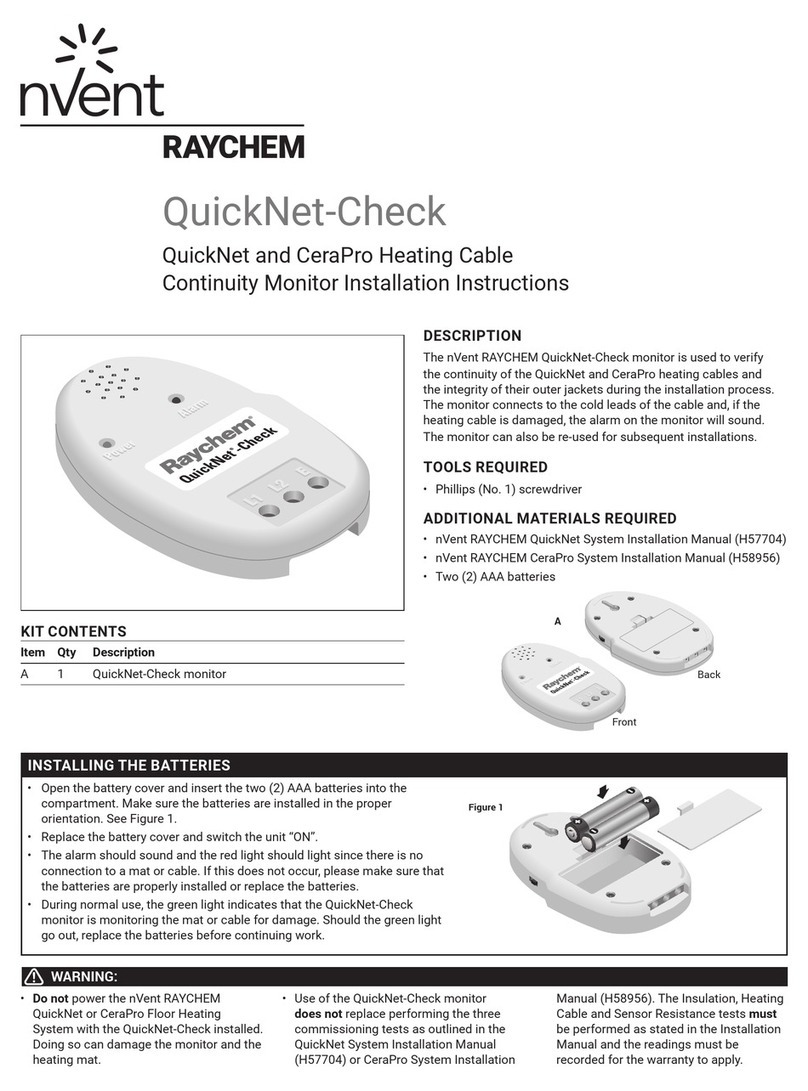

DESCRIPTION

The PolyMatrix nVent RAYCHEM PMKG-J2LP is a NEMA 4X rated

connection kit for use with nVent RAYCHEM BTV-CR, BTV-CT, QTVR-CT,

XTV-CT, KTV-CT and LBTV2-CT self-regulating heating cables.

Materials for one powered splice are included in this kit.

For technical support call nVent at (800)545-6258.

TOOLS REQUIRED

• Screwdriver • Needle-nose pliers

• Wire cutters • Utility knife

• Adjustable pliers

• Heat gun or mini-torch (for LBTV2 only)

ADDITIONAL MATERIALS REQUIRED

• Pipe straps

• Tape

– GT-66 Installation temperature above 40°F (5°C)

– GS-54 Installation temperature above –40°F (–40°C)

• HCS-100-A (Required for LBTV2)

• Grommets (Required for KTV and LBTV2)

This component is an electrical device which must

be installed correctly to ensure proper operation

and to prevent shock or fire. Read these important

warnings and carefully follow all of the installation

instructions.

• To minimize the danger of fire from sustained

electrical arcing if the heating cable is damaged

or improperly installed, and to comply with the

requirements of nVent and the 1996 National Electrical

Code, ground-fault equipment protection must be used

on each heating cable branch circuit. Arcing may not

be stopped by conventional circuit protection.

• Component approvals and performance are based

on the use of specified parts only. Do not use

substitute parts or vinyl electrical tape.

• The black heating cable core and fibers are

conductive and can short. They must be properly

insulated and kept dry.

• Damaged bus wires can overheat or short.

Do not break bus wire strands when scoring the

jacket or core.

• Keep components and heating cable ends dry

before and during installation.

HEALTH HAZARD. Prolonged or repeated contact with

the sealant in the core sealer may cause skin irritation.

Wash hands thoroughly. Overheating or burning the

sealant will produce fumes that may cause polymer fume

fever. Avoid contamination of cigarettes or tobacco.

Consult MSDS RAY/5510 for further information.

CHEMTREC 24-hour emergency telephone:

(800) 424-9300

Non-emergency health and safety information:

(800) 545-6258.

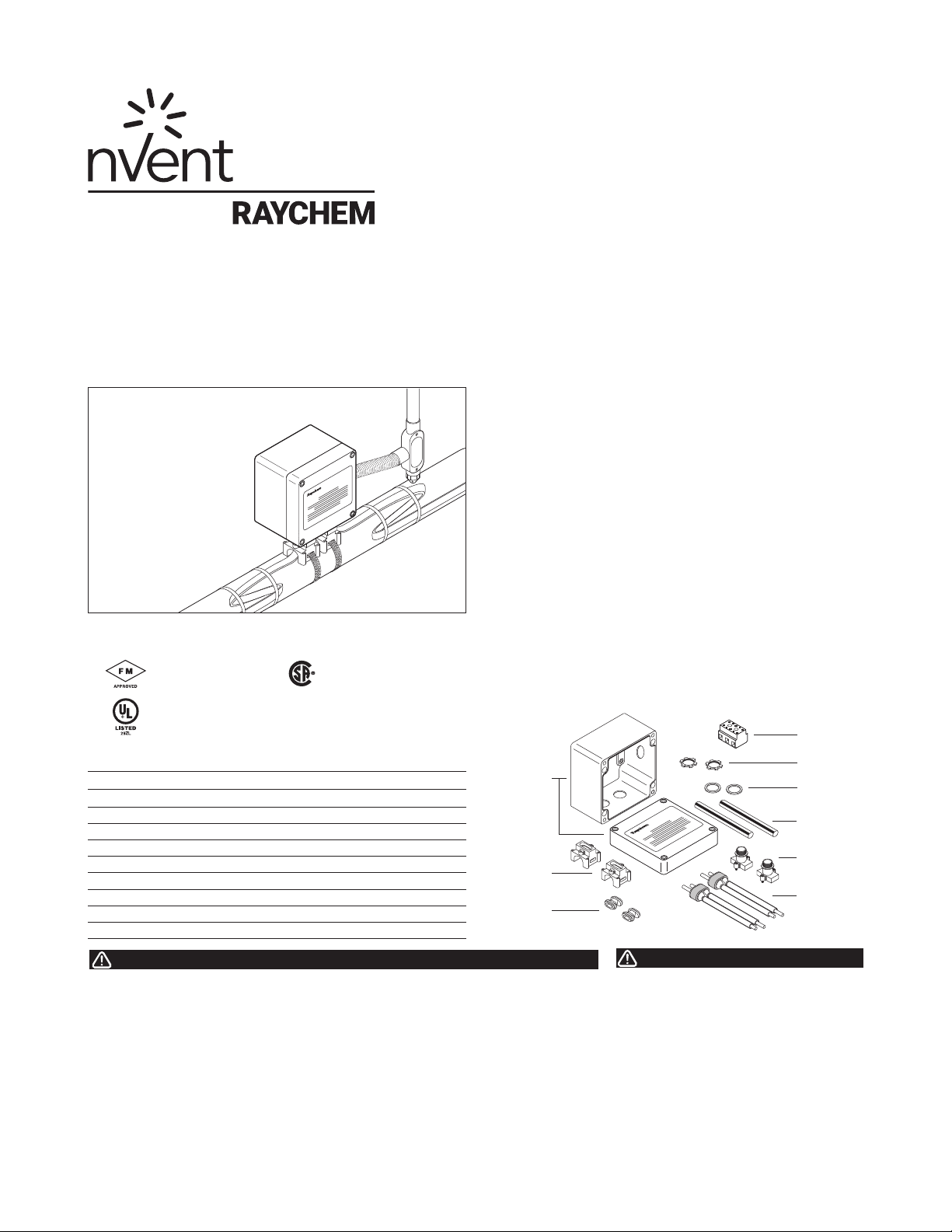

KIT CONTENTS

Item Qty Description

A 1 Junction box with lid

B 2 Bases

C 2 Red grommets

D 2 Core sealers

E 2 Tops (3/4 inch NPS thread)

F 2 Green/yellow heat-shrinkable tubes

G 2 Ring gaskets

H 2 Locknuts

I 1 Terminal block

A

B

C

F

E

D

G

H

I

APPROVALS

Hazardous Locations

Class I, Div. 2, Groups B, C, D

Class II, Div. 2, Groups F, G

Class III

Class I, Div. 2, Groups A, B, C, D

Class II, Div. 2, Groups F, G

Class III

Class I, Div. 2, Groups A, B, C, D

Class II, Div. 2, Groups F, G

For BTV and LBTV Heating Cable Systems Only

PMKG-J2LP

Polymatrix Powered Splice Kit Installation Instructions