TECH A V GMAW User manual

GAS METAL ARC WELDING

(GMAW)

Learner Guide

TABLE OF CONTENTS

INTRODUCTION PAGE 1

LEARNERS INSTRUCTIONS (HOW TO USE THIS PROGRAMME) PAGE 2

PROGRAMME 1 - THE GMAW PROCESS

INTRODUCTION PAGE 3

RESOURCE NOTES PAGE 4

SELF-TEST NO. 1 PAGE 12

GLOSSARY OF TERMS PAGE 14

PROGRAMME 2 - EQUIPMENT PARTS AND FUNCTIONS

PART 1 - EQUIPMENT PARTS AND FUNCTIONS PAGE 19

RESOURCE NOTES PAGE 20

SELF-TEST EXERCISE 2.1 PAGE 26

PART 2 - WELDING EQUIPMENT PREPARATION PAGE 28

SELF-TEST EXERCISE 2.2 PAGE 36

PRACTICAL EVALUATION - EXERCISE 2.2 PAGE 37

PROGRAMME 3 - WELDING PRACTICES AND PROCEDURES

INTRODUCTION PAGE 38

RESOURCE NOTES PAGE 39

PART1 - BASIC SKILLS PAGE 39

PART 2 - PRACTICAL EXERCISES PAGE 44

PRACTICAL EXERCISE NO. 1 PAGE 49

EXERCISE NO. 2PAGE 50

PRACTICAL EXERCISE NO. 2 PAGE 52

EXERCISE NO. 3PAGE 53

PRACTICAL EXERCISE NO. 3 PAGE 55

EXERCISE NO. 4PAGE 56

PRACTICAL EXERCISE NO. 4 PAGE 57

CONCLUSION PAGE 58

SOME USEFUL GMAW TIPS PAGE 59

WELDING CHART 1 PAGE 60

CONTACT DETAILS:

https://techav.co.za

info@techav.co.za

Back to Table of Contents 1

GAS METAL ARC WELDING

INTRODUCTION

This learning aid, consisting of your "Learners Guide" and video programmes, has been

designed to assist you to learn the BASIC SKILLS and KNOWLEDGE involved in "Gas Metal

Arc" welding processes.

OBJECTIVES: (PURPOSE OF THIS MATERIAL)

This series serves to assist you, the "Learner", in achieving a "Learnership" in any of the

engineering fields where GMAW welding is stated as being a "unit of learning".

PURPOSE STATEMENT (WHAT YOU WILL LEARN)

During this learning programme you will learn:

oTo describe basic GMAW welding processes.

oTo identify, by name, the equipment, components, accessories and consumables

used in typical processes.

To set up and prepare for welding.

To use GMAW equipment in flat weld position.

LEARNING ASSUMED TO BE IN PLACE (WHAT YOU SHOULD ALREADY KNOW / BE ABLE TO

DO)

oA working knowledge of Industrial Safety and Arc welding PPE.

oIdentify common metals and "alloys".

oAn understanding of AC and DC current.

oUse SMAW equipment.

LEARNING OUTCOMES (WHAT YOU WILL BE ABLE TO DO AFTER COMPLETING THE GMAW

MODULE)

oPrepare a typical MIG/MAG welding unit for operation.

oProduce "down-hand" welds, utilising both "Short-Circuit" and "Spray Transfer"

modes, on mild steel plates.

Back to Table of Contents 2

LEARNERS INSTRUCTIONS (HOW TO USE THIS LEARNING AID)

Step 1 - Read the Resource Notes and follow any written instructions.

Step 2 - View the relevant video section (where applicable).

Step 3 - Complete any "Self-Test Exercise" (as applicable).

Step 4 - Perform a practical exercise (as applicable).

Step 5 - Have your Mentor/Instructor assess your work.

Back to Table of Contents 3

PROGRAMME 1

THE GMAW PROCESS - AN INTRODUCTION

THE BASIC "GAS METAL ARC WELDING" PROCESS

In this section you will learn:

oTo describe the concept I principles of Gas Metal Arc Welding processes.

oDescribe/Identify by name, typical equipment constituting a GMAW system.

oExplain in basic terms how MIG/MAG/FCAW processes operate.

oExplain in basic terms the modes of metal transfer (Short arc, globular, spray and

pulsed).

BEGIN THIS SECTION OF LEARNING BY READING THE NOTES THAT BEGIN ON THE

NEXT PAGE.

Back to Table of Contents 4

RESOURCE NOTES

PROGRAMME 1

1. PRINCIPLES OF GAS METAL ARC WELDING

Gas metal arc welding, or GMAW, is a welding process that involves the "continuous

feeding" of filler material into a weld-pool.

Gas Metal Arc Welding has become the most popular welding process, especially in

fabrication industries. Although the majority of GMAW is performed "manually" (by

hand skill) much is also performed using "robotic equipment" (Automobile

manufacturing is a major user of such systems).

In this series of programmes we will concentrate upon "manual practices".

GMAW is a very easy process to operate, and anyone having had experience

with other "traditional welding processes such as "gas welding" and "stick

welding (Shielded Metal Arc) will find the GMAW process a "pleasure" to use!

Although the term GMAW has been used several times already in this text, you will

rarely hear this in the "work-place". Other common terms used to describe this

process include:

oMIG or Metal Inert Gas.

oMAG or Metal Active Gas.

oFCAW or Fluxed Cored Arc Welding, also known as CO2 Welding.

These terms are based primarily on the method in which the weld pool (molten

metal) is protected or "shielded" from the atmosphere. In order to understand these

terms you need to first understand how a GMAW process works, in principle. There

is a lot of science involved in welding, especially in the GMAW process, and more

especially in the process of "metal transfer". We shall in this module explain those

issues that affect the "weld quality" and the manner in which you, the welder,

prepare and use the equipment. In this programme you will learn all that is

necessary to understand the process, however let us start at the beginning and get

to know what equipment is used in GMAW.

2. AN OVERVIEW OF BASIC GMAW EQUIPMENT

The main parts of any GMAW system typically comprise the following:

oA "Power Supply" that delivers DC welding current at Constant Voltage.

oA "Wire Feeder" -either fixed speed or variable speed.

oFiller-wire, also called "electrode wire". This is a "consumable item".

oShielding gas -either "inert" or "active". This too is a "consumable item".

oA "welding gun" and its connecting "power cable" and supply lines.

oA work lead or "ground-lead" (cable).

oSome systems include a "liquid cooling system" that cools the welding gun.

Back to Table of Contents 5

3. HOW DOES GMAW WORK?

It is important that you understand the operating principles of your GMAW

equipment as this knowledge will assist you to set-up and operate your equipment

more efficiently.

In any arc welding process metal parts are locally heated to "melting temperatures"

using the "heat" generated from an electrical arc.

Causing an electrical current to "jump across a gap" produces an ARC. In "arc

welding", the arc is deliberately created between an "electrode" and the metal to

be welded (base metal). It must be understood that an arc is established through

voltage, but the "intensity' (heat power) is generated through current (amps).

A welding machine or "power source" provides electrical energy to create an arc

(electric equivalent of flame from a gas torch). The arc is directed onto the work

(base metal) to be joined (welded) where the "heat energy" produces "local melting"

of the metal.

The arc is created at the tip of the electrode wire that is constantly being fed

into the "weld pool". The electrode, in effect, "melts" into the weld adding "filler

material" into the molten pool. In this regard the electrode is also the filler-

material and is therefore a "consumable" item in the process.

Electrodes are produced in the form of "wire" and supplied on reels or spools

(Like fishing line). The wire is normally very thin, ranging in size (diameter) from

about 0.76mm -2.38mm (0.030 inch -0.090 inch). In "common language" the

electrode is known as "wire".

There are many TYPES of wire in terms of the "material" from which they are

produced and the "wire-size" or diameter.

Note: It must be understood that when you put metal into a weld, the filler

material must be "compatible" with (the same as or "similar to) the base metal.

(Base metal is sometimes called the "parent metal"). You must be aware there are

many types of metal and "alloys" on the general market and most of these need to

be "welded" in fabrication processes. Selecting the correct "wire" for the type of

Back to Table of Contents 6

metal, and for the weld-process, is vital as a mistake could result in catastrophic

damage, and possible loss of life. For this reason the "responsible welder" will seek

advice on the correct wire type for any given task if he or she is in any doubt.

As a rule the wire type is provided in a "welding specification" for a given task, and

this in turn is given by the designing engineer or welding authority.

The point being made is that you simply cannot use "any old wire type" for any

job!

Filler-wire (the electrode) is carried to the weld-zone via a "welding-gun" or torch.

The welding gun is attached to the end of a cable assembly, sometimes known as a

"conduit:'. The cable serves many functions and strictly speaking it is a combination"

unit consisting of:

oA "liner" through which the electrode is fed.

oA conductor wire or "electrode lead", through which the "welding current"

passes.

oA "gas line" (or tube) through which the shielding gas flows.

o"Signal wires" (or sensor wires) through which the gun "communicates" with

the welding machine.

oAnd in some cases, "water lines" (hoses) through which "coolant' flows to

and from the welding-gun.

This cable is connected to an adapter (socket) at the wire-feeder outlet. With the

cable connected, and the machine is "powered up", upon operating the trigger on

the welding-gun (depending on make, type and design) the welding machines'

"contactor" is activated. A contactor is usually a "solenoid (or electronic) activated

switch" that "connects the welding current to the welding terminals of the machine

(In other words the welding -circuit is activated and the machine terminals are live!)

At the same time other circuits are activated that do the following:

oOpen the shielding gas valve (providing gas flow).

oOpen the coolant valve (providing coolant, where applicable).

oOperate the "wire feeder motor" and thereby drive the electrode-wire

through the gun.

In order for welding to happen the "welding circuit' must be "closed" (or

completed).

The circuit is complete as soon as an arc has been established. As already

mentioned, an arc is the "source of "heat" in a weld-zone. The resultant heat causes

local melting of the parent metal and the tip of the wire which "transfers" into the

melted "weld pool". The manner in which the electrode I filler metal enters or

"transfers" into the weld-pool is particularly important and we will deal with this in

more detail when we describe "metal transfer modes" in the next section, but first a

word about "shielding".

Most metals will, especially when in their molten state, readily "react" with the

gases in the atmosphere (notably with oxygen and nitrogen) to form "oxides" and

Back to Table of Contents 7

"nitrides". Simply stated, the result of this "chemical combination" results in the

metal becoming "oxidised" or, in "welding language", porous. A "porous weld" is

extremely weak and cannot be tolerated in any joint that will carry load (or stress),

as the weld will fracture. To avoid "porosity" the weld zone must be protected or

"shielded" from the atmosphere and this is part of the reason we need "shielding

gas" in the system. In a pure Metal Inert Gas (MIG) process the shielding gas is an

INERT gas, such as ARGON or HELIUM. Inert gases will not react (mix or combine)

with heated metal (in the weld pool).

Note: Argon is the most widely used gas type in MIG processes, mainly because

helium is extremely costly.

Shielding gas, supplied in pressurised cylinders, is forced through the welding gun

and exits via a "gas nozzle" at the "nose" of the gun. This gas is directed onto (over)

the weld pool where it surrounds the weld zone and "drenches" the hot metal.

Atmospheric gases cannot penetrate the gas shield as a positive pressure is created

in the gas envelope. (Gas shield pressure exceeds atmospheric pressure).

Some "shielding gases" are "mixtures" of inert and reactive gases. The commonest

reactive gas used is "carbon dioxide" (C02). The addition of a reactive gas into the

"shielding gas cylinder' is not to improve shielding but to improve other factors such

as "arc stability", weld penetration and various other factors that are far too

technical to launch into right now! When a welding process makes use of "mixed

gases", that include an active gas such as C02, then that process should technically

be considered as Metal Active Gas (MAG) process.

Note: This distinction varies according to countries and many (including South

Africa) consider the MAG process to be one that uses purely "active gas", normally

C02 , as the total means of "shielding". In contrast to MIG and MAG processes that

use "solid wire electrodes", the FCAW process uses "hollow electrode wire" and the

hollow "core" of the wire is filled with "flux". Flux is a mixture of various substances

(chemicals and other compounds) which, when subjected to the heat of the welding

process, release shielding gas and, in some cases, add elements into the weld that

improve the quality of the weld material. The flux also acts to "clean" the metal

surfaces during the process. Conventional FCAW electrodes do not generate

sufficient shielding for the weld and additional shielding is provided, most usually,

with carbon dioxide. Some flux-cored wires, known as "self-shielding electrodes", do

not require additional shielding during the welding process.

The most usual (common) gases used in GMAW processes are:

oArgon -a fully inert gas -commonly used for welding aluminium.

oHelium -a fully inert gas -not commonly used alone, often mixed with argon

and CO2for high quality welds in stainless steel. Thick section aluminium

(over 25mm) requires at least 75% helium 25% argon mix to achieve the

desired heat input.

oCarbon Dioxide -Usually known by its "chemical designation, CO2'' This is a

"reactive gas" that, if permitted, will combine "chemically" with the metal in

Back to Table of Contents 8

a weld-pool. This gas is used only with "ferrous metals" and, with the

exception of FCAW welding, is mixed in small quantities with inert gases.

oOxygen -a reactive gas and used only in minute quantities for purposes of

improving arc stability and heat transfer when welding steel using "spray

transfer". Oxygen is normally mixed with argon in quantities rarely exceeding

5% of total volume.

Note: Gas providers or suppliers usually have their own "brand names" for their

"commercial gas mixes". Ask your gas vendor for the information regarding the

proportions and suitability of gases for a particular application.

4. METAL TRANSFER MODES

We move now to a topic that is often misunderstood namely, metal transfer modes,

or "the way in which the electrode wire gets into the weld!"

There are 3 "modes of transfer" namely:

oShort-Circuit transfer, sometimes called "dip transfer", "short arc transfer"

and "buried arc".

oGlobular transfer, and

oSpray transfer.

4.1 SHORT CIRCUIT TRANSFER (SHORT ARC AND DIP TRANSFER)

Short Circuit Transfer is the "preferred mode" for welding the following:

oThin metal up to approximately 2 to 3mm thick.

oOut of Position welding.

oFilling large gaps.

oRoot runs in heavy gauge material (V-grooved).

The short circuit mode is considered to provide a "cool weld" owing to the "on and

off' nature of the arc.

In the short circuit mode the "cycle" begins when an arc jumps across the small gap

between the electrode wire and the work (base-metal). An instant later the

electrode-wire makes contact with the base metal or weld-pool as it is fed through

the gun by the wire feeder, and a "dead short" occurs in the circuit. The welding

machine (power source) tries to maintain the pre-set voltage and it does this by

increasing the amperage (current). As a result of the increased current a "pinch

force" is created at the electrode tip, and a small section of the wire fuses (breaks)

off into the weld-pool. At this instant the "arc gap" is recreated between the

electrode tip and the base metal and the arc is re-generated, due to the voltage

returning to its set value. The electrode wire is then fed back into the weld pool

creating a short circuit again, and so the cycle continues.

This "cycle" of shorting, wire tip pinching off and the arc re-establishing happens

between 80 and 200 times per second!

Back to Table of Contents 9

INDUCTANCE CONTROL

With short circuit transfer, the current rise, at the time of the short circuiting occurring

may take place too quickly causing the electrode tip to explode.

Some power sources include "inductance control" in the form of "tapings" to which the

"work lead" is attached.

Increasing inductance, in "short circuit transfer mode", will prevent the electrode from

exploding (spattering) as well as result in a more fluid weld pool.

SLOPE ADJUSTMENT

Slope adjustment, featured on some power sources, is used to alter the value of the

maximum "short circuit current". When the slope is "increased" the maximum current is

"decreased". The ultimate effect is the reduction of spatter.

BURN BACK CONTROL

In short circuit mode there is a chance that the wire will stick or "freeze" to the weld at the

moment that the gun trigger is released when welding stops. (Releasing the trigger when set

to the 2 times or "2T" trigger mode position, effectively stops the welding current, the gas

flow and the wire feeder). Burn back control delays the current "contactor" from cutting•

out for a fraction of a second after the wire feeder motor stops. In this way the wire tip will

still be energised (although the feed has stopped) and the tip will burn back thereby

preventing it from sticking to the work. Many modern machines incorporate automatic burn

back control in the electrical circuit. Note that the welder (operator) could simply break the

arc by pulling the gun away from the weld, but this action would remove the "post flow" of

shielding gas from the weld pool and result in a "porous" crater at the end of the weld.

SUMMARY (SHORT CIRCUIT)

Short-circuit transfer will be achieved on carbon-steel typically using:

oWire sizes ranging from 0.98mm to 1.2mm.

oVoltage range of 15 to 20 volts.

oWire feed speeds between 2.5 to 10 metres per minute.

oCurrent range -approximately 80 to 200 amps.

oArgon + 5 - 10% C02 for steel thickness below 1. 75mm.

oArgon + 15 - 25% C02 for thicker material.

4.2 SPRAY TRANSFER

In "Spray Transfer" the electrode melts in the arc to form small droplets roughly the

same diameter as the wire. These droplets are carried into the weld pool by electro-

magnetic forces in a continuous stream or "spray". Spray transfer places a lot of heat

into the base metal thereby making it more suitable for joints requiring deep

penetration and for metal thickness of 6mm and greater.

Back to Table of Contents 10

It is however difficult to weld steel "out of position" with spray transfer owing to the

"excessive fluidity" of the weld-pool and the risk of "spill over". Metals with good

heat dissipation ("conductivity") such as aluminium, can be welded out of position

using spray transfer.

Spray transfer occurs, with carbon steel when:

oWelding voltage is set relatively high, typically 25 to 35 volts.

oWire size 0.98mm -1.2mm.

oWire feed speed between 9 to 14 metres per minute.

oCurrent range -approximately 180 -380 amps.

oShielding-gas comprising at least 80% inert gas (Argon or Helium).

You will notice that a "long arc" is generated when spray transfer is used, owing to

the relatively high voltage.

4.3 GLOBULAR TRANSFER

Globular transfer occurs when the electrode (wire) tip melts in the arc to form a

relatively large ball (or globule) that falls in a "random fashion" into the weld pool.

Globular transfer occurs when the welding "voltage" is set higher than for "short circuit

transfer" but too low for "spray transfer", in other words it is a "transitional" transfer-

mode between dip and spray.

4.4 PULSED SPRAY

In an effort to achieve a "spray transfer mode" using lower welding currents the

manufacturers of welding "power sources" created welding machines called "pulsed-

arc units".

A pulsed-arc unit basically combines two power sources into one machine.

One power source provides a "background current" which effectively keeps the wire

tip in a "molten state". The other generates "peak-current pulses", that are higher

than the "background current", at a "frequency of between 60 and several hundred

times per second. Upon each "peak-pulse" a small droplet separates from the tip of

the electrode-wire and is carried into the arc stream (sprayed) and deposited in the

weld pool in a steady (constant rate) stream.

Pulsed arc welding typically imposes welding currents of between 50 and 220 amps

when using arc voltages of 23 -25volt thereby creating a "cooler weld" than

conventional spray transfer, making it possible to weld thin gauge material.

IN SUMMARY

Keep the following facts in mind regarding metal transfer modes:

It is the welding "voltage" that determines the arc length and it is the "wire feed speed' that

determines the "welding current (amps)".

Back to Table of Contents 11

That the mode of metal transfer is the result of a combination of the following factors:

oWire size (diameter).

oWire feed speed (Current).

oWelding voltage.

oType or mix of welding gas.

5. SAFETY AND PPE

For most practical applications you must take the same precautions with GMAW

welding processes as you would with SMAW (Stick welding) namely:

oAlways wear a welding helmet (mask or hood) when welding or when

observing a weld in progress. The visor must be fitted with at least a #12

shaded lens.

oWhen working in the "general area" of GMAW welding operations, always

wear "flash goggles".

oErect "welding screens" around the work area in order to protect those

around you.

oWear welding gloves.

oWear overalls and roll the sleeves down to protect against skin burns.

oWear a "welders apron" especially if you are doing "overhead welding".

oAlways work in a properly ventilated area. (Special safety precautions are

required if you have to weld in a "confined space"-see Tech A.V programme

CS-1).

oUse a "fume extractor" when welding indoors or in a small workshop.

oTake care when welding upon certain metals, notably those alloys containing

zinc, as fumes are "toxic". Many FCAW electrodes also emit toxic or "noxious"

fumes (Always read the warnings given on the labels where applicable).

oAlways adhere to mandatory safety rules applicable to your industry.

NOW VIEW VIDEO GMAW-1.

THEN COMPLETE THE SELF• TEST EXERCISE ON THE FOLLOWING PAGE.

Back to Table of Contents 12

SELFTEST NO. 1

GMAW OPERATING PRINCIPLES

INSTRUCTIONS

Complete the following exercise without reference to your notes or the video. When you

have completed the exercise check your answers/responses by:

oReferring to the notes.

oReviewing the video material.

oAsking your Instructor/Mentor.

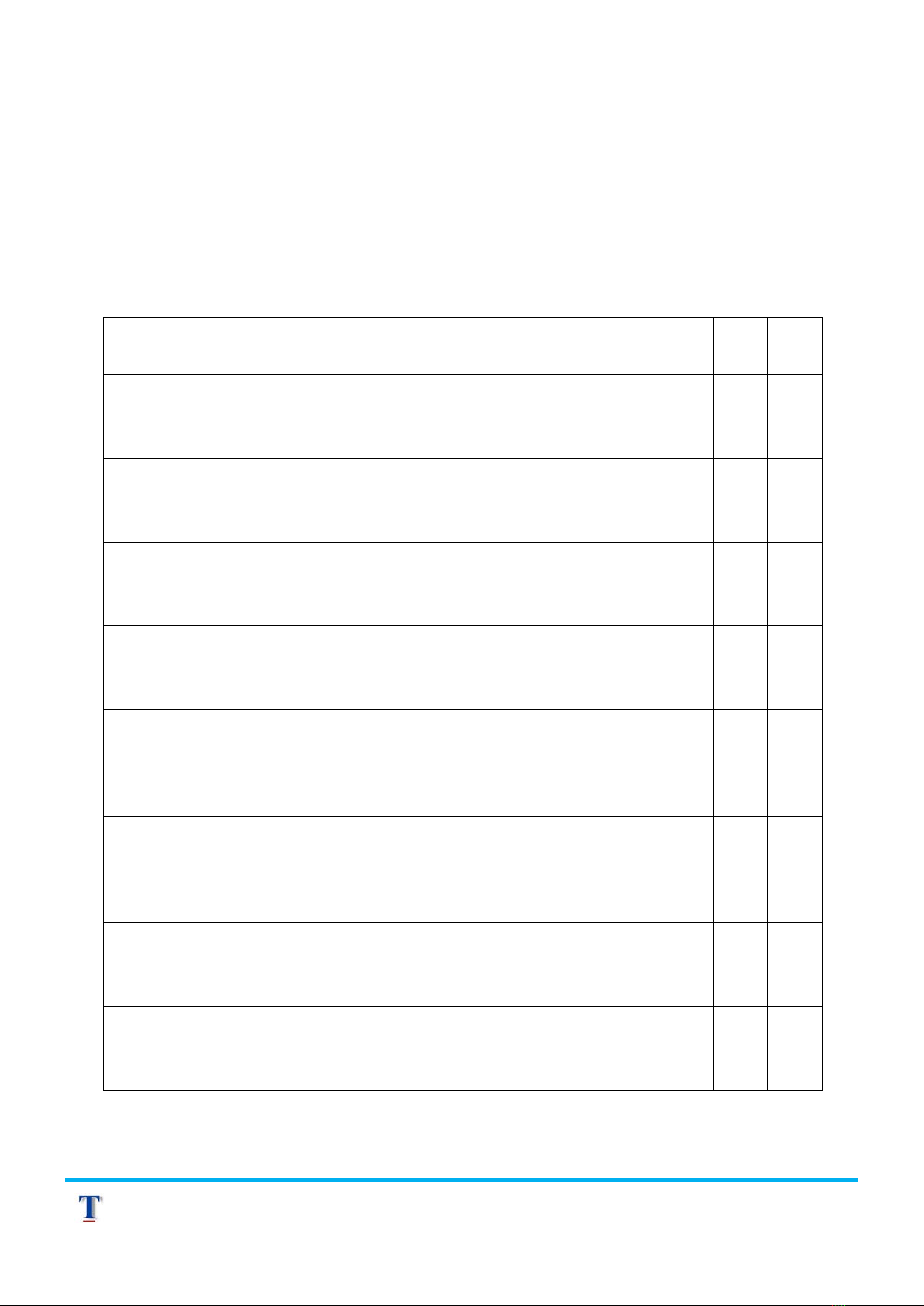

QUESTION YES NO

1. What do the letters "GMAW" mean?

___________________________________________________________

2. What do the letters "MIG" mean?

___________________________________________________________

3. What does "MAG" mean?

___________________________________________________________

4. What is "FCAW"?

___________________________________________________________

5. What makes a GMAW process different from Shielded Metal Arc

welding?

___________________________________________________________

6. What is the "primary reason" for a "welding gas" in most GMAW

processes?

___________________________________________________________

7. Which part of the welding equipment supplies the "welding current"?

___________________________________________________________

8. Which part of the equipment moves the electrode to the welding gun?

___________________________________________________________

Back to Table of Contents 13

9. What 3 main types of "shielding gases" are used with MIG and MAG

processes?

i) _________________________________________________________

ii) _________________________________________________________

iii) _________________________________________________________

10. What are the 3 modes of metal transfer?

i) __________________________________________________________

ii) _________________________________________________________

iii) _________________________________________________________

11. List 3 items of "personal protective equipment" that you should always

use when welding.

i) __________________________________________________________

ii) _________________________________________________________

iii) _________________________________________________________

THIS CONCLUDES PROGRAMME NO. 1.

Back to Table of Contents 14

GLOSSARY OF TERMS (RELEVANT TO PROGRAMME NO. 1)

A brief explanation of certain "technical terms" or words that may appear in the text or be

used in the video programme.

A

Active Gas: A gas that will combine easily or readily with molten weld material. Carbon

Dioxide and Oxygen are active gases.

Air Cooled Gun: A GMAW welding gun used mainly for light duty work, The nozzle and

contact tip are cooled by the flow of air and "shielding gas" surrounding them, These guns

are rarely used where the welding current exceeds 200 amps.

Alloy: A pure metal that has been mixed, during the molten state, with other metals or

metallic elements. Brass, for example, is an "alloy" of copper and zinc.

Arc: The flow of electricity that jumps across a gap in an electric circuit.

Argon: An "inert gas" found in the atmosphere.

Automatic Welding: A welding process that is controlled "mechanically" using a "robot" or

any other device other than a "human welder".

B

Background current: A relatively low current that remains on all the time during "pulsed

spray transfer". The background current maintains a "continuous arc".

Base Metal: Metal that is to be welded also called the "work".

Bead: The shape of a finished fusion-weld.

C

Carbon Dioxide: Known as C02 by most welders, is a gas commonly used for "shielding" in

GMAW processes.

Carbon Steel: Steel that has been produced by adding small amounts of carbon to pure iron

in the molten state.

Circuit: The path through which "electrons" flow from a "source", through various electrical

components and back to the "source".

Constant Current (CC): The term used to describe a power source that delivers "near

constant" amps" even if the circuit voltage fluctuates. Most SMAW machines are of the CC

type.

Constant Voltage (CV): Also known as "constant potential" is the term used to describe a

welding machine that delivers "near constant volts" even if the "amperage fluctuates, Most

GMAW welding machines are of the CV type.

Consumable (welding): Any item in a welding process that is used in the creation of the

weld and enters the weld-pool is considered to be a "welding consumable". The electrode in

the GMAW process is the main "consumable" in such a process.

Continuous Weld: A weld that is started and finished, in a single operation, without having

to stop.

Back to Table of Contents 15

Current: The volume or flow of electrons that pass through an electrical circuit. Current is

measured in Amperes or Amps.

D

Deposition Rate: The weight (mass) of material (filler) that is deposited into a weld over a

given time period, normally expressed in Kg/Hr.

Direct Current (DC): The flow of electrons in one direction only, for example from the

negative to the positive connection of a power source.

Duty Cycle: The amount of time, in a given period (usually 10 minutes), that a welding

machine can operate, at its rated load (amps), without "overloading" or "overheating".

E

Electrode: The point to which the "welding current" is brought in order to generate the

"arc" that generates the "heat" that melts the "base metal". An electrode may be made of

the "filler material" required to create a "bead" in which case it is a "consumable electrode".

In some cases the electrode may be "non-consumable", such as the "tungsten electrode"

used in TIG welding.

F

Filler Metal: Metal or Alloy that is used to create the weld bead.

Flash:The bright intense arc, generated in Arc-welding processes, as seen by the human

eye.

G

Gas Metal Arc Welding (GMAW): the arc welding process that uses a continuously fed,

consumable electrode in conjunction with a "shielding gas". (Also called MIG/MAG welding).

Globular Transfer: The deposition of metal from an electrode (melting in the arc), in the

form of large "blobs" of molten metal.

H

Helium: An inert gas which, like argon, is used to provide shielding in certain MIG welding

processes. Generally associated with "critical welding", especially with Stainless Steel.

I

Inching: The term used to "advance" the electrode wire, in a "controlled manner" (little at a

time).

Inductance: An electrical term of complex meaning, but from a Welders' point of view it is a

manner of controlling the "rate of increase" (rise) of a welding current to reduce excessive

"spattering" when welding.

Inert Gas: Gases such as Argon and Helium that do not react (cause change} in a weld.

Back to Table of Contents 16

Insulation: Any material that will not permit an electric current to pass through it. The

handle surrounding the welding gun is made of "insulative-material".

L

Lead: The cable, wire or "conductor" that carries electricity. In welding terms this is usually

the "work lead" that returns the electricity from the work back to the "power source".

Liner: The flexible tube through which the electrode passes between a "wire feeder" and

the "welding gun".

M

Metal Active Gas (MAG welding): The use of "mixed shielding gases", both active and inert,

result in the term MAG. MAG welding normally involves the use a shielding gas containing

mostly Argon plus around 15-25% C02 and very small amounts of Oxygen (2-5%). The MAG

process is mainly restricted to the welding of steel (ferrous metals).

Metal Transfer: The movement of metal from one surface to another. This can occur in

various ways but it is mostly used to describe the "molten transfer" as in "fusion welding".

N

Nozzle: A metal or a ceramic tube or cup fitted to the end of a welding gun. The nozzle

directs the flow of "shielding gas" onto the weld area.

O

Open Arc: Any arc that is VISIBLE is considered an "open arc".

Open Circuit voltage: The voltage in a welding machine circuit when the machine is

"powered up" but the arc has not been struck.

Out of Position Welding: Welds made in the vertical, overhead or horizontal position. That

is any position other than "flat" or "down-hand".

Oxidation: The process in which Oxygen combines with a material or substance to form a

chemical compound called an "oxide". (Normally associated with "burning" and "heating").

P

Pinch Force: An electrical "force", associated with Short Circuit Transfer. It is a "magnetic

force" that causes a droplet of metal to be "pinched off' at the end of the electrode during

the short circuit phase.

Porous / porosity: The presence of gas pockets or "holes" in a weld bead.

Post Flow: The flow of shielding gas that continues for a short time after the welding current

has been stopped. Normally required to prevent "oxidising" and "porosity" whilst metal is in

the "molten state".

Pressure Regulator: Device used to convert cylinder gas pressure to a usable "working

pressure".

Pulsed Spray transfer: Alternative mode of spray -transfer, where spray transfer is achieved

with reduced current.

Back to Table of Contents 17

Pull Gun: A welding gun that has an in-built wire-feeder that pulls the electrode-wire

through the gun cable.

R

Rated Output-Current: The maximum current or "load" that can be generated from a

welding machine.

Resistance: In electrical terms, the property of a material to "resist" (slow down) the flow of

electricity through it.

S

Shielding (gas): The protection of a weld-pool and arc from the atmosphere. An "inert gas"

is used to surround the weld-zone and prevent atmospheric gases (oxygen and nitrogen)

from reacting with the heated surfaces.

Short Circuit: An electrical term used to describe an electrical current moving directly to its

source by bypassing the electrical devices in the circuit.

Short Circuit Transfer: A term used to describe the manner in which filler material breaks

away from the electrode when the electrode "shorts out" against the weld or the base

metal.

Slope: The electrical "losses", in terms of volts and amps, as a result of resistance in an

electrical circuit.

Stainless Steel: An alloy of steel with elements such as "chromium" that result in a product

that can withstand "corrosion" and oxidation (rust).

T

Tap (or Tapping): An electrical connection point on a welding machine to which the work-

lead may be attached.

V

Voltage: The "force" or "electrical pressure" in an electric circuit, that causes current to

flow.

Volt drop: The loss of "voltage" as a result of resistance in a circuit. (As in slope).

Voltmeter: A device used to measure voltage.

W

Water-cooled gun: A welding-gun or welding torch that is cooled using liquid, normally

water. Water-cooling prevents a gun from overheating especially when welding currents

above 200 amps are generated.

Weld: The mixing of two or more materials (metal or non-metal) using heat to bring them to

a molten state where the elements "fuse" to become one.

Weldment: An assembly of parts (pieces) that have been joined together by welding.

Welding Station: The work area, including all the welding equipment, where a welding

operation will be (is being) performed.

Back to Table of Contents 18

Wire: In GMAW terms this is the name used, by most "Welders", for the electrode-wire.

Wire-Feeder: The device used to deliver the electrode-wire in a continuous action, to the

weld area.

Work piece: The material to be (being) welded.

NOW MOVE ON TO PROGRAMME 2:

EQUIPMENT - PARTS, FUNCTIONS AND PREPARATION".

Table of contents

Popular Welding System manuals by other brands

Air Liquide

Air Liquide PRESTOTIG 160 PFC Safety instruction for use and maintenance

MESSER

MESSER SolidWELD TIG 185AC/DC FP operating manual

voestalpine

voestalpine Bohler TERRA 270 RC instruction manual

Dohle

Dohle ExOn7 operating instructions

Technoflux

Technoflux Drago I-E instruction manual

ESAB

ESAB Caddyt Tig 150i instruction manual

Colindusnria

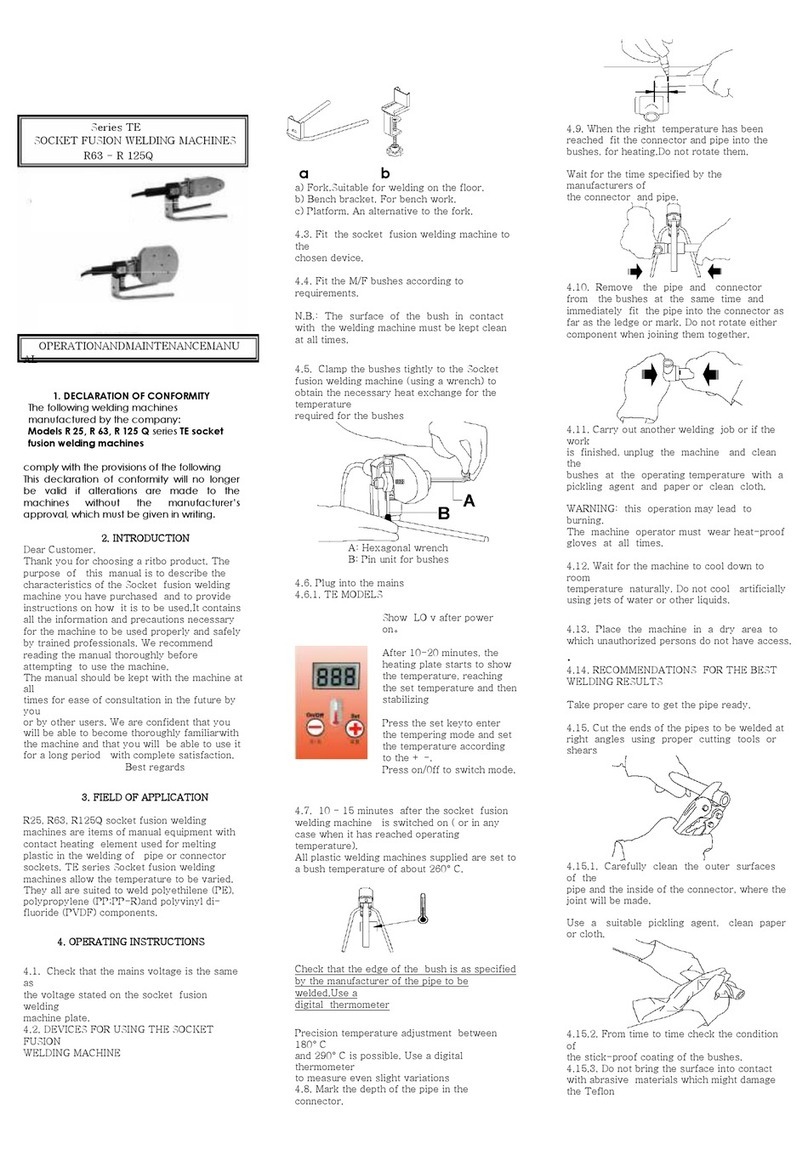

Colindusnria TE Series OPERATION AND MAINTENANCE MENU

ESAB

ESAB Caddy Mig C200i instruction manual

Miller Electric

Miller Electric Big 40 C owner's manual

GÜDE

GÜDE GIS 200 Translation of the original instructions

Greencut

Greencut MMA180 instruction manual

ET Hydrogen

ET Hydrogen L/350 Operating instructions and maintenance