Tecnoautomazione BOB User manual

WARNING!! Before installing, thoroughly read this manual that is an integral

part of the pack

The CE mark conforms to European directive

EEC 89/336 + 92/31 + 93/68 D.L. 04/12/1992 N. 476.

Our products if installed by qualified personnel capable to evaluate risks,

comply with norms UNI EN 12453, EN 12445

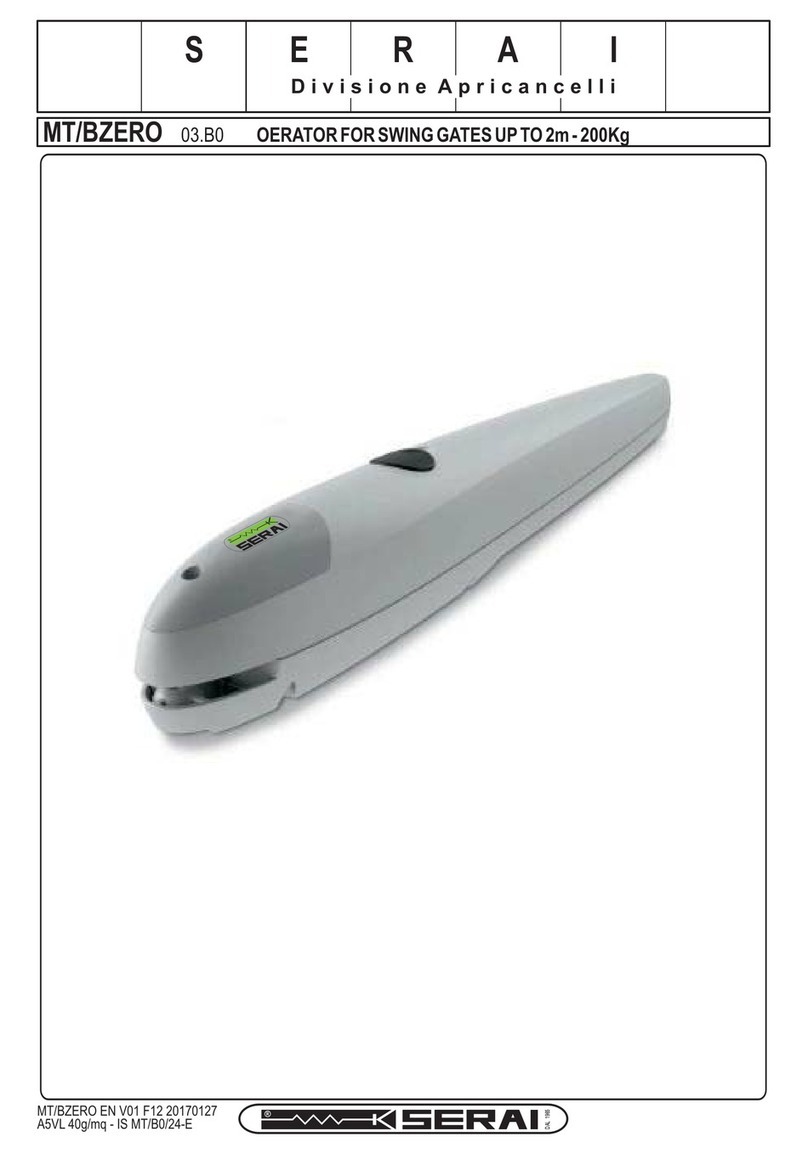

BOB

T.A. TECNO AUTOMAZIONE S.R.L.

Via Vicinale snc

03018 - Paliano - (FR) - Italy

+39 0775 533677

+39 06 97625593

FAX +39 0775 533299

+39 339 5877324

tecnoautomation.com tecnoautomation

PACKING CONTENTS ............................................................................. 2

VIEW OF TYPICAL AUTOMATION AND NAMES OF COMPONENTS............. 3

TECHNICAL DATA.................................................................................... 3

DIMENSIONS......................................................................................... 4

TYPICAL CONNECTION AND CABLE SECTION.......................................... 4

CONSIDERATIONS FOR INSTALLATION................................................... 5

INSTALLATION....................................................................................... 5-6

7

SAFETY PRECAUTIONS ..........................................................................

PACKING CONTENTS

1- OPERATOR

1- KIT FASTENING PLATES AND

RELATIVE ACCESSORIES

1- UNLOCKING KEY

1- CONDENSER (230Vca)

BOB

tecnoautomation

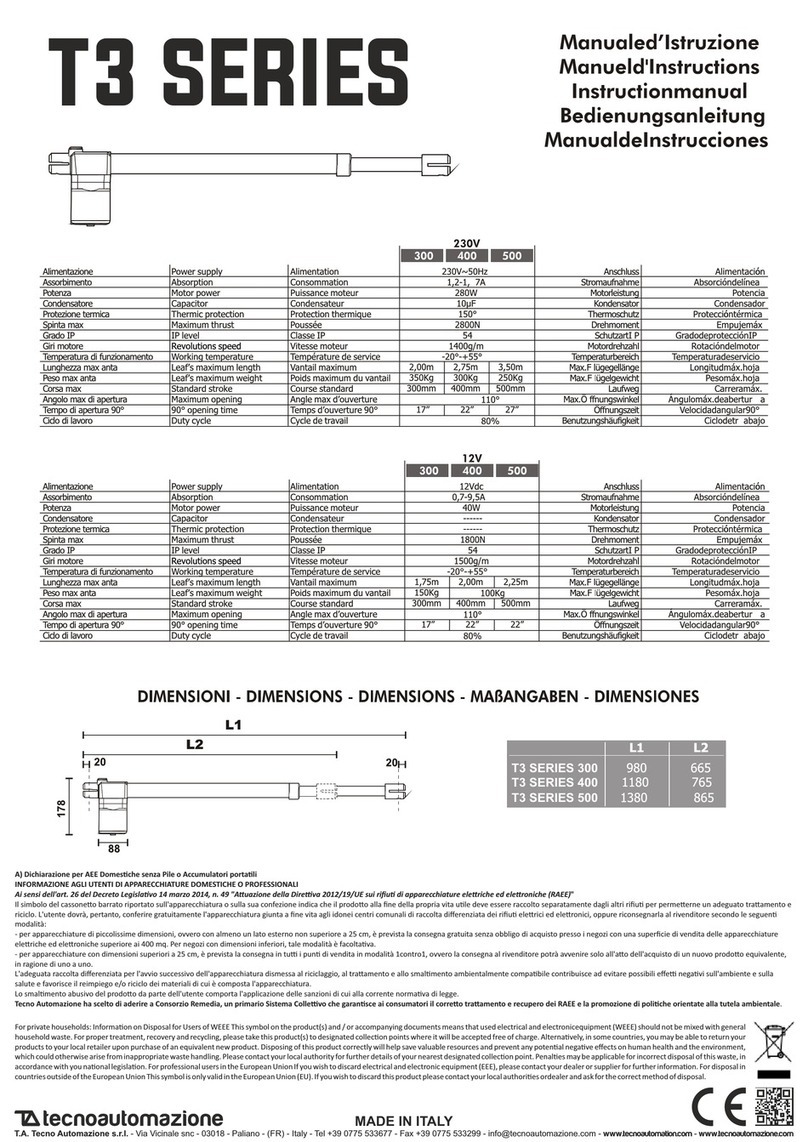

TECHNICAL DATA

Max. weight of gate

Max. width of gate

Motors power supply

Motor power

Motor RPM

Condenser

Mechanical unlock for emergency manoeuvre With key

Working temperature

weight

Protection rating

Opening time 90°

Rod stroke

Force of thrust

motor current input

2

5

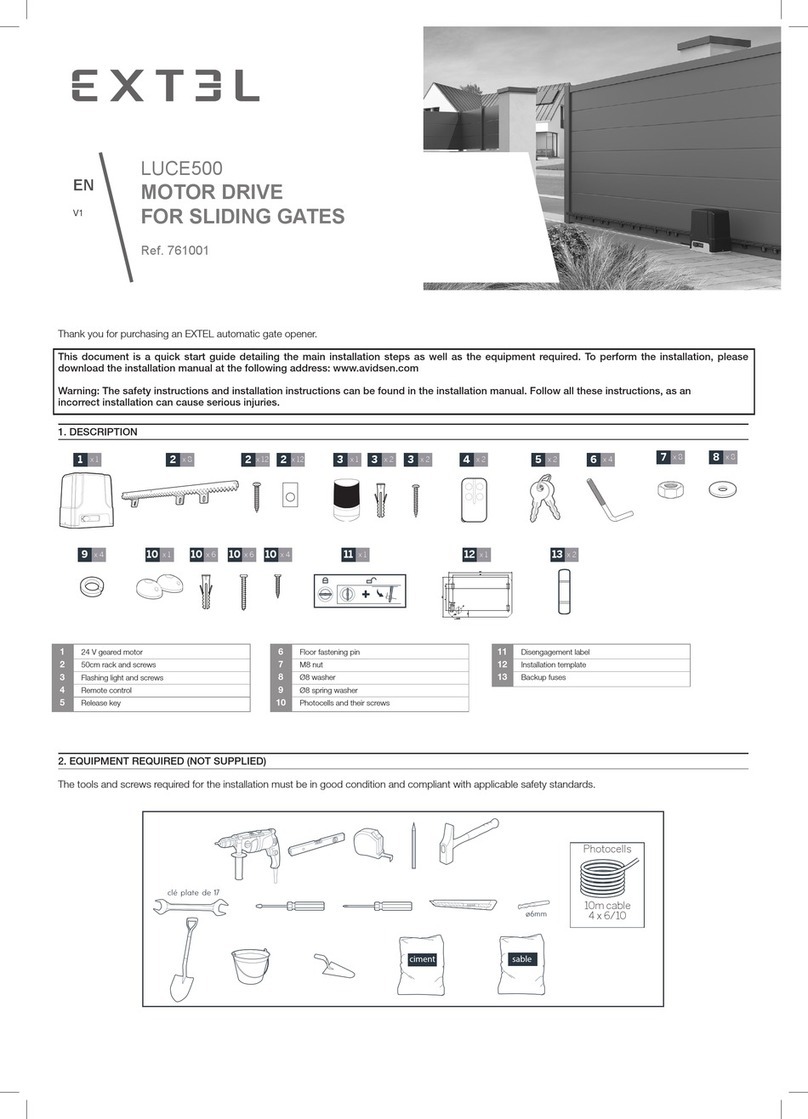

VIEW OF TYPICAL AUTOMATION AND NAMES OF COMPONENTS

1- Operator

2- External photocell

3- Flashing warning light

4- Antenna

Optimal installation

43

1

1

5

5- Internal photocell

6- Electronic control unit

7- Key-switch

8- Remote control

6

7

8

250 Kg

1,80 (300) -2,50 (400) -3,50 (600)mt

230 Vac

250 W

800

12,5 µF

-20° C / +55° C

7.5 Kg

IP 55

15/25/30 sec

300/400/600

1500 N

1 A

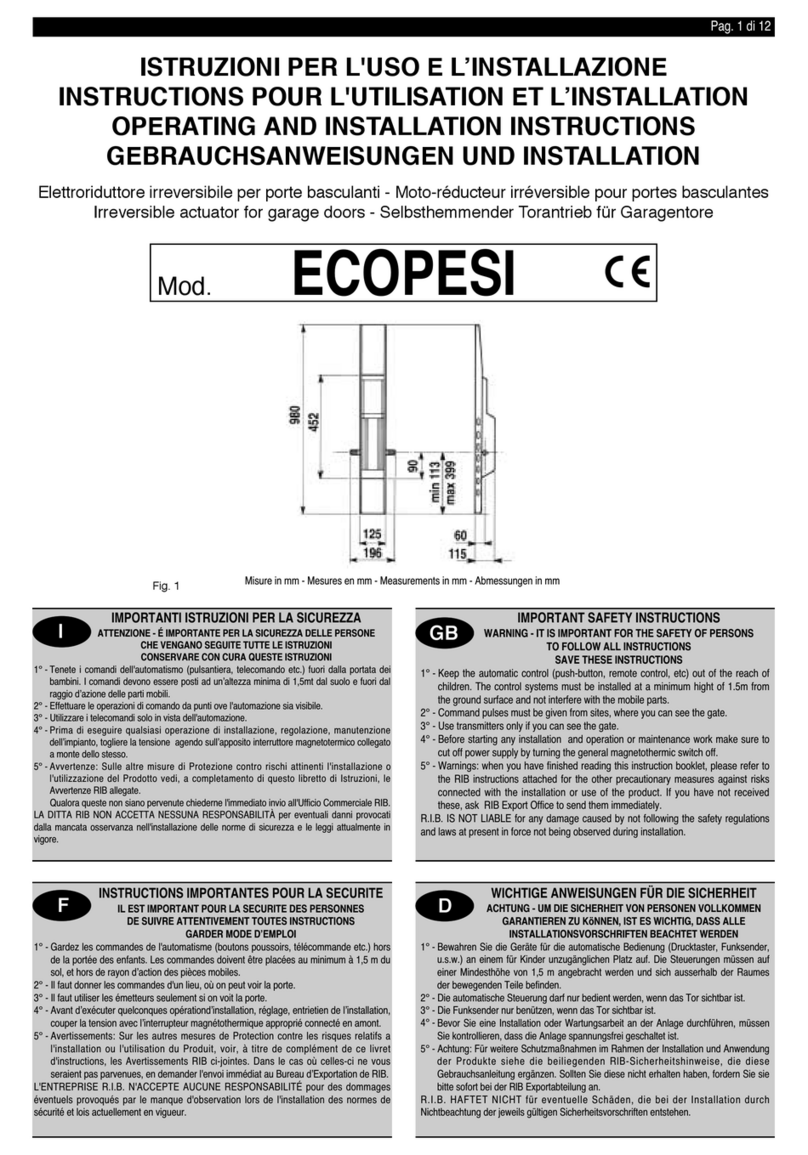

DIMENSIONS

TYPICAL CONNECTION AND CABLE SECTION

2X1,5mm2 (12 Vdc )

4X1,5mm2 (230 Vca )

2X0,75mm2

4X0,75mm2

4X0,75mm2

RX Photocell TX Photocell

2X0,75mm2

3X1,5mm2

230V Line

95 mm

280 mm

330 mm

375/475/675 mm 300/400/600 mm

95 mm

BOB

tecnoautomation

INSTALLATION

CONSIDERATIONS FOR INSTALLATION

1- Before fastening the brackets provided, establish the coordinates using the data given in

Table 1,

bearing in mind that they are valid if the operator is at maximum extension minus one

centimetre of the available stroke (CD) when the gate is closed to obtain maximum working

efficiency.

2- Data B in the table, with reference to the single values A, are to be considered as values

(recommended).

3- To anchor the piston, use the fastening brackets provided.

COORDINATES AND TABLE

TABLE 1

Opening angle A B Cu

90

80 80 160

90 90 180

100 100 200

100 150 250

100

110 110 220

120 120 240

120 100 220

110

130 130 260

140 140 280

150 150 300

90° Available stroke = 400mm

160 160 320

175 175 350

190 190 380

200 200 400

90°stroke 600 mm 300 300 600

Note1: A+B = CU(Stroke used) CD= (Available stroke)= 300 mm /400 mm /600mm

· The installation and testing operations must be performed solely by qualified personnel in

order toguarantee the proper and safe operation of the automatic gate.

· The company declines any responsibility for damage caused by incorrect installations due

to incompetence and/or negligence.

· Before assembling the automatism, check that the gate is in perfect working order, hangs

well on its hinges and is suitably lubricated. It must also comply with the safety standards

in force in the country of installation..

1. Establish coordinatesA + B that are

to be used.

2. Note: The stroke used (CU) of the

operator must never be equal or

greater than the available stroke CD

3. The sum of coordinates A + B,

establishes the stroke us e d CU.

INSTALLATION OF FASTENING PLATES

Fasten the plate provided to the

post(fig. 1)

Anchor the rear part of the piston to

the plate and fasten it firmly(fig. 2).

Warning!When establishing the height off the ground at which to fasten the plate to the post

(fig. 1), keep in mind that the plate for anchoring the piston to the gate must be fastened at the

same level(fig. 3)

Installing the anchor plate on the piston to the gate

Release procedure

Open the plug located

underneath on the lower

part of the piston, insert

the key provided and turn

clockwise

(FIG. 2)

(FIG. 3)

(FIG. 1)

(FIG. 4)

1. Fit the anchor plate onto the piston (fig. 4)

2. Close the gate

3. Move the piston with the plate already

fitted towards the gate

4. Move the fitting to limit stop, then move it

back by approximately 1 cm and mark the

position of the plate.

5. realize the same operation in opening.

6. If positions correspond, fix the plate on the

gate; otherwise revise A and B units

(table 1)

T.A. TECNO AUTOMAZIONE S.R.L.

Via Vicinale snc

03018 - Paliano - (FR) - Italy

+39 0775 533677

+39 06 97625593

FAX +39 0775 533299

+39 339 5877324

tecnoautomation.com

BOB

tecnoautomation MADE IN ITALY

SAFETY PRECAUTIONS

These warnings are an essential, integral part of the product and must be given to the user. They

provide important indications on the installation, use and maintenance and must be read carefully.

This form must be preserved and passed on to subsequent users of the system. The incorrect

installation or improper use of the product may be dangerous.

INSTALLATION INSTRUCTIONS

The installation must be performed by professionally skilled personnel and in compliance with

current local, state, national and European legislation.

Before beginning the installation, check the integrity of the product.

The laying of cables, electrical connections and adjustments must be workmanlike performed.

The packing materials (cardboard, plastic, polystyrene, etc.) are a potential hazard and should

be disposed of correctly and not left within reach of children.

Do not install the product in potentially explosive environments or environments disturbed by

electromagnetic fields. The presence of inflammable gases or fumes is a grave danger to

safety.

Set up a safety device for overvoltage, a disconnecting and/or differential switch suitable for

the product and conforming to current standards.

The manufacturer declines any and all responsibility for product integrity, safety and operation

in the event incompatible devices and/or components are installed.

Solely original spare parts should be used for repairs and replacements.

The installer must provide all the information relating to the operation, maintenance and use of

the individual parts, components and system as a whole.

WARNINGS FOR THE USER

Read the instructions and enclosed documentation carefully.

The product must be used for the express purpose for which it was designed. Any other use is

considered improper and therefore hazardous. In addition, the information given in this

document and in the enclosed documentation may be subject to modifications without prior

notice. It is given as an indication only for product application. The company declines any

responsibility for the above.

Keep products, devices, documentation and anything else provided out of reach of children.

In the event of maintenance, cleaning, breakdown or faulty operation of the product, cut off the

power and do not attempt to operate on the product. Contact solely the professionally skilled

personnel responsible for these operations. Failure to adhere to the above indications may be

dangerous.

The data and images are for guidance only

TA reserves the right to change at any time characteristics of the products described in

its sole discretion, without notice.

Table of contents

Other Tecnoautomazione Gate Opener manuals

Popular Gate Opener manuals by other brands

Extel

Extel LUCE500 quick start guide

Mirrow

Mirrow Moovo LN4 Series Installation and use instructions and warnings

Nice Apollo

Nice Apollo 72001K installation manual

Chamberlain

Chamberlain Smart Garage MYQ-G0401 quick start guide

Cardin

Cardin 200/BL3924ESB instruction manual

Beninca

Beninca BULL 10M Operating instructions and spare parts catalogue