Mechanical Operation -CDHF

Overview

The following description applies to

the Trane Model CDHF Centrifugal

Chiller only. Refer to the appro-

priate operation manual for refri-

geration cycle descriptions

of

other

models.

Each CDHF unit is composed

of

basic components.

-The Evaporator

- 2 Stage Compressor (2 ea.)

-Water-Cooled Condenser

-Single-Stage Economizer (2 ea.)

-Related Interconnecting Piping

Important: The manual is written

describing a SINGLE REFRI-

GERATION CIRCUIT. Please note

that the Duplex has

1WO

(2)

independentcircuits.

refrigerant from the gas), first-stage Lubrication System

variable inletguide vanes, and into

the first-stage impeller. The CDHF compressor lubrication

system, which supplies oil to the

Nota: Inlet guide vanes are compressor motor bearings, is

designed to modulate the flow

of

illustrated in Figure

3.

gaseous refrigerant to meet system

capacity requirements; they also Oil is pumped from the oil tank (i.e.,

prerotate the gas allowing itto enter by a pump and motor located within

the impeller atan optimal angle that the tank) through an oil pressure-

maximizes efficiency at all regulating valve designed to

conditions. maintain a net oil pressure

of

12

to

Compressed gas from the first-

stage impeller is discharged

through the second-stage variable

guide vanes and into the

second-stage impeller. Here, the

refrigerant gas is again

compressed, and then discharged

into the condenser.

18 psid. Itisthen filtered and sent

to the compressor motor bearings.

The oil filterassembly is equipped

with a single rotary valve to isolate

the filter during replacement.

From the bearings, the oil drains

backto the oil tank through return

lines.

Baffles within the condenser shell To ensure proper lubrication and

distribute the compressed prevent refrigerant from condensing

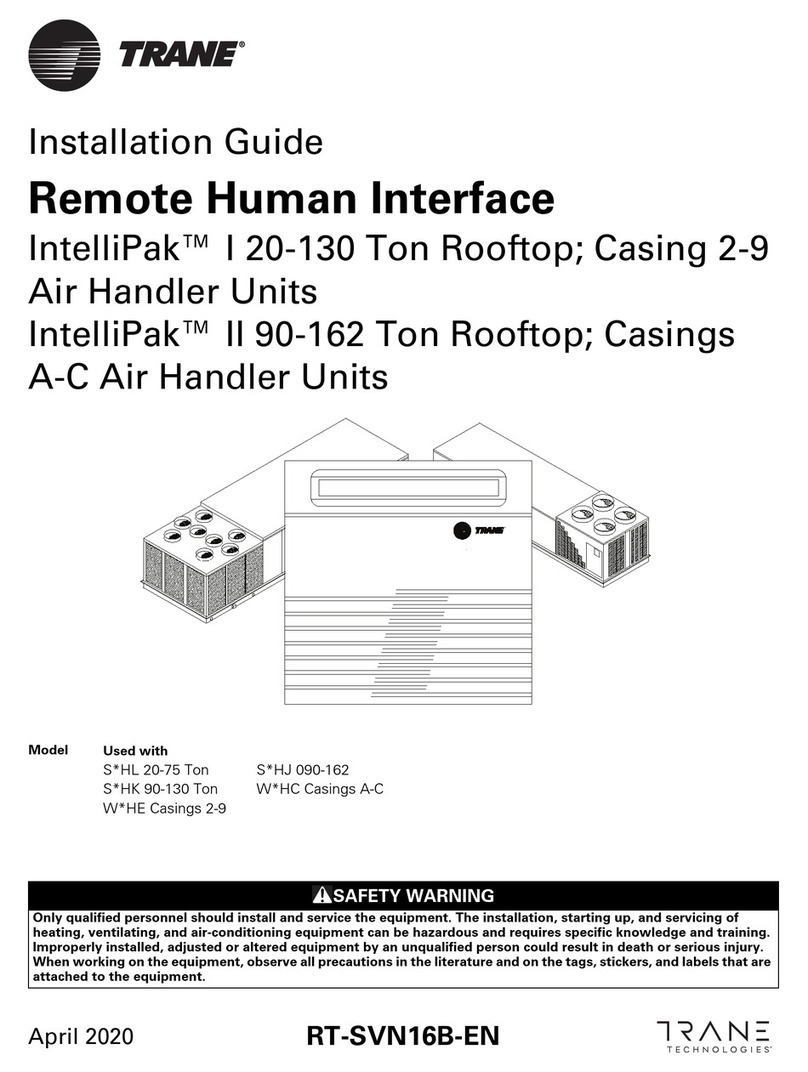

Figure 1 illustrates the general refrigerant gasevenly across the in the oil tank, a 750-watt heater

is

component layout

of

a typical CDHF condenser tube bundle. Cooling immersed in the oil tank. Operating

chiller. tower water, circulated through the in response to a signal from the

condensertubes, absorbs heatfrom UCP, this heaterenergizes as

The duplex unit has (2) CDHF the refrigerant, causing itto needed to maintain an oil tank tem-

compressors on independent condense. The liquid refrigerant perature

of

140 to 145 F {60-63°

C}.

evaporator and condensercircuits. then flows out

of

the bottom

of

the When the chiller is operating, the

Control is accomplished

by

a duplex condenser, passing through an temperature

of

the oil tank is

control module (DCM) as explained orifice plate and into the typically 1150 to 1600 F (46 -720

C).

in

"Electrical Sequence

of

economizer.

Operation" sections

of

this manual. WARNINGI

The economizer reduces the energy A Use

caution

while

working

Cooling-Only Cycle requirements

of

the refrigeration

on

certain

areas

of

the

unit.

When the CDHF is functioning in cycle

by

eliminating the need

to

Surface

temperatures

may

the cooling mode, liquid refrigerant pass all gaseous refrigerant through exceed 150° F

on

the

compressor

is distributed along the length

of

the both stages

of

compression. See discharge,

oil

tank

(heater),

oil

evaporator and sprayed through Figure

2.

Notice that some

of

the

filter,

and

oil

lubrication

lines.

small holes

in

a distributor (Le., liquid refrigerant flashes to a gas

running the entire length

of

the because ofthe pressure drop The oil tank is vented between the

shell) to uniformly coateach created by the orifice plate, thus compressor inletvanes and the

evaporator tube. Here, the liquid further

COOling

the liquid refrigerant. first-stage impeller suction cover.

refrigerant absorbs enough heat This flash gas is then drawn directly During normal system operation,

from the system watercirculating from the economizer into the motorbarrel pressure is greater

through the evaporatortubes to second-stage impeller

of

the than that

of

the oil tank. Therefore,

vaporize. compressor. All remaining liquid any gaseous refrigerant that enters

The gaseous refrigerant is then

drawn through the eliminators

(which remove droplets

of

liquid

refrigerant flows out

of

the the motorbearing cavities

;s

drawn

economizer, passes through toward the oil tank where it is

anotherorifice plate and into the removed by the vent line.

evaporator.

9 CDHF-OM-1