Copyright 2011 The Energy Conservatory (revised 02-11)

Fan Configuration Flow Range (cfm)

For Series B Duct Blaster

Open (no Flow Ring) 1,500 - 600

Ring 1 800 – 225

Ring 2 300 – 90

Ring 3 125 – 10

Quick Guide DB-PR700

One-Point 25 Pascal Total Leakage Duct Pressurization Test

(blowing air into the duct system)

Using the Minneapolis Duct Blaster

and DG-700 Digital Gauge

1. Connect the Duct Blaster fan to the duct system.

a) Choose a location to install the Duct Blaster fan. In single, double or triple returned systems, the largest and closest return to the

air handler is usually the best choice. Note: In multi-return systems (a return in every room), installing at the air handler cabinet is

often best.

b) Remove any remote filters from the chosen return and then connect the black square transition piece to the return using

temporary tape. Completely seal the remaining open area of the return with

tape.

c) Pull the Duct Blaster fan and flex duct out of the carrying case. Connect

the flex duct to the exhaust side of the fan (i.e. the side with the metal

guard) using the round transition piece and connect trim. Connect the open

end of the flex duct to the square transition piece using the velcro strap on

the flex duct.

d) Connect the fan speed controller to the fan and plug it into a grounded

power outlet.

e) Install the Flow Ring which you think best matches the needed fan flow.

f) If your DG-700 gauge and fan speed controller are compatible with Cruise Control, install the fan control cable into the 3.5 mm

communication jacks located on top of the DG-700 and on the side of the speed controller (otherwise skip this step). **

2. Prepare the duct system and house for the Test.

a) Adjust the HVAC system controls so that the air handler does not turn on during the Test.

b) Temporarily seal off all remaining supply and return registers, and combustion or ventilation air inlets which are connected to the

duct system. Use Duct Mask

temporary register sealing material provided with your Duct Blaster, or use painters tape and paper.

c) Turn off any exhaust fans, vented dryers, and room air conditioners.

d) Remove all central filters (i.e. in air handler or return plenum).

e) Open a door or window between the building and outside to prevent changes in building pressure when the Duct Blaster is

running.

f) If the Duct Blaster is installed in an attic,

garage or crawlspace - open vents or access

panels or doors from these spaces to the outside.

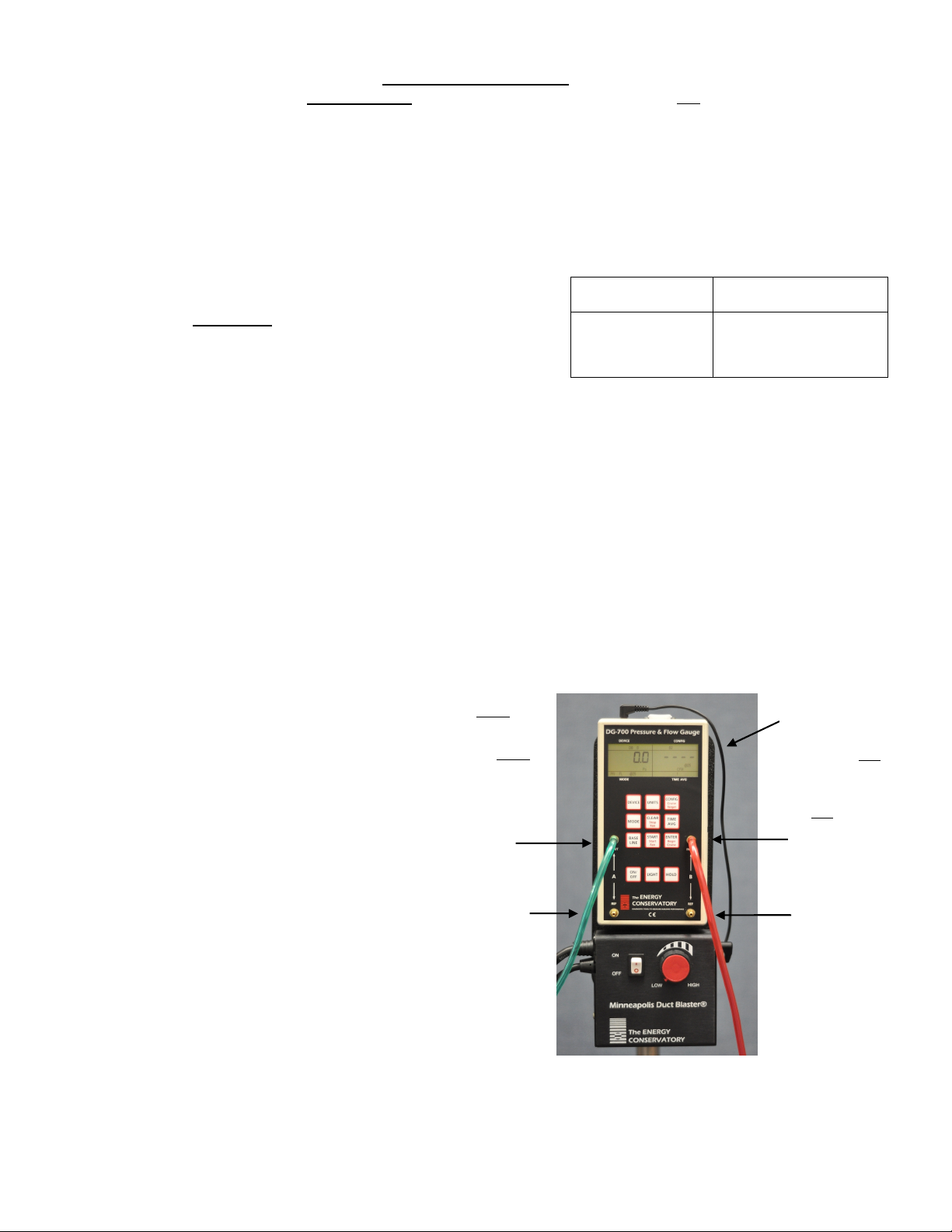

3. Connect tubing to the DG-700 Pressure

Gauge.

a) Select a location to measure duct pressure.

The best location for measuring duct pressure is

often in the supply trunkline or plenum. Drill a

small hole (1/4" to 3/8" OD) into the duct to

allow a static pressure probe to be installed.

Install the static pressure probe with the end of

the probe pointing into the air flow that will be

coming from the Duct Blaster fan. If the duct

system is reasonably airtight (e.g. less than 200

cfm25 of leakage), duct pressures can be

measured at any supply register by inserting a

piece of tubing through the temporary register

seal.

b) Connect tubing to the DG-700 as shown in

the illustration to the right.

** Your DG-700 gauge is compatible with Cruise Control if the CONFIG, CLEAR, START and ENTER keys have additional red

lettering below the main black script. Cruise Control also requires a Duct Blaster speed controller with a 3.5 mm communication jack

installed on the side of the controller box, and a fan control cable.

Connect the Red

tubing to the

Chan B Input tap.

The other end of

the Red tubing

should be

connected to the

brass tap in the

middle of the DB

fan housing.

Connect Chan A Ref

tap to inside of

building (if gauge is

located in the

building, leave this

tap open). Be sure

window is open.

Connect Chan B Ref

tap to space where

the fan is installed (if

fan and gauge are in

the same space,

leave this tap open).

Connect the Green (or

Clear) tubing to the

Chan A Input tap. The

other end of the Green

tubing should be

connected to the duct

system (by either

inserting into a sealed

register, or connecting

to the end of the

installed static

pressure probe).

Optional fan

control cable

(for Cruise Control).