TECH ST-26 Assembly instructions

ST – 26

Manual Guide

ST-26 – Manual Guide

TECH

Declaration of compatibility number 7/2006

We, the TEC Company, 14, St. Batorego Street, 34-120

Andrychów, declare with absolute liability that this

thermoregulator ST – 26 230V, 50 Z, produced by our

company, fulfils the requirements of Ordinance of the

Minister of Economy, Labour and Social Policy (Dz.U.

03.49.414) from 12th March 2003, implementing the

provisions of Low Voltage Directive 73/23/EEC and

Ordinance of the Minister of Infrastructure (Dz.U.

03.90.848) from 2nd April 2004 implementing the

provisions of Directive EMC 89/336/EEC.

To conformity assessment there were used harmonized

standards

PN-EN 60730-2-1:2002.

The product was marked with CE for the first time on 3rd

January 2006

Proprietors:

Paweł Jura, Janusz Master

Andrychów, 03.01.2006r

- 2 -

TECH

Attention!

THE LIVE ELECT IC DEVICE!

Before doing any activities connected with

power supply (connecting wires,

installation of the device, etc) it is

necessary to make sure that the regulator

is not connected to the grid!

Assembly and installation should only be

carried out by qualified electrician.

Before activating the controller it is

necessary to do the measurement of

effectiveness of resetting electric motors,

the boiler and the measurement of

insulation of electric wires.

- 3 -

ST-26 – Manual Guide

I. Description

The temperature regulator ST-26 is designed for the central heating

boiler. It controls the circulation of water pump and air-blow (fan).

●If the temperature of the stove is lower than Set temperature, the

regulator is in operating mode in which the air blow is working all the

time.

●If the temperature of the stove is equal or higher than Set

temperature, the regulator is in back-up mode.

- 4 -

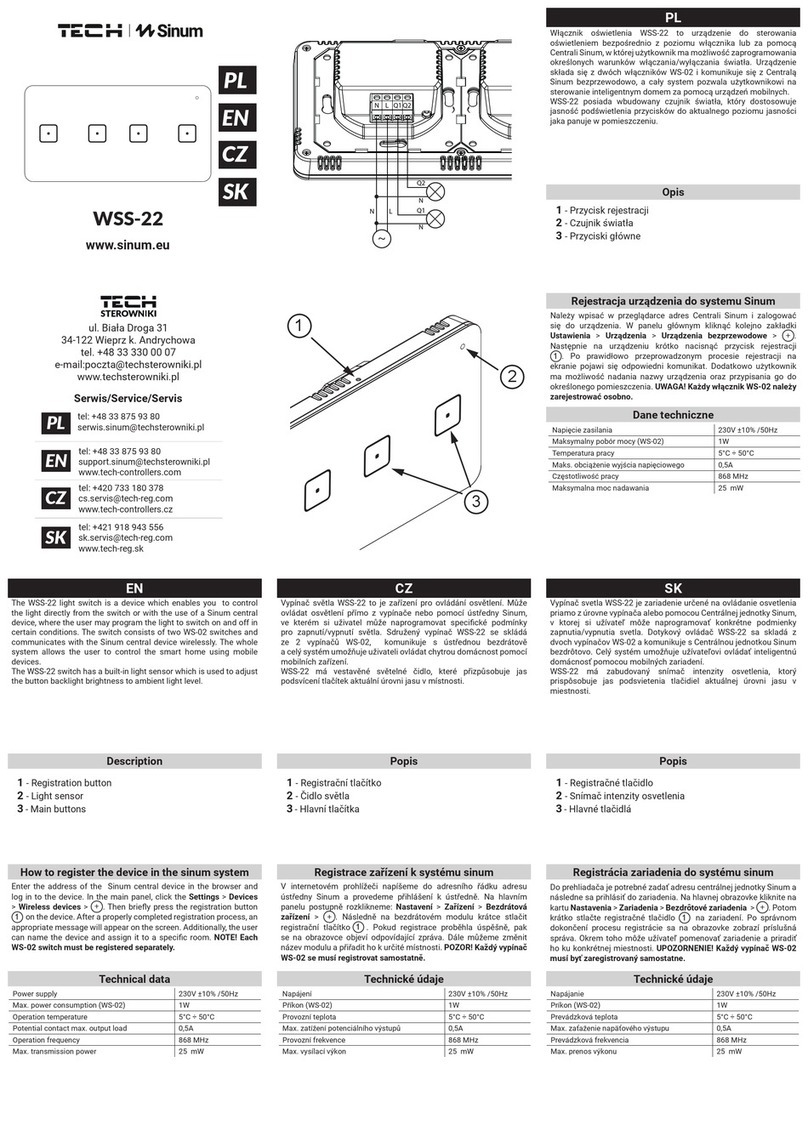

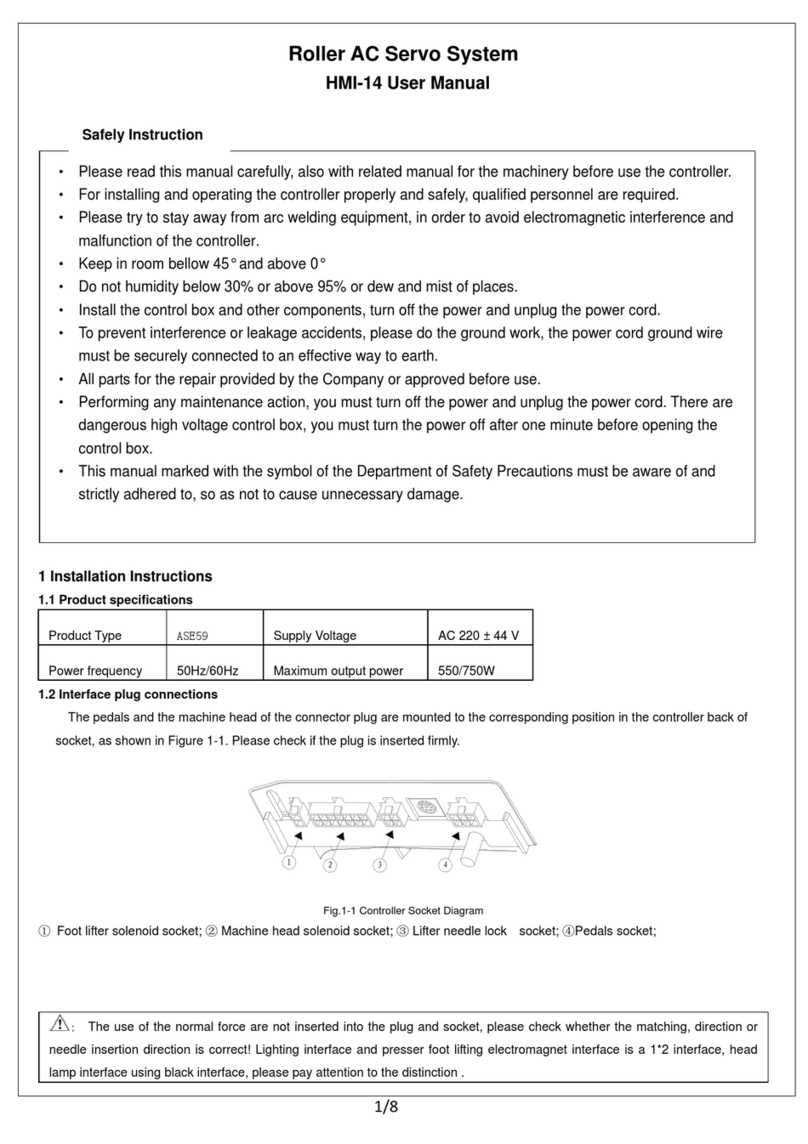

MINUS button

Return from the

menu and cancel

the settings button

Entrance to

submenu and

confirmation of

settings button

PLUS button

TECH

II. Functions of the regulator.

This section describes functions of the regulator, the way of

changing settings, and moving the menu.

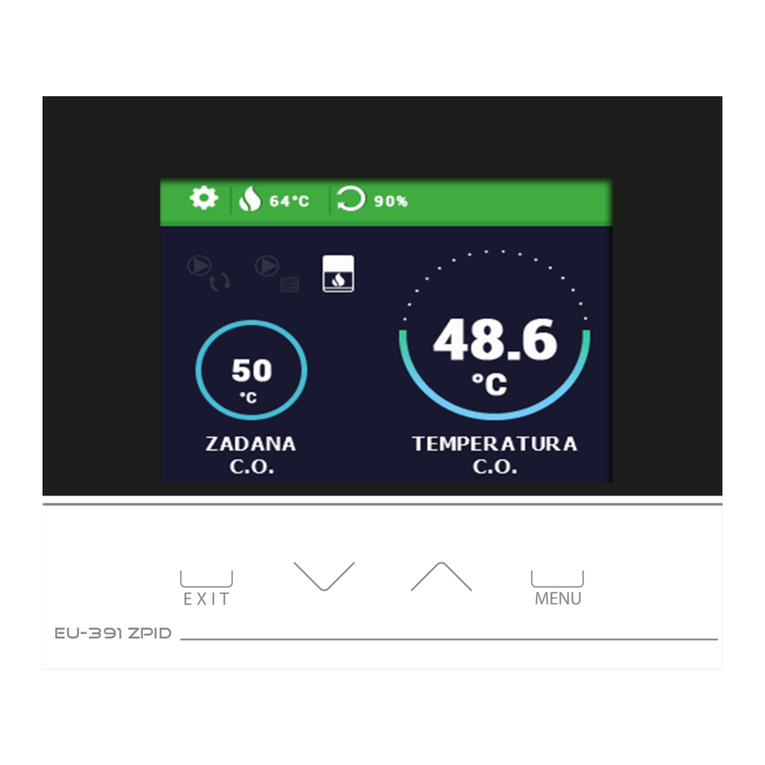

II.a) Main page

During normal working of the regulator in the LCD display you can

see the main page on which there are displayed following informations:

●Temperature of the stove

●Set temperature

This screen makes possible quick change of set temperature by the

PLUS and MINUS buttons. Pressing the options button will move the

user to first level menu. On the display there are displayed the two first

lines of the menu. On the menu you can move by using PLUS and

MINUS buttons. Pressing the Options button will move you to the next

submenu or it will start the option. EXIT moves you back to main menu.

II.b) Lighting

The lighting function is designed for turning the fan on and off

during continuous controller’s work. If the boiler reaches the

temperature over 30°C and the boiler does not reach set temperature,

then the button fulfils START-STOP function. By using this function you

can turn the fan on and off while his working. It is signalized by pulsar

shining Manual Work diode. This function is designed for enabling the

user safe service of the boiler. When the fan is on, you mustn’t open the

hearth’s door.

II.c) Manual Work

In order to user’s comfort, the regulator has Manual Work. In this

function, every element of the system is turned on and off irrespective of

the rest.

- 5 -

62oc 72oc

CH temp req temp

62oc 72oc

CH temp req temp

ST-26 – Manual Guide

Pressing OPTIONS buttons activates the air-blow. The air-blow

remains activated till pressing again OPTIONS.

Pressing MENU turns on / off the water’s pump.

Pressing MENU turns on / off the alarm

II.d) Air-blow’s speed

This function controls the fan’s working speed. Range of adjustment

is from 1 to 6 (it can be said that these are fan’s gears). The biggest the

gear is, the faster the fan is working. The first gear – it is a minimum

speed of the fan and 6th gear is a maximum speed of the fan.

To change the range of fan’s gears, press the button PLUS and

MINUS. The fan always turns on in the beginning with full speed – it

makes possible turning the fan on when the motor is a little dusty.

- 6 -

Air blow

pump

pump

ALARM

03 gear

air-blow's speed

Air-blow's speed

air-blow's brea

Air blow

Pump

62oc 72oc

CH temp req temp

TECH

II.e) Burning

This function is used to regulate working the boiler during its

working in back-up mode. It prevents from extinguishing the boiler when

the temperature of the boiler remains over set temperature.

In this function you can set time of air-blow’s break. After set time, on

the time set by the boiler’s producer, the air-blow turns on. The time of

air-blow working you can change in the service functions. Time of

burning’s break you should set dependence on the fuel and a type of the

boiler.

ATTENTION: Wrong setting the options included above can cause

continuous rising the temperature! Time of burning’s break shouldn’t be

too short.

II.f) Minimal re olutions

On this gear the fan reaches set temperature – for instance you set

the second gear, and the fan will be gradually slowing down by every

single degree Celsius from the 6th gear to the minimal value (that is 2).

The fan will be working on the 2nd gear till reaching set temperature.

- 7 -

Air-blow's brea

Air-blow's wor

1 gear

minimal rev.

62oc 72oc

CH temp req temp

62oc 72oc

CH temp req temp

ST-26 – Manual Guide

II.g) Factory settings

The fan is tentatively preset to work. owever, you should adjust it

to your own needs. In every moment it is possible to return to factory

settings.

III. Protection

In order to ensure maximum safe and failure-free working, the

regulator has a number of protections. In the case of an alarm, the sound

signal encloses and there appears adequate message on the display.

When you press MENU the controller returns to working.

III.a) Thermal protection

It is additional mini bimetallic sensor (it is placed near the stove

sensor) which cuts off the output of the fan in the case of exceeded

90°C. It prevents from boiling the water in the case of damage of

thermoregulator.

III.b) Automatic controlling the sensor

In the case of damage of central heating temperature’s sensor, the

alarm becomes active and it signals additionally the fault on the display.:

The air-blow is turned off. The pump is turned on irrespective from

current temperature. The regulator is waiting for pressing MENU button

and then the alarm is turned off and the controller returns to normal

working.

- 8 -

A L A R M

sensor damaged

no

yes

f

factory settings

62oc 72oc

CH temp req temp

TECH

III.c) Temperature protection

In the case of damage of bimetallic sensor the regulator has

additional protection: after exceeding the 95°C temperature, the alarm is

turned on and it is signaled on the display:

III.d) The fuse

The regulator has cartridge fuse WT 1,6A which protects the grid.

IV. Maintenance of the controller.

Before heating season and in the time of his duration there should

be checked the technical status of the wires in the controller ST 26. The

fastening of the controller, cleaning up and dusting must be checked, too.

It must be done the measurement of effectiveness of motors’ earthing

(pump and blow)

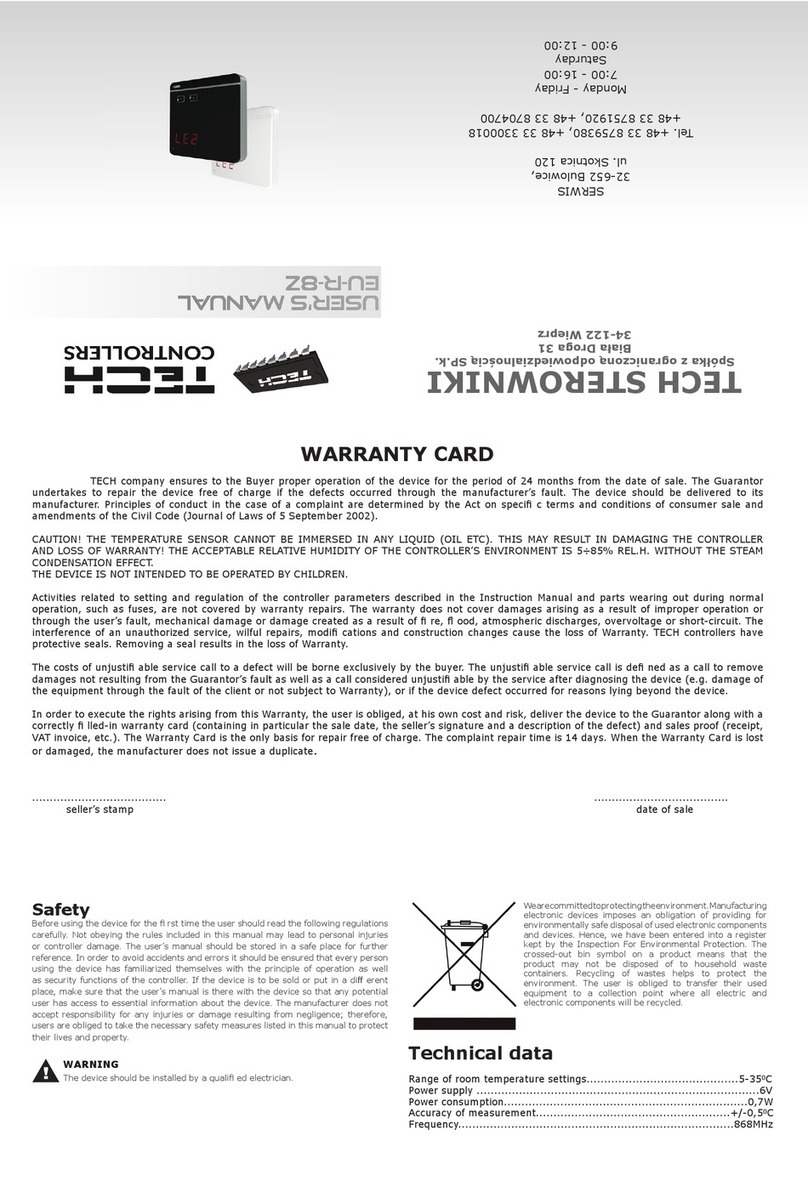

L.p. Specification Unit

1 Power supply V 230V/50 z +/-10%

2 Power consumption W 2

3 Surroundings temperature OC 00

4 Output load of circulating pump A 1

5 Temperature measuring range OC 0

6 Measuring accuracy OC 1

7 Temperature setting range OC

8 Temperature strength of sensor OC-

- 9 -

A L A R M

temp too high

ST-26 – Manual Guide

V. Service

In the case of appearing faults you should contact with:

TEC Civil Partnership

14, St. Batorego Street, 34-120 Andrychów, Poland

Phone: +48 33 8705105, +48 33 8759380

VI. Assembly

Attention: The assembly should be done only by the person with

proper qualifications! The device in this time mustn’t be live (you should

ensure that plug is disconnected from the grid)!

ATTENTION: wrong connection of wires can cause the

damage of the regulator!

The regulator cannot work in closed circuit of central heating. The

balance tank, safety valves and pressure valves that protect by boiling

the water in the central heating circuit must be mounted.

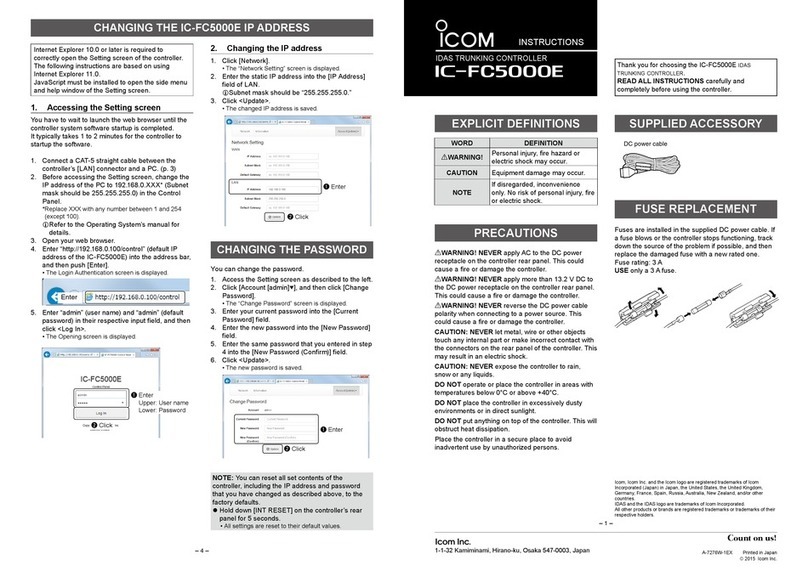

VI.a) The diagram of cables connection to the

controller.

While assembly of wiring of the controller you should pay special

attention to correct connecting ground wires.

PE – earthing (yellow and green)

N – neutral (blue)

L – phase (brown)

- 10 -

PE

FUSE 6.3A

230V AC

air-blow

230V AC

central heating pump

N

L

~

relay

~

relay

Spis treści

II. Functions of the regulator.....................................................5

II.a) Main page....................................................................5

II.b) Lighting.......................................................................5

II.c) Manual Work.................................................................5

II.d) Air-blow’s speed............................................................6

II.e) Burning .......................................................................7

II.f) Minimal revolutions.......................................................7

II.g) Factory settings............................................................8

III. Protection.........................................................................8

III.a) Thermal protection.......................................................8

III.b) Automatic controlling the sensor....................................8

III.c) Temperature protection.................................................9

III.d) The fuse.....................................................................9

IV. Maintenance of the controller...............................................9

V. Service.............................................................................10

VI. Assembly........................................................................10

VI.a) The diagram of cables connection to the controller..........10

WA ANTY

The TECH Company guarantees the buyer correct functioning

of the device for 30 months from the date of purchasing. Guarantor

obliges to repair without charge of the device if the fault appears

from the guilt of the producer. The device should be delivered to

the place where the product was purchased. All connected with

these costs incur the user.

ATTENTION!! The temperature sensor mustn’t be

immersed in any liquid (oil etc.). It menaces damage of the

controller and the loss of the warranty!

You mustn’t remove insulation that is put on the

bimetallic minisensor. Its removal can cause that the

controller will wrong work.

The warranty does not include damages arising out of misuse,

or due to user; the mechanical damages and appeared due to

atmospheric discharge, over voltage, and short-circuit.

The warranty without attached receipt, date of sale, date of

delivery and signatures is invalid.

The warranty card is the only base of free repair.

In the case of loosing or destroying the warranty card the producer

does not give the duplicate

................... ................... ................

Date of delivery Salesman’s stamp Date of sale

Table of contents

Other TECH Controllers manuals