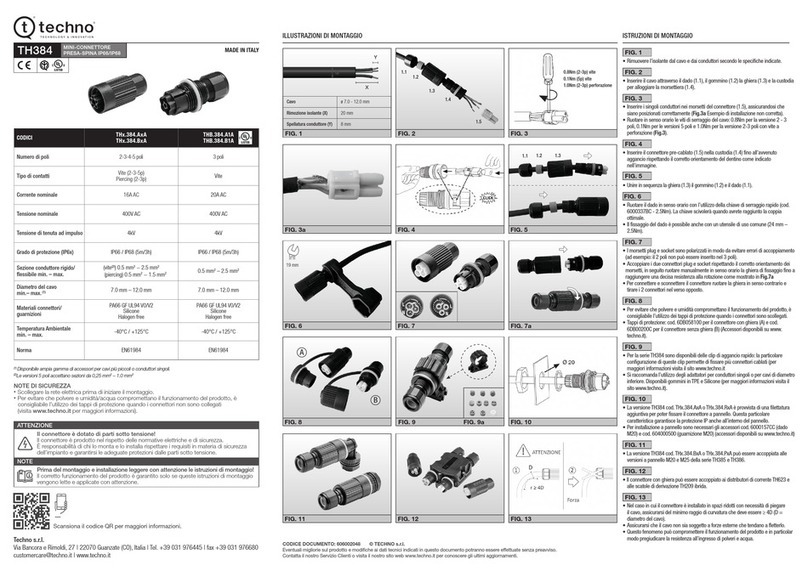

Strip the cable a length of 0.788 inches

(20 mm) (Fig. 2.1)

In case of screw connection

(PN: THB.385.xxx) strip the wires a

length of 0.315 inches (8 mm) and twist

them together (Fig. 2.1)

In case of piercing screw connection (PN:

THP.385.xxx) do not strip the wires (Fig.

2.2)

Connect the wires to the male connector

insert (or female connector insert) with a

screw driver.

Screws must be closed using a torque of

0.8 Nm for pressure wire

Insert the male connector insert in the

housing until it stop. Make sure the

connector insert’s protrusion match

with the housing’s cavity until you hear

a “click”

The female connector insert and the

male connector insert can be inserted in

both connector housings (male or

female) depending on the application

needs.

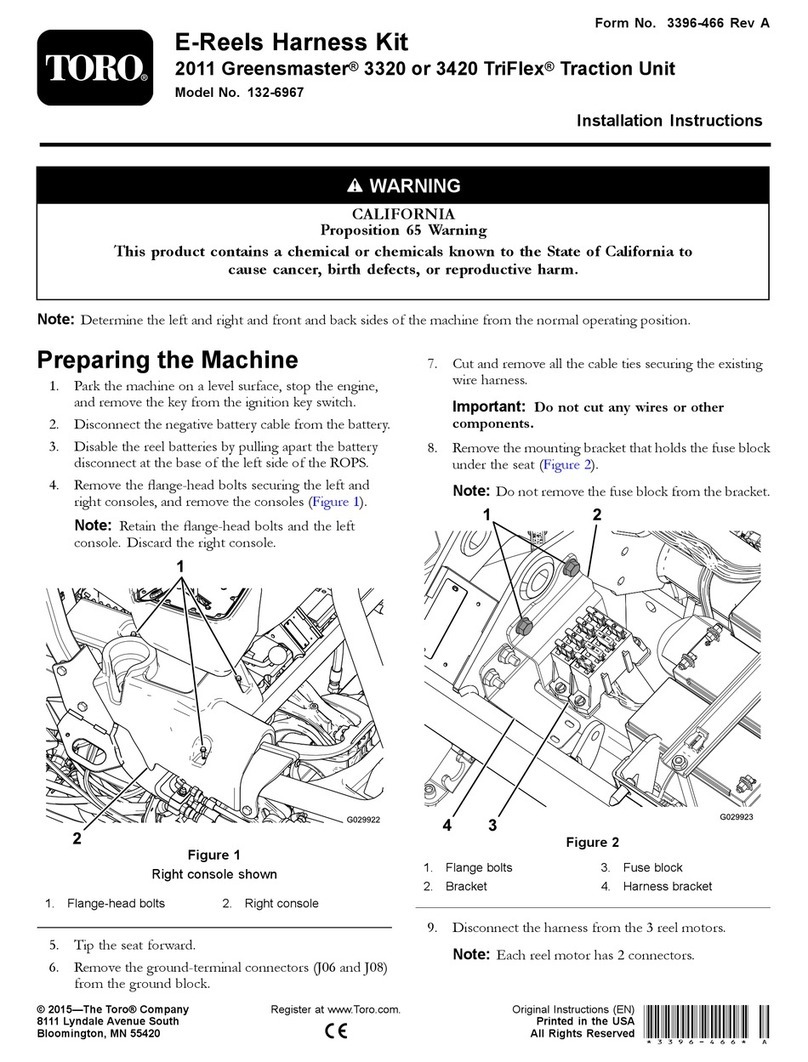

Firstly create a hole in the mounting

surface with Ø25 for the linear (Fig. 7.1)

and Ø20 for 90° version (Fig. 7.2)

Secondly, tighten the lock nut using the

appropriate tool to a torque of 2.5 Nm

and 4 Nm

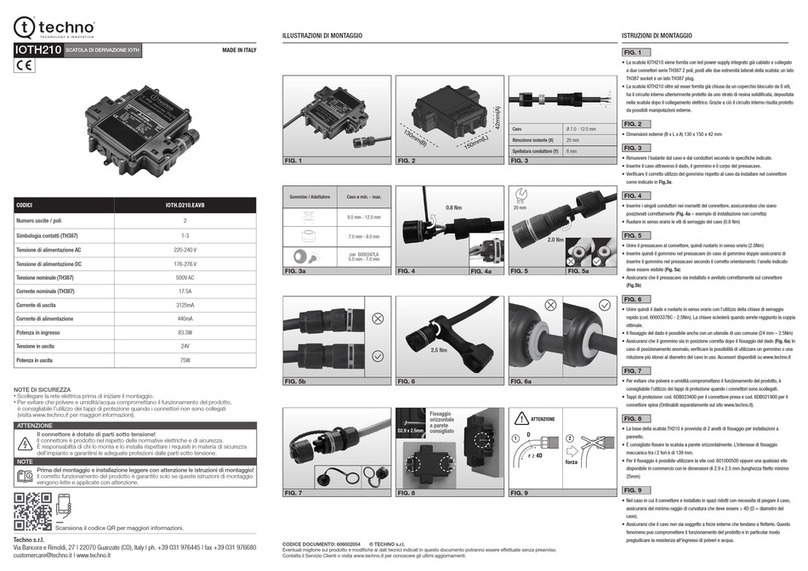

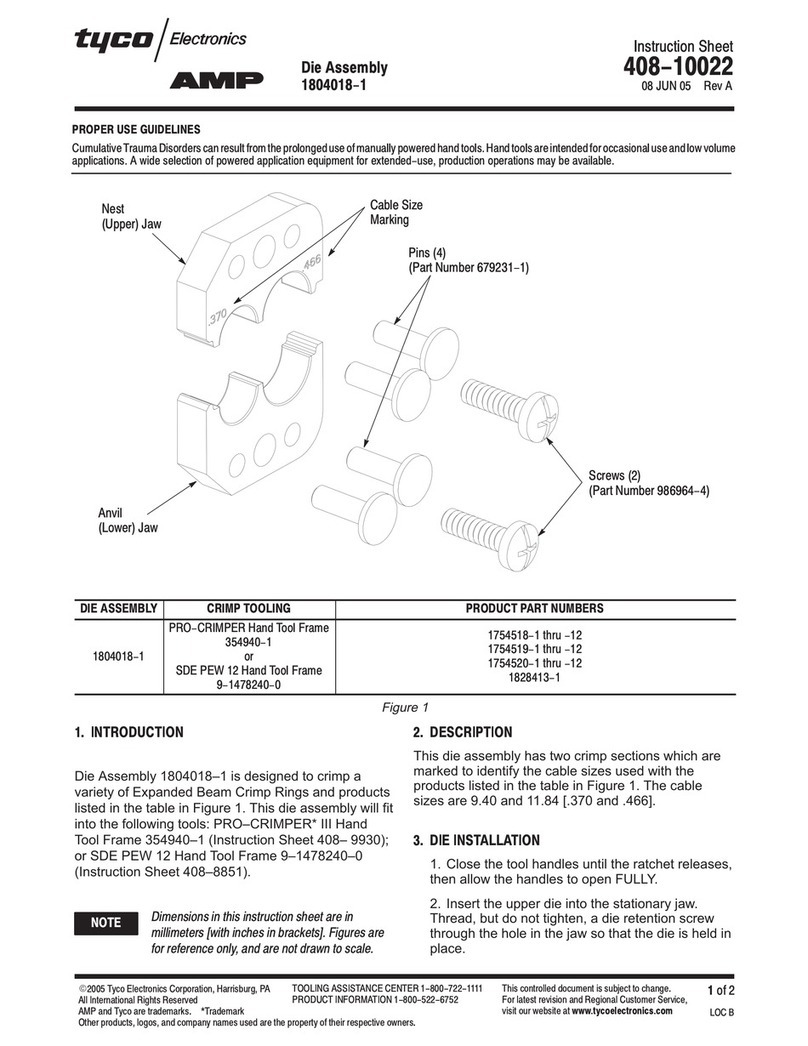

Set-up of the female connector: (a)

Pressure nut, (b) locking nut,

(c) cable seal, (d) connector housing, €

connector insert (male or female)

Unscrew the pressure nut till it comes

out from the connector housing (Fig.

9.1).

Pull out the locking nut from the

connector housing (Fig. 9.2).

Choose the cable seal and the cable

adapter according to the cable diameter

(Fig. 10.1).

Push the pressure nut and the cable seal

over the cable (Fig. 10.2).

Insert the cable in the female connector

housing (Fig. 10.2). Do not insert the

cable nut and seal in the connector

housing.

Strip the cable a length of 0.788 inches

(20 mm) (Fig. 11.1)

In case of screw connection

(PN: THB.384.xxx) strip the wires a

length of 0.315 inches (8 mm) and twist

them together (Fig. 11.1)

In case of piercing screw connection

(PN: THP.384.xxx) do not strip the wires

(Fig. 11.2)