Techniks SHRINKPRO User manual

www.techniksusa.com

Model 00500-M

ShrinkPRO Quencher

SHRINKPRO MACHINE

OPERATIONS MANUAL

COMPLETE INSTALLATION AND TROUBLESHOOTING GUIDE

Model 00600-M

ShrinkPRO

Techniks Inc. 9930 E. 56th St. Indianapolis, IN 46236 | 800.597.3921 | www.techniksusa.com | [email protected]

Techniks is a proud member of Techniks Tool Group. Connect with Techniks Tool Group

1

The Model 00500-M and the Model 00600-M have been constructed using the latest technology and are

extremely safe and easy to operate. Despite that, there is still some danger if these units are operated

incorrectly and/or by untrained personnel.

Pay particular attention to the following Cautions and Warnings marked with the “Attention” and “Danger”

symbols. Failure to follow safe operating practices may cause injuries, death, or damage to the machine,

and may void your manufacturers’ warranties.

• Before attempting to use the unit you must have

read and fully understood this Owners Manual.

Keep this Owners Manual within easy reach of

operating personnel.

• Visually inspect the unit, power cord, and

accessory items for any signs of wear or

damage before operating the unit. Do not use

the unit if there is any sign of damage, or if the

unit is not performing normally.

• Never operate the machine without the correct

induction stop ring in place on the induction

head. Do not allow any part of the induction

head to contact the toolholder or cutting tool

during operation or damage to the machine may

occur.

• Do not wear rings, bracelets, or other metallic

objects while operating the machine. Metallic

objects may heat up very quickly when near the

induction head during operation.

• Use the provided thermal insulated glove

whenever handling tools or toolholders. Never

try to handle hot tools or toolholders until the

cooling cycle is complete.

• If the machine is moved from a cold environment

to a warm one, wait two hours before operating

to prevent condensation build-up from causing

electronic system errors.

• Persons with heart pacemakers may not

operate the machine, and must maintain a

minimum safe distance of 6 feet (2 meters)

from the machine at all times.

• Cutting tools have sharp edges. Handle with

caution.

• Operating the unit while improperly connected

or at the wrong voltage may damage the unit

and could possibly cause death or injury.

• Position the power cord so it cannot be damaged

by fork trucks or other equipment, or cause a

tripping hazard for personnel.

• Do not operate the machine in a wet environment

where exposure to coolant or spills are likely

to occur. Electric shocks or damage to the

machine may occur.

• Never operate the machine around flammable

materials, or fumes. Do not use flammable

liquids or aerosols to clean toolholders. Never

expose the machine or hot tools to combustible

materials.

• Never open the machine or attempt repairs

or you will VOID the manufacturer’s warranty.

Dangerous residual voltage is inside that may

cause death or injury.

• Unauthorized modifications or changes

to the ShrinkPRO machine will VOID your

manufacturer’s warranty. Do not try and service

your unit yourself. Techniks can provide any

necessary repairs or maintenance. Do not

modify or disable the built-in safety features of

the machine.

• Turn off the power switch and disconnect the

power cord from the outlet before cleaning,

servicing, or storing the unit.

Make sure you read, understand and follow these Cautions and Warnings, as well as the complete technical notes,

setup and operation instructions before installing and using your machine.

IMPORTANT - CAUTIONS & WARNINGS

2

Satisfaction guaranteed on all our CNC tooling solutions | www.techniksusa.com

IMPORTANT – TECHNICAL NOTES

POWER REQUIREMENTS

ShrinkPRO Models 00500-M and 00600-M have been designed to operate on 480VAC 3 phase power.

The maximum power output exceeds 22,000 watts.

NOTE: Do not activate the heat controls without a toolholder in position.

AUDIBLE FEEDBACK

During operation, ShrinkPRO machines power source generates an audible feedback tone that changes

frequency depending on the toolholder size and temperature. It is not unusual to hear a pitch change as

the toolholder temperature increases. Do not be alarmed if you hear this tone as it is normal.

SHRINKFIT TOOLHOLDERS

Techniks ShrinkPRO machines make it easy and safe to perform shrink fit tool changes without causing

damage to the toolholder or cutting tool, as long as the machine is correctly installed and proper operating

procedures are followed.

ShrinkPRO machines are designed to work best with Techniks shrinkfit toolholders made from H13 tool

steel with bore diameters from 1/8” to 1-1/4” (3mm to 32mm). They are designed for shrink fitting tools

with carbide shanks. Tool shank diameter tolerance is critical. At least an H6 tolerance is advised for

optimum performance.

Make sure toolholders are clean and free from defects before inserting the tool in the toolholder. If debris

or a burr is inserted into the toolholder with the tool, tool-life may be reduced. Damage to the tool or

toolholder may also occur as the tool may be difficult or impossible to extract.

NOTE: Toolholders must be at room temperature before attempting to extract the cutting tool.

CUTTING TOOLS

Cutting tool shanks must be perfectly clean and free from burrs, scoring, or any damage. Any imperfections

in the shank can cause the cutting tool to lodge permanently in the toolholder. Burnished shanks can slip

in Shrink Fit holders under some conditions. Sand blasting the cutter shanks has improved the holding

power.

Techniks ShrinkFIT holders are made of H13 tool steel, tempered at >1000˚F. Heating a toolholder to or

above temper point will permanently damage the holding power of the toolholder. Never use an alternate

heat source on shrink fit toolholders or damage to the toolholder and cutting tool may occur.

3

00600-M PARTS IDENTIFICATION & MACHINE REQUIREMENTS

Model 00600-M ShrinkPRO

width 20” x depth 20” x height 37” - Weight: 84 lbs

Induction Head

Pedestal & Pedestal Ring

Touch Screen

Power Switch

NPT Air Inlet (on back)

MACHINE IDENTIFICATION

FEATURES

• Induction coil technology enables

tool changes in 3-6 seconds

• Easy to use touch screen design

• Heating time is automatically set

by tool diameter

• Cooling cycle uses shop air

PRODUCT SPECS

1

1

3

5

2

4

2

3

4

5

toolholder seats

induction ring insulated glove

rated to 500˚ F / 260˚ C

Part No. Tool Diameters Power L x D x H Ship Wt.

00600-M 1/8” -1-1/4” 480V, 30A, 3 phase 20” x 20” x 37” 84 lbs

Part No. Description

00165 Induction Ring (3 - 5mm shanks)

00166 Induction Ring (6 - 12mm shanks)

00167 Induction Ring (14 - 20mm shanks)

00168 Induction Ring (25 - 32mm shanks)

00600-9006 Tool Holder Adapter – HSK63/HSK100

00600-9002 Tool Holder Adapter – 40 taper

00600-9003 Tool Holder Adapter – HSK40

00600-9004 Tool Holder Adapter – HSK50

00600-9005 Tool Holder Adapter – 30 taper

00600-9006 Tool Holder Adapter – PSC6

26139-L Thermal Insulated Glove

EACH SHRINKPRO AND QUENCHER SHIPS WITH:

REQUIREMENTS:

• Electrical Supply: 480 VAC,

3 phase, 30 amp connection

(recommended).

• 50/60 Hz. Power output is 22,000

watts. NEMA L16-30R receptacle.

• Air Supply: 90 psi supply of dry

shop air. The use of an in-line

filter is required.

4

Satisfaction guaranteed on all our CNC tooling solutions | www.techniksusa.com

00500-M PARTS IDENTIFICATION & MACHINE REQUIREMENTS

FEATURES

• Induction coil technology enables

tool changes in 3-6 seconds

• Easy to use touch screen design

• Heating time is automatically set

by tool diameter

• Coolant bath and air-drying system

cools tools in under 30 seconds

PRODUCT SPECS

Quencher features a liquid cooling

cycle that is 250% FASTER than

air-cooled units.

Model 00500-M ShrinkPRO Quencher

width 36.75" x depth 24" x height 71" - Weight: 292 lbs

MECHANICALS

Pedestal Speed Flow Controls

Mechanical Access Door

Coolant Flow Bypass Control

Coolant Flow Control

Air Pressure Regulator

Coolant Drain Valve

3

1

5

4

2

6

1

2

3

4

5

6

MACHINE IDENTIFICATION

REMINDER: Always use the supplied insulated glove and exercise

caution when handling toolholders. All personnel should be clear of the

machine before starting the tool change or Quench cycle. Never touch

any toolholders that are not properly cooled. The Quenching Time and

coolant flow must be set to provide adequate cooling time to protect

personnel from injury caused by improperly cooled toolholders.

Part No. Tool Diameters Power L x D x H Ship Wt.

00500-M 1/8” -1-1/4” 480V, 30A, 3 phase 37” x 24” x 71” 660 lbs

Part No. Description

00500-C 1 Gallon Quencher Coolant

EACH QUENCHER SHIPS WITH:

5

coolant

nozzles

SETUP & INSTALLATION

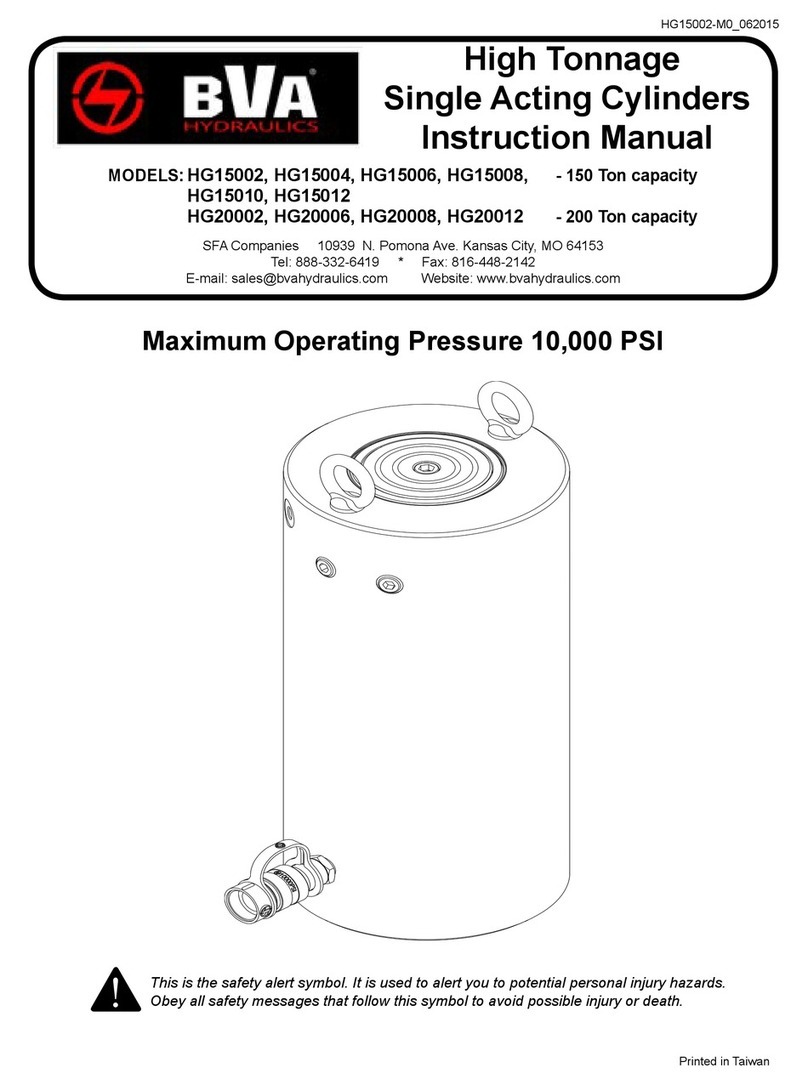

• Turn the power switch clockwise to turn on the machine. Wait as your

machine powers up and displays the input screen.

• Touch “Head Air On” to test the Air connection. “Head Air Off” to cancel.

• Touch the “Quench Start” button on the touch screen. The pedestal

should lower into the coolant well and return automatically.

• Verify coolant is flowing from the internal coolant nozzles, filling the

pedestal well.

• Your Quencher is now ready for use.

VERIFYING PROPER INSTALLATION (QUENCHER)

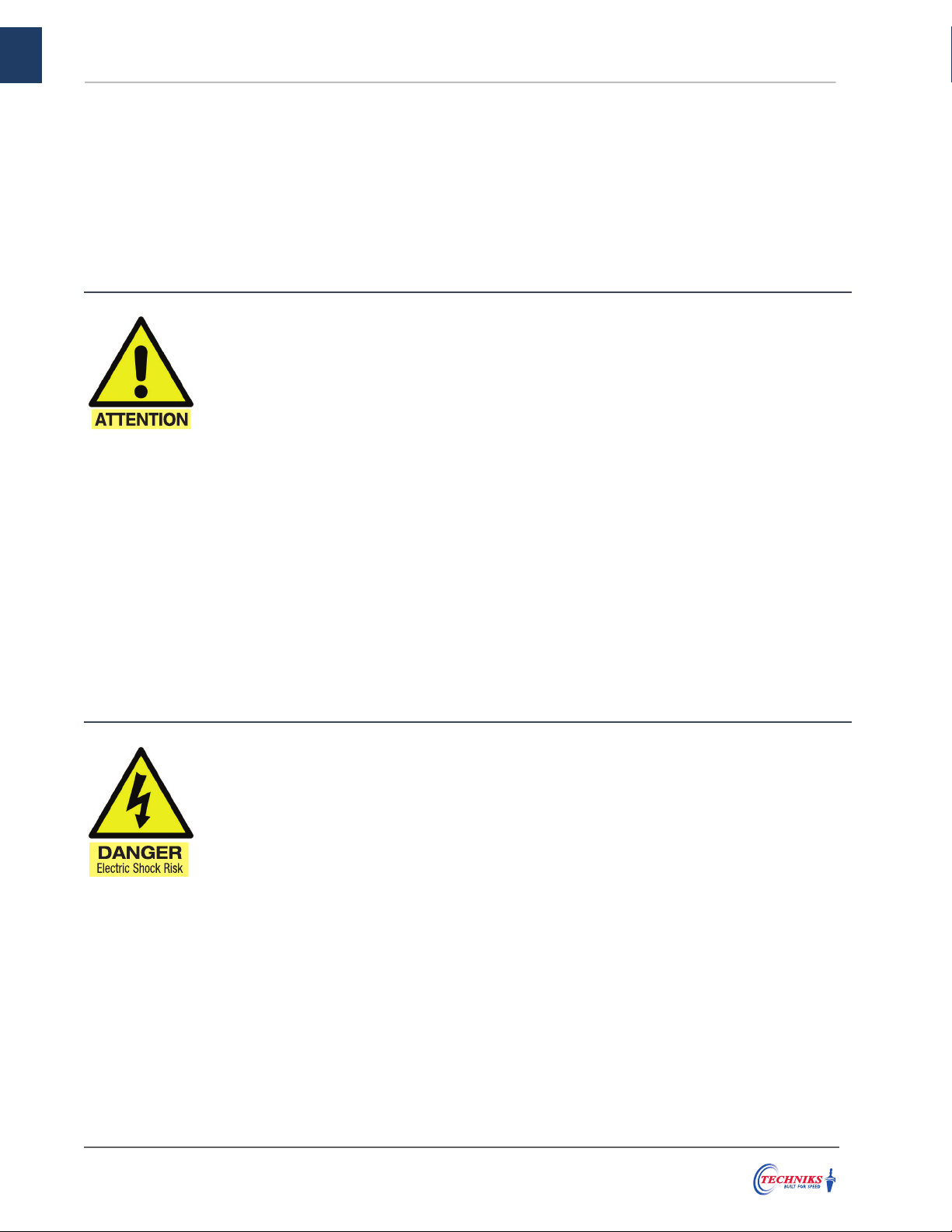

• Connect the machine to your power supply.

• Connect the source air line to the machine’s air inlet.

• Verify the gauge on the Air Pressure Regulator reads 90 psi.

• Carefully pour approximately 20 gallons of clean water into the Quench

tank through the pedestal hole.

• Fill tank up to Fluid Level line. Do not spill any water on the machine.

QUENCHER SETUP

VERIFYING PROPER INSTALLATION (SHRINKPRO)

• Turn the power switch clockwise to turn on the machine.

• Wait as your machine powers up and displays the input screen.

• Touch “Head Air On” to test the Air connection. “Head Air Off” to cancel.

• Your ShrinkPRO is now ready for use.

• The 00600-M ShrinkPRO requires a level, stable surface and good

ventilation for proper operation. Keep the machine clean and dry at all

times.

• Connect the machine to your power supply. The machine operates on

208V-480VAC on a 3-phase 30 amp circuit.

• Connect the source air line to the machine’s air inlet (90 psi required).

SHRINKPRO SETUP

6

Satisfaction guaranteed on all our CNC tooling solutions | www.techniksusa.com

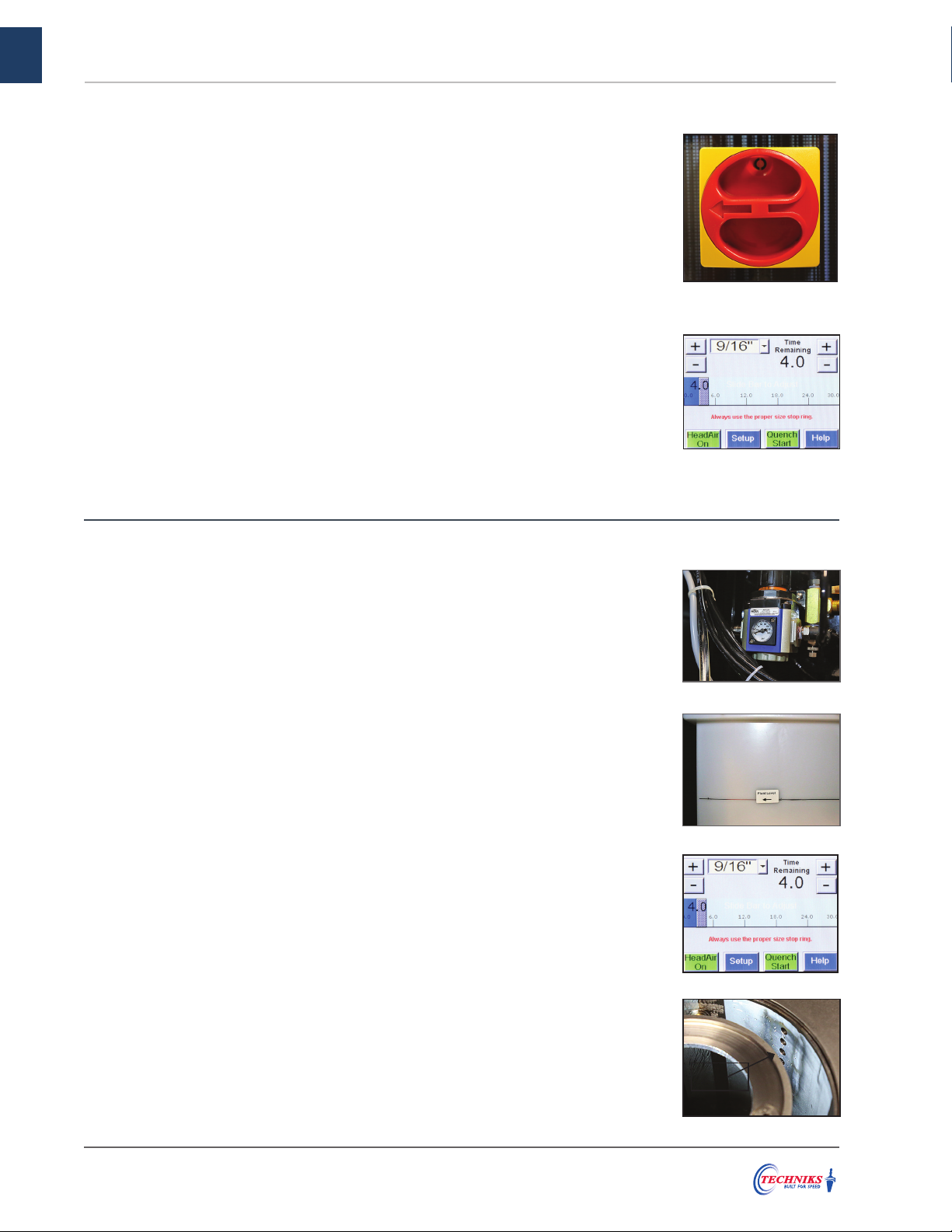

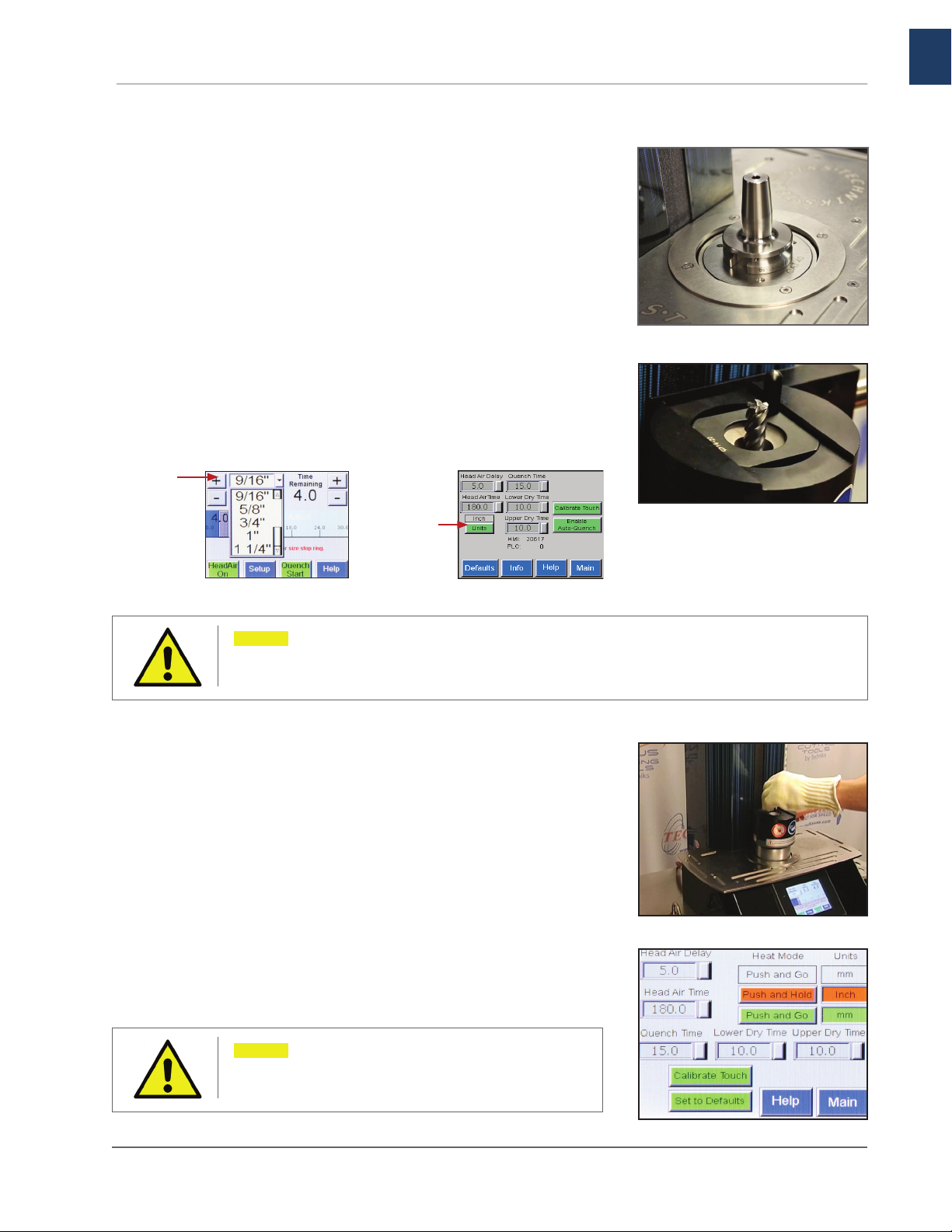

• Choose the toolholder seat that corresponds with your toolholder.

• Place the seat over the pedestal hole and insert your toolholder.

• Choose the induction stop ring that corresponds with your

toolholder.

• Place the stop ring into the induction head, rotate it 90˚ to secure

its position.

• Lower the induction head until there is an a 1/8” gap between the

stop ring and the end of the toolholder.

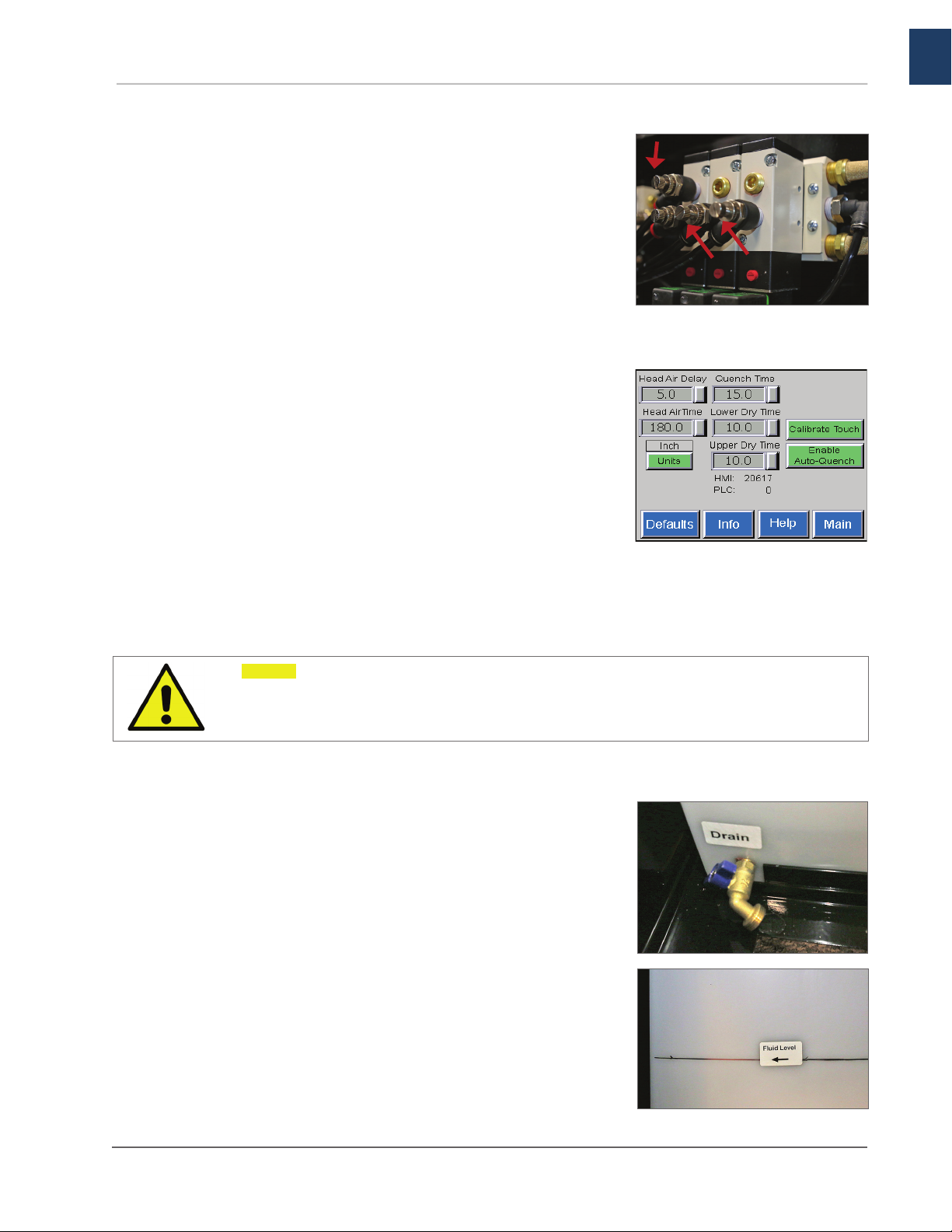

• From the main screen, select your tool shank size. You can switch

between inch or millimeter using the setup screen.

INSERTING YOUR CUTTING TOOL

• Heating duration is set by default based upon shank size. Use the

gray slider bar on the touch screen to add or subtract time.

• Wearing the insulated glove on one hand, with your other hand,

press and hold the red button located on the induction head.

• After 2–3 seconds attempt to insert the cutting tool into the

toolholder. Continue holding the button until the cutting tool is

successfully inserted into the toolholder. You can stop the heating

cycle at any time by releasing the red button.

HEATING CYCLE

Note: Never allow any part of the induction head

to contact the toolholder or cutting tool during

the heating cycle or damage to the machine may

occur.

REMINDER: Always inspect your cutting tool for any imperfections on the shank such as chips, burrs, or scarring. If you find any,

do not use that cutting tool in a shrink-fit toolholder, or it may no be able to remove it. The ability to insert and remove tools is

enhanced when cutting tools and holders are dry and clean.

REMINDER: If the heat cycle ends before the cutting tool can be inserted,

increase the duration by 10%. If the cutting tool is inserted before the

cycle ends, you may reduce the duration for that shank size.

Use the drop

down menu to

choose your

shank size

Touch units to

switch between

inches or metric

OPERATIONS GUIDE

7

EXTRACTING YOUR CUTTING TOOL

• The cooling cycle automatically begins 5 seconds after the heating

cycle ends. The cooling cycle automatically stops after 3 minutes.

• You can manually stop the cooling cycle after 30 seconds by

touching the “Head Air Off” button.

• Touch the“Head Air On” buttons to restart.

COOLING CYCLE (00600-M SHRINKPRO)

• Touch the “Quench Start” button to begin the 30 second cooling

cycle. The hot tool will be automatically lowered into the coolant

tank, the Head Air will automatically begin cooling the head.

• As the toolholder returns to the start position, high-pressure air

nozzles will remove excess moisture.

• Raise the induction head out of the way to make room to remove

the cutting tool.

COOLING CYCLE (00500-M QUENCHER)

Note: Always wear the insulated glove when

handling tools, even after the cooling cycle has

completed.

Note: Toolholders for smaller cutting tools

require less power to heat, but must be heated

to a higher temperature than larger tools to

perform insertion and extraction.

• Toolholders must be at room temperature before attempting

to extract the cutting tool. Place the toolholder / cutting tool

assembly into the seat and secure the stop ring into the induction

head. Lower the head until there is an 1/8” gap between the stop

ring and the end of the toolholder.

• From the main screen, select your tool shank size.

• Begin heating procedure: Wearing the insulated glove on one

hand, with the other hand, press and hold the red “Start” button

located on the induction head. Continue holding the “Start” button

throughout the heating cycle.

• Approximately 2-3 seconds before the heating cycle ends, attempt

to remove the tool from the toolholder with the gloved hand.

• The heating cycle will stop automatically at the end of the set

duration.

OPERATIONS GUIDE

REMINDER: If the tool cannot be extracted on the first try, cool the tool to

room temperature and increase the heating duration by 10% and try again.

8

Satisfaction guaranteed on all our CNC tooling solutions | www.techniksusa.com

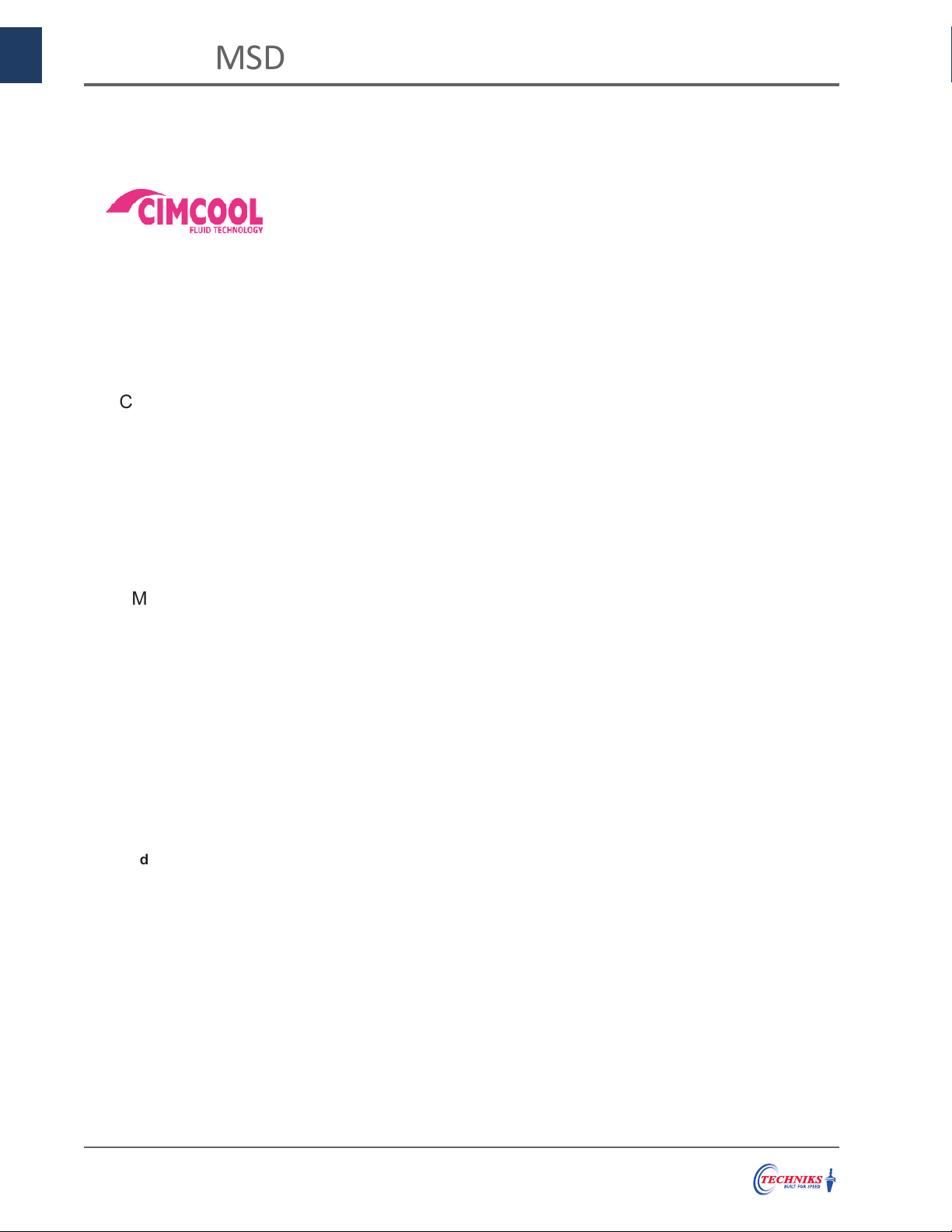

ADJUSTING COOLING TIME

• The descending speed of the toolholder is adjusted by the speed

flow control on Port B of the air valve.

• If the descending speed is set too slow, there may not be adequate

cooling time.

• On the Setup screen, adjust the “Quench Time” to account for poor

cooling due to a slow descending speed.

ADJUSTING DRYING TIME

• The ascending speed of the toolholder is adjusted by the speed

flow control on Port A of the air valve. If the ascending speed is

too high, there may not be adequate time for the toolholder to dry.

• On the Setup screen, adjust the “Lower Dry Time” so the lower dry

air valve shuts off after the pedestal passes the lower nozzles.

• Adjust the “Upper Dry Time” so the upper dry air valve shuts off

when the pedestal reaches the top position.

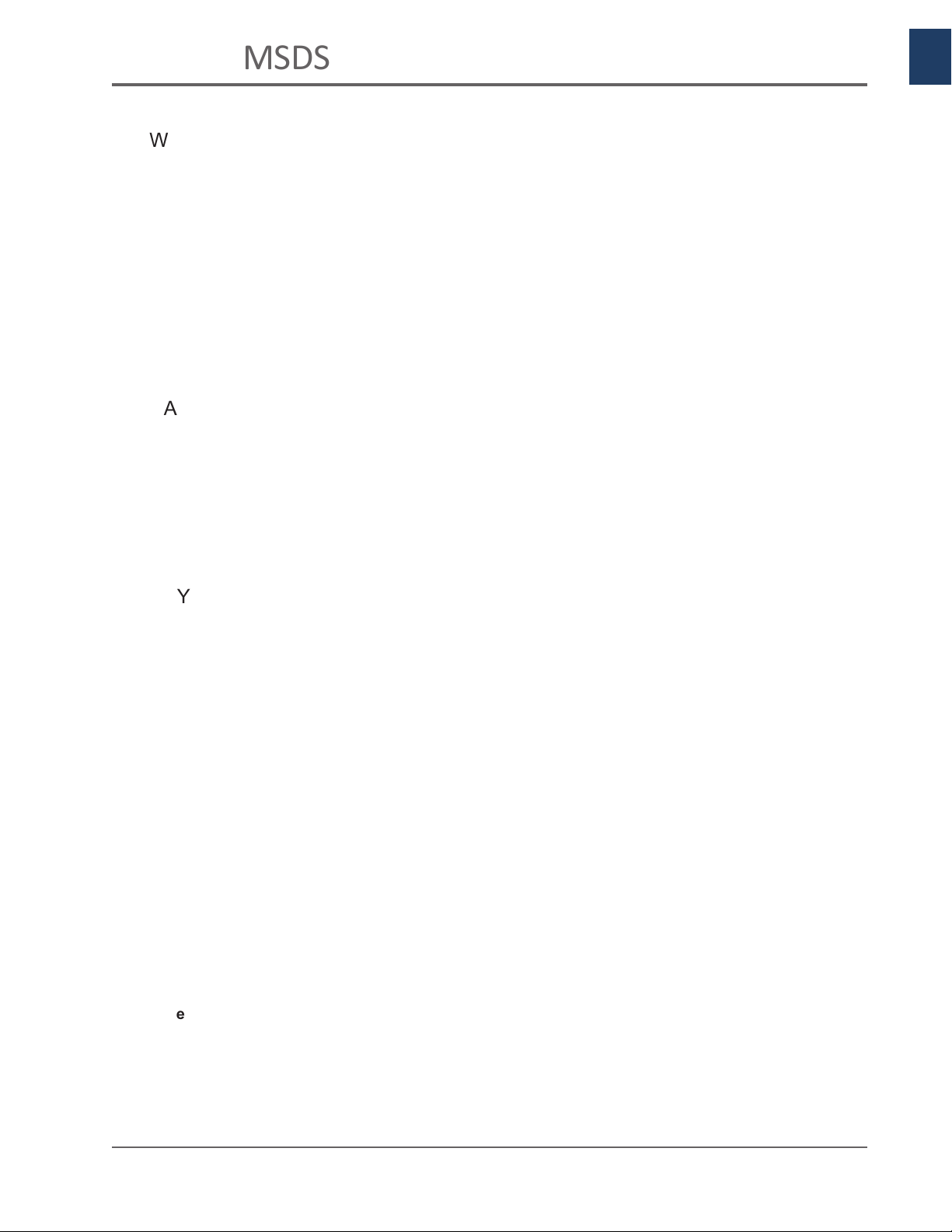

• If the coolant becomes contaminated it will need to be replaced.

• Begin by draining the coolant through the Coolant Drain Valve.

Then flush the Quench tank and close the drain valve. Be sure

to dispose of the contaminated coolant following the appropriate

environmental guidelines in the back of this manual.

• Remove, clean and replace the strainer from the pump inlet hose

in the tank.

• Add 1 gallon CIMTECH 310 (Techniks Part No. 00500-C) to 20

gallons fresh water. Refill the tank with clean approved coolant

and run a Quench cycle to verify coolant is flowing properly.

REMINDER: Always use the supplied insulated glove and exercise caution when handling toolholders. All personnel should be

clear of the machine before starting the tool change or Quench cycle. Never touch any toolholders that are not properly cooled.

The Quenching Time and coolant flow must be set to provide adequate cooling time to protect personnel from injury caused by

improperly cooled toolholders.

00500-M QUENCHER SYSTEM ADJUSTMENTS

A ports

B ports

IN CASE OF CONTAMINATED COOLANT

Note: The drying cycle is not meant to remove all

of the moisture from the toolholder. The drying

cycle should be adjusted to remove most of the

dripping coolant from the toolholder.

9

MSDS Sheets for CIMTEC Coolant

10

Satisfaction guaranteed on all our CNC tooling solutions | www.techniksusa.com

.

MSDS Sheets for CIMTEC Coolant

11

.

MSDS Sheets for CIMTEC Coolant

12

Satisfaction guaranteed on all our CNC tooling solutions | www.techniksusa.com

MSDS Sheets for CIMTEC Coolant

13

MSDS Sheets for CIMTEC Coolant

14

Satisfaction guaranteed on all our CNC tooling solutions | www.techniksusa.com

MSDS Sheets for CIMTEC Coolant

15

Satisfaction guaranteed on all our CNC tooling solutions | www.techniksusa.com

SHRINK-LOCKED tool holders are enhanced with our

patented TTG-594 compound for 6X the gripping force

of standard shrink fit holders.

WHY TRY SHRINK-LOCKED?

• Enjoy the peace of mind knowing your tool

will never slip, even in the most aggressive

applications.

• Run harder – higher speeds and feeds.

• Never spin or pull out a cutting tool..

• No modification to your tool shank required.

• No impact to accuracy or tool changes.

• Locked drive on standard carbide round shanks

.

IT’S NOT JUST SHRINK-FIT,

IT’S SHRINK-LOCKED!

Techniks Inc. 9930 E. 56th St. Indianapolis, IN 46236 | 800.597.3921 | www.techniksusa.com | [email protected]

Techniks is a proud member of Techniks Tool Group. Connect with Techniks Tool Group

Proprietary TTG-594 compound is embedded

in the I.D. bore of the holder, creating millions

of microscopic teeth adding bite to the

cutting tool/tool holder connection.

Unleash the full power of your CNC

machine and cutting tool with the

strongest shrink-fit connection.

This manual suits for next models

3

Table of contents

Other Techniks Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Haufftechnik

Haufftechnik HRD150 SGi x b60 installation instructions

Pulsar

Pulsar 7/20/SATEL/PUSTA instructions

COREMO OCMEA

COREMO OCMEA A3-3N User and maintenance manual

SCHUNK

SCHUNK KSC-D 125 Installation and operating instruction

FlexArm

FlexArm GH-24 Installation & operation manual

Ecolab

Ecolab VANGUARD WASH MAX Installation and operation manual