Teccpo AJ23 User manual

User Manual

Delta Sander

SALES NO.:TAMS23P

MODEL NO.:AJ23

Company:Shenzhen Allsight E-business Co., Ltd

Web: www.teccpotools.com

Facebook: www.facebook.com/Teccpo.US

E-mail:[email protected]

Add.: Room 104, Building P09, south China City

Electronic trading Center, Longgang District, Shen Zhen, CHINA

Made in China

English 01~08

Contents

TECCPO is committed to providing the best After-sale Service,

we strive for your FIVE STAR satisfaction!

WARNING

Read all operating instructions carefully and comply with them.

Do not allow familiarity with power tools breed carelessness or contempt.

NOTICE

The term "power tool" in the warnings refers to your mains-operated (corded) power tool /

appliance or battery-operated (cordless) power tool / appliance

Work Area Safety

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

Keep children and bystanders away while operating a power tool. Distractions can cause you

to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets

will reduce the risk of electric shock.

Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords

increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location or where water and electricity in close proximity is

unavoidable, use an earth-leakage circuit-breaker such as a residual current device (RCD) or

ground fault circuit interrupter (GFCI) protected supply. Use of an RCD or GFCI reduces the

risk of electric shock.

Tools marked “Double Insulated” do not require grounding. They have a special double

insulation system which satisfies OSHA requirements and complies with the applicable

standards of Underwriters Laboratories, Inc., the Canadian Standard Association, and the

National Electrical Code.

Personal safety

Stay alert, watch what you are doing and use common sense when operating a power tool. Do

not use a power tool while you are tired or under the influence of drugs, alcohol or medication.

A moment of inattention while operating power tools may result in serious personal injury.

Prevent unintentional starting. Ensure the switch is in the off-position before connecting to

power source and/or battery pack, picking up or carrying the tool. have the switch on invites

accidents.

Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. This enables better control of

- 01 -

1.

a)

b)

c)

2.

a)

b)

c)

d)

e)

f)

g)

3.

a)

b)

c)

d)

It is important to understand these instructions and to acquaint yourself with the tool, its

correct usage and all safety requirements. Failure to to do so may result in electric shock, fire

and/or serious personal injury.

Keep this owners manual in a safe and readily-available place.

If you give the tool to any other person, give them these operating instructions as well.

•

•

•

•

美

the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

If devices are provided for the connection of dust extraction and collection facilities, ensure

these are connected and properly used. Use of dust collection can reduce dust-related

hazards.

WARNING

Use personal protective equipment. Always wear eye protection. Protective equipment such

as dust mask, strong gloves, non-skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries. Always use certified e.g. ANSI safety

equipment.

Wear protective safety glasses with side shields. The operation of any power tool can

result in flying debris. Everyday prescription eyeglasses are NOT protective safety

glasses.

Wear hearing protection. Under some conditions and duration of use, the operation of

this power tool may become noisy and affect hearing.

Wear a dust mask. Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities, contain harmful chemicals. Reduce your risk of exposure to

these chemicals: work in a well ventilated area, and work with approved safety equipment,

such as those dust masks that are specially designed to filter out microscopic particles.

General Power Tool Use and Care

Do not force the power tool. Use the correct power tool for your application. The correct power

tool will do the job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or the battery pack from the power tool before

making any adjustments, changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power tool accidentally.

Store idle power tools out of the reach of children and do not allow persons unfamiliar with the

power tool or these instructions to operate the power tool. Power tools are dangerous in the

hands of untrained users.

Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts

and any other condition that may affect the power tool's operation. If damaged, have the

power tool repaired before use. Many accidents are caused by poorly maintained power tools.

Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking

into account the working conditions and the work to be performed in a hazardous situation.

Have your power tool serviced by a qualified repair person using only identical replacement

parts. This will ensure that the safety of the power tool is maintained.

Specific Power Tool Safety Warnings

Hold the tool by its insulated gripping surfaces when performing an operation where the tool

may contact hidden wiring or its own cord.

Unplug the sander before changing accessories. Accidental startups may occur if sander is

plugged in while changing an accessory.

Always wear safety goggles and a dust mask when sanding, especially when sanding

overhead.

A suitable breathing respirator must be worn while sanding chemically pressure treated

e)

f)

g)

h)

i)

4)

a)

b)

c)

d)

e)

f)

g)

h)

5)

1)

2)

3)

4)

- 02 -

WARNING

Some dust created by power sanding, sawing, grinding, drilling and other construction

activities contains chemicals known to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are: Lead from lead- based paints, Crystalline silica from

bricks, cement, other masonry products, Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals work in a well ventilated area, and work with approved safety

equipment, such as dust masks that are specially designed to filter out microscopic particles.

CAUTION

Risk of injury due to vibrations. Vibrations may, in particular for persons with circulation

problems, cause damage to blood vessels and/or nerves. If you notice any of the following

symptoms, stop working immediately and consult a doctor. Numbness of body parts, loss of sense

of feeling, itching, pins and needles, pain, changes in skin colour.

You can reduce the risks considerably by following the tips below:

In The Box

- 03 -

Maintain the device in accordance with the instructions in the operating instructions.

Avoid working at low temperatures.

When it is cold, make sure your body and your hands, in particular, are kept warm.

Take regular breaks and move your hands at the same time to promote circulation.

–

–

–

–

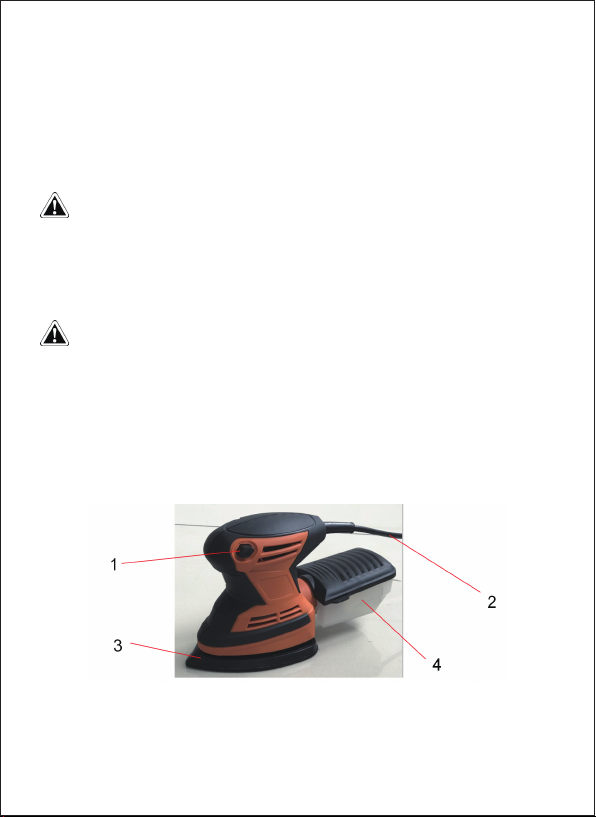

On/Off switch

Power Cord

Sanding baseplate

Dust box

1.

2.

3.

4.

objects.

Always wear ear protection during extended periods of operation.

Whenever possible, use clamping devices or other suitable means to secure the workpiece to

a firm surface.

Do not sand wet materials (e.g., wallpaper) or moist surfaces. Penetration of water into the

machine increases the risk of an electric shock.

Do not use sandpaper larger than needed. Extra paper extending beyond the sanding pad can

also cause serious lacerations.

Use the dust bag and empty it frequently. Do not throw sanding dust on an open fire because

materials in particle form may be explosive.

5)

6)

7)

8)

9)

Sandpaper 12pcs

Dustbox 1pc

For cleaning, deburring, smoothing, and sanding metal, wood, and plastic surfaces. Effective

removal of corrosion and surface contamination. Finish on metal surfaces. Smoothing wood

surfaces, removal of wood fibres before and after priming.

The unit is designed exclusively for non-commercial use to dry-sand wood, metal, plastic, plaster

and varnished surfaces. The appliance is not suitable for sanding plaster-based substrates.

SPECIFICATIONS

Model

Motor: 120V/60HZ 1.6A

No load speed: 15500R/MIN

Papertype: Hook & loop

OPERATING INSTRUCTIONS

INSTALLING AND REMOVING THE ABRASIVE DISC

CAUTION

For your safety, always turn off the switch and unplug the sander from the power source

before performing any maintenance or cleaning.

Replacement Sandpaper

Uses universal Velcro 3 7/8 in. x 5 1/2 in. detail sanding sheets with hook and loop backing found

in most home improvement stores. Sanding sheets can have holes, removable discs or slots.

To Remove.

- 04 -

Unplug the sander.

Remove all sanding dust or dirt from the sanding pad fig. 2

Align the holes on the abrasive disc with the holes in the sanding pad, making sure that the pad

is centered and the edges are aligned with the edges of the sanding pad.

Note: The holes in the abrasive disc must line up with the sanding pad holes for the dust

collection system to function properly.

Press the abrasive disc to the pad.

1.

2.

3.

4.

Unplug the sander.

Peel the disc off the sanding pad.

1.

2.

Fig.2

INSTALLING AND REMOVING THE DUST BOX

Your tool is equipped with a dust box , empty it frequently during use and before storing the sander.

Note: The sander’s dust collection system will only work if the sandpaper has holes that line up

with the dust collection holes in the baseplate (there are 4 other holes in the baseplate for the

screws). Sanding dust is only partially absorbed. Some dust remains on the work piece.

CAUTION

Be extremely careful of dust disposal, materials in fine particle form may be explosive. Do

not throw sanding dust on an open fire. Combustion from mixture of varnishes, lacquers,

polyurethane, oil or water with dust particles can occur if there is a static discharge, spark

introduced in the box, or excessive heat.

ON/OFF SWITCH

NOTICE

Always hold the sander off the work piece when turning the switch on or off. Contact the work piece

after the sander has reached its full speed and remove it from the work before turning the switch

off. Operating in this manner will prolong the tool life and will greatly increase the quality of your

work.

This random orbit sander is equipped with a ON/OFF switch, located on the front of the handle.

Make sure that the switch is in the off position (the “0” position, Fig. 4), then plug in the tool.

- 05 -

To install dust box, align the notches on both sides of dust bag with the buckles on both sides of

dust port and push the dust bag completely onto place over the dust port on the back of the

sander (Fig. 3).

To remove dust box , simply pull away from the tool.

1.

2.

TO TURN OFF: press the switch to the off position (the ”0” position, Fig. 4).

TO TURN ON: press the switch to the on position (the “I” position, Fig. 5).

1.

2.

Always hold the sander off the work piece when turning the switch on or off. Run the sander for a

few seconds before contacting the work piece and remove it from the work piece before turning the

switch off.

Contact the work piece with minimal pressure. If the sander is not removing enough material, try

a heavier grit piece of sandpaper.

Note:

Maintenance

CAUTION

For your safety, always turn off the switch and unplug the sander from the power source

before performing any maintenance or cleaning.

Periodic maintenance of your sander allows for long life and trouble free operation. The sander can

generate considerable quantities of sanding residue. A cleaning and maintenance schedule should

be maintained. As a common sense and preventive maintenance practice, follow these

recommended steps:

- 06 -

Inspect the pad; check it for wear or damage.

Keep the ventilation slots of the motor clean to prevent overheating of the motor. Remove all

dust from the ventilation slits of the motor. Use a vacuum cleaner or a brush.

Electric tools are subject to accelerated wear and possible premature failure when they are

used to work on fiberglass, wallboard, spackling compounds or plaster. The chips and grindings

from these materials are highly abrasive to electrical tool parts, such as bearings, brushes,

commutators, etc. Consequently, it is not recommended that this tool be used for extended work

1.

2.

3.

To minimize sanding marks, keep the sander moving slowly while it is touching the work piece.

Occasionally stop the sander and check the sandpaper for tears, wear, or fraying. If necessary,

replace the sandpaper.

Empty the dust bag regularly in order to ensure the optimum removal of dust by suction.

From time to time, clean the dust exhaust opening with a dry brush.

CIean the housing only with a damp cloth, do not use any solvents!

a.

b.

c.

d.

e.

Troubleshooting

CAUTION

Disconnect power supply before service.

- 07 -

on any fiberglass material, wallboard, spackling compound, or plaster. During any use on these

materials, it is extremely important that the tool is cleaned frequently by blowing with an air-jet.

Use a soft clean and damp cloth to wipe the tool housing. A mild detergent can be used but

nothing with alcohol, petrol or other cleaning agent. Never use caustic agents to clean plastic

parts.

The sander requires no additional lubrication.

4.

5.

- 08 -

Problem

Tool will not start.

Possible cause

Cord not connected.

No power at outlet.

Fault correction

Tool’s thermal reset breaker

tripped (if equipped).

Tool operates slowly.

Performance

decreases over

time.

Excessive noise or

rattling.

Overheating

Extension cord too long or wire

size too small.

Sandpaper is worn or damaged. Replace as needed.

Have authorized service center

replace brushes

Carbon brushes worn or damaged.

Internal damage or wear. (Carbon

brushes or bearings, for

example.)

Forcing tool to work too fast.

Accessory misaligned.

Sandpaper is worn or damaged.

Blocked motor housing vents

Motor being strained by long or

small diameter extension cord.

Eliminate use of extension cord. If

an extension cord is needed, use

one with the proper diameter for its

length and load.

Wear ANSI-approved safety

goggles and NIOSH-approved

dust mask/ respirator while

blowing dust out of motor using

compressed air.

Check and correct accessory

alignment.

Allow tool to work at its own rate.

Replace as needed.

Have authorized service center

service tool.

Eliminate use of extension cord. If

an extension cord is needed, use

shorter/ heavier gauge cord.

Check that cord is plugged in.

Check power at outlet. If outlet is

unpowered, turn off tool and check

circuit breaker. If breaker is

tripped, make sure circuit is right

capacity for tool and circuit has no

other loads

Turn off tool and allow to cool.

Press reset button on tool.

Have authorized service center

service tool.

Internal damage or wear. (Carbon

brushes or switch, for example.)

This manual suits for next models

1

Table of contents

Other Teccpo Sander manuals