TECH ST-19 User manual

Principle of operation

The ST-19 regulator is responsible for controlling the central heating pump. It is used

to start the pump when the temperature exceeds a given value and stop it when the

boiler has cooled down (as a result of damping). This is to prevent the pump from

runningunnecessarilyandsaveenergyconsumedbytheboiler(upto60%depending

on the amount of use), as well as extend the life of the pump, while increasing its

reliabilityandreducingrunningcosts.

Operation

The pump switch-on temperature is set with a potentiometer (between 25oC and

85oC). The pump is stopped when the actual temperature drops 2oC below the

setpoint value (set with the potentiometer). Thus, the pump is not switched on and off

incycles(reducingitslifespan)asaresultofsmallchangesofthetemperature.

Apart from the potentiometer, the regulator is fitted with an ON/OFF switch

(POWER LED lit), manual pump start-up button (MANUAL MODE LED lit) and a

DUTY LED to indicate that the pump is running.

ANTI-STOP

The regulator is also intended for protecting the motor against blockage. The pump is

started every 10 days for 5 minutes. Additionally, the current time is stored within

EEPROMmemorytomakesurethetimeiscorrectevenafterapowerfailure.

TheregulatorisprotectedwithaWT1.6Atubefuse.

Installation

Allconnectionworksmustonlybecarriedoutbyqualifiedelectricians.

The sensor should be located at the boiler outlet with a band clip and separated from

externalconditionswithaninsulationtape.

The power supply line should be connected as follows: blue and brown – 230 V,

yellow-green(protective)shouldbeearthed

Thedistancebetweentheinstallationholesis123.6mm.

ATTENTION!

High voltage!

Make sure the regulator is disconnected from the mains before installation (pump

cableconnections,deviceinstallation,etc.)!

Donotdisassembletheregulatoranddonotinsertanyobjectsthroughtheinstallation

holes. The regulator must be protected against contamination and humidity. Any

damage to the housing may lead to an electric shock. The device needs to be

connectedtoagroundedcircuit.

Principle of operation

The ST-19 regulator is responsible for controlling the central heating pump. It is used

to start the pump when the temperature exceeds a given value and stop it when the

boiler has cooled down (as a result of damping). This is to prevent the pump from

runningunnecessarilyandsaveenergyconsumedbytheboiler(upto60%depending

on the amount of use), as well as extend the life of the pump, while increasing its

reliabilityandreducingrunningcosts.

Operation

The pump switch-on temperature is set with a potentiometer (between 25oC and

85oC). The pump is stopped when the actual temperature drops 2oC below the

setpoint value (set with the potentiometer). Thus, the pump is not switched on and off

incycles(reducingitslifespan)asaresultofsmallchangesofthetemperature.

Apart from the potentiometer, the regulator is fitted with an ON/OFF switch

(POWER LED lit), manual pump start-up button (MANUAL MODE LED lit) and a

DUTY LED to indicate that the pump is running.

ANTI-STOP

The regulator is also intended for protecting the motor against blockage. The pump is

started every 10 days for 5 minutes. Additionally, the current time is stored within

EEPROMmemorytomakesurethetimeiscorrectevenafterapowerfailure.

TheregulatorisprotectedwithaWT1.6Atubefuse.

Installation

Allconnectionworksmustonlybecarriedoutbyqualifiedelectricians.

The sensor should be located at the boiler outlet with a band clip and separated from

externalconditionswithaninsulationtape.

The power supply line should be connected as follows: blue and brown – 230 V,

yellow-green(protective)shouldbeearthed

Thedistancebetweentheinstallationholesis123.6mm.

ATTENTION!

High voltage!

Make sure the regulator is disconnected from the mains before installation (pump

cableconnections,deviceinstallation,etc.)!

Donotdisassembletheregulatoranddonotinsertanyobjectsthroughtheinstallation

holes. The regulator must be protected against contamination and humidity. Any

damage to the housing may lead to an electric shock. The device needs to be

connectedtoagroundedcircuit.

Principle of operation

The ST-19 regulator is responsible for controlling the central heating pump. It is used

to start the pump when the temperature exceeds a given value and stop it when the

boiler has cooled down (as a result of damping). This is to prevent the pump from

runningunnecessarilyandsaveenergyconsumedbytheboiler(upto60%depending

on the amount of use), as well as extend the life of the pump, while increasing its

reliabilityandreducingrunningcosts.

Operation

The pump switch-on temperature is set with a potentiometer (between 25oC and

85oC). The pump is stopped when the actual temperature drops 2oC below the

setpoint value (set with the potentiometer). Thus, the pump is not switched on and off

incycles(reducingitslifespan)asaresultofsmallchangesofthetemperature.

Apart from the potentiometer, the regulator is fitted with an ON/OFF switch

(POWER LED lit), manual pump start-up button (MANUAL MODE LED lit) and a

DUTY LED to indicate that the pump is running.

ANTI-STOP

The regulator is also intended for protecting the motor against blockage. The pump is

started every 10 days for 5 minutes. Additionally, the current time is stored within

EEPROMmemorytomakesurethetimeiscorrectevenafterapowerfailure.

TheregulatorisprotectedwithaWT1.6Atubefuse.

Installation

Allconnectionworksmustonlybecarriedoutbyqualifiedelectricians.

The sensor should be located at the boiler outlet with a band clip and separated from

externalconditionswithaninsulationtape.

The power supply line should be connected as follows: blue and brown – 230 V,

yellow-green(protective)shouldbeearthed

Thedistancebetweentheinstallationholesis123.6mm.

ATTENTION!

High voltage!

Make sure the regulator is disconnected from the mains before installation (pump

cableconnections,deviceinstallation,etc.)!

Donotdisassembletheregulatoranddonotinsertanyobjectsthroughtheinstallation

holes. The regulator must be protected against contamination and humidity. Any

damage to the housing may lead to an electric shock. The device needs to be

connectedtoagroundedcircuit.

Principle of operation

The ST-19 regulator is responsible for controlling the central heating pump. It is used

to start the pump when the temperature exceeds a given value and stop it when the

boiler has cooled down (as a result of damping). This is to prevent the pump from

runningunnecessarilyandsaveenergyconsumedbytheboiler(upto60%depending

on the amount of use), as well as extend the life of the pump, while increasing its

reliabilityandreducingrunningcosts.

Operation

The pump switch-on temperature is set with a potentiometer (between 25oC and

85oC). The pump is stopped when the actual temperature drops 2oC below the

setpoint value (set with the potentiometer). Thus, the pump is not switched on and off

incycles(reducingitslifespan)asaresultofsmallchangesofthetemperature.

Apart from the potentiometer, the regulator is fitted with an ON/OFF switch

(POWER LED lit), manual pump start-up button (MANUAL MODE LED lit) and a

DUTY LED to indicate that the pump is running.

ANTI-STOP

The regulator is also intended for protecting the motor against blockage. The pump is

started every 10 days for 5 minutes. Additionally, the current time is stored within

EEPROMmemorytomakesurethetimeiscorrectevenafterapowerfailure.

TheregulatorisprotectedwithaWT1.6Atubefuse.

Installation

Allconnectionworksmustonlybecarriedoutbyqualifiedelectricians.

The sensor should be located at the boiler outlet with a band clip and separated from

externalconditionswithaninsulationtape.

The power supply line should be connected as follows: blue and brown – 230 V,

yellow-green(protective)shouldbeearthed

Thedistancebetweentheinstallationholesis123.6mm.

ATTENTION!

High voltage!

Make sure the regulator is disconnected from the mains before installation (pump

cableconnections,deviceinstallation,etc.)!

Donotdisassembletheregulatoranddonotinsertanyobjectsthroughtheinstallation

holes. The regulator must be protected against contamination and humidity. Any

damage to the housing may lead to an electric shock. The device needs to be

connectedtoagroundedcircuit.

!! !!

ST-19 ST-19

tech tech

....................... ....................... ....................... .......................

Salespersonstamp Dateofsale Salespersonstamp Dateofsale

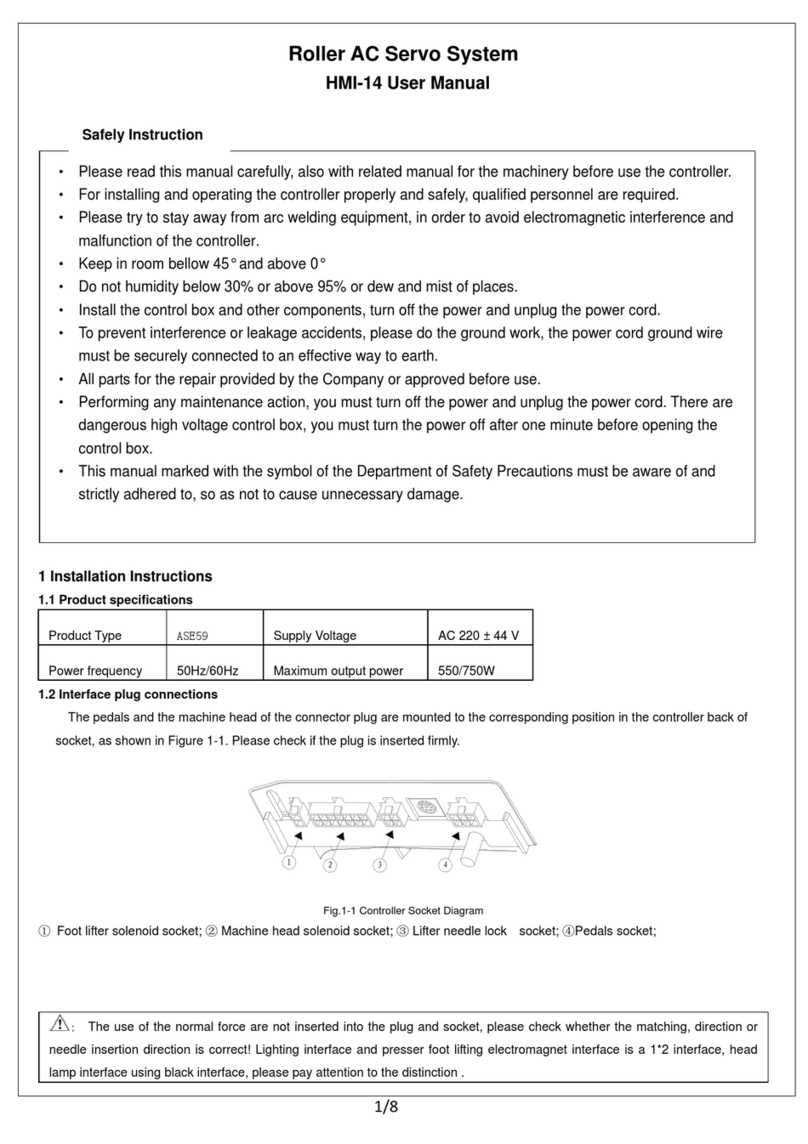

1. Potentiometer 1. Potentiometer

2. Powerswitch 2. Powerswitch

3. PowerindicationLED 3. PowerindicationLED

4. PumpdutyindicationLED 4. PumpdutyindicationLED

5. Temperaturesensor 5. Temperaturesensor

6. Centralheatingpumpoutput 6. Centralheatingpumpoutput

7. Powersupply 7. Powersupply

8. 1Afuse

9. ManualmodeindicationLED

10.Manualmodebutton

8. 1Afuse

9. ManualmodeindicationLED

10.Manualmodebutton

O O

Ambienttemperature 0 C-40 C O O

Ambienttemperature 0 C-40 C

WARRANTY WARRANTY

Tech warrants to the Buyer that the device will be free of any defects for a period of

24monthsfromthedateofsale(upto30monthsfromthedateofproduction).Adefectivedevice

should be returned to the point of sale, accompanied by this Warranty Card with a confirmed

date of purchase. The faulty device will be replaced by the warrantor provided that the fault is

attributabletothemanufacturer.

Tech warrants to the Buyer that the device will be free of any defects for a period of

24monthsfromthedateofsale(upto30monthsfromthedateofproduction).Adefectivedevice

should be returned to the point of sale, accompanied by this Warranty Card with a confirmed

date of purchase. The faulty device will be replaced by the warrantor provided that the fault is

attributabletothemanufacturer.

The Warranty does not cover damage due to improper use or attributable to the user,

mechanicaldamageordamagecausedbyatmosphericdischarges,overvoltage,short-circuits. The Warranty does not cover damage due to improper use or attributable to the user,

mechanicaldamageordamagecausedbyatmosphericdischarges,overvoltage,short-circuits.

This Warranty Card is valid only with a receipt (invoice) containing the date of sale,

dateofdeliveryandsignatures.Itisrecommendedtoencloseabriefdescriptionofthefault.The

parcelshouldbeprovidedwithsender’sfulladdressandtelephonenumber.

This Warranty Card is valid only with a receipt (invoice) containing the date of sale,

dateofdeliveryandsignatures.Itisrecommendedtoencloseabriefdescriptionofthefault.The

parcelshouldbeprovidedwithsender’sfulladdressandtelephonenumber.

1 1

5 5

6 6

7 7

8 8

2 2

Temperatureadjustmentrange O O

25 C-85 C Temperatureadjustmentrange O O

25 C-85 C

O

Hysteresis 2 C O

Hysteresis 2 C

Powerconsumption 1W Powerconsumption 1W

Supplyvoltage 230V/50Hz+/-10% Supplyvoltage 230V/50Hz+/-10%

Sensorcablelength do1.5m Sensorcablelength do1.5m

Output 230V/50Hz Output 230V/50Hz

Max.outputloadcurrent 1A Max.outputloadcurrent 1A

O

Measurementerror +/-1 C O

Measurementerror +/-1 C

10 10

ST-19 ST-19

2-YEAR

WARRANTY

2-YEAR

WARRANTY

Temperature Regulator Temperature Regulator

Anti-Stop Anti-Stop

Other TECH Controllers manuals