Tecfluid FLOMAT FX FlomatFX User manual

Table of contents

Other Tecfluid Measuring Instrument manuals

Tecfluid

Tecfluid CU Series User manual

Tecfluid

Tecfluid LS Series User manual

Tecfluid

Tecfluid FLOMID Series User manual

Tecfluid

Tecfluid LTDR series User manual

Tecfluid

Tecfluid FLOMID Series User manual

Tecfluid

Tecfluid AD Series User manual

Tecfluid

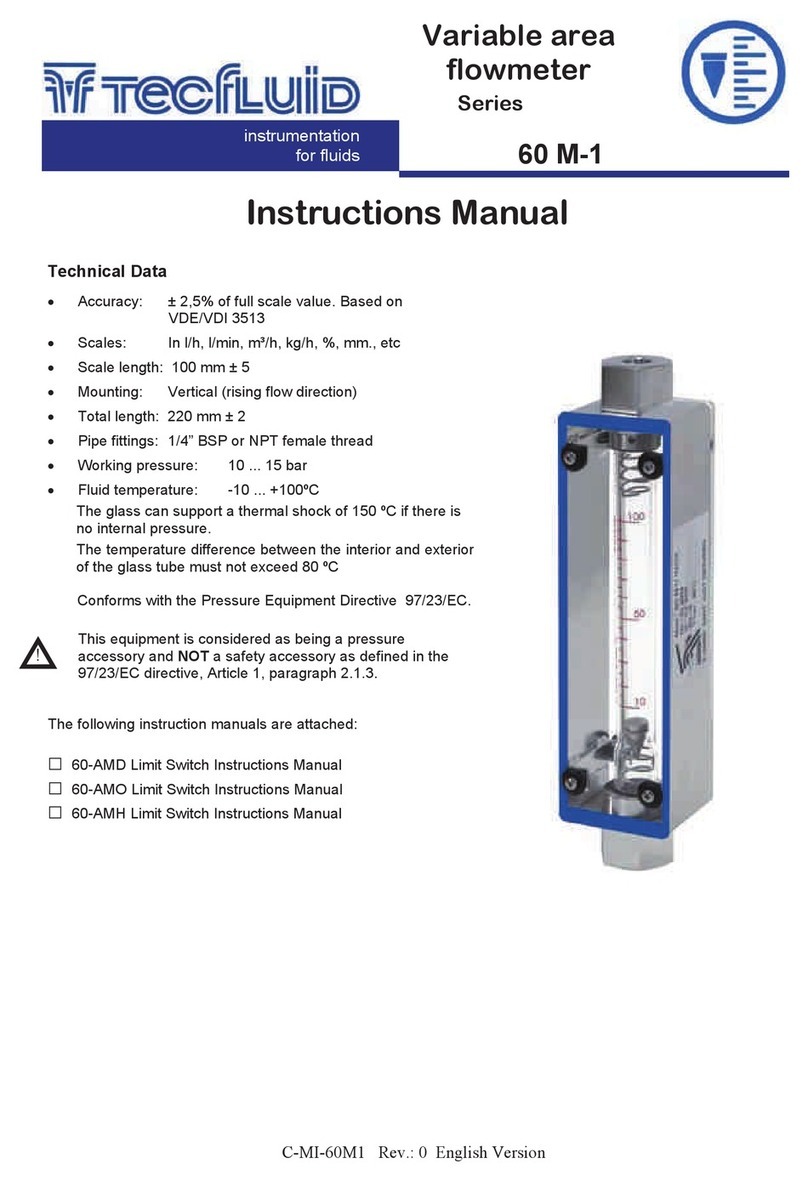

Tecfluid 60 M-1 Series User manual

Tecfluid

Tecfluid FLOMAT Series User manual

Tecfluid

Tecfluid 2100 Series User manual

Tecfluid

Tecfluid Series LT User manual

Popular Measuring Instrument manuals by other brands

PP Systems

PP Systems TARGAS-1 Operation manuals

Emerson

Emerson Rosemount 3051 quick start guide

MARTINDALE

MARTINDALE VI13800 instruction manual

Newtons4th

Newtons4th PPA55 Series Startup guide

Oxford PRECISION

Oxford PRECISION OXD-315-2740F Operator's manual

Global Specialties

Global Specialties GSK-118 quick start guide

ProTest engineering

ProTest engineering AM1 user manual

TSI Instruments

TSI Instruments 5300 Series quick start guide

Anaheim Scientific

Anaheim Scientific H400 instruction manual

Kapro

Kapro Prolaser 862 user manual

Alcatel

Alcatel TA 101 instruction manual

HOKUYO AUTOMATIC

HOKUYO AUTOMATIC UST-05LN user manual

Mahr

Mahr Multimar 844 T operating instructions

PRECISION DIGITAL

PRECISION DIGITAL PD6800 instruction manual

Camille Bauer

Camille Bauer SINEAX DME 400 Series operating instructions

Fieldpiece

Fieldpiece ARH5 Operator's manual

MICRO-EPSILON

MICRO-EPSILON surfaceCONTROL 3D 35 Series operating instructions

Tektronix

Tektronix TDP0500 Quick start user manual