................................................3-12

3.13 Simplified RAM Test.......................................................................................................3-13

3.14 RAM Installation Test .....................................................................................................3-14

3.15 Key Input Count Reading ...............................................................................................3-15

3.16 Network Controller Information Read .............................................................................3-16

3.16 Number of Print Lines Reading ......................................................................................3-16

3.17 General Test...................................................................................................................3-17

3.18 Print Density Setting.......................................................................................................3-19

4. PERIODIC MAINTENANCE .......................................................................................4- 1

5. TROUBLESHOOTING................................................................................................5- 1