TechnipFMC Smith Meter AccuLoad III User manual

Electronic Preset Delivery System

Smith Meter®AccuLoad®III with ALX Firmware

Installation Manual

Bulletin MN06135 Issue/Rev 1.3 (6/17)

Caution

The default or operating values used in this manual and in the program of the AccuLoad III

are for factory testing only and should not be construed as default or operating values for

your metering system. Each metering system is unique and each program parameter must

be reviewed and programmed for that specific metering system application.

Disclaimer

FMC Technologies Measurement Solutions, Inc. hereby disclaims any and all responsibility

for damages, including but not limited to consequential damages, arising out of or related to

the inputting of incorrect or improper program or default values entered in connection with

the AccuLoad III.

Receipt of Equipment

When the equipment is received the outside packing case should be checked immediately for any shipping damage.

If the packing case has been damaged, the local carrier should be notified at once regarding his liability. Carefully

remove the unit from its packing case and inspect for damaged or missing parts.

If damage has occurred during shipment or parts are missing, a written report should be submitted to the Customer Ser-

vice Department, FMC Technologies Measurement Solutions, Inc., 1602 Wagner Avenue, Erie, Pennsylvania 16510.

Prior to installation, the unit should be stored in its original packing case and protected from adverse weather

conditions and abuse.

Caution:

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with this Instruction Manual, may cause interference to radio communications. It has not

been tested to comply with the limits for a Class A computing device pursuant to Subpart J of Part 15 of

FCC Rules, which are designed to provide reasonable protection against such interference when operat-

ed in a commercial environment. Operation of this equipment in a residential area is likely to cause inter-

ference, in which case the user, at his own expense, will be required to take whatever measures may be

required to correct the interference.

Warning

These preset devices must be used with fail-safe backup equipment to prevent accidental runaway delivery of

product. Failure to provide backup equipment could result in personal injury, property loss and equipment damage.

Warning

On initial power-up of a new unit or after installation of a new computer board, there are several alarms that will

be triggered which cannot be cleared until the AccuLoad is programmed.

United States NIST Handbook 44 UR.3.5.1. and UR.3.5.2.

For compliance to United States NIST Handbook 44 UR.3.5.1. and UR.3.5.2., invoices printed using a mechanical

numeric-only printer (e.g., Smith Meter Load Printer) must contain in preprinted form the following information:

a. Volume corrected to 60 degrees F

b. API/C of E _____________________

c. Temperature ____________________

d. Gross Volume ____________________

where the API/C of E, temperature, and gross volume may be hand-written on the ticket. Refer to Handbook 44,

UR.3.5.1. and UR.3.5.2. for current requirements.

This page intentionally left blank.

Table of Contents

Section I - Introduction................................................................................................................................................1

Receipt of Equipment..............................................................................................................................................1

Warning and Precautions........................................................................................................................................1

Weights and Measures Requirements....................................................................................................................2

Section II - Pre-Installation Considerations ................................................................................................................3

Mechanical..............................................................................................................................................................3

Electrical..................................................................................................................................................................3

Environmental.........................................................................................................................................................4

Section III - Installation ...............................................................................................................................................5

Mechanical..............................................................................................................................................................5

Electrical..................................................................................................................................................................5

Input Frequency x2..............................................................................................................................................6

Start-Up ...............................................................................................................................................................6

General Requirements............................................................................................................................................6

Section IV - Diagrams.................................................................................................................................................7

Switch Settings..................................................................................................................................................... 10

Analog Module Settings (JP1 on EAAI)............................................................................................................... 11

Bi-State DC Inputs and Output Jumper Settings (JP1 on the BSE) .................................................................... 13

Pulse Inputs ......................................................................................................................................................... 15

Dual Pulse Inputs for Rev. 10.07 and Above Firmware (With Flow Controlled Additive).................................... 18

Promass 80, 83, and 84....................................................................................................................................... 33

Wiring Terminals, 4-20mA and 1-5 Vdc Inputs/Outputs ...................................................................................... 49

Digital Inputs ........................................................................................................................................................ 50

Wiring Terminals, Digital Inputs ........................................................................................................................... 51

Digital Outputs...................................................................................................................................................... 52

Wiring Terminals, Digital Outputs ........................................................................................................................ 53

Digital Inputs – AICB............................................................................................................................................ 67

Optional AICB Board(s) (Additive Inputs/Outputs)............................................................................................... 69

Communications (AICB Boards).......................................................................................................................... 72

Jumper Locations................................................................................................................................................. 72

Optional ComFlash Mass Storage Expansion Board .......................................................................................... 81

Section V - Maintenance ......................................................................................................................................... 83

Maintenance......................................................................................................................................................... 83

Battery replacement procedure............................................................................................................................ 83

Firmware updates ................................................................................................................................................ 84

Enclosure Maintenance....................................................................................................................................... 84

Special Environments .......................................................................................................................................... 85

Section VII - Completing the Installation.................................................................................................................. 86

Explosion-proof housing closure.......................................................................................................................... 86

Sealing ................................................................................................................................................................. 87

Section VIII - Related Publications.......................................................................................................................... 88

This page intentionally left blank.

Section I – Introduction

MN06135 Issue/Rev. 1.3 (6/17) 1

This manual is to be used for the installation of the

AccuLoad III Electronic Preset Controller with Accu-

Load III firmware. The manual is divided into the fol-

lowing sections: Introduction, Pre-Installation Con-

siderations, Installation, Diagrams, Maintenance,

Completing the Installation, and Related Publica-

tions.

Receipt of Equipment

When the equipment is received the outside pack-

ing, case should be checked immediately for any

shipping damage. If the packing case has been

damaged, the local carrier should be notified at once

regarding his liability. Carefully remove the unit from

its packing case and inspect for damaged or missing

parts.

If damage has occurred during shipment or parts are

missing, a written report should be submitted to the

Customer Service Department, FMC Technologies

Measurement Solutions, Inc., 1602 Wagner Avenue,

Erie, Pennsylvania 16510.

Before installation, the unit should be stored in its

original packing case and protected from adverse

weather conditions and abuse.

Warnings and Precautions

Before you begin please read all of the following

warnings and cautions to reduce the risk of injury,

equipment damage or malfunction.

Emergency Shutdown –The AccuLoad has an ex-

tensive set of built-in safety features.

IMPORTANT: The AccuLoad should never be relied

upon to act as the primary safety system control for

the flow valve and pump controls, i.e. emergency

stop, overfill, ground protection, etc. These should

always be handled by separate systems specifically

designed for that application. For example, Safety

systems specifically to meet SIL requirements. Any

power control circuits from these external systems

shall be wired in series ahead of the AccuLoad to

remove power to the ancillary devices.

Hazardous Voltages –There are hazardous volt-

ages involved in the installation and maintenance of

the AccuLoad and only qualified individuals should

perform installation.

Hazardous Locations –The S and Q models are

approved for use in an explosive (Class I, Div. I,

Groups C & D and Zone 1 Ex d ia, IIB Gb) atmos-

phere but there are specific installation methods re-

quired to produce a comprehensive explosion-proof

system. This manual provides guidance for the Ac-

cuLoad installation only. In general, keeping the

front cover bolted close in accordance with the in-

structions in Section VII is the key to maintaining ex-

plosion protection.

Any modification of the AccuLoad housing inval-

idate the hazardous location rating of the Accu-

Load.

•Do not replace the bolts in the front cover

except with those supplied by the manufac-

ture. Using unapproved bolts invalidates the

explosion-proof rating of the enclosure.

•Do not drill or machine the housing.

•Do not attempt to replace the touchscreen or

glass except as part of the factory supplied

assembly.

Electrostatic Discharge Precautions – The elec-

tronic components in the AccuLoad are susceptible

to damage by static discharge. To minimize the risk

of damage, the following precautions should be fol-

lowed:

•Before touching a circuit board with hands or

tools, personnel/tools should be grounded

using a wrist strap.

•Avoid touching components or traces on the

circuit boards and handle by the edg-

es/mounting holes.

•Circuit boards should be kept in conductive

bags when not installed.

ATEX / IEC Installations –There are special re-

quirements for ATEX approved installations. Please

refer to Section III for a detailed list of the specific

requirements.

RF Radiation - The AccuLoad generates, uses, and

can radiate radio frequency energy and, if not in-

stalled and used in accordance with this Manual,

may cause interference to radio communications. It

has not been tested to comply with the limits pursu-

ant to Part 15 (CFR 47) of FCC Rules, as electronic

control equipment utilized by an industrial complex is

exempt from the rules.

Section I – Introduction

MN06135 Issue/Rev. 1.3 (6/17) 2

Operation of this equipment in a residential area

may cause interference, in which case the user, at

his own expense, will be required to take whatever

measures that may be required to correct the inter-

ference. The AccuLoad has been evaluated against

the standard EN 61326-1: “Electrical equipment for

measurement, control and laboratory use” and has

been found to comply to the European Community

EMC Directive 2014/30/EU.

Weights and Measures Requirements

The AccuLoad is a device marketed for a global

market. Requirements vary depending on the region.

It is a user requirement to verify that the AccuLoad is

programmed and operated in a manner consistent

with local codes and that proper notification (permit

for use) or registration has been filed with the local

authority or jurisdiction.

Section II – Pre-Installation Considerations

MN06135 Issue/Rev. 1.3 (6/17) 3

Mechanical

In addition to the following, all previous warnings

and cautions should be reviewed before installation.

1. A solid base (pedestal or shelf) should be used

to support the explosion-proof AccuLoad III

housing.

Weight: = 50 lb. (22.7 kg) ALIII-S Hardware

Weight: = 125 lb. (57.5 kg) ALIII-Q Hardware

2. The location and the height of AccuLoad III

should be selected to permit easy viewing of the

display and to provide convenient access to the

keypad by all users.

3. Access for servicing AccuLoad III is through the

front cover. For ease of service and removal of

parts the cover must swing open more than 90°.

The explosion-proof AccuLoad III is hinged on

the left.

4. Conduit entry to the explosion-proof AccuLoad

III is both through the bottom and top. The top

entries are used for those units where the CI-

VACON Grounding and overfill board is installed.

For the ALIII-S hardware there are three 1-1/4"

11.5 NPT conduit entrances in the bottom of the

unit and two 1" 11.5 NPT conduit entrances in

the top of the unit. For the ALIII-Q hardware

there are two 1-1/4" 11.5 NPT conduit entrances

and five 1" 11.5 NPT conduit entrances in the

bottom of the unit and one 1" 11.5 NPT conduit

entrance in the top of the unit.

5. In warm climates, AccuLoad III should be shad-

ed from direct sunlight. The maximum external

temperature of the AccuLoad III housing must

not exceed 140°F (60°C) to ensure that the in-

ternal temperature limit is not exceeded.

Electrical

1. All DC wiring must be routed into AccuLoad III

through the conduit entries located in the bottom

of the housing. Do not route DC and AC wiring

through the same conduit entry.

2. The DC signal wires must be multi-conductor

shielded cable of 18 to 24 AWG minimum strand

copper.

Note: The following recommendations are based on our

knowledge of the electrical codes. The local electrical codes

should be reviewed to ensure that these recommendations follow

the local code. Also installation manuals of all the equipment be-

ing wired into the AccuLoad should be reviewed for transmission

distances and wire recommendations.

Table 1. Typical Wire Sizes

Equipment Number &

Gauge of

Wire

Belden

Number or

Equivalent

Transmitters 4 / 18 Ga.

4 / 20 Ga. 9418

8404

Temp. Probes

Density & Pressure

Transmitters 4 / 22 Ga. 8729

OR

9940

EIA-232

Communications 3 / 24 Ga. 9533

EIA-485

Communications 4 / 24 Ga. 9842

Table 2. Maximum Cable Length and Baud Rate

(EIA-232)

Baud Rate Feet Meters

38,400 250 75

19,200 500 150

9,600 1,000 305

4,800 2,000 610

2,400 4,000 1,220

1,200 4,000 1,220

Table 3. Maximum Cable Length and Baud Rate

(EIA-485)

Baud Rates

Feet

Meters

1,200 to 38,400 4,000 1,220

Note: For Ethernet communications, refer to standard IT

practices for connecting any AccuLoad using routers,

hubs, switches, etc.

Section II – Pre-Installation Considerations

MN06135 Issue/Rev. 1.3 (6/17) 4

3. All AC wiring must be routed into AccuLoad III

through the conduit entries located in the bottom

of the housing. Connectors sized for a maximum

of 14-gauge wire, consult the local electrical

codes for the minimum AC wire size required for

your application. Do not route AC and DC wiring

through the same conduit entry.

4. All AC wiring should be stranded copper and

must comply with federal, state and local codes

and specifications.

5. Two separate AC circuits must be provided from

the breaker panel. One circuit will supply isolat-

ed power to the AccuLoad III electronics (in-

strument power). The second circuit will supply

power to the external devices.

6. For proper operation the AccuLoad III must be

earth grounded. The grounding point should be

as close to the unit as possible. To ensure proper

earth ground:

a) The resistance between the ground lug in

the AccuLoad III and the grounding point

must not exceed 2 Ω.

b) The proper grounding point is a ½" to ¾" di-

ameter copper stake that extends into the

water table. Where this is not practical, a

ground plane may be used.

Note: Electrical conduit, piping, and structural steel are

not considered proper grounding points for equipment

using electronics.

c) No other devices, except AccuLoad IIIs and

ancillary equipment such as load printers,

should be connected to any point in the

grounding circuit.

7. If external relay permissives are used in series

with AccuLoad III relays, an RC network must be

placed in parallel with the permissive to prevent

a false turn-on of the AccuLoad III relays. Rec-

ommended RC network = 0.1 UF capacitor and

a 680 Ωresistor (Electrocube part number RG

2031-11).

8. Interposing relays must be installed between the

pump controller, alarming device, and the Accu-

Load III permissive sense relays.

Environmental

Models ALIII-S-XP and ALIII-Q-XP

The enclosures of Explosion / Flame proof models

are manufactured from aluminum alloy, and are de-

signed to be operated in normal environmental con-

ditions free of corrosive agents.

In areas including but not limited to environmentally

corrosive atmospheres, special considerations for

additional environmental protections shall be made if

installing into near shore areas that are subject to

wind borne salt sea water spray and subject to pos-

sible continuous accumulations of wetted salt water

on the equipment. The recommended protection is

exclusion of the environment by placing the equip-

ment into secondary protected environment such as

a kiosk or a control room. If exclusion of the envi-

ronment is not possible, then extra means must be

taken to maintain the equipment integrity, this in-

cludes frequent cleaning and inspection intervals.

See Section IV for additional information.

In areas where the ambient temperature is very

high, it is recommended that the equipment be in-

stalled under a canopy / sun shield to limit direct

sunlight radiation.

In areas of high humidity (tropical) or with varying

temperature swings, it is recommended to place

TechnipFMC P/N 647 001 443 or similar desiccant

packs inside of the enclosures, and to maintain

these while in service.

Section III – Installation

MN06135 Issue/Rev. 1.3 (6/17) 5

Mechanical

See Pre-installation Considerations.

Electrical

ATEX & IEC EX - Approved Units

(a) Cable Entry must be in accordance to IEC

60079-1 section 13:

For systems utilizing cable glands, the gland

and/or thread adaptor must be Ex certified.

The cable end must be securely installed

and, depending on the cable type, be

properly protected from mechanical dam-

age. Requirements outlined in Section 10.4

of IEC 60079-14 shall be followed.

(b) Cable Entry must be in accordance to IEC

60079-1 section 13:

For systems utilizing conduit, an Ex certified

sealing device must be immediately at the

entrance of the enclosure. Any unused entry

must be suitably blocked with an Ex d IIB

certified plug. Requirements outlined in Sec-

tion 10.5 of IEC 60079-14 shall be followed.

(c) Installation:

General Installation to be in accordance with

IEC 60079-14, wiring system to be in ac-

cordance with section 9.

(d) Flame Path Dimensions:

AccuLoad Joint Dimensions: Flanged joint

widths are 19.05 mm minimum and gaps are

0.051 mm maximum. Flameproof joints shall

be maintained as outlined in section 10.4 or

IEC 60079-14.

(e) Cover Fasteners:

AccuLoad Special Fasteners: Cover Bolts –

steel grade 12.9, M8 x 1.25.

(f) Cautions and Warnings:

Caution: To prevent ignition of hazardous

atmospheres, disconnect from supply circuit

before opening, keep tightly closed when

circuits are in operation.

Warning:Contains internal battery-powered

circuit, to prevent ignition of hazardous at-

mospheres, do not open enclosure unless

area is known to be non-hazardous.

General Requirements

It is imperative that the electrical installation be per-

formed by a competent individual that is familiar with

associated risks involved with the installation, opera-

tion, and maintenance, of electrical equipment in

hazardous (classified) locations. This individual must

possess knowledge of local, national electrical

codes, and/or ordinances concerned with hazardous

location safety requirements. It is recommended

(may be required in some jurisdictions) that the final

installation should be verified / inspected by the au-

thority having jurisdiction before placing the equip-

ment into service.

Electrical installations in hazardous areas have fea-

tures specifically designed to make them suitable for

use in such locations and it is the operator’s respon-

sibility to maintain the integrity of those special fea-

tures.

The operator must ensure that electrical equipment

is:

a. Installed and operated correctly

b. Monitored on a regular basis

c. Maintained with due regard to safety

d. Follow all requirements of National Electrical

Code for the country of installation.

e. AC Circuits must be isolated from DC circuits

and brought into the unit through their respec-

tive conduit openings.

f. Be sure all connections on the terminal blocks

are tight.

g. All shields must be connected to terminals 3,

13, 14, or 15 on terminal block TB4 on the EAAI

Board or terminal 3 and 4 on terminal block

TB6 on the KDC Board, or terminals 9 and 10

on TB14 on the BSE Board.

All exposed shields must be properly insulated

to prevent short circuits to other terminals or to

the chassis. The shield at the device (e.g., tem-

perature device, transmitter, etc.) must be cut

back to the insulation and taped off. All shields

should be continuous. If splices are required,

they must be soldered and properly insulated. If

other communicating devices are used with the

AccuLoad III, refer to the manual for that unit for

shielding information. Shields for other com-

municating equipment should not be terminated

in the AccuLoad III.

Section III – Installation

MN06135 Issue/Rev. 1.3 (6/17) 6

Note: Shields must not be terminated at the ground lugs.

h. Sufficient slack should be provided for the wir-

ing in the AccuLoad III to permit easy removal

of the boards. With sufficient slack, the terminal

blocks can be removed and laid back out of the

way so that the boards can be replaced without

removing individual wires.

i. There is a ground lug provided in the unit. The

wire from the lug should be connected to the

proper grounding point. See Pre-Installation

Considerations, page 2.

j. Typical electrical installation diagrams are pro-

vided in the following sections to show the Ac-

cuLoad III and ancillary equipment. Before wir-

ing the ancillary equipment, refer to its installa-

tion manual.

Installing and Removing the Analog I/O Module

Caution: Turn off the power at the unit prior to installing

or removing the Analog I/O Module. Failure to do so will

damage modules.

Care should be taken when installing or removing

the Analog I/O modules so as not to damage the

board or the module. To install the module, line up

the alignment pins with the socket and push down

on the module. Once it is seated, screw in the

mounting screw until tight. Do not over-tighten the

screw. To remove the modules from the board, loos-

en the mounting screw and pull up on the module.

Figure 1. Analog Modules

Input Frequency x2

If the application requires a pulse rate that is higher

than the meter is capable of putting out, the Accu-

Load III can multiply the incoming pulses times 2.

This option is activated by switches located on the

PIB boards. The PIB boards are located on the EAAI

and the BSE boards.

Figure 2. Connector and Switches on PIB Board

The default setting from the factory is “times 1.” The

switch is closed (ON). To multiply the incoming puls-

es times 2, push the switch of the incoming pulse

channel to the open (OFF) position. The switches

are located on the PIB boards, as shown in Figure 2.

The PIB board that is located on the EAAI board is

for pulse inputs 1 through 6. The PIB board that is

located on the BSE board is for pulse inputs 7

through 12.

Note: The switches correspond to the pulse input channels (i.e.,

Meter Pulse In #1 is equal to Switch #1.) See Table 6 for corre-

sponding Pulse Input channels.

Start-Up

When the wiring is completed and verified, power

may be applied to the unit. The displays should light,

indicating that the AccuLoad III is ready for Start-Up.

Please reference the Operator Reference Manual.

Section IV– Diagrams

MN06135 Issue/Rev. 1.3 (6/17) 7

Figure 3. AccuLoad III-Q Dimensions

Section IV – Diagrams

MN06135 Issue/Rev. 1.3 (6/17) 8

Figure 4. AccuLoad III-S Dimensions

Section IV – Diagrams

MN06135 Issue/Rev. 1.3 (6/17) 9

Figure 5. KDC Layout

Configurable jumper locations are heavily circled on the diagram above. It is important to note that all but one of

these jumpers, J22, are factory defaults and should not be configured by the user. The proper settings are provid-

ed below so if one of these is accidentally changed, it can be returned to its original position. J22 is the jumper

used to zero the passcodes and security input access level (151-157). Jumpers are configured using the plugs

that fit over the jumper prongs. A jumper with no prongs plugged, or with one prong plugged, is OUT. A jumper

with both prongs plugged is IN.

Note: Should Program Mode be inaccessible after changing PROMs, or if the operator loses or forgets the access code, set J22 to In, then

power up. Entry to the program mode is provided. Check passcodes and remove jumper J22 when finished.

1 – In

4 – Out

7 – Out

10 – Out

13 – In

16 – Out

25 – Out

2 – In

5 – Out****

8 – Out

11 – In

14 – Out

23 – In*

3 – In

6 – In***

9 – Out

12 – Out

15 – In

24 – In**

* Jumper 23 if removed indicates there is not a BSE board in the System (ALIII-S Hardware)

** Jumper 24 if removed indicates there is only one display (ALIII-S Hardware)

*** For units shipped prior to October 2001: J6 must be in the “in" position for Optrex Model DMF5003N.

For units shipped after October 2001: J6 must be in the “out" position for Model MTG-2406 displays.

**** For units shipped prior to August 2005: J5 must be in the “out” position. After August 2005 and for all units with Rev. B displays,

the Jumper J5 must be in the “in” position.

Section IV – Diagrams

MN06135 Issue/Rev. 1.3 (6/17) 10

Switch Settings

A new 8 pin DIP switch will be available for use (SW SW1-8). The switch will be utilized as follows:

SW1-1 force firmware upgrade (powers up waiting for firmware upgrade)

SW1-2 SW1-3

OFF OFF use programmed IP address

ON OFF use 192.168.0.1

OFF ON use 10.0.0.1

ON ON use DHCP

Figure 6. EAAI Layout

The user-configurable jumper on the EAAI board is indicated by a circle and arrow in the diagram above. See the

table on the following page for an explanation of analog module settings. This jumper has been configured for the

modules that were shipped with the unit. Changes should only be made if different modules are added or deleted.

Modules must be installed with inputs first, followed by outputs.

Ribbon Cable

Section IV – Diagrams

MN06135 Issue/Rev. 1.3 (6/17) 11

Analog Module Settings (JP1 on EAAI)

6 Inputs, 0 Outputs

2 Inputs, 4 Outputs

5 Inputs, 1 Output

1 Input, 5 Outputs

4 Inputs, 2 Outputs

0 Inputs, 6 Outputs

3 Inputs, 3 Outputs

Table 4. Analog Module Settings

Section IV – Diagrams

MN06135 Issue/Rev. 1.3 (6/17) 12

Figure 7. BSE Layout

Note: JP1 3 through 6 define the number of BIOB inputs. JP1 1 and 2 are not used.

Section IV – Diagrams

MN06135 Issue/Rev. 1.3 (6/17) 13

Bi-State DC Inputs and Output Jumper Settings (JP1 on the BSE)

8 Inputs, 0 Outputs

3 Inputs, 5 Outputs

7 Inputs, 1 Output

2 Input, 6 Outputs

6 Inputs, 2 Outputs

1 Inputs, 7 Outputs

5 Inputs, 3 Outputs

0 Inputs, 8 Outputs

4 Inputs, 4 Outputs

Table 5. Bi-State Inputs and Outputs

Section IV – Diagrams

MN06135 Issue/Rev. 1.3 (6/17) 14

Figure 8. KDC/EAAI/PIB/BSE Boards

Table of contents

Other TechnipFMC Measuring Instrument manuals

TechnipFMC

TechnipFMC Smith Meter JB10 S1 User manual

TechnipFMC

TechnipFMC Smith Meter C2 User manual

TechnipFMC

TechnipFMC Smith Meter MPU C Series Instruction manual

TechnipFMC

TechnipFMC Smith Meter Instruction manual

TechnipFMC

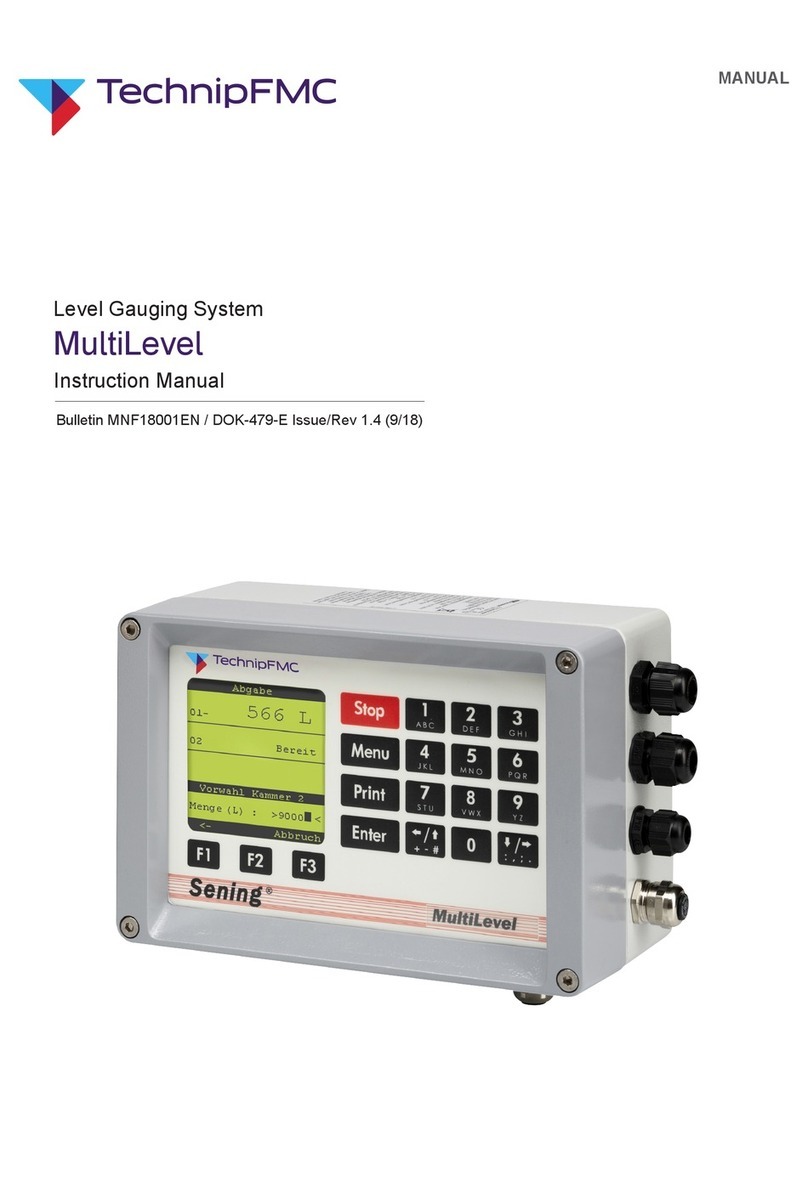

TechnipFMC Sening MultiLevel User manual

TechnipFMC

TechnipFMC 4728 User manual

TechnipFMC

TechnipFMC Smith Meter PRIME 4 User manual

TechnipFMC

TechnipFMC Proline Promass E 500 Instruction Manual

TechnipFMC

TechnipFMC Smith Meter AccuLoad IV Series Manual

TechnipFMC

TechnipFMC Smith Meter Genesis Series User manual