Ecolab VANGUARD WASH MAX User manual

VANGUARD®WASH MAX

Installation and Operation Manual

22937/0404/0602 Copyright Ecolab Inc. 2001 9237-2457

Institutional Division

Ecolab Center

St. Paul, MN 55102

R

This page intended

to be blank.

iii

TABLE OF CONTENTS

VANGUARD®WASH MAX

Installation and Operation Manual

Section...

1.0 PREFACE........................................................................................................ 1

2.0 INTRODUCTION.............................................................................................. 1

2.1 Principle of Operation.............................................................................. 1

3.0 SPECIFICATIONS........................................................................................... 2

3.1 Dimensions.............................................................................................. 2

3.2 Plumbing Requirements .......................................................................... 2

3.3 Electrical Requirements .......................................................................... 2

3.4 Components Not Supplied ...................................................................... 2

4.0 INSTALLATION PROCEDURES .................................................................... 3

4.1 Machine Mounting the Reservoir............................................................. 3

4.2 Wall Mounting the Reservoir ................................................................... 3

4.3 Initial Electrical Connections ................................................................... 3

4.4 Install Wash Tank Connector and Tubing ............................................... 3

4.5 Determining the Reservoir Water Supply ................................................ 4

4.6 Plumbing into the Water Supply.............................................................. 4

4.7 Start-up Procedures ................................................................................ 4

4.8 Guardian ................................................................................................. 4

4.9 Power Activator ....................................................................................... 5

4.10 Electronic Overshoot Control Board Adjustment..................................... 5

4.11 Timer Setting Procedures........................................................................ 5

5.0 TROUBLESHOOTING..................................................................................... 6

5.1 Inadequate Water To/From Reservoir Into Dishmachine ........................ 7

5.2 Low Product (effluent) Concentration Causing False Alarm.................... 7

5.3 Power to Solenoid Valve - No water Feed to Reservoir .......................... 7

5.4 Excessive Overshoot (POWER ACTIVATOR only)................................. 7

This page intended

to be blank.

1

1.0 PREFACE

Thismanualhasbeenwrittentopresentthebasicinstallation

and operational characteristics of the VANGUARD Wash

Max.

Thismanualapplies,initsentirety,tocurrentunits.

Guidelines will be suggested in reference to the preferred

methodofinstallation,however,thevarietyofequipmentand

the surrounding physical environment will dictate the actual

installation of the VANGUARD Wash Max

WARNING - These installation and servicing in-

structions are for use by qualified personnel only.

The installation must be made in accordance with

local plumbing and electrical codes.

The VANGUARD Wash Max Reservoir is a system de-

signedtoconvertsolidorpowderedwarewashingdetergent

into a high strength liquid for dispensing into the wash tank

of a dishmachine. The system consists of a reservoir,

possiblyaGuardianKitoraPowerActivatorKitandisused

in conjunction with the VANGUARD EcoCenter, Control

Max,VANGUARD2026,Senso-Matic26electroniccontrol,

or the Centron.

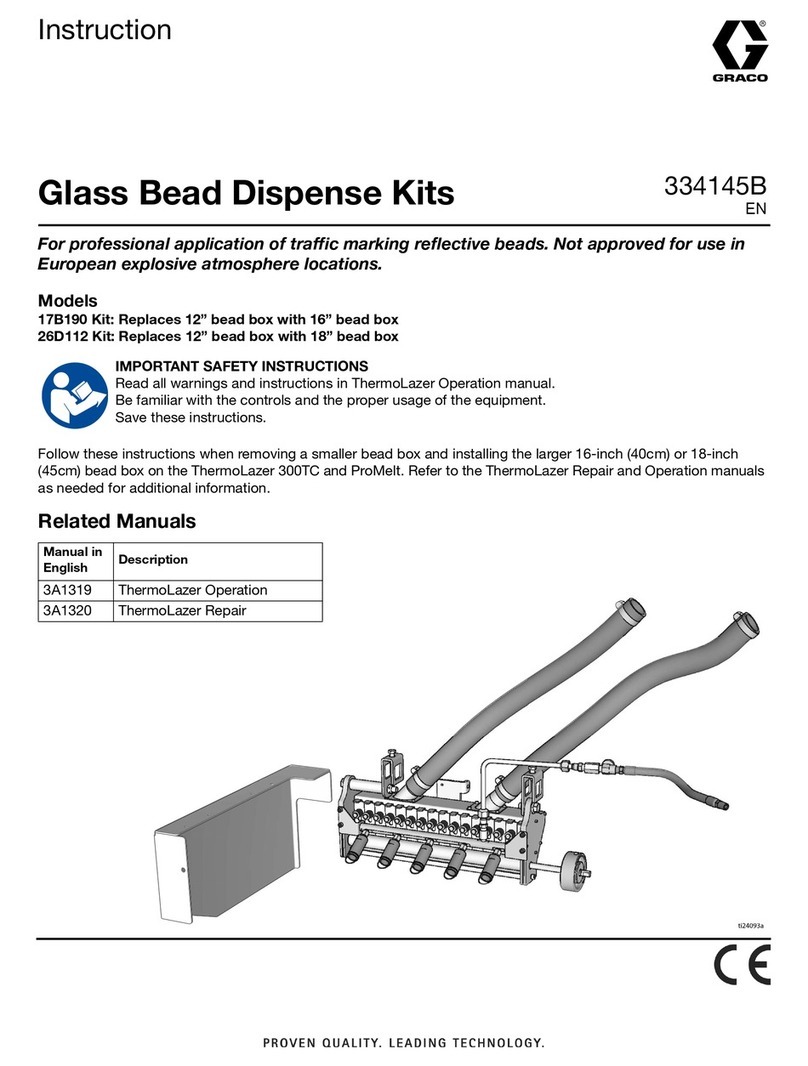

TheVANGUARDWashMaxReservoir consists of aheavy

duty reservoir for holding a solid detergent or powder, a

vacuum breaker, tubing, an empty capsule light, a cover

safetyswitchandaspraynozzlelocatedatthebottomofthe

reservoir.The reservoirwill holdonecapsuleofsoliddeter-

gent or up to 6 pounds of powdered detergent.

2.1 Principle of Operation

The basic principle of operation of the VANGUARD Wash

Max Reservoir is that it converts solid or powdered

warewashing detergent into an extremely high strength

liquid and directs this liquid into the wash tank of a

dishmachine.Product capsulesorpowderareaddedtothe

dispensersupply compartmentbyliftingthelidofthereser-

voir and inserting the capsule or pouring the powder.

Asolenoidvalve,activatedbytheconcentrationcontrolunit,

allows water to flow through the vacuum breaker to the

spray nozzle. The nozzle is designed to apply a uniform

spray pattern to the product surface. The solid detergent

dissolves and flows, by gravity, into the dishmachine wash

tank.

When the conductivity sensor in the wash tank senses the

needformoreproduct,theVANGUARDEcoCenter,Control

Max,VANGUARD2026,Senso-Matic26orCentronModel

526 opens the 24 volt AC solenoid valve allowing water to

flow to the VANGUARD Wash Max Reservoir through the

vacuum breaker to the spray nozzle. The nozzle is de-

signed, to apply a uniform spray pattern to the product

surface.Thesoliddetergentdissolvesandflows,bygravity,

throughtubingintothewashtankofthedishmachine.When

the conductivity sensor in the wash tank senses an ad-

equate detergent strength, the VANGUARD EcoCenter,

ControlMax,VANGUARD2026,Senso-Matic26orCentron

Model 526 closes the solenoid valve.

2.0 INTRODUCTION

2

WD

H

3.0 SPECIFICATIONS

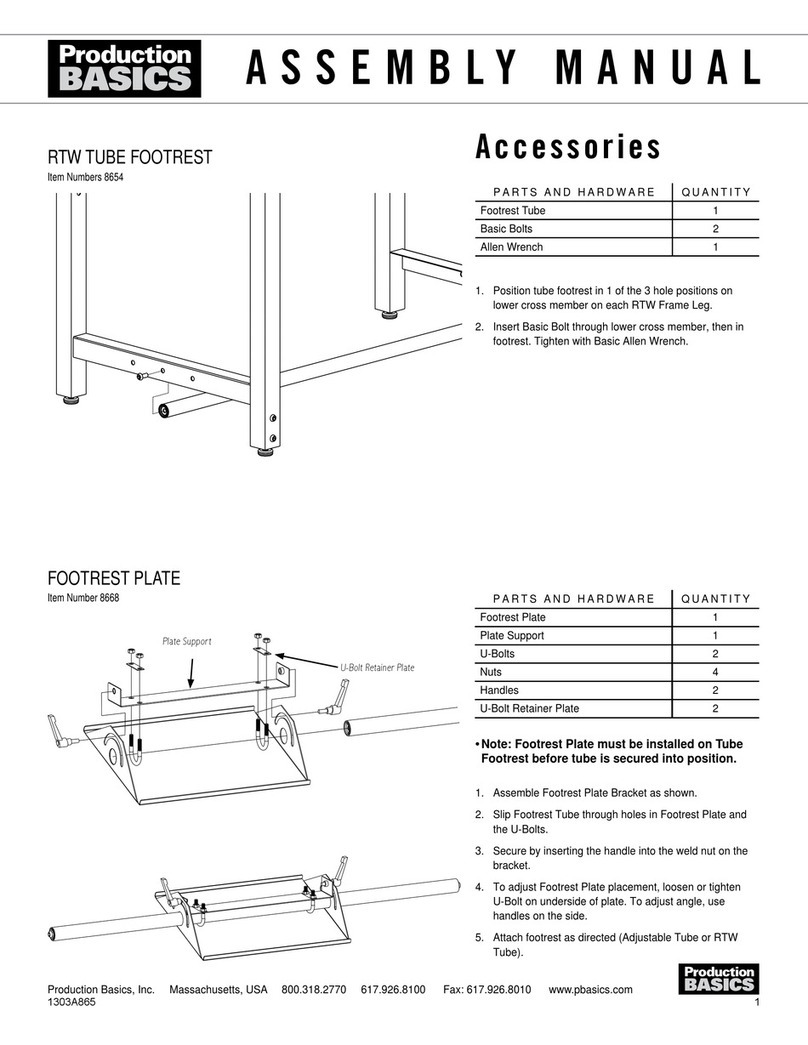

Component Diagram

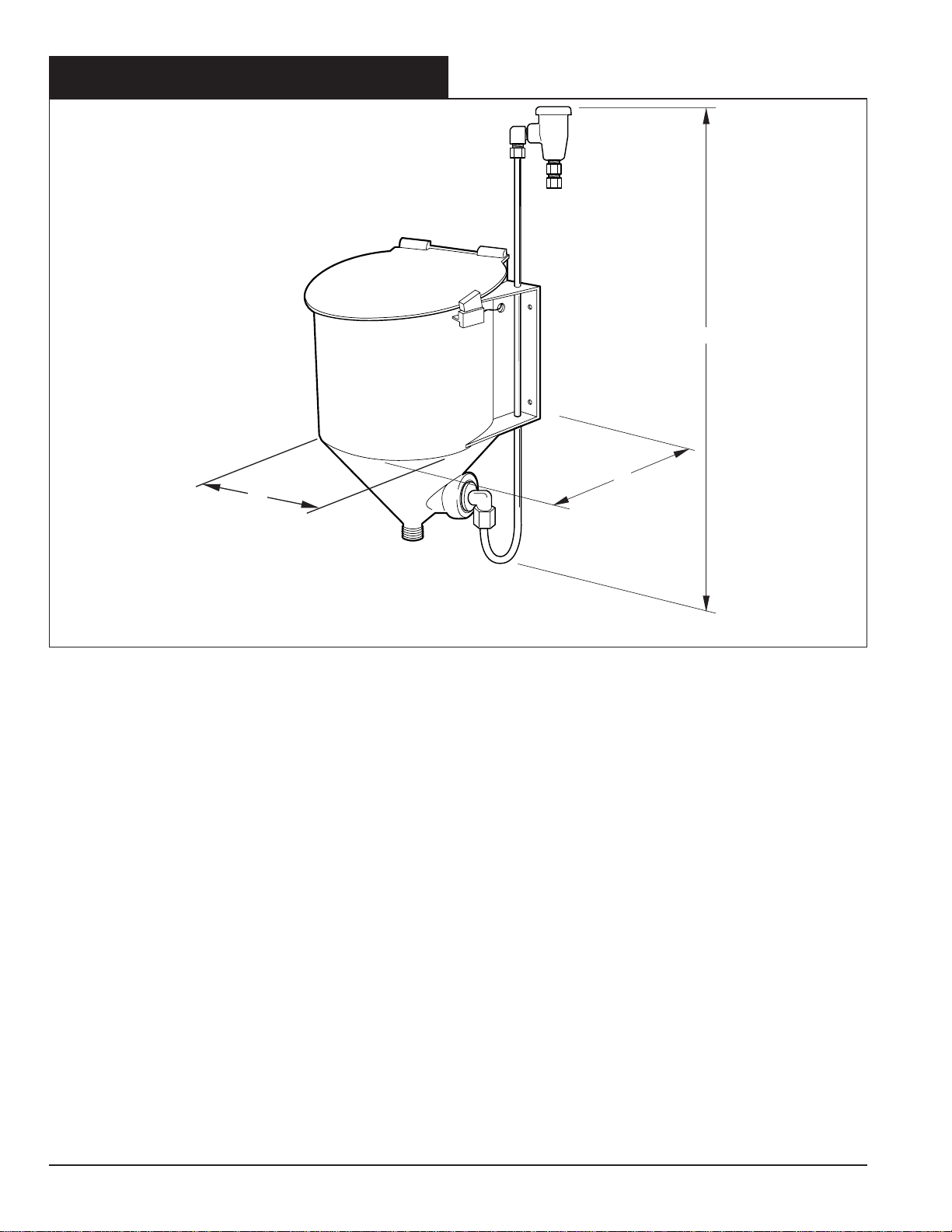

3.1 Dimensions

• Height: 21" (53.3 cm)

• Width: 10-1/2" (26.7 cm)

• Depth: 8-1/2" (21.6 cm)

This reservoir may be wall mounted or machine mounted.

Allow appropriate space, about 8" (20.3 cm), above the

reservoir for opening the cover as well as for the vacuum

breaker assembly.

3.2 Plumbing Requirements

A source of 120°F (48.9° C) to 150°F (65.5° C) water at a

minimum of 12 psi (.844 kgm/cm2) and 1 gallon per minute

(.063 liters/sec.) flow rate are required for the VANGUARD

Wash Max Reservoir.

Mayon tubing, 5/8" I.D. (15.9 mm), is required to direct the

effluent from the reservoir to the wash tank.

3.3 Electrical Requirements

The VANGUARD Wash Max Reservoir is supplied with a

20' (6 meter) length of 2 conductor cable. The conductors

are connected to the safety switch on the reservoir.

3.4 Components Not Supplied

• 5/8" I.D. (15.9mm) Mayon tubing

• 1/4" O.D. (6.4mm) copper tubbing

• Wall anchors (standard wall anchors or toggle bolts)

• Special mounting bracket (if required)

NOTE: Included in the VANGUARD Wash Max Reser-

voir package will be components common to both the

GUARDIAN and the Power Activator (vacuum breaker,

hose and assembly, hose clamps, needle valve, etc.).

To adapt the reservoir for a GUARDIAN product or

SOLID POWER product, one of the following must be

ordered.

1. GUARDIAN KIT

a. GUARDIAN Screen

b. Retaining Ring

c. GUARDIAN Safety Label and Nameplate

d. GUARDIAN Wall Chart

2. POWER ACTIVATOR KIT

a. Safety Grate

b. POWER ACTIVATOR Nameplate

c. POWER ACTIVATOR Wall Chart

d. Instructions - Conversion GUARDIAN to

POWER ACTIVATOR

3

Figure 4-1

Figure 4-2

4.0 INSTALLATION PROCEDURES

NOTE:RefertotheappropriateVANGUARDEcoCenter,

Control Max, VANGUARD 2026, Senso-Matic 26 or

Centron Model 526 I/O Manual for installation instruc-

tions of the control unit, conductivity cell and the

solenoid valve hook-up.

Theinstallationofthe VANGUARD Wash MaxReservoiris

essentially the same whether machine mounted or wall

mounted.

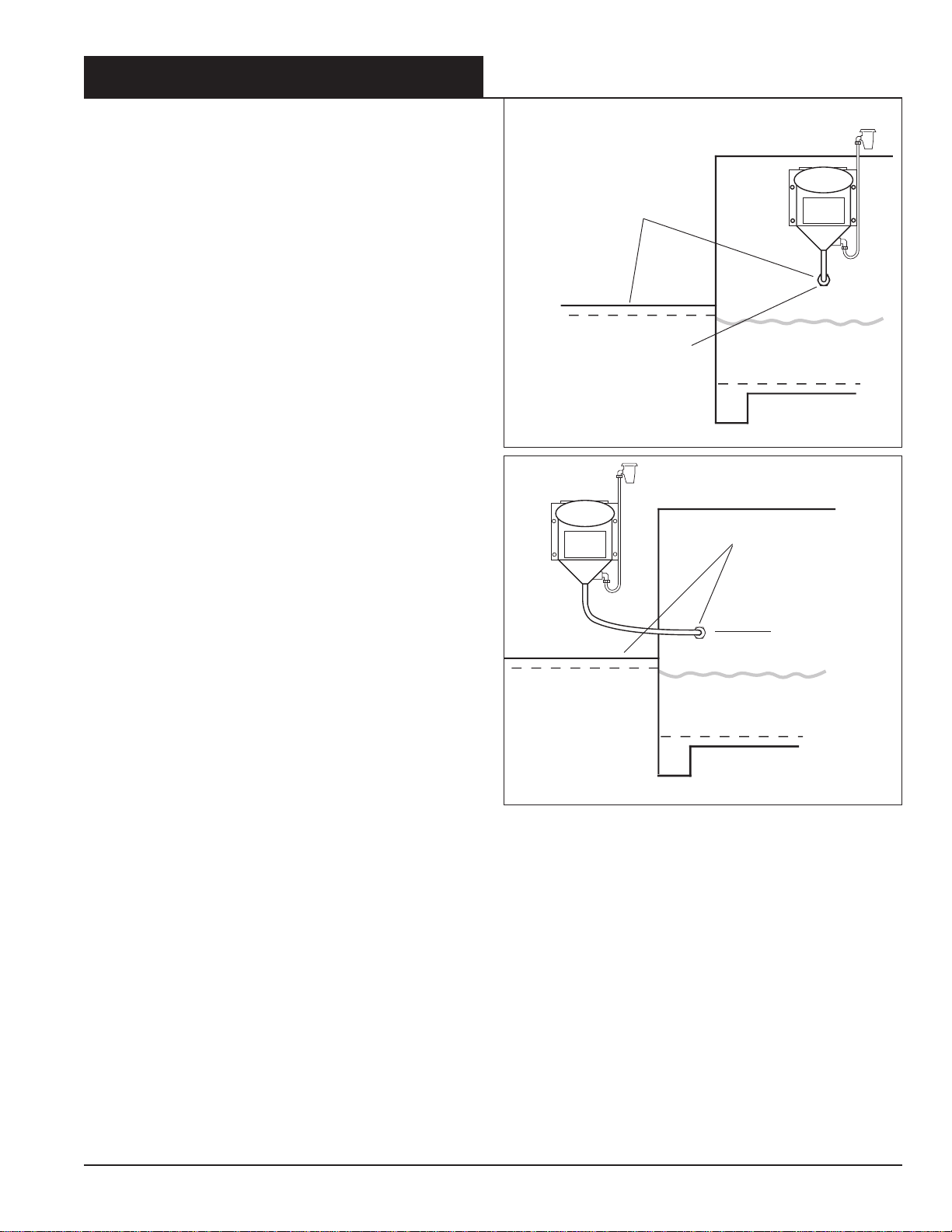

4.1 Machine Mounting the Reservoir

1. The reservoir must be mounted at a height below eye

level,buthigh enoughtoensurea downhillslopeof the

detergentdischargetubefromthereservoirtothewash

tank inlet connector.

Refer to Figure 4-1.

2. Mount the reservoir unit to the dishmachine wash sec-

tion. To prevent crimping of the discharge tubing, the

bottom two (2) mounting holes should be located at

leasteleven(11)inches(27.9cm)abovethewashtank

inlet connector. Use the mounting template to ensure

proper location of the holes. Use the four (4) bolts and

nuts supplied with the kit to secure the reservoir to the

dishmachine wall.

Refer to Figure 4-1.

NOTE: The shortest possible outlet tube run, be-

tween the bottom of the reservoir and the inlet

connector, is required. The outlet tube should not

have any dips in it.

4.2 Wall Mounting the Reservoir

1. Be sure to mount the dispenser at a height below eye

level and use the mounting template to mark four (4)

mounting hole positions. Secure the unit to the wall

usingappropriatewallanchors and/or toggle bolts.Itis

essentialthattheVANGUARDWashMaxReservoirbe

fastened firmly as the weight of the capsule being

placedinto

thereservoirrequiressufficientsupport.

Referto

Figure 4-2.

4.3 Initial Electrical Connections

1. TheVANGUARDWashMaxReservoirissuppliedwith

a 25' (7.6 meters) 2 conductor wire. The RED and

BLACK wires will be used to wire to the designated

safety switch wiring in the dispenser controller. These

should be connected as illustrated in the controller

wiring diagram.

4.4 Install Wash Tank Connector and Tubing

1. ToInstallthewashtankconnectorandtubing,locatethe

wash tank connector above normal water level in the

wash tank. Position the connector in a manner, such

that the effluent from the reservoir will not directly

contacttherackorutensils in the dishmachine,

referto

Figure 4-1.

NOTE: Ensure a continuous downhill flow of deter-

gent from the reservoir Into the wash tank

SOLUTION SUPPLY MUST BE

ABOVE FLOOD STAGE

(OVERFLOW RIM)

OVERFLOW RIM

OVERFLOW RIM

SOLUTION SUPPLY

MUST BE ABOVE

FLOOD STAGE

(OVERFLOW RIM)

WASH TANK

CONNECTOR

WASH TANK

CONNECTOR

2. Cut a 7/8" hole in the wash tank wall and install the

connector with the locknut and gaskets supplied.

NOTE: While drilling, it is recommended to catch

the shavings with a rag.

3. Cut and install the 5/8" I.D. (15.9mm) Mayon tubing

betweenthereservoirproductoutletandthewashtank

connector. Secure the tubing with clamps supplied in

the kit.

NOTE: Do not crimp the tubing.

4

Wash Max

Figure 4-3

4.5 Determining the Reservoir Water Supply

The hot water supply for the VANGUARD Wash Max

Reservoir should fall within the range 120° F (48.9°C) to

150°F(65.5°C.).Itmustbe a minimum of 12psi(.844kgm/

cm2) flow pressure with a minimum of 1 gallon per minute

(.063 liter/sec.) water flow.

1. Select the point for connection to the water supply so

that there is a minimum distance between the water

sourceandthereservoir.Ifthisdistanceislessthan15'

(4.6 meters) and a minimum of 12 pounds (.844 kgm/

cm2)flowpressureisavailable,1/4"O.D.coppertubing

is recommended,

refer to Figure 4-3.

If this distance is greater than 15' (4.6 meters) and/or

less than 12 pounds flow pressure (.844 kgm/cm2),

3/8"coppertubingisrecommendedforoptimumperfor-

mance.

NOTE: DO NOT USE 180°F WATER SOURCE.

4.6 Plumbing into the Water Supply

1. Shut off water supply. Tap into the water source and

installtheneedlevalvesuppliedwiththereservoir,

refer

to Figure 4-3.

The needle valve provides a means to regulate water

flow to the dispenser and it permits servicing the sole-

noid valve without the need to shut off the main water

supply.

2. Installcoppertubingbetweentheneedle valve and the

solenoidvalveatbottomofdetergentcontrollercabinet.

3. Install a length of copper tubing between the solenoid

valve and the vacuum breaker on the VANGUARD

Wash Max Reservoir.

4.7 Start-up Procedures

1. Adjust the VANGUARD EcoCenter, Control Max or

VANGUARD 2026 for proper detergent concentration.

Refer to the respective I/O Manual for instructions.

2. Fill the dishmachine with fresh water and turn on the

dishmachine with no detergent in the reservoir. The

controller will call for feed.

3. Check for water leaks and proper safety switch opera-

tion by lifting cover - the water flow should stop.

NOTE: Refer to Sections 4.8 - 4.11 only if you are using

the Guardian or Power Activator dispensers.

4.8 Guardian

InsuretheGUARDIANnameplateandsafetylabelisneatly

and firmly attached to the front side of the reservoir. The

surfacemustbecleanforpermanentattachment.Attachthe

GUARDIAN wall chart where it can easily be seen by the

dishmachine operators.

When the reservoir is used with a powdered GUARDIAN

detergent,thelargefinemeshGUARDIANscreenmust be

DETERGENT

CONTROLLER

SOLENOID VALVE

HOT WATER

SOURCE

NEEDLE

VALVE

TO WASH

TANK

Figure 4-4

inserted into the reservoir (before adding product). The

screenisinstalledwiththesmallknobatthecentertopofthe

screen facing up. The screen retainer ring is next inserted,

snugagainsttheouterrimofthescreen(withtheprongsup).

This retainer ring is to hold the screen firmly in place,

refer

to Figure 4-4.

Up to 6 pounds (2.7 kg) of GUARDIAN detergent can now

be added to the GUARDIAN reservoir.

NOTE:Alwayswet anewscreenbeforeaddingproduct

to avoid potential powder sift through.

AdjusttheSenso-matic26 forproperdetergentconcentra-

tion.RefertoSenso-Matic26I/OManual(#6435)fordetails.

GUARDIAN

SCREEN

RETAINER

RING

POWER

ACTIVATOR

GRATE

5

4.9 Power Activator

InsurethePowerActivatorlabelisneatlyandfirmlyattached

tothefrontside of thereservoir.Thesurfacemust be clean

forpermanentattachment.DisplaythePowerActivatorwall

chart where it can easily be seen by the dishmachine

operators.

The Power Activator reservoir is for use with the solid

capsule detergents (i.e. SOLID POWER or EXCALIBER).

Thesmallgratewiththelargemeshmustbeinsertedintothe

bottom of the reservoir. This grate is to keep any large

particles that may drop from the capsule and clog the tube,

refer to Figure 4-4

.

4.10 Electronic Overshoot Control Board

Adjustment

Thefollowingrecommendedtimersettingsaregeneraland

"fine tuning" of the Overshoot Control Board must be done

attheaccounttodealwiththespecificconditions(i.e.,water

temperature, pressure etc.) Follow procedures below:

Recommended Timer Settings

MACHINE ON OFF TOTAL PERCENT

TYPE TIME TIME TIME FEED

Door Type 2.5 sec. 7.5 sec. 10 sec. 25%

Conveyor/ 4 sec. 11 sec. 15 sec. 25%

Flight

Setting 9:00 11:30

On Timer -9:30 -12:30

4.11 Timer Setting Procedures

1. The left timer pot controls the "on" time and the right

timer pot controls the "off" time. The "on" time is when

theunitactuallyfeedsdetergent,andthe"off"timeisthe

pause while dissolved detergent solution drains into

and disperses within the wash tank. The "on" timer is

always energized first and is identified by the red LED

lightbeingilluminated.Thislightisnotonduringthe"off"

time.

The "on" - "off" cycle repeats itself during the time the

Senso-Matic 26 is calling for feed.

2. Fill the dishmachine with fresh water and turn on the

dishmachine with no detergent in the reservoir. The

S-26 will call for feed. Adjust the timers.

3. Refer to the above chart for approximate time settings.

Adjust the left timer for "on" time and the right timer for

"off" time. These times can be easily measured by

observing the red LED light on the Overshoot Control

Board. As the S-26 is calling for feed, the red light will

pulseon andoff.Timetheseandcomparetotheabove

chart.

NOTE: Rotate timers clockwise to increase time

and counterclockwise to decrease time.

Figure 4-5

Figure 4-7

Figure 4-6

GUARDIAN

SENSO-MATIC 26

TO SAFETY SWITCH

POWER ACTIVATOR

SENSO-MATIC 26 WITH OVERSHOOT CONTROL

EXCEPT CENTRON

POWER ACTIVATOR

SENSO-MATIC 26 OVERSHOOT CONTROL

IN CENTRON*

*CONNECT TO POWER ACTIVATOR PER CENTRON

MODEL 526 I/O MANUAL

6

5.0 TROUBLESHOOTING

The following Troubleshooting procedures are specific to the VANGUARD Wash Max Reservoir System. These

proceduresassumethattheVANGUARDEcoCenter,ControlMaxorVANGUARD2026arefullyoperational-ifnecessary

to troubleshoot these components, refer to the VANGUARD EcoCenter, Control Max or VANGUARD 2026 I/O Manuals.

Symptom Action

5.1 Inadequate Water To/From Reservoir Into

Dishmachine

ObservewhetherornoteffluentisflowingfromtheRESER-

VOIR into the dishmachine while controller is in “feed”

condition. Water volume should be a minimum of 1 GPM.

1. If there is no (or very little) effluent flow:

a. CheckandinsureRESERVOIRcoveriscompletely

closed (safety switch closes when cover is at cor-

rect angle).

b. Check to insure all shut-off valves (and needle

valve) at the water source are fully open.

c. Checkfor24voltsatthesolenoidvalvecoil.Ifno24

volts,refertoStepC-NOPOWERTOSOLENOID.

If24volts,checktomakesurethevalveisopening.

If it is not opening, it is defective and must be

replaced.

d. Check for clogging in the water line, the solenoid

valve/line strainer, and the vacuum breaker (i.e.,

loosen compression fittings to check for water).

e. Check for broken or plugged spray nozzle. Check

for blocked or crimped product outlet (Mayon) tub-

ing.

2. Ifthereiseffluentflowbutlessthan1gpm,checkfor12

psi (.844 kgm/ cm2) minimum water pressure at outlet

side of vacuum breaker: use the Guardian Pressure

Tester (fitting with pressure gauge P/N 9270-1O77). If

pressure is less than 12 psi (.844 kgm/cm2):

a. Check to insure no kinks in water feed tube, mini-

mum bends and length of feed tube, and for pos-

sible clogging of shut-off/needle valve, solenoid

valve, etc. as described above. Check pressure

reducing valve if present.

b. Iflowwaterpressurepersists,convertthe1/4"(6.3

mm)waterfeedtubeto3/8"(9.5mm)tubing(Guard-

ian Low Pressure Kit, P/N 9237-6003). This will

correct or help most low water pressure problems.

7

Symptom Action

5.2 Low Product (effluent) Concentration Causing

False Alarm

If the alarm repeatedly goes off with product still In the

reservoir(presumingdelaytime is properlyadjusted)prod-

uctisnot beingdissolved.Effluentconcentration shouldbe

a minimum of 5O drops (Titrate 5 - Indicator P) for “solid”

Power Activator detergents.

1. If concentration of effluent is low:

a. Checkforlowwatervolumeandlowwaterpressure

(see 1 and 2 on page 5).

b. Check to insure cap is removed from detergent

“capsule.

c. Check for misaligned, partially plugged or broken

spray nozzle.

d. Checkforwatertemperaturebeingtoocold(solubil-

ityisgreatlydecreasedattemperaturesbelow120°

F (48.9° C).

2. Ifeffluentconcentrationisstillinadequate(after check-

ing1a-e)installalternate5.6nozzletoincreaseeffluent

concentration(SprayNozzleP/N8531-2213).Ifeffluent

concentrationischeckedtobeokayandfalseorprema-

ture empty capsule alarm still occurs:

a. Check to insure delay time is set long enough (do

not exceed cycle time on timed cycle machines,

including D-Energizer controlled machines).

1. Check for water supply to solenoid valve. If no water to

valve, check:

a. Needle valve open and water coming from it.

b. Makesuretubingisnotpluggedorcrimpedandthat

there is water at the solenoid valve.

2. Checkforwaterfromsolenoidvalvewithcontrollerina

feed condition. If no water check for:

a. Defectivevalvecoil,plunger,spring,ordiaphragm.

b. Plugged line strainer in solenoid valve. If there is

water through the solenoid valve, check:

c. Crimped or plugged tubing to reservoir, defective

vacuum breaker or plugged spray nozzle.

If there is excessive overshoot titration in the wash tank,

makenecessaryadjustmentstotheovershootcontrolboard

reducingthepercentageof"on"time.Ifadjustments do not

alterthepulsedfeedtime/rate,replacetheOvershootCon-

trol board. If there is a pulsed feed but overshoot is exces-

sive and cannot be controlled, reduce feed water tempera-

ture.

5.3 Power to Solenoid Valve - No water Feed to

Reservoir

5.4 Excessive Overshoot (POWER ACTIVATOR

only)

Table of contents

Other Ecolab Industrial Equipment manuals

Ecolab

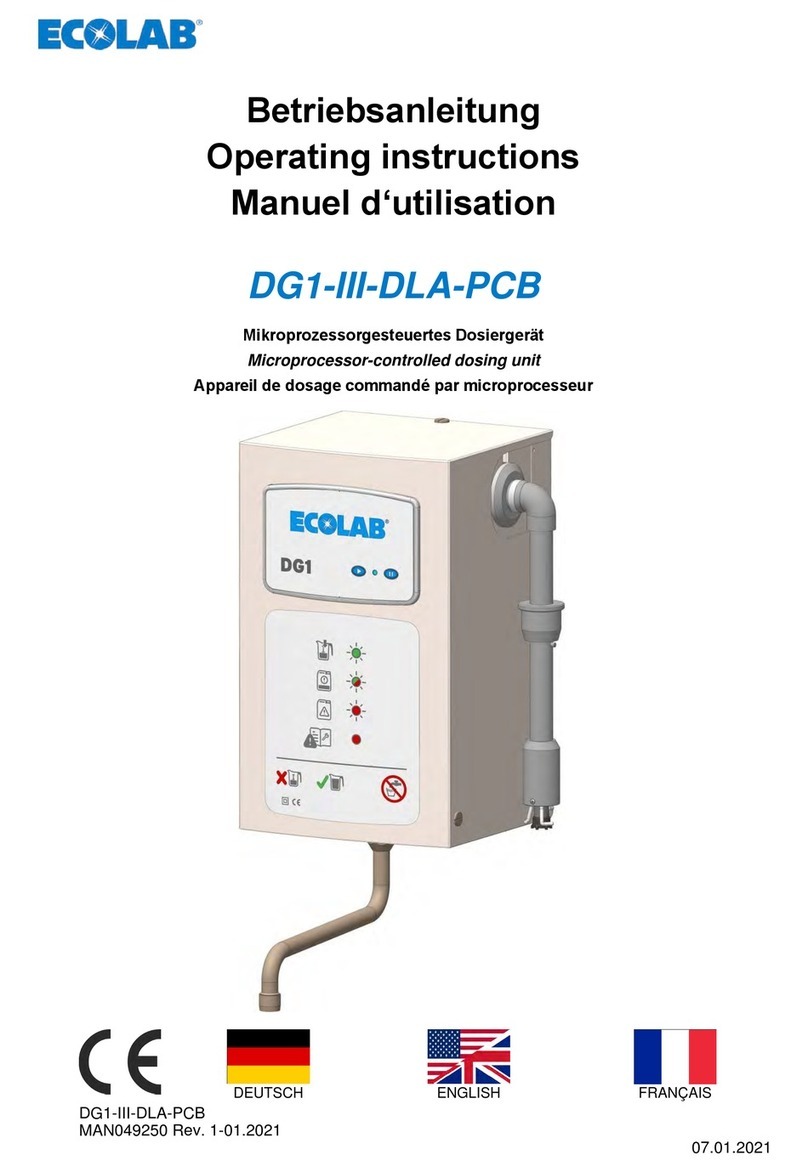

Ecolab DG1-III-DLA-PCB User manual

Ecolab

Ecolab Chameleon PLUS BW3 User manual

Ecolab

Ecolab Inspexx SD - Mrk. II Manual

Ecolab

Ecolab Booster 6 User manual

Ecolab

Ecolab ECO User manual

Ecolab

Ecolab Hybrid 7 BF4 Manual

Ecolab

Ecolab Lubo-DryExx -Basic User manual

Ecolab

Ecolab FoamGuard Airomatic Manual

Ecolab

Ecolab Connexx Basic Quick start guide

Ecolab

Ecolab BFE3 User manual

Popular Industrial Equipment manuals by other brands

All Power Labs

All Power Labs PP30 Operation manual

Fitel

Fitel S327 operating instructions

Tsubaki

Tsubaki ECHT-FLEX COUPLING NES Series installation manual

Hunter

Hunter AutoComp Elite operation instruction

Rothenberger

Rothenberger ROWELD P160-630B/Plus Instructions for use

GRUP ARGE

GRUP ARGE KSK 10 user manual