TechnipFMC Smith Meter microLoad.net User manual

MANUAL

Electronic Preset Delivery System

Bulletin MN06150 Issue/Rev 0.7 (9/18)

Installation Manual

Smith Meter®microLoad.net™

Caution

The default or operating values used in this manual and in the program of the Smith Meter®microLoad.net™are for

factory testing only and should not be construed as default or operating values for your metering system. Each metering

application.

Disclaimer

TechnipFMC Measurement Solutions, Inc. hereby disclaims any and all responsibility for damages, including but

not limited to consequential damages, arising out of or related to the inputting of incorrect or improper program or

default values entered in connection with the microLoad.net.

Receipt of Equipment

When the equipment is received the outside packing case should be checked immediately for any shipping damage.

remove the unit from its packing case and inspect for damaged or missing parts.

If damage has occurred during shipment or parts are missing, a written report should be submitted to

the Customer Service Department, TechnipFMC Measurement Solutions, Inc., 1602 Wagner Avenue, Erie, Penn-

sylvania 16510.

Prior to installation, the unit should be stored in its original packing case and protected from adverse weather

conditions and abuse.

Caution

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with this Instruction Manual, may cause interference to radio communications. It has not

been tested to comply with the limits for a Class A computing device pursuant to Subpart J of Part 15

of FCC Rules, which are designed to provide reasonable protection against such interference when

operated in a commercial environment. Operation of this equipment in a residential area is likely to cause

interference, in which case the user, at his own expense, will be required to take whatever measures may

be required to correct the interference.

Warning

These preset devices must be used with fail-safe backup equipment to prevent accidental runaway delivery

of product. Failure to provide backup equipment could result in personal injury, property loss and equipment

damage.

Warning

On initial power-up of a new unit or after installation of a new computer board, there are several alarms that will be

triggered, which cannot be cleared until the microLoad.net is programmed.

Section I – Introduction.......................................................................................................................................... 6

Section II – Pre-Installation Considerations .........................................................................................................7

Mechanical ............................................................................................................................................................8

Electrical ...............................................................................................................................................................8

Section III – Installation ........................................................................................................................................10

Mechanical ..........................................................................................................................................................10

Electrical .............................................................................................................................................................10

Start-Up .............................................................................................................................................................. 11

Section IV – Diagrams...........................................................................................................................................12

Pulse Inputs ........................................................................................................................................................16

Wiring Diagrams..................................................................................................................................................17

Analog Inputs ......................................................................................................................................................26

Communications .................................................................................................................................................27

Promass Coriolis Meter Communications ...........................................................................................................

Digital Inputs .......................................................................................................................................................

Digital Outputs.....................................................................................................................................................

Instrument Power Wiring.....................................................................................................................................

Sample Application Wiring ..................................................................................................................................

Interposing Relays ..............................................................................................................................................

Section V – Appendix A – ATEX Installation .......................................................................................................44

Section VI – Related Publications........................................................................................................................45

Table of Contents

Tables and Figures

Tables

Table 1. Typical Wire Sizes....................................................................................................................................8

..................................................................................8

..................................................................................8

Table 4. Wiring Checklist .....................................................................................................................................10

Table 5. MNET Board Terminal Assignments.......................................................................................................15

..........................................................................................16

Table 7. Promass Modeling for Single Pulse Wiring ............................................................................................21

Table 8. Promass Modeling for Dual Pulse Wiring...............................................................................................21

Table 9. Wiring Termination for T-568B and T-568A ............................................................................................

Figures

Figure 1. I/O Block Diagram ....................................................................................................................................7

Figure 2. microLoad.net Dimensions.....................................................................................................................12

..........................................................................................................................

Figure 4. MNET Board...........................................................................................................................................14

Figure 5. Wiring Diagram, Prime 4 ........................................................................................................................17

Figure 6. Wiring Diagram, PEX-P Transmitter Single Pulse..................................................................................18

Figure 7. Wiring Diagram, PPS Transmitters ........................................................................................................19

Figure 8. Wiring Diagram, PA-6 Transmitters........................................................................................................ 20

Figure 9. Wiring Diagram, Promass Coriolis Meter ...............................................................................................22

Figure 10. Wiring Diagram, Universal Pulse Transmitter (UPT)..............................................................................

Figure 11. Wiring Diagram, Open Collector Output.................................................................................................24

Figure 12. Wiring Diagram, Typical Metered Injector ..............................................................................................25

............................................................................................26

Figure 14. General Wiring for Serial Communications ............................................................................................27

Figure 15. Multiple microLoad.net Serial Communications .....................................................................................28

.........................................................................................................................29

Figure 17. RS-485 Shared Printing .........................................................................................................................

Figure 18. microLoad.net Ethernet Communications ..............................................................................................

Figure 19. Additive Injector Communications..........................................................................................................

Figure 20. Lubrizol EIA-485 Additive Injector Communications ..............................................................................

Figure 21. Promass Coriolis Meter Communications ..............................................................................................

Figure 22. DC Digital Inputs ....................................................................................................................................

.................................................................................................................................

Figure 24. AC Digital Outputs..................................................................................................................................

Figure 25. MACF Board / Instrument Power Wiring ................................................................................................

Figure 26. Sample Application Worksheet...............................................................................................................40

Figure 27. Sample Application AC Wiring................................................................................................................41

Figure 28. Sample Application DC & Signal Wiring.................................................................................................42

Figure 29. Sample Application Power Wiring ..........................................................................................................

Section I – Introduction

Introduction

This manual is to be used for the installation of the Smith Meter®microLoad.net™Electronic Preset Controller with

“Pre-Installation Considerations” describes the areas that must be considered prior to the installation of the

microLoad.net.

“Installation” describes the areas that have to be considered when installing the microLoad.net.

“Diagrams” covers dimensional outline drawings, wiring schematics, typical interconnect diagrams etc.

“Related Publications” lists the literature that is associated with the microLoad.net.

Section II – Pre-Installation Considerations

Supervisory Computer

Supervisory Computer,

SCADA, Printers, Card

Readers, Smart Additive

Injectors, Mass Meters,

Shared Printing

Pumps, Digital Valves,

Alarm Relays, Stop Relay,

Piston Injector, Metered

Injector, Additive Pumps,

General Purpose

External To talizer

Pulse Output

AC Digital Output

AC Digital Output

AC Digital Output

AC Digital Output

DC Digital Output

DC Digital Output

Ethernet

EIA-232/EIA-485

EIA-232/EIA-485

EIA-232/EIA-485

Security Switch,

Permissives, High

Flow Switches,

Remote Start, Remote

Stop,Transaction

Reset, Printer Tr ay

Switch, Piston Injector

Feedback, General

Purpose

DC Digital Input

DC Digital Input

DC Digital Input

Temperature, Pressure, or

Density

Temperature

Flow Meter

Pulse Input

Pulse Input

RTD

4-20 ma

Figure 1. I/O Block Diagram

The Smith Meter®microLoad.net™is a micro-processor based single arm, single product electronic preset instrument

Section II – Pre-Installation Considerations

An important pre-installation consideration is the se-

lection of the ancillary equipment to be used with the

microLoad.net and how that equipment is interfaced.

(Table 6, page 16) which will assist in the assignment

of devices to the microLoad.net’s various I/O positions.

The Worksheet lists the available I/O points versus

possible devices or functions which may be applied.

By checking the appropriate boxes on the Worksheet

I/O map of your application is established. A sample

application starts on page 40.

Mechanical

In addition to the following, all previous warnings and

cautions should be reviewed before installation.

1. A solid vertical or slanted surface should be used

for mounting the explosion-proof microLoad.net

housing.

2. The location and the height of microLoad.net should

be selected to permit easy viewing of the display

and to provide convenient access to the keypad

by all users. See Figure 2 for dimensions of the

microLoad.net.

cover. For service, wiring and removal of parts the cover

must removed.

4. Conduit entry to the explosion-proof microLoad.net

is both through the bottom and sides. There are two

the unit.

5. Inwarm climates,microLoad.net shouldbe shadedfrom

direct sunlight. The maximum external temperature

of the microLoad.net housing must not exceed 140°F

(60°C) to ensure that the internal temperature limit is not

exceeded.

Electrical

Note: See Appendix A for information regarding ATEX electrical

installation.

1. All DC wiring must be routed into microLoad.net

through the conduit entries located in the bottom of

the housing. Do not route DC and AC wiring through

the same conduit entry.

2. The DC signal wires must be multi-conductor

shielded cable of 18 to 24 AWG minimum stranded

copper.

at a minimum. Direct Ethernet connections between

computer and microLoad.net require a crossover

-

ration is used where the microLoad.net units are

networked through a hub or switch.

Note: The following recommendations are based on our knowledge

of the electrical codes. The local electrical codes should be reviewed

to ensure that these recommendations follow the local code. Also

installation manuals of all the equipment being wired into the micro-

Load.net should be reviewed for transmission distances and wire

recommendations.

Table 1. Typical Wire Sizes

Equipment Number & Gauge

of Wire

Belden

Number or

Equivalent

Transmitters

4 / 18 Ga.

4 / 20 Ga.

9418

8404

Temp. Probes

Density and

Pressure

ransmitters 4 / 22 Ga.

8729

OR

9940

EIA-485 Comm 4 / 24 Ga. 9842

Table 2. Maximum Cable Length and Baud Rate (EIA-232)

Baud Rate Feet Meters

250 75

19,200 500 150

9,600 1,000

4,800 2,000 610

2,400 4,000 1,220

1,200 4,000 1,220

Table 3. Maximum Cable Length and Baud Rate (EIA-485)

Baud Rates Feet Meters

4,000 1,220

4. All AC wiring must be routed into microLoad.net

through the conduit entries located in the side of

the housing. Connectors sized for a maximum of 14

gauge wire, consult the local electrical codes for the

minimum AC wire size required for your application.

Do not route AC and DC wiring through the same

conduit entry.

5. All AC wiring should be stranded copper and must

comply with federal, state and local codes and

6. Two separate AC circuits must be provided from

the breaker panel. One circuit will supply isolated

power to the microLoad.net electronics (instrument

power). The second circuit will supply power to the

external devices.

7. For proper operation, the microLoad.net must be

earth grounded. The grounding point should be as

close to the unit as possible. To ensure proper earth

a) The resistance between the earth ground lug in

the microLoad.net and the grounding point must

not exceed 2 Ω.

copper stake that extends into the water table.

Where this is not practical, a ground plane may

be used.

Note: Electrical conduit, piping, and structural steel are

not considered proper grounding points for equipment using

electronics.

c) No other devices, except the microLoad.net

and ancillary equipment such as load printers,

should be connected to any point in the ground-

ing circuit.

Section II – Pre-Installation Considerations

8. All user wiring is terminated at compression-type

screw terminal strips. These terminal strips may be

removed from the microLoad.net MACF and MNET

circuit boards to facilitate ease of wiring. Once wir-

ing is complete, the terminal strips are then “plugged

into” their respective positions on the circuit boards.

9. If external relay permissives are used in series with

microLoad.net AC digital outputs, an RC network

must be placed in parallel with the permissive to

prevent a false turn-on of the microLoad.net digital

capacitor and a 680 Ωresistor (Electrocube part

10. Interposing relays must be installed between the

pump controller, alarming device, and the micro-

Load.net permissive sense relays. Permissive

sense inputs are DC voltage.

Mechanical

1. Mount the microLoad.net using four (4) 5/16 - 18

bolts. See Figure 2 for mounting hole layout.

2. Attach the required conduit runs to the microLoad.

net. Be sure to plug all unused conduit entries.

cover/keypad/display. This is done by removing six

(6) cap screws, which hold the cover to the micro-

Load.net enclosure. Carefully pull the cover away

from the enclosure and unplug factory-installed

cables by removing the terminal blocks at the MNET

circuit board. Note the position of these connections

for reinstallation later.

4. Care must be taken in handling the microLoad.net

enclosure and cover to avoid scratching the ground

Electrical

1. AC circuits must be isolated from DC circuits and

brought into the unit through their respective conduit

openings.

ATEX / IECEx

Cable entry must be in accordance to EN/IEC

For wiring systems utilizing cable glands, the gland

cable end must be securely installed and, depend-

ing on the cable type, be properly protected from

mechanical damage.

sealing device must be used immediately at the

entrance of the enclosure.

Any unused entry must be suitably blocked with an

applications.

For North American Zone applications, the plug must

be listed metal close up type.

The maximum ambient temperature for the enclo-

sure is 60°C.

Equipment bonding shall be provided at the external

grounding facility terminal, external connection is not

required when using metallic conduit or armored ca-

Cover to body fasteners must be either DIN 912

-

less steel), or DIN 912-A2-70 (18-8 stainless steel).

Keypad is protected by an intrinsic safe barrier, the

enclosure must be grounded as per national electri-

cal code regulations, for example NEC/CEC etc.

Battery back-up option (if equipped) use only ap-

proved AAA NiMH (1.2V/Cell Nominal) rechargeable

batteries meeting IEC 61951-2 requirements, IEC

Section III – Installation

capacity of 1.5 Ah at a 1 h discharge rate.

Caution: To prevent ignition of hazardous atmo-

spheres, disconnect from supply circuit before

opening, keep tightly closed when circuits are in

operation.

Warning: Contains internal battery-powered circuit,

to prevent ignition of hazardous atmospheres, do

not open enclosure unless area is known to be

non-hazardous.

Note: Refer to page 42 for certication and marking information.

2. All signal and DC wiring should be connected before

connecting AC wiring.

tight.

4. All exposed shields must be properly insulated to

prevent short circuits to other terminals or to the

chassis. The shield at the device (e.g., tempera-

ture device, transmitter, etc.) must be cut back to

continuous. If splices are required, they must be

soldered and properly insulated.

If other communicating devices are used with the

microLoad.net, refer to the manual for that unit for

shielding information. Shields for other communi-

cating equipment should not be terminated in the

microLoad.net.

Note: Shields must not be terminated at the earth ground lugs.

in the microLoad.net to permit easy removal of the

be removed and laid back out of the way so that the

boards can be replaced without removing individual

wires.

6. There is an earth ground lug provided in the unit.

The wire from the lug should be connected to the

proper grounding point. See Pre-Installation Con-

siderations, page 4.

Note: CENELEC approved microLoad.nets require that the

customer install ferrules (Aderendhulsen) per DIN 46 228 on

the grounding wires prior to installation into the grounding lugs.

7. Typical electrical installation diagrams are provided

in the following sections to show the microLoad.net

and ancillary equipment. Before wiring the ancillary

equipment, refer to its installation manual. Use the

installation diagrams in conjunction with the following

checklist to make all necessary connections to your

microLoad.net.

8. Reconnect all terminal blocks to their respective

positions on the MACF and MNET boards. These

terminals blocks are not “keyed”, therefore take

extreme care to be certain that terminal blocks are

returned to the correct position and are in the correct

orientation.

Section III – Installation

Table 4. Wiring Checklist

Install Pulse Input Wiring (from Meters and Metered

Injectors)

Install Pulse Outputs Wiring

Install Analog Input Wiring (RTD and 4-20ma)

Install Communications Wiring

Install Digital Input Wiring (DC)

Install Digital Output Wiring (DC)

Install Digital Output Wiring (AC)

Install Earth Ground

Install Instrument Power Wiring

Cable entries must be in accordance to EN/IEC 60079-1

For wiring systems utilizing cable glands the gland

The cable end must be securely installed and depending

on the cable type be properly protected from mechanical

damage.

-

ing device must be used immediately at the entrance

of the enclosure. Any unused entry must be suitably

and IECEx applications. For North American Zone

applications, the plug must be listed 'metal close-up

type.

The maximum ambient temperature for the enclosure

Equipment bonding shall be provided at the external

grounding facility terminal, external connection is not

required when using metallic conduit or armoured

Cover to body fasteners must be either DIN 912 grade

or DIN 912-A2-70 (18-8 stainless steel).

Keypad is protected by an intrinsic safe barrier, the

enclosure must be grounded as per national electrical

code regulations, for example NEC/CEC etc.

Battery back-up option (if equipped) use only approved

AAA NiMH (1.2V/Cell Nominal) rechargeable batteries

meeting IEC 61951-2 requirements, IEC IEC Designa-

a 1 h discharge rate.

Warning: Contains internal battery-powered circuit.

To prevent ignition of hazardous atmospheres, do not open

enclosure unless area is known to be non-hazardous.

To reduce the risk of ignition of hazardous atmospheres,

within 18 inches of the enclosure. Substitution of com-

ponents may impair intrinsic safety. To prevent ignition of

hazardous atmospheres and to prevent electrical shock,

disconnect from supply circuits before opening, keep

tightly closed when circuits are in operation.

Start-Up

instrument power to the unit. The displays should light,

indicating that the microLoad.net is ready for Start-Up.

to match the inputs and outputs to which it has been

connected. The Reference Manual (MN06148) provides

of the inputs to the microLoad.net. Next, apply external

device power and check the operation of output devices.

The microLoad.net is now ready for use. The Operations

Manual (MN06149) describes the procedures used in

the day to day use of the instrument.

Section IV – Diagrams

Figure 2. microLoad.net Dimensions

2.50

(64)

5.70

(145)

3.69

(94)

7.36

(187)

9.65

(245)

2.50

(64)

2.50

(64)

3.69

(94)

8.63

(219)

4.75

(121)

Two (2) 3/4" NPT Conduit Connection

1/2" NPT Conduit Connection

1/2" NPT Conduit Connection

Mounting

Hole

Layout

2.38

(60)

5.75

(146)

Inches (mm)

Section IV – Diagrams

Figure 3. Opening microLoad.net

Section IV – Diagrams

Figure 4. MNET Board

Switch “S2” Functions

Note: Factory setting for all S2 switches is OFF

Switch 3 Switch 4 Function

OFF OFF

ON OFF Forces IP address to 192.168.0.1

OFF ON Forces IP address to 10.0.0.1

ON ON Enables DCHP

Switch “S1” Functions (RS-485 termination)

Position 1 Position 2 Position 3 Position 4 Position 5 Position 6

COM1 COM1 COM2 COM2

Note: Factory settings for all positions of “S1” is OFF

Section IV – Diagrams

Table 5. MNET Board Terminal Assignments

Connector: CN1

1COM2232Tx 485Tx-

2COM2485Tx+

3COM2232Rx 485Rx+

4COM2485Rx-

5Common

6COM3232Tx 485Tx-

7COM3485Tx+

8COM3232Rx 485Rx+

9COM3485Rx-

10 Common

Terminal #Description232 485

Connector: CN2

1COM1232Tx 485Tx-

2COM1485Tx+

3COM1232Rx 485Rx+

4COM1485Rx-

5Common

Terminal #Description 232485

Connector: CN3

1RTD +

2SIG +

3SIG -

4RTD -

5Shield

Terminal #Description

Connector: CN4

1Input (DC) #1 +

2Input (DC) #1 -

3Input (DC) #2 +

4Input (DC) #2 -

5Input (DC) #3 +

6Input (DC) #3 -

7Pulse Out +

8Pulse Out-

Terminal #Description

Connector: CN5

1Meter Pulse Input/Channel A +

2Meter Pulse Input/Channel A-

3Factory Use Only - Do not connect

4Factory Use Only - Do not connect

5Shield

6Meter Pulse Input/Channel B/Metered Inj +

7Meter Pulse Input/Channel B/Metered Inj-

8Factory Use Only - Do not connect

9Factory Use Only - Do not connect

10 Shield

11 Output (DC) #1 +

12 Output (DC) #1 -

13 Output (DC) #2 +

14 Output (DC) #2 -

Terminal #Description

Connector: CN6

1Factory Cable to MACF (DC PW R +)

2Factory Cable to MACF (Common)

3Factory Cable to MACF (+12 Vdc Transmitter) power

4Factory Cable to MACF (Common)

5Factory Cable to MACF (Earth/Enclosure Gnd)

Terminal #Description

Connector: CN7

1AC Output Common

2N.C.

3Output (AC) #6

4Output (AC) #5

5Output (AC) #4

6Output (AC) #3

Terminal #Description

Connector: CN8

RJ-45 Ethernet Port

14-20 mA input +

2Return - (Common).

Connector: CN9

Terminal #Description

Connector: CN15

Factory Cable to MACF (CN1)

Note: Electronically connected to common

Section IV – Diagrams

Table 6. microLoad.net I/O Conguration Worksheet

Section IV – Diagrams

Figure 5. Wiring Diagram PRIME 4

PRIME 4 Wire Codes:

Note: Pulse Inputs

• If EPLD (U24 chip) is Rev. 0, dual pulse will not function under 25 Hz. Only single pulse will count from 25 Hz

down to 3 Hz. Above 25 Hz, dual pulse will function as normal.

• If EPLD (U24 chip) is Rev. 1 or higher, dual pulse will function from 3 Hz and higher.

• Pulse doubling will not function for input pulses below 25 Hz.

14

13

12

11

10

9

8

7

6

5 Shield

4

3

2 A-

1 A+

CN5

5

4 Gnd

3 +12Vdc

2

1

CN6

WHITE

BLACK

RED

YELLOW

PRIME 4PRIME 4

YELLOW

RED

BLACK

WHITE

CN6

1

2

3 +12Vdc

4 Gnd

5

CN5

1 A+

2 A-

3

4

5 Shield

6 B+

7 B-

8

9

10

11

12

13

14

MNET Board

MNET Board

Prime 4, Single PulsePrime 4, Dual Pulse

Section IV – Diagrams

Figure 6. Wiring Diagram, PEX-P Transmitter Single Pulse

PEX-P Wire Codes:

Note: Pulse Inputs

• If EPLD (U24 chip) is Rev. 0, dual pulse will not function under 25 Hz. Only single pulse will count from 25 Hz

down to 3 Hz. Above 25 Hz, dual pulse will function as normal.

• If EPLD (U24 chip) is Rev. 1 or higher, dual pulse will function from 3 Hz and higher.

• Pulse doubling will not function for input pulses below 25 Hz.

PEX-P

RED

BLACK

WHITE

CN6

1

2

3 +12Vdc

4 Gnd

5

CN5

1 A+

2 A-

3

4

5 Shield

6

7

8

9

10

11

12

13

14

MNET Board

PEX-P, Dual Pulse

Section IV – Diagrams

Figure 7. Wiring Diagram, PPS Transmitters

PPS Terminal Connections:

1. Common

4. B Bar

5. Signal A

6. A Bar

Note: Pulse Inputs

• If EPLD (U24 chip) is Rev. 0, dual pulse will not function under 25 Hz. Only single pulse will count from 25 Hz

down to 3 Hz. Above 25 Hz, dual pulse will function as normal.

• If EPLD (U24 chip) is Rev. 1 or higher, dual pulse will function from 3 Hz and higher.

• Pulse doubling will not function for input pulses below 25 Hz.

14

13

12

11

10

9

8

7

6

5 Shield

4

3

2 A-

1 A+

CN5

5

4 Gnd

3 +12Vdc

2

1

CN6

PPS MNET Board

PPS, Single Pulse

6

5

4

3

2

1

14

13

12

11

10

9

8

7

6

5 Shield

4

3

2 A-

1 A+

CN5

5

4 Gnd

3 +12Vdc

2

1

CN6

PPS MNET Board

PPS, Dual Pulse

6

5

4

3

2

1

Section IV – Diagrams

Figure 8. Wiring Diagram, PA-6

PA-6 Terminal Connections

Note: Pulse Inputs

• If EPLD (U24 chip) is Rev. 0, dual pulse will not function under 25 Hz. Only single pulse will count from 25 Hz

down to 3 Hz. Above 25 Hz, dual pulse will function as normal.

• If EPLD (U24 chip) is Rev. 1 or higher, dual pulse will function from 3 Hz and higher.

• Pulse doubling will not function for input pulses below 25 Hz.

14

13

12

11

10

9

8

7

6

5 Shield

4

3

2 A-

1 A+

CN5

5

4 Gnd

3 +12Vdc

2

1

CN6

PA-6

MNET Board

PA-6, Single Pulse

5

3

1

14

13

12

11

10

9

8

7

6

5 Shield

4

3

2 A-

1 A+

CN5

5

4 Gnd

3 +12Vdc

2

1

CN6

PA-6

MNET Board

PA-6, Dual Pulse

5

3

1

PA-6

5

3

1

Table of contents

Other TechnipFMC Control Unit manuals

Popular Control Unit manuals by other brands

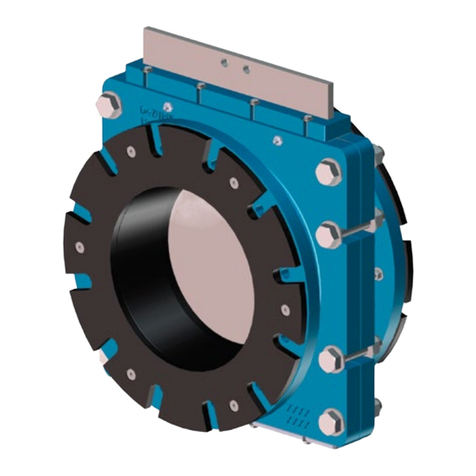

DeZurik

DeZurik KSL-LA manual

Ross

Ross Vision 4800DR-332-02 installation guide

Circutor

Circutor CBS-4 Series instruction manual

Renschler

Renschler Picolario2 single quick start guide

Sierra Wireless

Sierra Wireless AirPrime EM7565 Hardware integration guide

Sioux Tools

Sioux Tools 1785 Service and operation manual