TECALEMIT TankQuick eco Operational manual

Translation of the original operating manual

TankQuick eco

Item-No.: 013896200, 013896210

2 44 1657 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco

Copyright

The operating manual is always to be read before commissioning the equipment.

The operating manual is always to be read before commissioning the equipment. The operating manual is always to be read before commissioning the equipment.

The operating manual is always to be read before commissioning the equipment.

No

No No

No warranty claim will be granted for faults and damage to the equipment arising

warranty claim will be granted for faults and damage to the equipment arising warranty claim will be granted for faults and damage to the equipment arising

warranty claim will be granted for faults and damage to the equipment arising

from insufficient knowledge of the operating manual.

from insufficient knowledge of the operating manual.from insufficient knowledge of the operating manual.

from insufficient knowledge of the operating manual.

© HORN GmbH & Co. KG. All rights reser ed.

Text, graphics and layout copyright protected. Reproduction and copying, including in

part, only permitted with written permission. Technical changes reser ed.

Service Hotline 49 1805 900 301

Reparatur Service 49 1805 900 302

(0,14 €/Min: on the German landline network, Mobile telephone max. 0,42 €/Min.)

service@tecalemit.de

Document-No.: 44 1657 101-H

Translation of: 44 1657 001-L

As of: February 12, 2020

44 1642 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco 3

Table of content

1

11

1 Safety instructions

Safety instructionsSafety instructions

Safety instructions

................................

................................................................

................................................................

................................................................

................................................................

................................................................

..................................

....

..

4

44

4

2

22

2 Technical description

Technical descriptionTechnical description

Technical description

................................

................................................................

................................................................

................................................................

..............................................................

............................................................

..............................

6

66

6

2.1 Product description / Appropriate use ............................................................. 6

2.2 Product ersions ...................................................................................................... 6

2.3 Equipment .................................................................................................................. 6

2.4 Technical data ........................................................................................................... 7

2.5 Accessories ................................................................................................................ 7

2.6 Outline drawing ........................................................................................................ 8

2.7 Functional diagram ................................................................................................. 8

3

33

3 Inst

InstInst

Installation

allationallation

allation

................................

................................................................

................................................................

................................................................

................................................................

................................................................

.................................................

..................................

.................

9

99

9

3.1 Place of installation ................................................................................................ 9

3.2 Change of location ................................................................................................... 9

3.3 Compressed Air Supply .......................................................................................... 9

4

44

4 Commissioning

CommissioningCommissioning

Commissioning................................

................................................................

................................................................

................................................................

................................................................

................................................................

..........................................

....................

..........

9

99

9

4.1 Specifying the Liquid .............................................................................................. 9

4.2 Operation with exchange containers ............................................................. 10

4.2.1 Emptying the deli ery systems .......................................................... 10

4.2.2 Changing the drum .................................................................................. 10

4.3 Adjusting the Operating Pressure ................................................................... 10

5

55

5 Operation

OperationOperation

Operation

................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................

................................

................

10

1010

10

5.1 Safety instructions ............................................................................................... 10

5.2 Remo ing Fuel ....................................................................................................... 11

5.2.1 Extracting fuel ia the filler pipe ....................................................... 11

5.2.2 Preparation of the hose set .................................................................. 11

5.2.3 Extracting fuel ia the fuel line ........................................................... 12

5.3 Refilling the Vehicle with Fuel ......................................................................... 13

5.3.1 Preparation oft he hose set .................................................................. 13

5.3.2 Refilling ....................................................................................................... 13

5.4 Breaks in works ..................................................................................................... 14

6

66

6 Ser icing and maintenance

Ser icing and maintenanceSer icing and maintenance

Ser icing and maintenance

................................

................................................................

................................................................

................................................................

................................................

................................

................

14

1414

14

6.1 Cleaning ................................................................................................................... 14

6.2 Container ................................................................................................................. 14

6.3 Dirt trap ................................................................................................................... 15

6.4 Pressure regulator ................................................................................................ 15

6.5 Deli ery system .................................................................................................... 15

6.6 Wheels ...................................................................................................................... 15

6.7 Type Plate and Warning Signs .......................................................................... 15

6.8 Troubleshooting .................................................................................................... 16

7

77

7 Spare parts

Spare partsSpare parts

Spare parts

................................

................................................................

................................................................

................................................................

................................................................

................................................................

.............................................

..........................

.............

17

1717

17

8

88

8 Disposal

DisposalDisposal

Disposal

................................

................................................................

................................................................

................................................................

................................................................

................................................................

...................................................

......................................

...................

18

1818

18

9

99

9 Declaration of c

Declaration of cDeclaration of c

Declaration of conformity

onformityonformity

onformity

................................

................................................................

................................................................

................................................................

..................................................

....................................

..................

19

1919

19

4 44 1657 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco

1Safety instructions

This de ice was manufactured taking into account the rele ant laws and directi es

for ensuring security as well as the protection of the en ironment and health. Despite

this, its use may result in hazards for persons and material assets. Hence, it is

essential that the instructions in this manual are complied with.

Warning notices and symbols

Warning notices and symbolsWarning notices and symbols

Warning notices and symbols

In this operating manual, the following symbols are used to point out especially

important information:

Specific details on the economic use of the device

Specific details on the economic use of the deviceSpecific details on the economic use of the device

Specific details on the economic use of the device.

Specific details and/or instructions for damage prevention

Specific details and/or instructions for damage preventionSpecific details and/or instructions for damage prevention

Specific details and/or instructions for damage prevention.

Details and/or instructions for preventing injury to persons or extensive material

Details and/or instructions for preventing injury to persons or extensive material Details and/or instructions for preventing injury to persons or extensive material

Details and/or instructions for preventing injury to persons or extensive material

damages

damagesdamages

damages

Intended use

Intended useIntended use

Intended use

Use the de ice only when it is in perfect working condition and only for its intended

purpose while obser ing all safety precautions and risks. In particular, all

malfunctions that could pose a safety hazard are to be corrected immediately.

The de ice and its components are intended for use exclusi ely with the liquids listed

and only for the purpose described. Any other use or additional manner of usage is

not intended.

Organizational measures

Organizational measuresOrganizational measures

Organizational measures

This operating manual is to be kept within easy reach at the place of operation. The

nameplate and the warning labels on the de ice must be obser ed and kept

completely legible at all times.

Qualified personnel

Qualified personnelQualified personnel

Qualified personnel

The personnel for installation, commissioning, operation, and maintenance of the

de ice must possess the rele ant and adequate qualifications for these tasks. The

operator must ensure that the contents of this manual are fully understood and

implemented by the personnel.

Maintenance and repairs

Maintenance and repairsMaintenance and repairs

Maintenance and repairs

Do not make any changes, extensions and/or modifications to the de ice without the

manufacturer's permission. Replacement parts must conform to the technical

specifications defined by the manufacturer. For original parts, this conformity is

always guaranteed.

Hazardous substances

Hazardous substancesHazardous substances

Hazardous substances

In exceptional cases, the components of this de ice may contain hazardous

substances. In accordance with the requirements of the European REACH regulation,

we pro ide current information on this on our homepage, in the download section.

Obser e all safety regulations for the respecti e product when handling oils, greases,

fuels and other chemical substances!

44 1642 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco 5

Hydraulics

HydraulicsHydraulics

Hydraulics

Only personnel with special knowledge of and experience in hydraulics are allowed to

perform work of any type on hydraulic equipment. Depressurize the de ice before

performing any work on it. All pressure-bearing components are to be inspected

regularly for leaks and damage.

Pneumatics

PneumaticsPneumatics

Pneumatics

Only personnel with special knowledge of and experience in pneumatics are allowed

to perform work of any type on pneumatic equipment. Depressurize the de ice

before performing any work on it. All pressure-bearing components are to be

inspected regularly for leaks and damage.

Explosion protection

Explosion protectionExplosion protection

Explosion protection

The de ice has been constructed for use with potentially explosi e substances. The

design and production took place in accordance with pre ailing regulations, in

particular the ATEX directi e 2014/34/EU and technical regulations. The operator is

to obser e all regulations for the operation of such de ices, in particular the ATEX

guideline 1999/92/EC and the respecti e regulations applicable at the place of

operation.

Water protection

Water protectionWater protection

Water protection

The de ice has been constructed for use with water contaminants. It is to be operated

such that bodies of water cannot be polluted by it. All applicable regulations at the

place of operation are to be complied with!

6 44 1657 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco

2Technical description

2.1

2.12.1

2.1 Product description

Product descriptionProduct description

Product description

/

/ /

/ Ap

ApAp

App

pp

propriate use

ropriate useropriate use

ropriate use

The TankQuick eco is a de ice for transferring fuel out of ehicle tanks into the

de ice's own containers, and for returning it to the empty tank. It was specifically

designed to be used in ehicle workshops, at filling stations and similar sites. It can be

used for emptying the tanks of ehicles on which repairs are to be carried out, and

for emptying tanks that ha e been wrFongly filled.

This

ThisThis

This

device is approved for use with potentially explosive liquids and for opera

device is approved for use with potentially explosive liquids and for operadevice is approved for use with potentially explosive liquids and for opera

device is approved for use with potentially explosive liquids and for opera-

--

-

tion in potentially explosive atmospheres. The permissible type of use is speci

tion in potentially explosive atmospheres. The permissible type of use is specition in potentially explosive atmospheres. The permissible type of use is speci

tion in potentially explosive atmospheres. The permissible type of use is speci-

--

-

fied by the Ex mark in the declaration of conformity and on the type plate. The

fied by the Ex mark in the declaration of conformity and on the type plate. The fied by the Ex mark in the declaration of conformity and on the type plate. The

fied by the Ex mark in the declaration of conformity and on the type plate. The

device may be opera

device may be operadevice may be opera

device may be operated exclusively with the liquids listed below.

ted exclusively with the liquids listed below.ted exclusively with the liquids listed below.

ted exclusively with the liquids listed below.

The de ice accords with the requirements of the applicable regulations, and in

particular with ATEX (2014/34/EU). This is certified by the Declaration of Conformity

and by the CE mark.

In addition the TankQuick has been subject to a GS-testing. The compliance of quality

and safety standards in engineering, production and quality management has been

appro ed. A regularly inspection by the testing authority is carried out. For

erification the de ice is marked with the GS-label.

In operation, the pneumatic double-membrane pump sucks the fuel out of the tank,

through the suction hose and into the container. The fuel is kept in the container

while the work is carried out. After changing o er the deli ery hoses, fuel is

discharged again from the container. The gas displacement de ice ensures that the

gases displaced during filling do not escape to the open air.

The container deli ered with the equipment is appro ed for the transport of the

appro ed liquids and can be exchanged with no great effort.

2.2

2.22.2

2.2 Product versions

Product versionsProduct versions

Product versions

The TankQuick eco is a ailable in two ariants. They differ in the type of suction

hose.

013 896 200 - TankQuick eco Suction hose 15x9 mm

013 896 210 - TankQuick eco S Suction hose 12x8 mm

2.3

2.32.3

2.3 Equipment

EquipmentEquipment

Equipment

•Four-wheeled trolley with 2 lockable steering rolls

•120 litre exchangeable container with le el display

•Pump unit with deli ery pump, fuel filter, compressed air regulator and starting

al e

•Hose system with filler pipe adapter, emptying/refilling hose and gas

displacement hose

•Accessories (optional): Adapter set for extraction ia the fuel hose

44 1642 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco 7

2.4

2.42.4

2.4 Technical data

Technical dataTechnical data

Technical data

Dimensions

Height

approx.

1096 mm

Width

approx.

483 mm

Depth

approx.

680 mm

Empty weight

With

container

approx.

35 kg

Noise emission

Free sound field,

accuracy class 2, EN ISO 11201

68,2dB +2,5dB

Container

Volume

120l

Useful olume

110l

Pump unit

Pumping capacity

approx.

7,5 l/min

Operating means

Compressed air, oil

-

free

filtered

Compressed air inlet

min 6

bar, max. 10 bar

Permissible ambient

temp.

Operation and breaks in work

5

°

…

40° C

Permissible media

temperature

5

°

…

40° C

Pumping media

Petrol, diesel,

E85 (ethanol fuel),

others on enquiry

2.5

2.52.5

2.5 Accessories

AccessoriesAccessories

Accessories

The following items can be used as accessories depending on the application:

Item-No.

Adapter set for extraction ia the fuel line 020 202 011

Exchange drum with le el display 013 896 300

Adapter for Mercedes C-Class 027 028 021

8 44 1657 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco

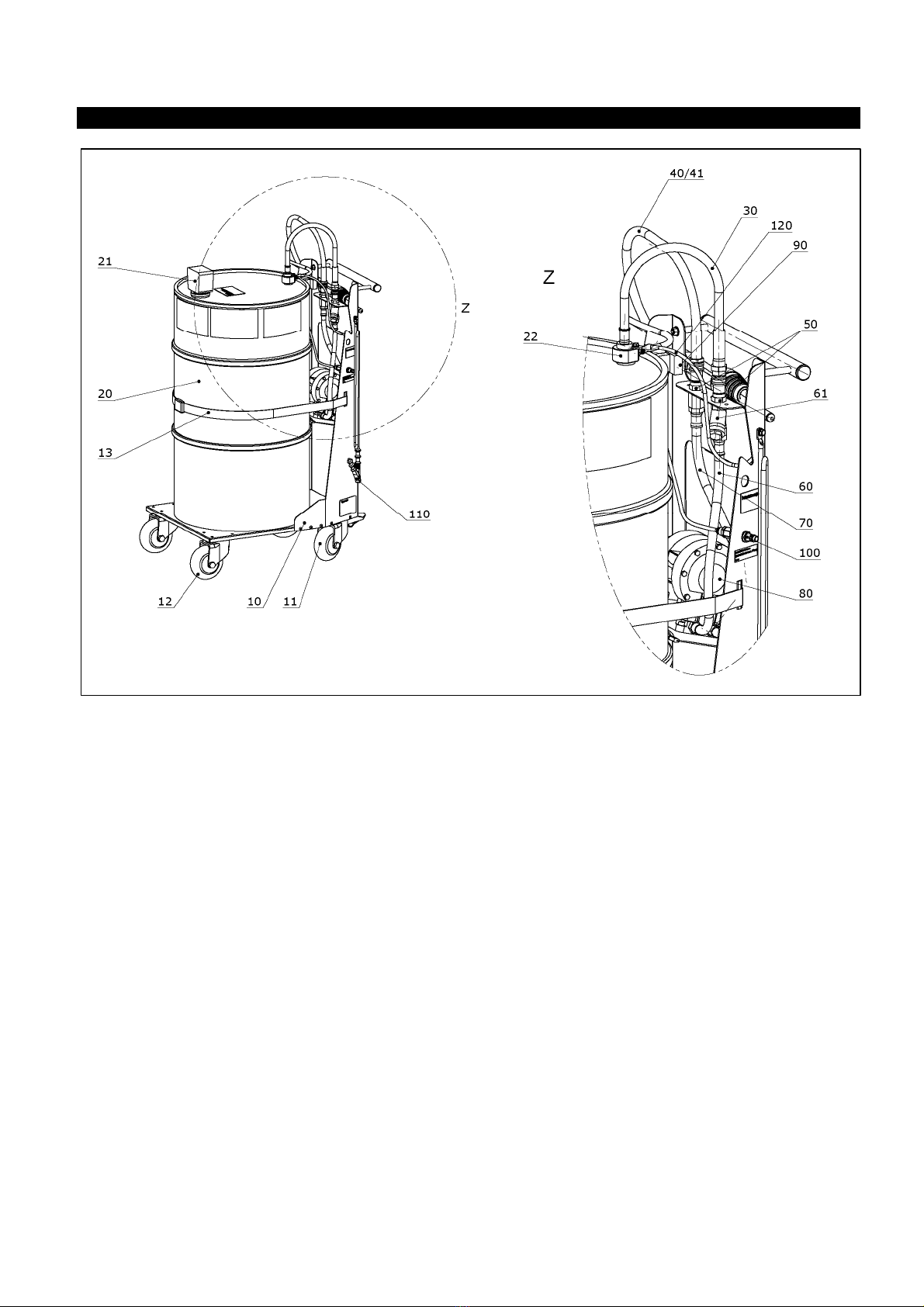

2.6

2.62.6

2.6 Outline drawing

Outline drawingOutline drawing

Outline drawing

Figure 1

2.7

2.72.7

2.7

Functional diagram

Functional diagramFunctional diagram

Functional diagram

Figure 2

44 1642 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco 9

3Installation

3.1

3.13.1

3.1 Place of installation

Place of installationPlace of installation

Place of installation

The TankQuick may only be used at sites such as petrol stations or workshops that

ha e been properly set-up for such work. The place of installation must be chosen in

such a way as neither to present danger to persons nor to pollute the en ironment.

The following points must be obser ed:

•The de ice must be used in such a way that any spilt fuel is trapped, is noticed,

and can be collected. It must therefore only be used and stored on a liquid-tight

floor. Spilt drops must be collected immediately.

•In accordance with TRBS 3151, the area with a radius of approx. 0.2 m around the

equipment is to be classified as Ex-zone 2. The de ice must therefore only be used

in the open air or in well- entilated rooms. The necessary explosi e hazard

protection measures must be taken.

In particular smoking, naked flames and working with tools that generate sparks

In particular smoking, naked flames and working with tools that generate sparks In particular smoking, naked flames and working with tools that generate sparks

In particular smoking, naked flames and working with tools that generate sparks

are forbidden in the vicinity of the device.

are forbidden in the vicinity of the device.are forbidden in the vicinity of the device.

are forbidden in the vicinity of the device.

•When not in use it must only be stored in rooms where people do not stay. Ensure

good entilation and that the temperature of the de ice will not rise.

•In order to disperse any static electric charge, the unit must not be placed on

insulating surfaces.

•The place of installation must offer sufficient protection against unauthorised use.

•It must be kept where it is protected from damage by third parties, e.g. not close

to the path of ehicles or working areas.

•The equipment is to be installed such that it is protected against influences of the

weather and also protected against heating up (e.g. direct sunlight).

3.2

3.23.2

3.2 Change of location

Change of locationChange of location

Change of location

When mo ing the TankQuick, it may be pushed / pulled exclusi ely by the handle of

the trolley. When parking it must always be ensured that the wheel locks are applied

securely.

3.3

3.33.3

3.3 Compressed Air

Compressed Air Compressed Air

Compressed Air Supply

SupplySupply

Supply

Fault

FaultFault

Fault-

--

-free operation involving relatively little servicing is only ensured if the

free operation involving relatively little servicing is only ensured if the free operation involving relatively little servicing is only ensured if the

free operation involving relatively little servicing is only ensured if the

supply of compressed air is free from dirt, water condensation and oil.

supply of compressed air is free from dirt, water condensation and oil.supply of compressed air is free from dirt, water condensation and oil.

supply of compressed air is free from dirt, water condensation and oil.

The use of a compressed air filter with an automatic condensate drain by the user is

to be greatly recommended.

An input pressure of at least 6 bar is necessary in order to reach the max. deli ery

flow rate.

4Commissioning

4.1

4.14.1

4.1 Specifying the Liquid

Specifying the LiquidSpecifying the Liquid

Specifying the Liquid

Liquid residues will be found e en when the container has been emptied. In order to

ensure that there is no mixing of sorts, the medium for a de ice must be specified

during commissioning (diesel, petrol or E85).

The operator is responsible for properly labeling the receptacles containing

The operator is responsible for properly labeling the receptacles containing The operator is responsible for properly labeling the receptacles containing

The operator is responsible for properly labeling the receptacles containing

hazardous materials.

hazardous materials.hazardous materials.

hazardous materials.

10 44 1657 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco

The hazardous material labels included in the scope of deli ery can be used for this

purpose.

4.2

4.24.2

4.2 Operation with exchange containers

Operation with exchange containersOperation with exchange containers

Operation with exchange containers

The container supplied with the unit is an open head drum, authorized for dangerous

goods transport of the appro ed medium (UN appro al no.

UN1A1/X300/2010/DBAM1166-GDH). It can, for example, be changed for single

ariety use with different mediums. Only replacement drums with a filling le el

indicator, a ailable as an accessory, may be used.

Emptying the delivery systems

Emptying the delivery systemsEmptying the delivery systems

Emptying the delivery systems

A small quantity of

A small quantity of A small quantity of

A small quantity of fuel remains in the delivery system after operation.

fuel remains in the delivery system after operation.fuel remains in the delivery system after operation.

fuel remains in the delivery system after operation.

In order to empty the system as completely as possible before exchanging the drum,

the extraction procedure should be carried out for approx. 15 sec with the suction

hose raised.

Changing the drum

Changing the drumChanging the drum

Changing the drum

In order to change the drum, dismount the drum connection, loosen the safety belt

and lift the drum off the trolley.

Place the new drum on the trolley, press it against the support plate and secure it

with the belt. Now mount the drum connection with fuel hose, gas displacement hose

and potential equalisation cable.

Check that the drum is secured after changing the drum and regularly during use!

Check that the drum is secured after changing the drum and regularly during use!Check that the drum is secured after changing the drum and regularly during use!

Check that the drum is secured after changing the drum and regularly during use!

4.3

4.34.3

4.3 Adjusting the Operating Pressure

Adjusting the Operating PressureAdjusting the Operating Pressure

Adjusting the Operating Pressure

The internal operating pressure is limited ia the de ice’s own pressure regulator. It

is preset in the factory to the max. permissible output pressure of 6 bar and fixed.

The max. pumping capacity of the de ice is reached at this pressure. A higher output

pressure is not possible.

Howe er, the operating pressure can be reduced if necessary with the pressure

regulator of the air supply system. For proper operation the input pressure may not

fall below 2 bar.

5Operation

5.1

5.15.1

5.1

Safety instructions

Safety instructionsSafety instructions

Safety instructions

The de ice may only be operated by trained personnel and under constant

super ision. The following points must be obser ed:

•Wear protecti e glo es when handling the TankQuick

•Inflammable fuels must only be put into containers that are suitable for this

purpose.

•The engine and the external heating of the ehicle whose fuel is to be remo ed or

returned must be switched off during operation.

•Suitable fire-fighting equipment must be to hand during operation (e.g. fire

extinguishers)

•The wheels' contact with the ground ensures that static buildup is discharged.

Hence, clean the wheels before operation if necessary.

•

Emergency stop In the e ent of a malfunction or an emergency, operation can be

stopped immediately by releasing the start button.

44 1642 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco 11

Hose to the ehide Hose to the container

BLACK RED

Left Right

5.2

5.25.2

5.2 R

RR

Removing Fuel

emoving Fuelemoving Fuel

emoving Fuel

Check the filling le el in the container before starting the extraction procedure.

Avoid overfilling the container

Avoid overfilling the containerAvoid overfilling the container

Avoid overfilling the container.

..

.

If o erfilling should ne ertheless occur, the excess pumping medium is fed back by

the gas displacement hose to the ehicle tank and o erfilling can be quickly

recognised in the transparent gas displacement hose. The extraction procedure must

then be stopped immediately.

Liquid can escape out of the level display if overfilling persists. This collects on

Liquid can escape out of the level display if overfilling persists. This collects on Liquid can escape out of the level display if overfilling persists. This collects on

Liquid can escape out of the level display if overfilling persists. This collects on

the drum lid and can be disposed of afterwards. The level display is to be cleaned

the drum lid and can be disposed of afterwards. The level display is to be cleaned the drum lid and can be disposed of afterwards. The level display is to be cleaned

the drum lid and can be disposed of afterwards. The level display is to be cleaned

and its functio

and its functioand its functio

and its functional capability checked.

nal capability checked.nal capability checked.

nal capability checked.

Extracting fuel via the filler pipe

Extracting fuel via the filler pipeExtracting fuel via the filler pipe

Extracting fuel via the filler pipe

As a rule the tank contents are extracted ia the ehicle filler pipe.

Prepa

PrepaPrepa

Preparation of t

ration of tration of t

ration of the hose set

he hose sethe hose set

he hose set

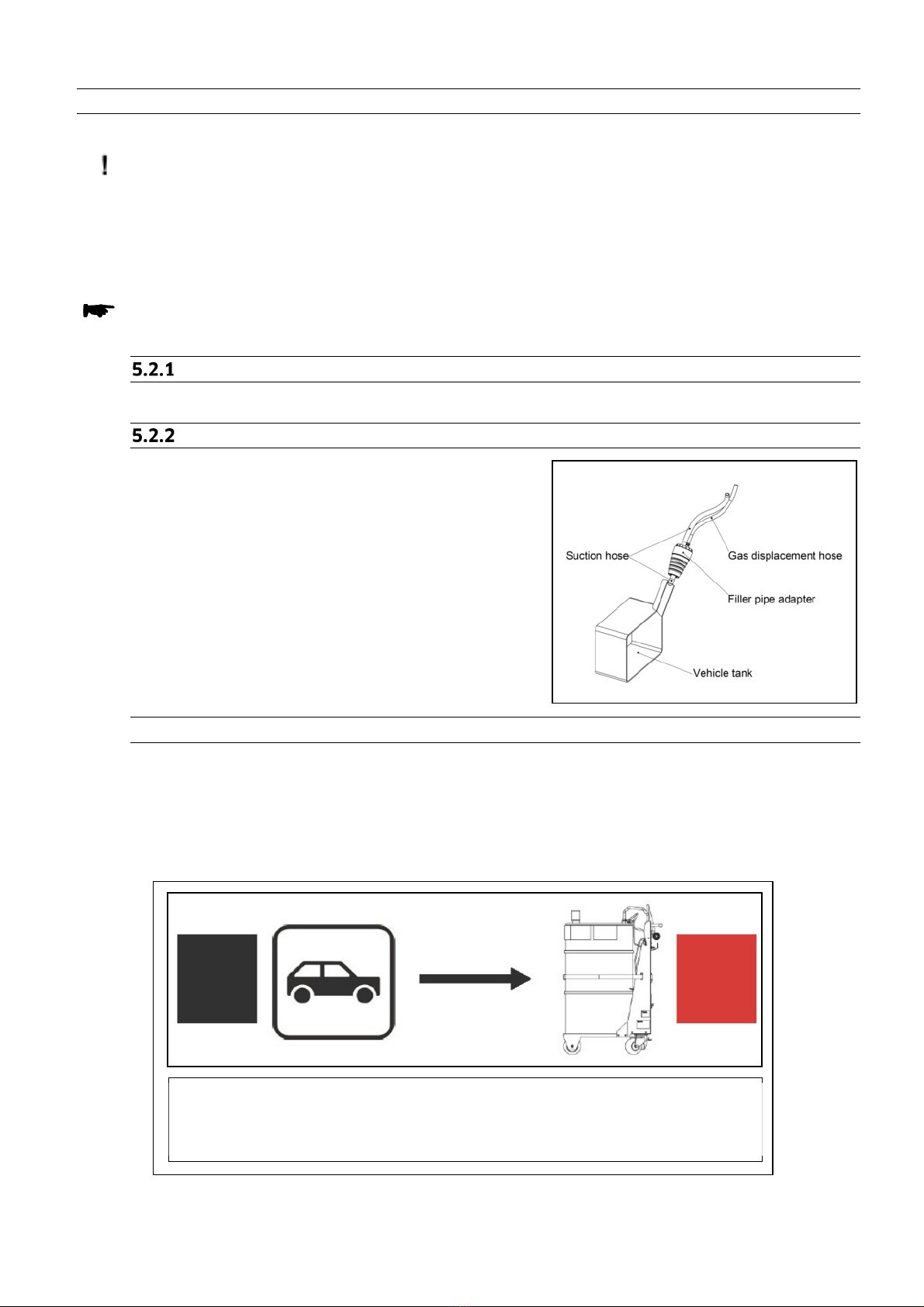

The suction hose set can be used as in the

deli ery condition with the suction hose fed

through the extraction adapter; see figure 3.

5.2.2.1

5.2.2.15.2.2.1

5.2.2.1

Extraction Procedure

Extraction ProcedureExtraction Procedure

Extraction Procedure

1. Mo e the TankQuick to the ehicle from which the fuel is to be extracted and

apply the parking brakes.

2. Attach the fastening clip of the potential equalisation cable to the ehicle.

3. Connect the deli ery hoses for the ‘extraction’ operating mode – pay attention to

the colour coding of the hoses:

Figure

3

Figure

4

12 44 1657 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco

4. Feed the suction/refilling hose into the ehicle tank and mount the filler pipe

adapter in the filler pipe.

During operation the filler pipe adapter must extend into the filler pipe and be

During operation the filler pipe adapter must extend into the filler pipe and be During operation the filler pipe adapter must extend into the filler pipe and be

During operation the filler pipe adapter must extend into the filler pipe and be

fixed securely!

fixed securely!fixed securely!

fixed securely!

5. Connect the compressed air.

6. Press the start button – the contents of the fuel tank are extracted.

The extraction procedure can be controlled ia the pumping noise of the pump. It

is possible that the pump may draw in air, e en though the ehicle tank has not

yet been fully emptied. In this case, the suction hose must either be pushed

further into the tank or pulled further out of the tank through the gripper piece in

the filler pipe. This should be done slowly and in short steps, since the suction

hose must first be refilled with liquid. Only then it is possible to discern the

pumping status of the pump.

The tank level must be monitored during the extraction procedure in order to

The tank level must be monitored during the extraction procedure in order to The tank level must be monitored during the extraction procedure in order to

The tank level must be monitored during the extraction procedure in order to

avoid overfilling.

avoid overfilling.avoid overfilling.

avoid overfilling.

7. After the extraction procedure is finished, allow the pump to run on briefly in

order to empty the hoses, then disconnect the de ice from the compressed air

supply.

Extracting fuel via the fuel line

Extracting fuel via the fuel lineExtracting fuel via the fuel line

Extracting fuel via the fuel line

Extraction takes place ia a suction hose connected to the ehicle’s fuel line. The

adapter set, which is a ailable as an accessory, is required for this.

Extraction via the fuel line may take place only with the permission of the

Extraction via the fuel line may take place only with the permission of the Extraction via the fuel line may take place only with the permission of the

Extraction via the fuel line may take place only with the permission of the

respective vehicle manufacturer!

respective vehicle manufacturer!respective vehicle manufacturer!

respective vehicle manufacturer!

5.2.3.1

5.2.3.15.2.3.1

5.2.3.1 Preparation of

Preparation ofPreparation of

Preparation of

the hose set

the hose setthe hose set

the hose set

The suction hose set must be mounted with the

adapter set according to figure 5. The assembly

instructions for the adapter set are to be

followed.

1. Pull the suction hose out of the filler pipe

adapter.

2. Fit the sealing plug into the free hole in the

filler pipe adapter.

3. Screw the hose adapter into the thread of the

ball point.

5.2.3.2

5.2.3.25.2.3.2

5.2.3.2

Extraction Procedure

Extraction ProcedureExtraction Procedure

Extraction Procedure

1. Mo e the TankQuick to the ehicle from which the fuel is to be extracted and

apply the parking brakes.

2. Attach the fastening clip of the potential equalisation cable to the ehicle.

3. Connect the deli ery hoses for the ‘extraction’ operating mode; see fig. 4.

4. Mount the filler pipe adapter with the gas displacement line in the filler pipe.

During operation the filler pipe adapter must extend into the filler pipe and be

During operation the filler pipe adapter must extend into the filler pipe and be During operation the filler pipe adapter must extend into the filler pipe and be

During operation the filler pipe adapter must extend into the filler pipe and be

fixed securely!

fixed securely!fixed securely!

fixed securely!

Figure

5

44 1642 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco 13

Hose to the container Hose to the ehicle

RED BLACK

Left Right

5. Feed the hose adapter with the suction hose into the fuel line.

6. Connect the compressed air.

7. Press the start button – the contents of the fuel tank are extracted.

The extraction procedure can be controlled ia the pumping noise of the pump.

During operation the filler pipe adapter must

During operation the filler pipe adapter mustDuring operation the filler pipe adapter must

During operation the filler pipe adapter must

extend into the filler pipe and be

extend into the filler pipe and be extend into the filler pipe and be

extend into the filler pipe and be

fixed securely!

fixed securely!fixed securely!

fixed securely!

8. If only air is still being sucked in by the pump, the extraction procedure can be

terminated. Allow the pump to run on briefly in order to empty the hoses, then

disconnect the de ice from the compressed air supply.

9.

5.3

5.35.3

5.3 Refilling the Vehicle with Fuel

Refilling the Vehicle with FuelRefilling the Vehicle with Fuel

Refilling the Vehicle with Fuel

Refilling the ehicle tank with fuel from the container may take place exclusi ely ia

the tank filler pipe.

Refilling the tank via the fuel line is not permitted!

Refilling the tank via the fuel line is not permitted!Refilling the tank via the fuel line is not permitted!

Refilling the tank via the fuel line is not permitted!

In order to avoid over

In order to avoid overIn order to avoid over

In order to avoid over-

--

-filling, only the

filling, only the filling, only the

filling, only the fuel that was removed from any particular

fuel that was removed from any particular fuel that was removed from any particular

fuel that was removed from any particular

vehicle should be returned to that vehicle.

vehicle should be returned to that vehicle.vehicle should be returned to that vehicle.

vehicle should be returned to that vehicle.

Preparation oft he hose set

Preparation oft he hose setPreparation oft he hose set

Preparation oft he hose set

The hose set is to be installed ia the filler pipe as for extraction (see chapter 5.2.1).

Refilling

RefillingRefilling

Refilling

1. Bring the TankQuick to the ehicle that is to be refuelled, and lock the wheels.

2. Attach the fastening clip of the potential equalisation cable to the ehicle.

3. Connect the deli ery hoses for the ‘refilling’ operating mode – pay attention to the

colour coding of the hoses:

Figure

6

14 44 1657 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco

4. Feed approx. 20 cm of the suction/refilling hose into the ehicle tank and mount

the filler pipe adapter in the filler pipe.

During operation the

During operation the During operation the

During operation the filler pipe adapter must extend into the filler pipe and be

filler pipe adapter must extend into the filler pipe and be filler pipe adapter must extend into the filler pipe and be

filler pipe adapter must extend into the filler pipe and be

fixed

fixedfixed

fixed

securely

securelysecurely

securely

5. Make the compressed air connection

6. Press the start button – the container contents are refilled into the tank.

7. To end the refilling procedure, release the start button and disconnect the de ice

from the compressed air supply.

5.4

5.45.4

5.4 Breaks in works

Breaks in worksBreaks in works

Breaks in works

The TankQuick is to be placed in special rooms during work breaks; see chapter 3.

The container on the device may be used exclusively for fuels in this particular

The container on the device may be used exclusively for fuels in this particular The container on the device may be used exclusively for fuels in this particular

The container on the device may be used exclusively for fuels in this particular

work step and must accordingly be emptied again after max. 1 day.

work step and must accordingly be emptied again after max. 1 day.work step and must accordingly be emptied again after max. 1 day.

work step and must accordingly be emptied again after max. 1 day.

If it is to be used for the storage of the extracted fuels, then the container must be

remo ed from the de ice and placed in a suitable storeroom that complies with the

regulations. The regulations applying to storage must be followed.

In order to ensure that the de ice works perfectly at all times, it should be emptied

before breaks in work if at all possible. To do this, carry out the emptying procedure

as described in the chapter “Refilling the Vehicle with Fuel” until only air exits from

the dispensing hose.

The ambient temperature specified in the chapter

The ambient temperature specified in the chapter The ambient temperature specified in the chapter

The ambient temperature specified in the chapter “Technical data” must also be

“Technical data” must also be “Technical data” must also be

“Technical data” must also be

maintained during breaks in work.

maintained during breaks in work.maintained during breaks in work.

maintained during breaks in work.

6Servicing and maintenance

6.1

6.16.1

6.1 Cleaning

CleaningCleaning

Cleaning

Clean the equipment only from the outside with cold or lukewarm water. Do not use

aggressi e detergents or soap. If a water hose is used, do not direct the water jet onto

the components at full pressure. Do not use steam-jet or high-pressure cleaners.

6.2

6.26.2

6.2 Container

ContainerContainer

Container

The container may only be filled with flammable liquids when in perfect condition. It

must be regularly checked for damages and corrosion.

A damaged container, or one which is not in perfect condition, may not be continued

to be used under any circumstances!

44 1642 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco 15

6.3

6.36.3

6.3 Dirt trap

Dirt trapDirt trap

Dirt trap

The dirt traps in the compressed air and deli ery system are to be cleaned at regular

inter als, examined for wear and renewed if necessary.

•Dirt trap on the suction side of the pump:

Undo the plug screw of the dirt trap and pull the sie e insert out in a downward

direction.

•Dirt trap in the compressed air supply:

Unscrew the pin of the compressed air connection from the threaded connection

of the pressure regulator. Unscrew the dirt trap from the connecting nozzle of the

pressure regulator using a suitable tool (e.g. flat-blade screwdri er). Seal the joint

when reassembling.

6.4

6.46.4

6.4 Pressure regulator

Pressure regulatorPressure regulator

Pressure regulator

Proper function of the air pressure regulator must be checked at regular inter als.

6.5

6.56.5

6.5 Delivery system

Delivery systemDelivery system

Delivery system

The deli ery system and in particular the deli ery hoses are to be examined regularly

for damage, check the couplings for leaks.

The metal sheathing of the deli ery hoses ensures the dissipation of static electric

charges.

Hoses without sufficient conductivity may not be used.

Hoses without sufficient conductivity may not be used.Hoses without sufficient conductivity may not be used.

Hoses without sufficient conductivity may not be used.

The connection of the wire mesh to the integrating parts must therefore be checked

regularly; the continuity must be measured if necessary.

6.6

6.66.6

6.6 Wheels

WheelsWheels

Wheels

The wheels of the TankQuick pro ide for potential equalisation to earth. They are also

to be cleaned and inspected for damage regularly.

The TankQuick is not to be operated if conductive contact with the ground cannot

The TankQuick is not to be operated if conductive contact with the ground cannot The TankQuick is not to be operated if conductive contact with the ground cannot

The TankQuick is not to be operated if conductive contact with the ground cannot

beensured.

beensured.beensured.

beensured.

Therefore, exclusively spare wheels

Therefore, exclusively spare wheels Therefore, exclusively spare wheels

Therefore, exclusively spare wheels procured from the manufacturer may be

procured from the manufacturer may be procured from the manufacturer may be

procured from the manufacturer may be

mounted!

mounted!mounted!

mounted!

6.7

6.76.7

6.7 Type Plate and Warning Signs

Type Plate and Warning SignsType Plate and Warning Signs

Type Plate and Warning Signs

The warning signs attached to the device and the type plate must be well legible.

The warning signs attached to the device and the type plate must be well legible. The warning signs attached to the device and the type plate must be well legible.

The warning signs attached to the device and the type plate must be well legible.

Dirty signs must be cleaned, and replaced if necessary.

Dirty signs must be cleaned, and replaced if necessary.Dirty signs must be cleaned, and replaced if necessary.

Dirty signs must be cleaned, and replaced if necessary.

16 44 1657 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco

6.8

6.86.8

6.8 Troubleshooting

TroubleshootingTroubleshooting

Troubleshooting

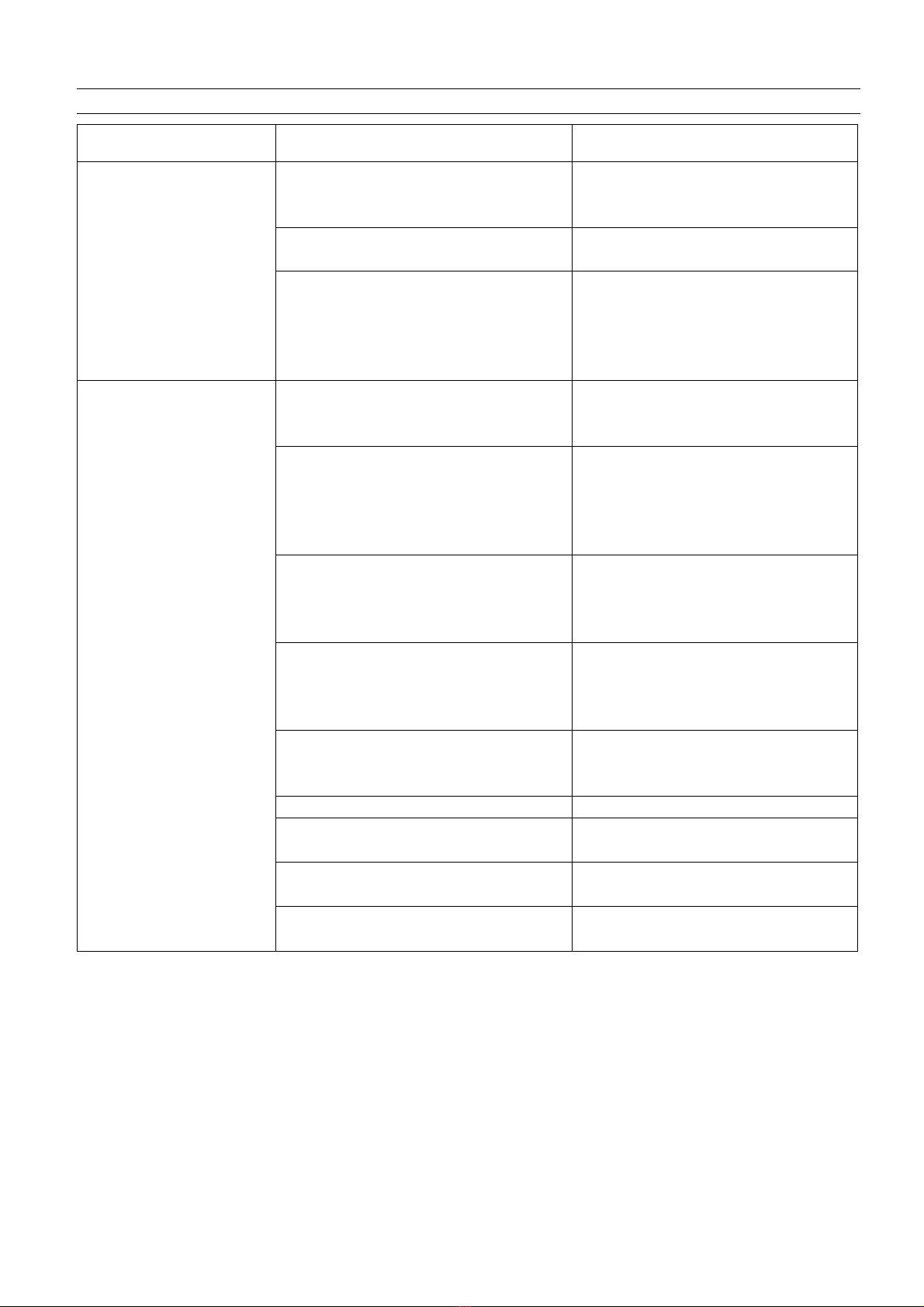

Fault Possible cause Action

Pump does not start

Compressed air not connected

Connect the compressed air

supply and check the input

pressure

Start button not pressed

The start button must be kept

pressed during operation

Operating pressure too low

–

input pressure to low

The input pressure is of < 2 bar

Check the adjustment of the

pressure regulator of the air

supply and switch to a higher

input pressure

Low or no pumping

capacity

Wrong pumping direction

Connect the

deli ery hoses

according to the desired mode

of operation (chapter 5)

Difficult operating conditions

The pumping capacity is limited

when extracting through

winding filler pipes and with

small suction hose cross-

sections.

Operating pressure too low

–

input pressure of the compressed

air supply too low

Check the input pressure of the

compressed air supply, the

input pressure must exceed the

desired operating pressure.

Leak in the compressed air

system

Examine the compressed air

system for leaks, clean and

replace damaged parts if

necessary

Dirt trap in the compressed air

system is dirty

Remo e the dirt trap from the

pressure regulator and clean it

(chapter 6.3)

Silencer on the pump is dirty

Clean the silencer

Dirt trap in the deli ery

system is

dirty

Remo e the sie e from the dirt

trap and clean it (chapter 6.3)

Suction line kinked or damaged

Check the fuel suction/refilling

line for possible damage

Ser ice life of the wearing parts

of the pump exceeded

Return the pump for

o erhaul

44 1642 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco 17

7Spare parts

Pos.

Designation Item no.

10 Chassis 516570001

11 Castor with brake – electrically conducti e 491102900

12 Castor – electrically conducti e 491103300

13 Safety belt 492000800

20 Barrel 120 Liter 816578001

21 Le el display with barrel adapter 816578005

22 Barrel adapter with suction tube 816578009

30 Barrel hose with quick coupling 816578004

40 Deli ery hose, quick coupling and tank adapter eco 816578003

41 Deli ery hose, quick coupling and tank adapter eco s 816578002

50 Plug for quick coupling 422322400

60 Fuel suction hose 816578010

61 Dirt trap 409001500

70 Fuel pressure hose 816578011

80 Feed pump 432202700

90 Start button 816578006

100 Compressed air connection with pressure regulator 816578007

110 Potential equalisation cable to the ehicle 813740012

120 Potential equalisation cable chassis to barrel 816578021

18 44 1657 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco

8Disposal

The de ice is to be emptied completely and the liquids properly disposed of in case it

is taken out of ser ice.

The equipment is to be disposed of properly when taken permanently out of ser ice:

- Return old metal for recycling.

- Return plastic parts for recycling.

- Return electronic waste for recycling.

The water legal regulations are to be followed.

The water legal regulations are to be followed.The water legal regulations are to be followed.

The water legal regulations are to be followed.

44 1642 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco 19

9Declaration of conformity

20 44 1657 101-H TankQuick eco

TankQuick ecoTankQuick eco

TankQuick eco

HORN GmbH & Co. KG

Mun etoft 42

24937 Flensburg

Germany

T +49 461-8696-0

F +49 461-8696-66

www.tecalemit.de

This manual suits for next models

3

Table of contents

Other TECALEMIT Service Equipment manuals

Popular Service Equipment manuals by other brands

Hofmann

Hofmann monty 3300 2speed 24/GP Operation manual

JBM

JBM 53873 instruction manual

AVL DITEST

AVL DITEST VAS 6910 Unpacking Instructions, Start-up, Brief instructions

Race Ramps

Race Ramps RR-STR instructions

Spin

Spin COUNTRY CLIMA Manual for use and maintenance

BGS technic

BGS technic 1674 instruction manual