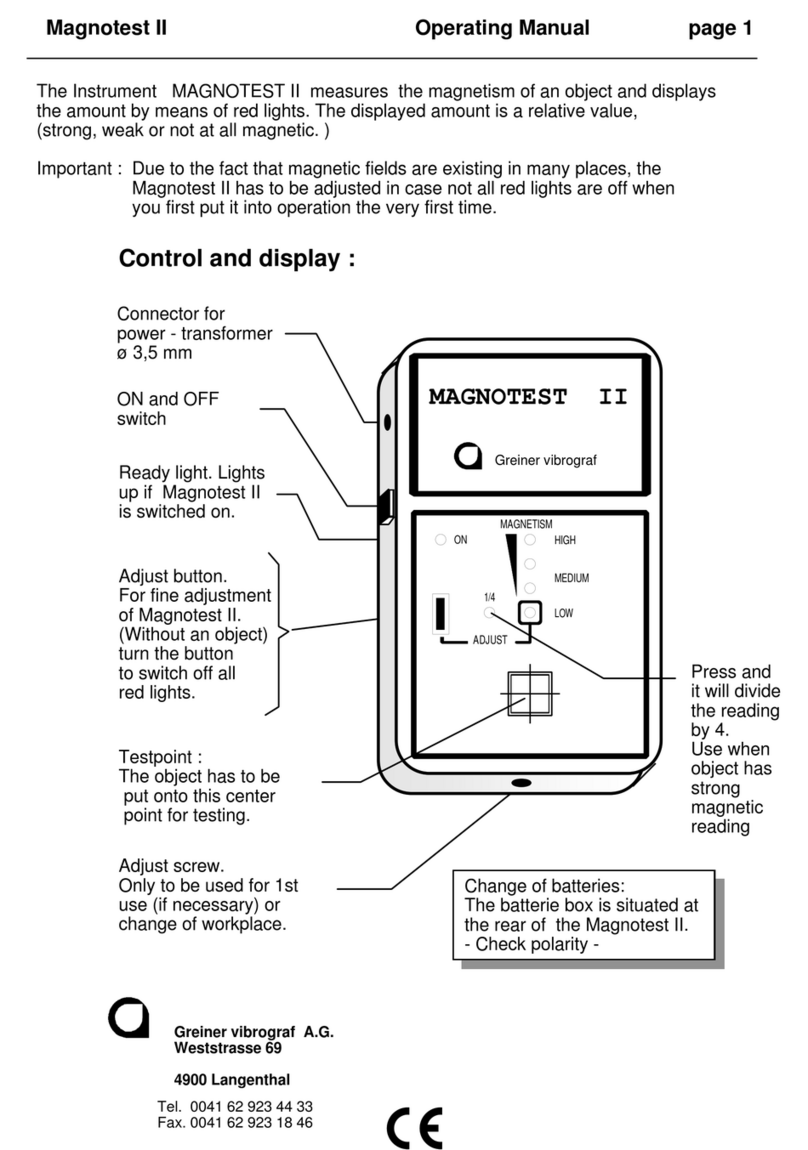

1 – Overview

®

-

-

-

Note:

1.1. Description

Smith Meter®

-

-

-

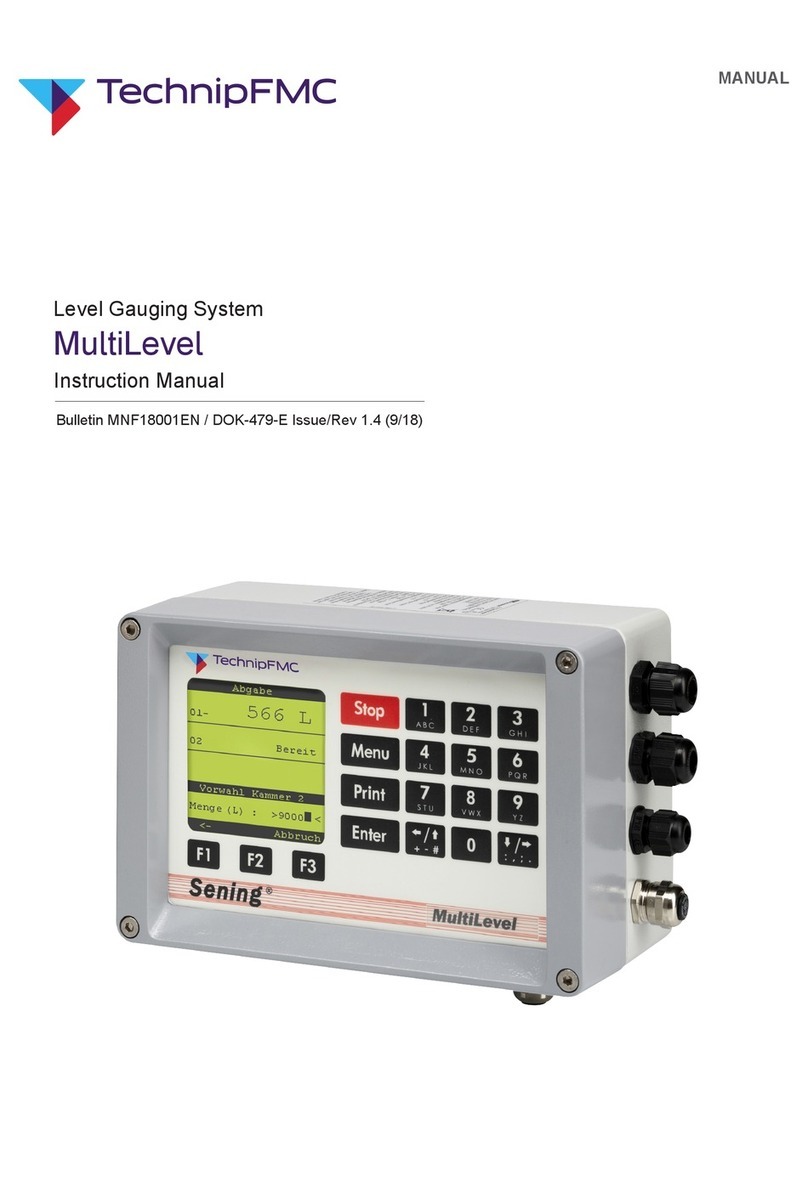

Figure 1

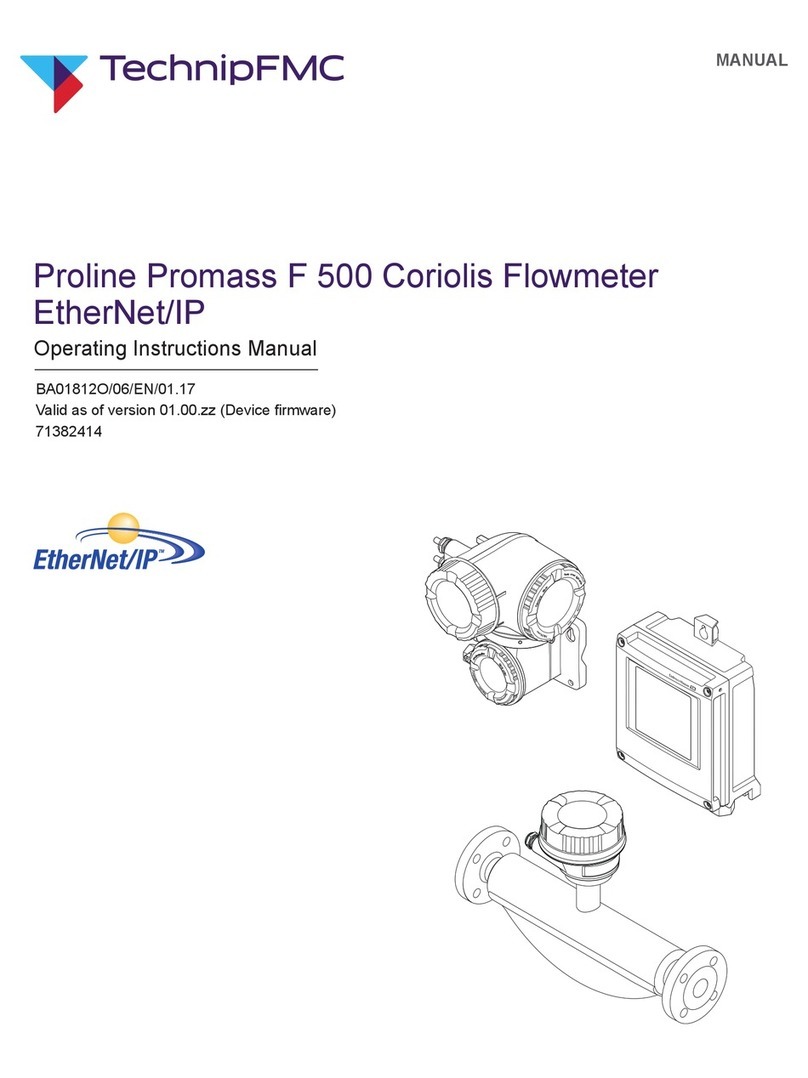

Figure 2 – Horizontal Double Case Meter

Universal Nameplate for PD Meters

Artwork # 554608701 Rev 1

ECN 80009698

FMC Measurement Solutions Inc.

Erie, PA 16510

MODEL

SERIAL NO.

ASSEM. NO.

MAWP

W&M

FLOW

RANGE

METER CLEARANCES SIZED FOR:

TEMP.

MAX. VISC.

MAX.