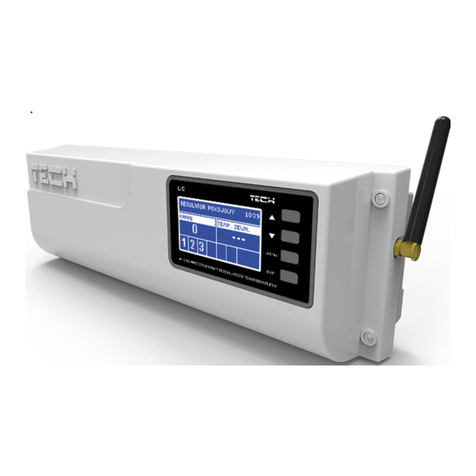

TECH ST-401N PWM User manual

Tech

- 1 -

User’s manual

ST-401N PWM

ST-401N User's Manual v 1.0.3

- 2 -

I. Safety

Before using the device for the first time the user should read the following regulations carefully. Not

obeying the rules included in this manual may lead to personal injuries and device damage. The user's

manual should be stored in a safe place for further reference.

In order to avoid accidents and errors it should be ensured that every person using has familiarized

themselves with the principle of operation and security functions of the device. If the device is to be

sold or put in a different place, make sure that the user's manual is kept with the device so that any

potential user has access to essential information about the device. The manufacturer does not accept

responsibility for any injuries or damage resulting from negligence; therefore, users are obliged to take

the necessary safety measures listed in this manual to protect their lives and property.

WARNING

High voltage. Make sure the regulator is disconnected from the mains before perform-

ing any activities involving the power supply (plugging cables, installing the device

etc.).

The device should be installed by a qualified electrician.

Before starting the controller, the user should measure the earthing resistance of the

electric motors as well as the insulation resistance of the cables.

The regulator should not be operated by children.

NOTE

The controller may be damaged if struck by lightning. Make sure the plug is discon-

nected from the power supply during storms.

Any use other than that specified by the manufacturer is forbidden.

Before and during the heating season, the controller should be checked for the condition

of its cables. The user should also check if the controller is properly mounted and clean

it if dusty or dirty.

After the editing of this manual was completed on June 29, 2015, changes in products specified in the

manual may have taken place. The manufacturer reserves the right to change the information in

regards to products. The illustrations may contain additional equipment. The printing technology may

affect differences in shown colours.

Tech

- 3 -

II. Application

The ST-401N type temperature regulator is intended for the operation of solar collectors for various

system configurations. This device controls the operation of collector pumps (or a pump and a valve)

on the basis of the measurement of the solar panel temperatures and the accumulation tank (two

tanks) temperature. There is an option to connect an additional device: circulation pump, electric heater

or feeding the signal to the CH boiler in order to fire it up.

It is possible to control the circulation pump and feed the firing-up signal to the CH boiler directly

from the controller, while an additional signal relay is necessary to control the heater.

III. Principle Of operation

Description of the Control Panel of a Sample System

Opis panelu sterującego przykładowego układu

The regulator is controlled through the use of buttons. The user may enter the menu and confirm the

settings by pressing the Menu button. Using the Plus and Minus buttons, the user moves through the

menu's functions. In order to accept the selected menu item, the user should press the Menu button.

In order to proceed to the main screen (or the menu of a higher level), the user should use the Exit

button. Any setting may be changed in a similar manner.

Switching Valve

Switching Valve

Timer

Collector

Temperature

Operation Mode

Additional Device

Started

MENU

PLUS Button

MINUS Button

EXIT

Heat Container's

Temperature

Collector Cump

Collector

Temperature

ST-401N User's Manual v 1.0.3

- 4 -

IV. User Menu

IV.a) Home Page

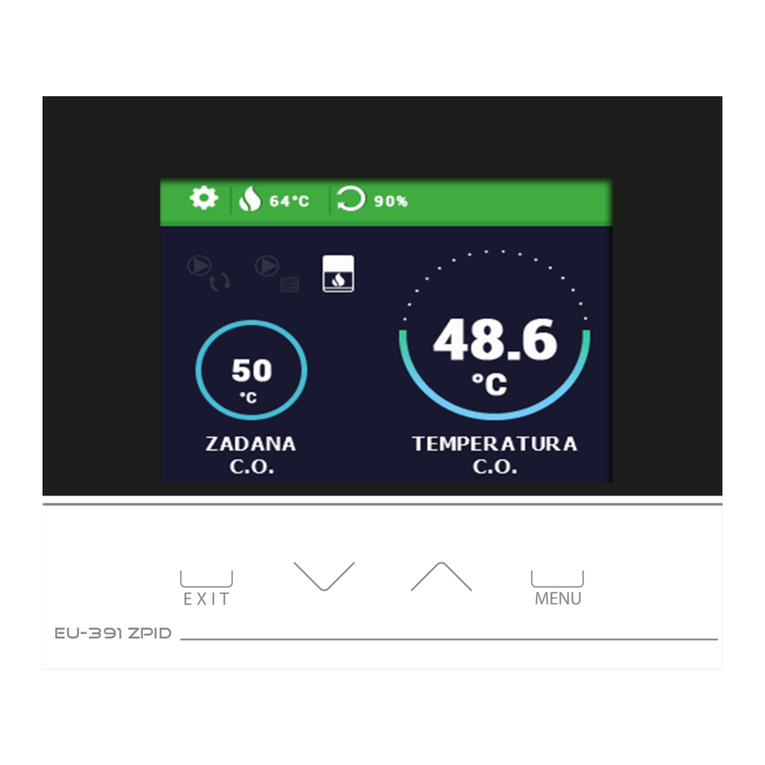

During the regulator's standard operation, the Graphic Display shows the Homepage which displays

the diagram of the selected system and:

- Operation mode (or alarm type),

- Current hour,

- Collector's temperature,

- Current heat container temperature,

- The temperatures of all additional sensors, depending on the configuration.

The following graphic elements are displayed on the right hand side:

The Symbol of Active Operation Mode:

The Symbol of Active Additional

Device (Peripherals):

Automatic Operation Mode

Circulation Pump

Collector Defrosting Mode

Firing-up the Pellet Boiler

(voltage-free signal)

Holiday Mode

Heater

Collector Overheat (alarm mode)

Anti-Legionella

Sensor Damage (alarm mode)

If one of the sensors is damaged, an additional icon will flash as an indicator in the place of

the displayed temperature of the damaged sensor, informing the user about the sensor that is

disconnected or is damaged.

Additionally, the installation system diagram shows a pump symbol (it rotates when in operation) and/or

a valve symbol (indicating the current circulation path)

Tech

- 5 -

IV.b) Main Menu – Flowchart

Due to its multifunctional nature, the controller's menu is divided into the Main Menu and the Service

Menu.

The Main Menu is used to adjust the controller's basic options such as changing the operation modes,

timer settings, date settings, changing the language etc. The layout of parameters in the Main Menu is

shown by the flowchart below.

*Parameter visible if an additional device (i.e. a heater) is connected.

IV.c) Operation Mode

Using this function, the user selects the operation mode.

IV.c.1) Automatic Operation

The pump operates during the Automatic Operation mode if the minimum difference of temperatures

between the collector and the tank is reached (the difference between these temperatures when the

pump is activated is determined by the function "Solar Pump Activation Delta" in: SERVICE MENU >

Pumps > Solar Pump Activation Delta).

The pump will operate until the set temperature is reached (the set temperature is adjusted in:

SERVICE MENU > Accumulation Tank > Set Temperature) or until the difference of temperatures

between the collector and the tank reaches the deactivation delta threshold: SERVICE MENU > Pumps

> Solar Pump Deactivation Delta (in this case, the pump will be activated again when the temperature

on the collector increases above the tank's temperature by the Solar Pump Activation Delta). When the

pump is deactivated after reaching the set temperature, it will be activated again if the temperature

drops below the set value by the amount specified by the Tank's Hysteresis (the hysteresis value is

adjusted in: SERVICE MENU > Accumulation Tank > Tank Hysteresis).

IV.c.2) Collector Defrosting

Using this mode, the user may manually activate the collector's pump in order to melt the snow on the

solar panels. After activation, this mode is active throughout a period of time defined by the user and

then the controller returns to its automatic operation (the defrosting time is set in: SERVICE MENU>

Solar Collector > Defrosting Time). This function may be switched off manually after a shorter operation

time by selecting a different operation mode.

Main Menu

Operation Mode

Automatic Operation

Collector Defrosting

Holiday Mode

Anti-Legionella*

Manual Operation

Timer

Date

Ethernet Module

Activate

IP Address

Reset Module Password

Advanced Settings

Information

GSM Activate

Information

Statistics

Gain

Collector Overheat

Power Supply Failures

Backlight

Display Contrast

Language

Information

Factory Settings

Service Menu

ST-401N User's Manual v 1.0.3

- 6 -

IV.c.3) Holiday Mode

After the user activates Holiday Mode, the pump operates when one of the following conditions is met:

The collector's temperature increases to the overheat temperature value (SERVICE MENU> Solar

Collector > Overheat Temperature) reduced by the value of the parameter Delta Holiday (SERVICE

MENU> Solar Collector > Delta Holiday). When this condition is met, the pump is activated to cool down

the collector. The pump is deactivated after the temperature is reduced by 5°C.

If the collector's temperature is lower than the tank's temperature – the pump is activated to cool

down the tank and will operate until the collector's and the tank's temperatures are level.

IV.c.4) Anti-Legionella

This function is only active when an additional device is connected (found under the function Peripherals

in the Service Menu and then activated). Thermal disinfection involves increasing the temperature to

the required disinfection temperature in the tank – this reading is taken from the upper sensor in the

tank (in the case of using an optional sensor, the user should make sure that this sensor measures the

temperature in the upper part of the tank because this is the priority sensor for this function). This is

to eliminate the Legionella pneumophila bacteria that reduce the body's cell immunity. These bacteria

often multiply in tanks with stagnant hot water (at an optimum temperature of 35°C). After the user

activates this function, the tank heats up to the defined temperature (SERVICE MENU > Peripherals >

Heater > Anti-Legionella > Anti-Legionella Temperature) and maintains such a temperature for the

time of disinfection (SERVICE MENU > Peripherals > Heater > Anti-Legionella > Anti-Legionella Time)

and then returns to the regular operation mode.

From the moment of activating the disinfection, the temperature of disinfection needs to be reached in

no longer than the time defined by the user (SERVICE MENU > Peripherals > Heater > Anti-Legionella

> Maximum Anti-Legionella Time), otherwise this function is deactivated automatically.

IV.c.5) Manual Operation

Using this function, the user may manually (by pressing the ‘Menu’ button) activate and deactivate the

following to control the installation's equipment:

- Solar Pump,

- Second Solar Pump or Switching Valve,

- Peripherals - Additional Device (voltage-free contact e.g. for firing up the pellet boiler).

IV.d) Timer

Using this function, the user adjusts the current hour for regulator operation.

IV.e) Date

Using this function, the user adjusts the current date. The correct adjustment of date and hour is

necessary to calculate energy in a proper manner.

IV.f) Ethernet Module

NOTE

Control of this type is possible after purchasing and connecting an additional ST-500 control module

(which is not added to the controller as a standard).

The Ethernet Module is a device for enabling remote control over the collector's operation via

the Internet or a local network. On the home computer screen, the user controls the status of all the

solar installation devices and the operation of each device is presented in the form of an animation.

After activating the Internet module and selecting the DHCP option, the controller automatically

downloads the following parameters from the local network: IP Address, IP Mask, Gateway Address and

DNS Address. In the case of any problems with downloading the network parameters, it is possible to

adjust these parameters manually. The method of obtaining the local network's parameters is described

in the manual for the Internet Module.

The function Reset Module Password may be used when the user changed the factory user's

password to his own password on the login page. When the new password is lost, it is possible to return

to the factory password after resetting the module password.

Tech

- 7 -

IV.g) GSM Module

NOTE

Control of this type is possible after purchasing and connecting an additional ST-65 control module

(which is not added to the controller as a standard).

The GSM module is an optional device designed to work in tandem with the collector's controller,

enabling remote control over the collector operation with the use of a mobile phone. The user is notified

with a text message about each alarm of the solar installation's controller and they receive a return

message with information on the current temperature of all sensors by sending an appropriate text

message at any time.

The ST-65 module may also operate independently of the collector. It has two inputs with

temperature sensors, one contact input to be used in any configuration (detecting closing/opening of

contacts) and one controlled output (e.g. possibility to connect an additional contactor to control any

electrical circuit).

When any temperature sensor reaches the set maximum or minimum temperature, the module

automatically sends a text message with such information. It is similar in the case of a closing or

opening of the contact input which may be used e.g. for the simple protection of property.

IV.h) Statistics

The parameters in this submenu allow the user to monitor the current conditions of the controller's

operation:

IV.h.1) Gain

This parameter allows the user to monitor the current values of gained energy in certain sections of

time: daily, weekly, monthly, annual and temporary.

CAUTION

Statistical data displayed in the controller is approximate – it is used only to determine the approximate

values of gained energy.

IV.h.2) Collector Overheat

After the user enters this submenu, the controller's display will show the list of the collector's overheats

(too high temperature of the collector's sensor). The user may see:

The date when the overheating occurred.

The hour.

The duration.

The reading from the collector's sensor.

IV.h.3) Power Supply Failures

After the user enters this submenu, the controller's display will show the list of power supply failures

registered by the controller. The user may see:

Date of occurrence.

Hour of occurrence.

Duration of occurrence.

IV.i) Backlight

This parameter regulates the display's brightness. This change takes place after a dozen or so seconds

of idleness.

IV.j) Display Contrast

This parameter regulates the display's contrast.

IV.k) Language

The user may select the controller's language version.

IV.l) Information

When the user selects this option, a screen with the controller's manufacturer logo and the current

ST-401N User's Manual v 1.0.3

- 8 -

program version appears.

IV.m) Factory Settings

This function allows the user to load factory settings previously recorded in the service menu.

V. Service Menu

In order to enter the service settings, the user should select the SERVICE MENU option and then select

code 0112 using the Plus and Minus buttons and confirm it by pressing the Menu button. In order to

return to the display's main view (exit the service menu), the user should use the Exit button by

pressing it several times or waiting for approx. 30 seconds (the device will then automatically leave the

service mode).

The flowchart of the Service Menu is given below.

The ST-401N controller is adapted to operate various heating installations. When the

installation's scheme is changed this may lead to the appearance of additional functions in the

controller's service menu – marked with an asterisk (*) in the following flowchart.

Tech

- 9 -

Service Menu

Accumulation Tank

Set Temperature

Maximum Temperature of Tank 1

Tank Hysteresis

Minimum Temperature of Tank 1

Cooling Down to Set Value

Holiday Delta

Valve Hysteresis*

Set Temperature of Tank 2*

Maximum Temperature of Tank 2*

Hysteresis of Tank 2*

Operation Algorithm*

Tank Reheating Priority*

Solar Collector

Overheat Temperature

Minimum Reheating Temperature

Alarm Hysteresis

Defrosting Time

Anti-Freeze Temperature

Collector Delta*

Pumps

Regulated Revolutions

Collector Maximum Temperature

Solar Pump Deactivation Delta

Solar Pump Activation Delta

Gear Coefficient

Solar Pump Operating Minimum

Solar Pump Operating Maximum

Circulation Sampling

Peripherals

None

Circulation Pump

Pellet Boiler Pump

Heater

Contact Not Consistent with Pump

Contact Consistent with Pump

Calculation of Energy

Flow

Type of Agent

Glycol Solution

Calibration

Installation's Options*

Alarm Sound

Factory Settings

ST-401N User's Manual v 1.0.3

- 10 -

V.b) Accumulation Tank

This menu allows the user to adjust all parameters related to the tank (heat container).

V.b.1) Set Temperature

This function is used to adjust the set temperature in the container which leads to the deactivation of

the Collector Pump.

V.b.2) Maximum Temperature of Tank 1

Using this option, the user may declare the maximum acceptable safe temperature value to which the

tank is allowed to heat in the case of Collector Overheat.

If the collector reaches its alarm temperature (Overheat), the pump is activated automatically

in order to cool down the heated collector, regardless of the set temperature. The pump operates until

reaching the Tank's Maximum Temperature or until the collector's temperature drops by the value of

the Alarm Hysteresis (see: SERVICE MENU > Solar Collector> Alarm Hysteresis)

V.b.3) Minimum Temperature of Tank 1

Using this parameter, the user may declare the minimum acceptable temperature value to which the

tank is allowed to cool. Below this temperature, the pump does not activate in the Collector Defrosting

mode.

V.b.4) Tank Hysteresis

Using this function, the user declares the tank hysteresis value. If the tank reaches the set temperature

and the pump is deactivated, it will be activated again after the tank's temperature drops below the set

value by the value of this hysteresis.

V.b.5) Cooling Down to Set Value

When the collector reaches the overheat temperature, the pump is activated in emergency mode to

cool it down. In this case, the tank receives heating until exceeding the set temperature (up to the

maximum temperature). To prevent the accumulation of water which is too hot in the container, the

Cooling Down to Set Value function should be started. After activating this option, when the collector's

temperature drops below that of the container, the pump is activated in order to cool down the tank

until it reaches the set temperature.

V.b.6) Delta Holiday

This function is active only in the Holiday Operating mode. This parameter determines how many °C

before reaching the collector overheat temperature the pump is activated in order to cool it down. The

pump is deactivated after the collector's temperature is reduced by at least 5°C.

IV.b) Solar Collector

This menu allows the user to adjust all parameters related to the Solar Collector.

V.c.1) Overheat Temperature

This is the Solar Collector's acceptable alarm temperature at which the pump is forced to activate in

order to cool down the solar panels. The discharge of warm water will take place regardless of the

tank's set temperature. The pump will operate until its temperature drops below the alarm temperature

by the Alarm Hysteresis Value (Service Settings > Solar Collector > Alarm Hysteresis) or until the tank

reaches the maximum acceptable temperature (Service Settings > Accumulation Tank > Maximum

Temperature)

V.c.2) Minimum Reheating Temperature

This is the collector's threshold temperature. If the temperature within the collector is higher and is

dropping after reaching the minimum reheating temperature, the pump is deactivated. On the other

hand, when the temperature on the collector is below this limit and is increasing - the pump is activated

after reaching the minimum reheating temperature plus hysteresis - 3°C. The threshold reheating

temperature is not active in the emergency mode, manual operation or collector defrosting.

V.c.3) Anti-Freeze Temperature

Due to the different freezing temperatures of the liquid in the solar installation, the Anti-Freeze

Tech

- 11 -

Temperature was introduced. This parameter determines the minimum safe temperature when the

glycol liquid does not freeze (temperature measured on the collector). In the case of a significant drop

in the collector's temperature (to the value of this parameter), the pump is activated and operates

continuously until the collector is heated to a safe temperature. The settings range of this coefficient is

within -50: +10°C.

V.c.4) Alarm Hysteresis

Using this function, the user declares the value of the collector's alarm hysteresis. If the tank reaches

the alarm temperature (Overheat Temperature) and the pump is activated, it will deactivate again when

the collector's temperature drops below the maximum temperature by the value of this hysteresis.

V.c.5) Defrosting Time

Using this function, the user determines for how long the pump is activated after the activation of the

function Collector Defrosting.

V.c.6) Collector Delta

Option active only in the case of setting the installation scheme number: 4.

Only one heating circulation is always active in this system. The switching valve is to switch the

circulation to the collector that currently has temperature higher at least by the value of collector delta

(this is the difference in temperatures of both Collectors).

V.e) Pumps

V.e.1) Pump's Revolutions, Adjusted or Constant

Using this function, the user defines the mode of the pump's operation. The use may select constant

revolutions when the pump operates at all times with full power (always when its operation is active)

or adjusted revolutions. In the case of adjusted revolutions, the user should adjust several additional

parameters (see below).

V.e.2) Collector's Maximum Temperature

Using this setting, the user declares the value of the collector's maximum alarm temperature when the

pump may be damaged. This temperature should be adjusted according to the collector's technical

data. Due to phenomenon of glycol "gelation" at high temperatures and the risk of damaging the Solar

Pump, the pump will be deactivated after reaching the maximum alarm temperature (the regulator

proceeds to the Collector Overheat mode).

V.e.3) Solar Pump Deactivation Delta

This function determines the difference between the collector temperature and the tank temperature

when the pump is deactivated (so as to avoid cooling down the tank).

V.e.4) Solar Pump Activation Delta

This function determines the difference between the Collector Temperature and the Tank Temperature

when the pump begins to operate (this is the pump activation threshold value).

V.e.5) Gear Coefficient

This parameter is active only if the pump's revolutions are set as adjusted. When the conditions for the

pump's activation are met, it is initially activated at minimum speed (Solar Pump's Operating Minimum).

Then, the pump increases its revolutions according to the setting of this coefficient, which determines

at how many °C of difference between the collector temperature and the tank temperature the pump

increases its operation revolutions by 10%. The gear coefficient applies only to the pump's operating

revolutions, namely the value of revolutions within the limits of the Solar Pump's operating minimum

(0% for the gear coefficient) as well as the solar pump operating maximum (100% for the gear

coefficient). The greater the difference in temperatures between the collector and the tank, the greater

the number of revolutions conducted by the pump.

Example:

If the gear coefficient value is 3, a change in the difference in temperatures between the collector and

the tank by each 3 degrees will lead to a change in the value of the pump's revolutions by 10%.

ST-401N User's Manual v 1.0.3

- 12 -

The table below contains examples of the coefficient's values depicting the operation of the gear

coefficient.

Gear Coeff. 3

Gear Coeff. 4

Gear Coeff. 5

Gear Coeff. 6

Pump's Operation

Revolutions

Value of Δ

(Collector's

Temperature –

Tank's

Temperature)

Δ3

Δ4

Δ5

Δ6

10%

Δ6

Δ8

Δ10

Δ12

20%

Δ9

Δ12

Δ15

Δ18

30%

Δ12

Δ16

Δ20

Δ24

40%

Δ15

Δ20

Δ25

Δ30

50%

V.e.6) Solar Pump Operating Minimum

This parameter is active only if the pump's revolutions are set as adjusted. Using this setting, the user

should define the pump's minimum initial revolutions.

V.e.7) Solar Pump Operating Maximum

This parameter is active only if the pump's revolutions are set as adjusted. Using this setting, the user

should define the pump's maximum percentage operation revolutions.

V.e.6) Circulation Sampling

This function allows the user to activate or deactivate circulation sampling aimed at updating the

temperature reading consisting in a short activation of the collector's pump (when normal conditions

for the pump's activation are not met). Sampling requires a short activation of the pump after growth

in the collector's temperature by at least 3°C.

V.f)

Peripherals

The user may connect and configure the settings of an additional device. If there is no additional device,

the user should select the position NO (deactivate). Additional available devices and examples of

connections supporting all available installation schemes are presented below.

In the case of using schemes 12 or 14, it is not possible to connect an additional device – the function

is inactive.

V.f.1) Circulation Pump

After selecting this device, the user should adjust the pump's periodical Operation Time and Stoppage

Time during its activity. Then, the user should define in which hours the pump will be active, with the

use of the "From" and "To" functions. Entering the same times ("From – To") will result in the device

being active throughout the whole day.

Tech

- 13 -

V.f.2) Firing up the PLT Boiler (pellet)

This option is used to adjust the voltage-free signal to fire up the pellet boiler. The user sets the

Activation Delta, namely the difference between the tank's set temperature and the tank's current

temperature which leads to the controller sending a signal to fire up the boiler. Then, the user selects

the time interval in which this function will be active (using the function "From" and "To")

V.f.3) Heater

The heater is used to electrically heat the tank. The principle of operation is similar to that in the

previous case but the heater should be connected by means of an additional contactor. The user sets

the activation delta (the difference between the tank's set temperature and the tank's current

temperature), below which the controller will activate the heater. Then, the user selects the time interval

in which the electric heating function will be active (by means of the "From" and "To" functions).

V.f.4) Contact (not) Consistent with Pump

This setting determines the operation of the voltage-free contact. If the icon "Contact Consistent with

Pump" is marked, then the voltage-free contact will close always when the pump operates (the

additional device will activate). Otherwise (when the icon is unmarked), the contact will open at each

activation of the solar pump.

V.g) Calculation of Energy

Entering the following values correctly will make it possible for measure the gained energy in a more

precise manner.

V.g.1) Flow

At this point, the user should specify the quantity of glycol that flows through the pump in one minute.

V.g.2) Type of Agent

This function allows the user to identify the agent used: ethylene glycol, propylene glycol or water.

V.g.3) Glycol Solution

At this point, the user should specify the percentage concentration of glycol in water.

ST-401N User's Manual v 1.0.3

- 14 -

V.g.4) Calibration

This function allows the user to calibrate the difference in temperatures between the sensors. The

temperature measurement takes place in the temperature sensor's installation place. There is a

possibility of deviations in the flow and temperature measurement at the return from the container.

The manufacturer does not recommend changing this setting.

V.h) Alarm Sound

This function allows the user to activate or deactivate the acoustic signal after an alarm.

V.i) Factory Settings

The regulator is pre-configured for operation. However, it should be adjusted for own needs. Return to

the factory settings is possible at any moment. Activating the factory settings option cancels all the

user's settings of the Solar Installation Controller (saved in the user's menu) and replaces them with

the settings saved by the boiler's manufacturer. From that moment, the user may once again adjust

their own parameters. Restoring factory settings will result in setting the default installation scheme as

current.

V. Protections

In order to ensure safe and failure-free operation, the regulator has been equipped with a range

of safeguards.

1. Installation Sensor Protection.

If one of the sensors is damaged, an acoustic signal is activated and the following symbol will appear

on the right hand side of the display: An additional icon informing the user about the sensor

that is disconnected or is damaged will flash in the place of the displayed temperature of the damaged

sensor. In order to deactivate the alarm signal in the sensor's error mode, the user should press the

Exit button.

2. Protection against Collector Overheat.

If the maximum temperature (alarm) is reached, the regulator proceeds to the so-called collector

overheat mode and the display will show the following symbol: . The pump begins to

operate in order to cool down the collector until the Tank's Maximum Temperature is reached or until

the collector's temperature drops by the value of the Alarm Hysteresis (see: SERVICE MENU > Solar

Collector> Alarm Hysteresis) In the case of two tanks, both of them are used to cool down the

overheated collector (at the same time or successively, depending on the operation algorithm setting).

3. Heat Container Protection.

In the case of collector overheat, each tank may be heated to no more than the set value of the

maximum safe temperature. After reaching this temperature, the pump of a given tank is stopped (in

the system with two tanks with a valve, the circulation is switched to the second tank).

4. Fuse.

The regulator is equipped with a WT 3,15A tube fuse-link protecting the network,

CAUTION

Higher amperage should not be used. Higher amperage fuse should not be used as it may damage the

controller.

Tech

- 15 -

V. Updating Software

NOTE

New software may be uploaded to the controller only by a qualified fitter. After the software is changed,

it is not possible to restore the previous settings.

In order to upload new software, the controller should be disconnected from the power supply. A USB

flash drive with new software should be inserted to the USB port. Then, the controller should be

connected to the power supply while holding the MENU button all the time. The MENU button should

be held until a single sound signal is heard – this means that the new software is being uploaded.

VI. Maintenance

Before and during the heating season, the ST-401N controller should be checked for the condition of

its cables. The user should also check if the controller is properly mounted and clean it if dusty or dirty.

Technical Data of ST-401N Controller

Power Supply Voltage

230V/50Hz +/-10%

Temperature Adjustment Range

8°C: 90°C

Power Consumption

max. 4W

Temperature Strength of PT 1000 Sensors

-30°C: 200°C

Measurement Accuracy

1°C

Ambient Temperature

5°C: 50°C

Load at Each Outlet

1A

Fuse Insert

3,15A

VII. Assembly

NOTE:

The device should be installed by a qualified electrician. Make sure that the plug is disconnected from

the power supply at that time.

CAUTION

The cable to the temperature sensor should be led in a shield and should be protected against weather

factors. The cable for connection to the solar controller should be permanent, made under a roof and

well insulated. Metal elements of the sensor and the collector installation should be earthed.

Schematic Diagram of the Collector Installation

ST-401N User's Manual v 1.0.3

- 16 -

*Schematic Diagram – the scheme does not replace the design of the CH installation It is aimed at

demonstrating the possibility for expanding the controller. The presented scheme of the heating

installation does not contain cut-off and protecting elements for the execution of its specialist

installation.

Tech

- 17 -

Table of contents

I. Safety.............................................................................................................................. 2

II. Application .................................................................................................................... 3

III. Principle Of operation ..................................................................................................... 3

IV. User Menu......................................................................................................................... 4

IV.a) Home Page .................................................................................................................. 4

IV.b) Main Menu – Flowchart.................................................................................................. 5

IV.c) Operation Mode ............................................................................................................ 5

IV.c.1) Automatic Operation................................................................................................ 5

IV.c.2) Collector Defrosting ................................................................................................. 5

IV.c.3) Holiday Mode .......................................................................................................... 6

IV.c.4) Anti-Legionella........................................................................................................ 6

IV.c.5) Manual Operation .................................................................................................... 6

IV.d) Timer.......................................................................................................................... 6

IV.e) Date ........................................................................................................................... 6

IV.f) Ethernet Module............................................................................................................ 6

IV.g) GSM Module................................................................................................................. 7

IV.h) Statistics ..................................................................................................................... 7

IV.h.1) Gain ...................................................................................................................... 7

IV.h.2) Collector Overheat .................................................................................................. 7

IV.h.3) Power Supply Failures.............................................................................................. 7

IV.i) Backlight ...................................................................................................................... 7

IV.j) Display Contrast............................................................................................................ 7

IV.k) Language .................................................................................................................... 7

IV.l) Information .................................................................................................................. 7

IV.m) Factory Settings .......................................................................................................... 8

V. Service Menu ................................................................................................................ 8

V.b) Accumulation Tank ....................................................................................................... 10

V.b.1) Set Temperature .................................................................................................... 10

V.b.2) Maximum Temperature of Tank 1 ............................................................................. 10

V.b.3) Minimum Temperature of Tank 1 .............................................................................. 10

V.b.4) Tank Hysteresis...................................................................................................... 10

V.b.5) Cooling Down to Set Value ...................................................................................... 10

V.b.6) Delta Holiday ......................................................................................................... 10

IV.b) Solar Collector....................................................................................................... 10

V.c.1) Overheat Temperature ............................................................................................ 10

V.c.2) Minimum Reheating Temperature ............................................................................. 10

V.c.3) Anti-Freeze Temperature ......................................................................................... 10

V.c.4) Alarm Hysteresis .................................................................................................... 11

ST-401N User's Manual v 1.0.3

- 18 -

V.c.5) Defrosting Time ..................................................................................................... 11

V.c.6) Collector Delta ....................................................................................................... 11

V.e) Pumps..................................................................................................................... 11

V.e.1) Pump's Revolutions, Adjusted or Constant ............................................................. 11

V.e.2) Collector's Maximum Temperature ........................................................................ 11

V.e.3) Solar Pump Deactivation Delta ............................................................................. 11

V.e.4) Solar Pump Activation Delta ................................................................................. 11

V.e.5) Gear Coefficient.................................................................................................. 11

V.e.6) Solar Pump Operating Minimum ........................................................................... 12

V.e.7) Solar Pump Operating Maximum........................................................................... 12

V.e.6) Circulation Sampling ........................................................................................... 12

V.f) Peripherals............................................................................................................... 12

V.f.1) Circulation Pump ................................................................................................ 12

V.f.2) Firing up the PLT Boiler (pellet) ............................................................................ 13

V.f.3) Heater............................................................................................................... 13

V.f.4) Contact (not) Consistent with Pump ...................................................................... 13

V.g) Calculation of Energy ................................................................................................ 13

V.g.1) Flow.................................................................................................................. 13

V.g.2) Type of Agent..................................................................................................... 13

V.g.3) Glycol Solution ................................................................................................... 13

V.g.4) Calibration ......................................................................................................... 14

V.h) Alarm Sound ............................................................................................................ 14

V.i) Factory Settings ....................................................................................................... 14

V. Protections ....................................................................................................................... 14

V. Updating Software ............................................................................................................. 15

VI. Maintenance.................................................................................................................... 15

VII. Assembly ....................................................................................................................... 15

Care for the natural environment is our priority. Being aware of the fact that we manufacture

electronic devices obligates us dispose of used elements and electronic equipment in a manner

which is safe for nature. As a result, the company has received a registry number assigned by the

Main Inspector of Environmental Protection. The symbol of a crossed out rubbish bin on a product

means that the product must not be thrown out to ordinary waste bins. By segregating waste

intended for recycling, we help protect the natural environment. It is the user's responsibility to

transfer waste electrical and electronic equipment to the selected collection point for recycling of

waste generated from electronic and electrical equipment.

Tech

- 19 -

Declaration of conformity no 62/2012

The company TECH, based in Wieprz 1047A, 34-122 Wieprz,

declares with complete liability that our temperature regulator

ST-401N 230V, 50Hz meets the requirements of the Regulation

of the Minister of Economy, Labor and Social Policy (Journal of

Laws No 155, item 1,089) dated August 21st, 2007 implementing

the provisions of the Low Voltage Directive (LVD)

2006/95/EC,, the Act dated April 13th, 2007 on

electromagnetic compatibility (Journal of Laws 07.82.556)

implementing the provisions of Directive (EMC) 2004/108/EC,

as well as the Regulation of the Minister of Economy dated May

8th, 2013 "on basic requirements on the restriction of the use of

certain hazardous substances in electrical and electronic

equipment" implementing the provisions of Directive ROHS

2011/65/EC.

Harmonized standards were used to assess the conformity

PN-EN 60730-2-9:2011, PN-EN 60730-1:2012.

The product was marked with CE :12-05-2014

Wieprz, April 14th, 2015

ST-401N User's Manual v 1.0.3

- 20 -

Table of contents

Other TECH Controllers manuals