Tecfluid M21 User manual

Other manuals for M21

1

Table of contents

Other Tecfluid Measuring Instrument manuals

Tecfluid

Tecfluid LS Series User manual

Tecfluid

Tecfluid FLOMAT FX FlomatFX User manual

Tecfluid

Tecfluid FLOMID Series User manual

Tecfluid

Tecfluid LTDR series User manual

Tecfluid

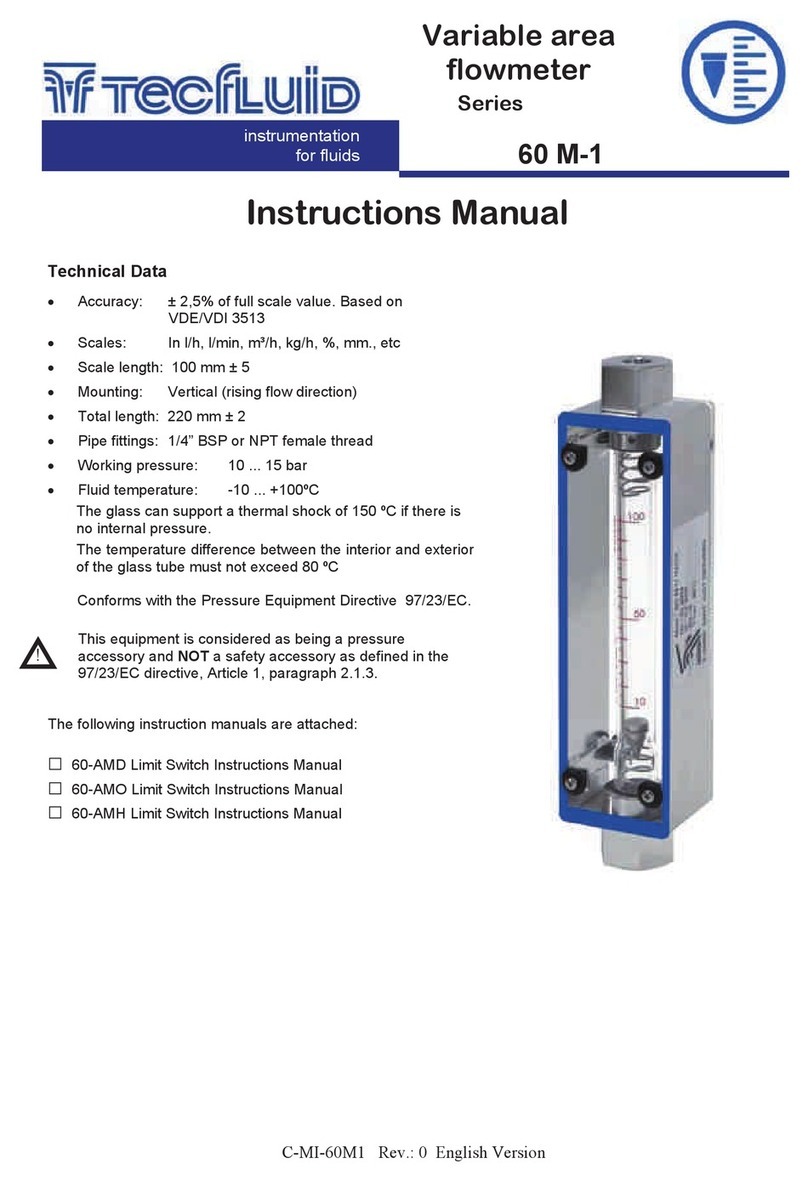

Tecfluid 60 M-1 Series User manual

Tecfluid

Tecfluid 2100 Series User manual

Tecfluid

Tecfluid AD Series User manual

Tecfluid

Tecfluid FLOMAT Series User manual

Tecfluid

Tecfluid Series LT User manual

Tecfluid

Tecfluid FLOMID Series User manual

Popular Measuring Instrument manuals by other brands

techem

techem Compact V e ames MID operating instructions

Lutron Electronics

Lutron Electronics DW-6064 Operation manual

FLIR

FLIR Extech 380941 user guide

Dynojet

Dynojet 224 installation guide

FILL-RITE

FILL-RITE 806C Owner's operation & safety manual

PCE Health and Fitness

PCE Health and Fitness PCE-VE 800 user manual

Thermo Scientific

Thermo Scientific SOLA II user guide

FISCHER DAREX

FISCHER DAREX 716002 Instructions for use

Milwaukee

Milwaukee Smart PH Meter user manual

Hexagon

Hexagon TESA FMS Series instruction manual

GORMAN-RUPP

GORMAN-RUPP SOTERA 820 Installation and operation manual

Ultraflux

Ultraflux Uf 811 CO user manual