Serai MT/BZERO User manual

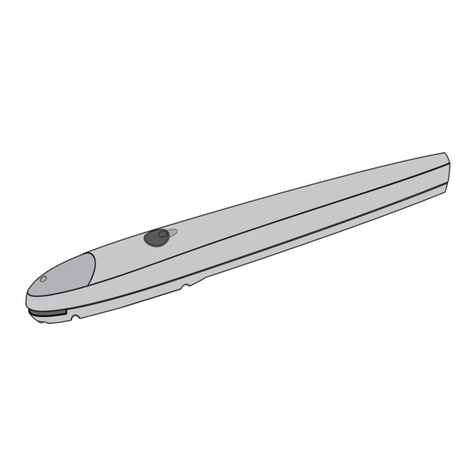

MT/BZERO

03.B0

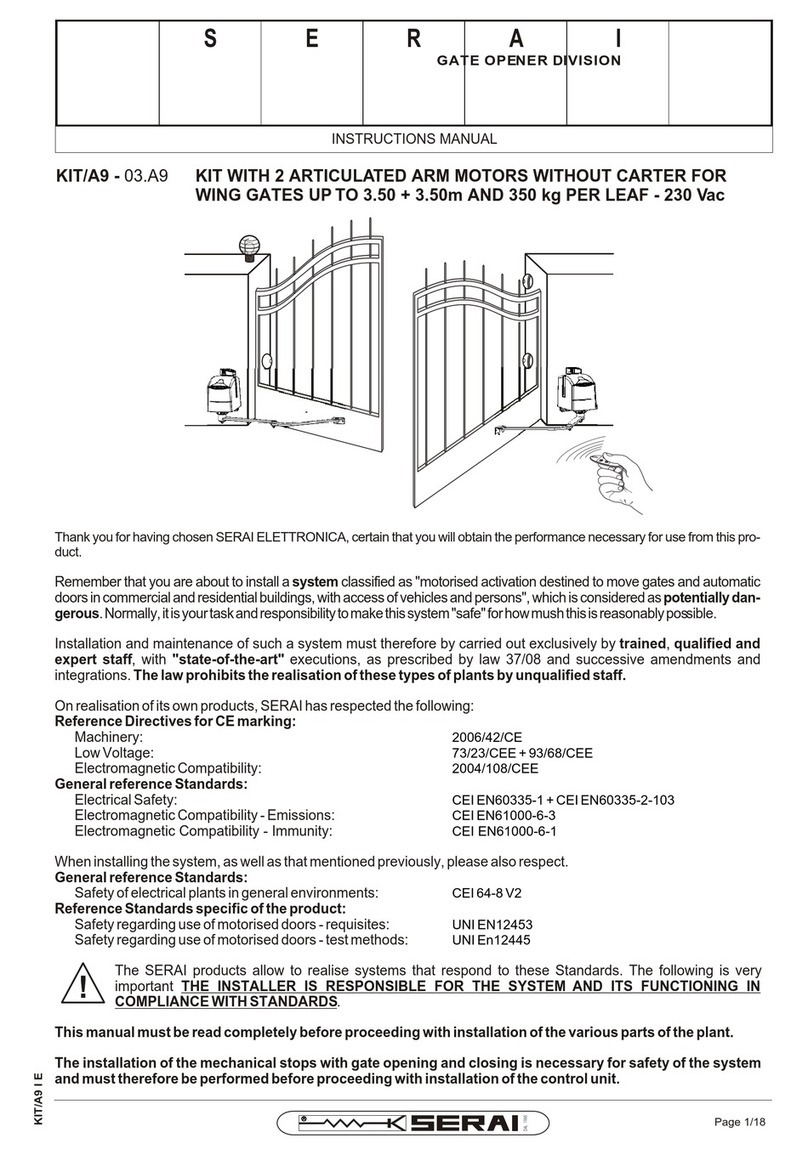

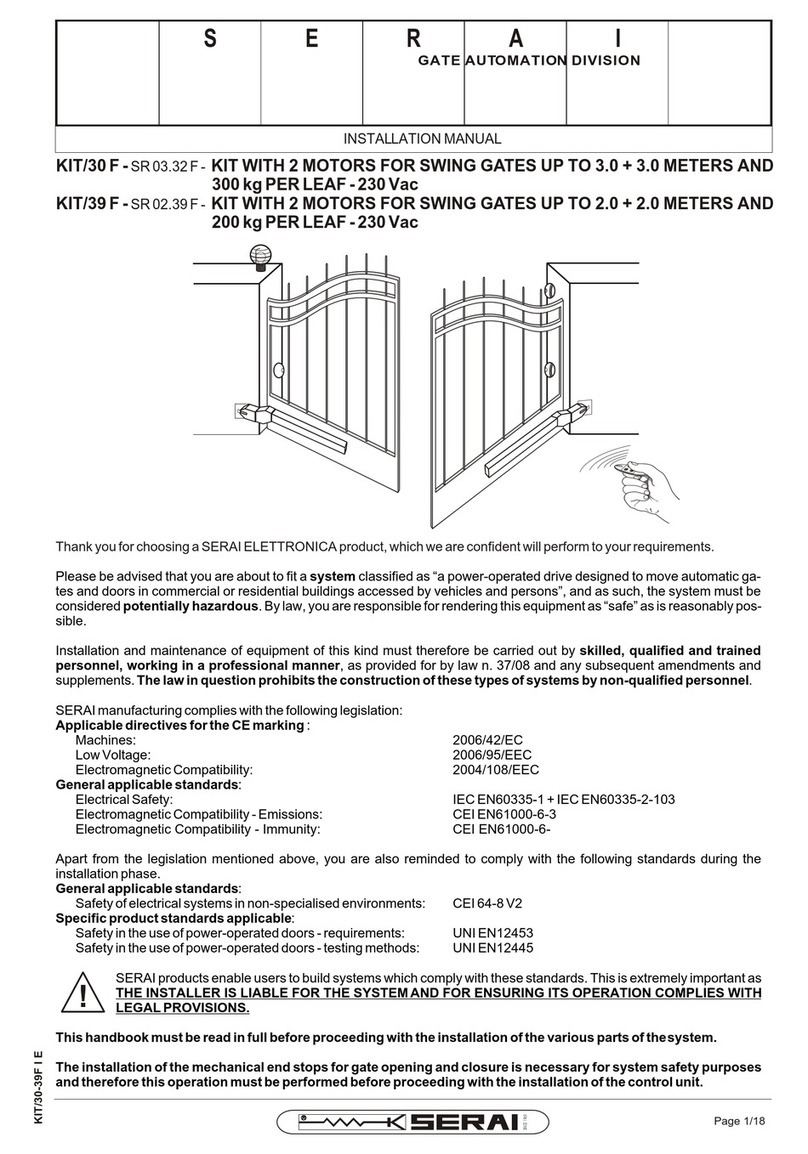

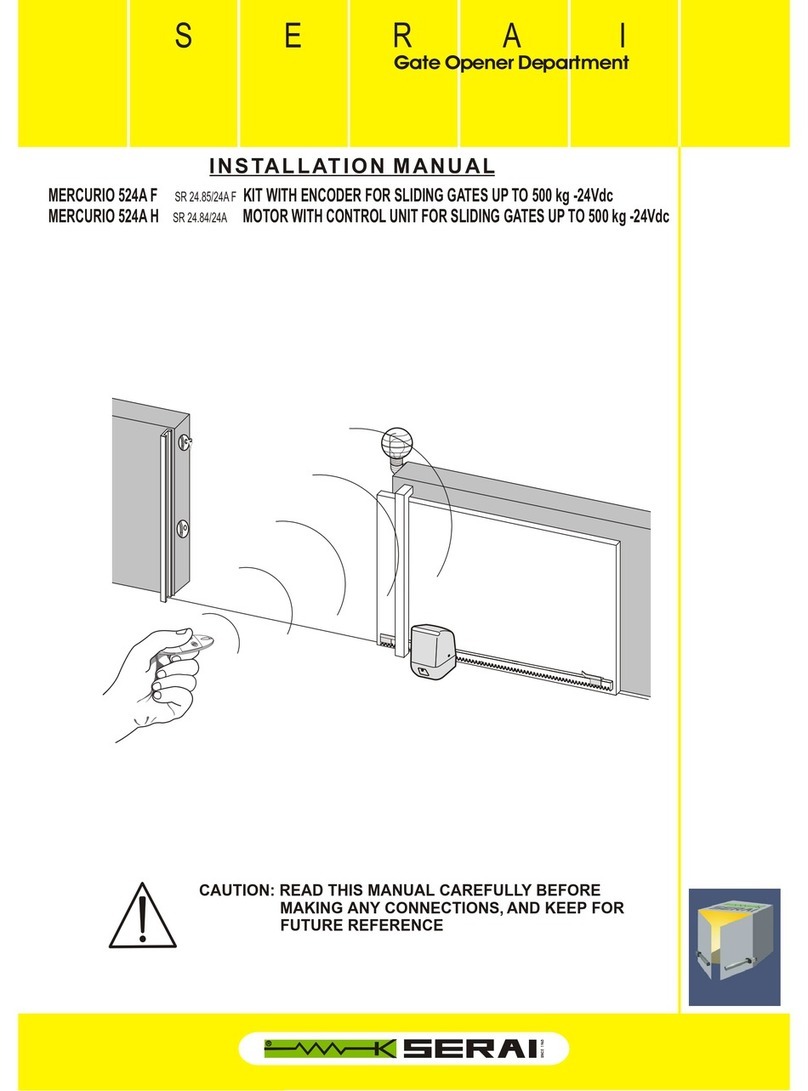

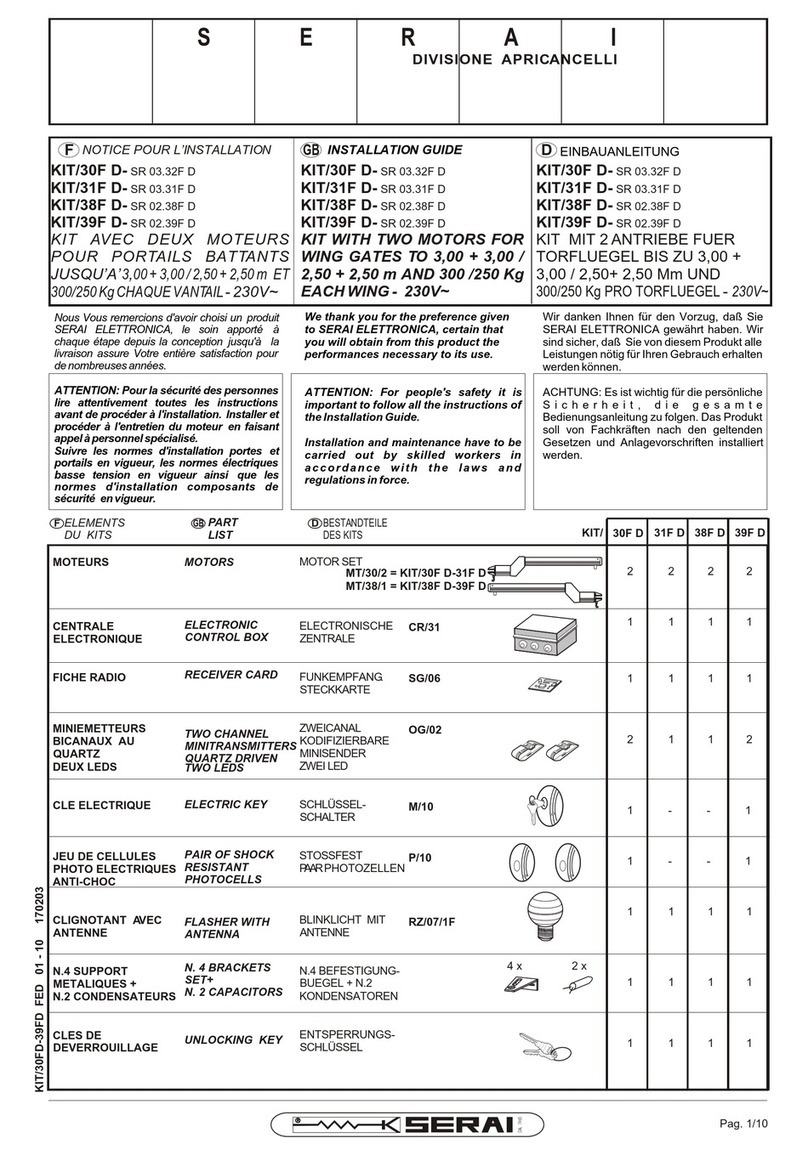

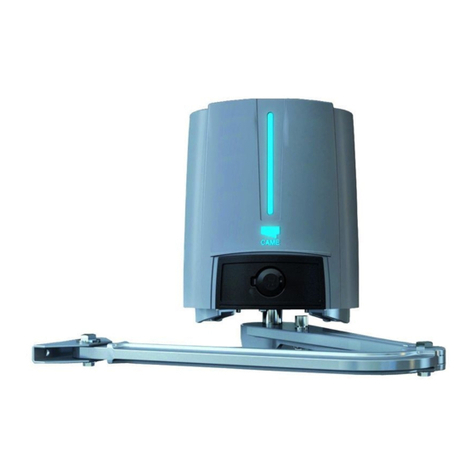

OERATORFORSWING GATESUPTO2m -200Kg

ERA IS

Divisione Apricancelli

DAL 1965

MT/BZERO EN V01 F12 20170127

A5VL 40g/mq - IS MT/B0/24-E

1A - WARNINGS

1B - TECHNICAL DATA

1 - GENERAL DESCRIPTION

Before proceeding with the installation check that all the safety conditions are observeded in full compliance with laws

rules and regulations. Unfulfilment of the below listed directions will release the SERAI srl, from any responsibility for

damage caused to people or things.

- When opening the packaging, verify the integrity of all the product parts.

- In case of functioning anomalies, power off immediately the operator, disconnect it from all power sources and manually

operate the gate until the failure has been individuated and repaired by qualified personnel.

- Do not modify the product in any part, follow the instruction manual indications.

- Dismantling an repairing of the unit is allowed exclusively to authorized and qualified personnel.

- Avoid to install the operator close to direct heating sources or in contact with liquid substances.

- Wire the operator to the automation system with the appropriate power supply cables (3 wires cable, min. 0.75mm2).

- To optimize the functioning of the automation, use only SERAI accessories.

- Installing, testing and first functioning have to observe the laws in force.

- Disposal of waste material has to observe local regulations.

- The gear-motor doesn’t require any particular maintenance because it is provided with a permament lubrification system.

Operator supply 7ED 24

Power 8 80

Speed NT

Travel NN

Protection degree *1 44

Operator weight LH 6

Max. lenght of the leaf N

Max. weight of the leaf LH

Work cycle 50

NN 100x104x780

Operator dimensions

Working temperature ¡$ -20 ÷ +50

200

DAL 1965

DAL 1965

1C - OVERALL DIMENSIONS

780

104

100

130

40

130

130

80

80

Front

bracket

Rear bracket

horizontally soldered

Rear bracket

vertically soldered

120

20

120

20

95

DAL 1965

2A - HOW TO USE THE GRAPH

Measure "E", and draw a horizontal line on the graph at the read measure.

Choose a point on the drawn line, considering the desired opening angle, suitable to the

column.

Draw a vertical line from that point and determinate the A value.

Verify that the A value allows the fixing of the rear bracket to continue the installation,

otherwise choose another point on the scheme.

Finally, bring the piston to the limit of the travel to fix the rear bracket to the leaf

(see the following picture).

This, however, by avoiding that the sliding pivot touches the aluminium body.

A

E

2 - BRACKETS INSTALLATION SCHEME

DAL 1965

2B - GRAPH

If the installation measures are not properly followed, the atomation could not work

correctly. For example:

- cyclical trends, and sudden accelerations,

- noise from the operator,

- limited opening degree or absent opening (if the operator was fixed counter-lever).

120 140 160 180 200

130

140

150

160

170

180

190

200

210

220

A (mm)

E (mm)

90°

100°

110°

3 - INSTALLATION

3A - INTRODUCTION

Read the instructions manual accurately before installing the product. The producer disclaims all responsibility for any

damage or bad functioning caused by non-observance of the instructions or bad connection that may result in poor safety

and functioning of the operator.

Fix the brackets allowing 35mm between the support planes in order to fix the operator with a perfect

horizontal alignment (see pic.1).

35mm

1

Fix the operator to the rear bracket (see pic.2).

Fix the operator to the front bracket (see pic.3).

23

DAL 1965

3B - BRACKETS HEIGHT

3C - FIXING THE OPERATOR TO THE BRACKETS

4A - INTRODUCTION

! Before operating the manual release disconnect the power.

Manual release of the gate was thought to open/close it manually in case of power loss or operator breakdown.

4B - MANUAL RELEASE

INSTRUCTIONS (see pic.4).

- Open the manual release cover.

- Insert the key in the cylinder and turn it 90° anticlockwise.

4 - OPERATING THE GATE MANUALLY

4

DAL 1965

4C - RESTORING THE AUTOMATION

INSTRUCTIONS (see pic.5).

- Insert the supplied key in the cylinder and turn it 90° clockwise.

- Close the manual release cover.

5

7

To connect the operator to the control unit proceed as follows:

01. Remove the lid of the operator as shown in pic.6.

02. Loosen the cable gland, pass the cable through it, screw its 3 wires to the terminal blocks, then tighten the gland.

03. Replace the lid on the operator.

To check the connections, the direction of rotation of the operator, the delay between the movements of the 2 leafs and to

program the gate main positions, refer to the instructions manual of the control unit.

6

DAL 1965

8

5 - ELECTRICAL CONNECTIONS

5A - CONNECTING THE OPERATOR TO THE AUTOMATION CONTROL UNIT

! Operators are supplied by fabric default with one internal mechanical stop, to set the opening position. If

the gate can't be provided with a closing external mechanical stop, an optional closing internal mechanical

stop (D) can be ordered separately (M/00, code 14.00).

6A - INTRODUCTION

An internal mechanical stop allows to stop the gate at a pre-set position, avoiding to hit the external leaf mechanical stop.

6B - ADJUSTMENT INSTRUCTIONS

INSTRUCTIONS (see pic.7):

- Release the operator for manual movement (see 4B).

- Loosen the screw of the supplied mechanical stop (B).

- Move the door to its wide open desired position.

- Place the mechanical stop next to the sliding pin (C), as a block.

- Firmly tighten the screw of the mechanical stop.

- Restore the operator automatic functioning (see 4C).

6 - MECHANICAL STOPS ADJUSTMENT

7

BCD

DAL 1965

TIPO:

Type:

MODELLO:

Model:

Attuatore elettromeccanico per cancelli a battenti

Electromechanical gearmotor for swing gates

MT/BZERO

Risulta conforme a quanto previsto dalle seguenti direttive europee:

Satisfies the essential requirements of the following Directives:

DIRETTIVA BASSA TENSIONE

Low Voltage Directive

2006/95/CE

EN60335-1

EN60335-2-103

DIRETTIVA MACCHINE

Machinery Directive

2006/42/CE

COMPATIBILITÀ ELETTROMAGNETICA

Electromagnetic Compatibility

2004/108/EC, 92/31/EEC, 93/68/EEC, 91/263/EEC

EN61000-6-1

EN61000-6-3

Come previsto dalla direttiva 2006/42/CE si avverte che non è consentita la messa in

servizio del prodotto sopra indicato finché la macchina, in cui il

prodotto è incorporato, non sia stata identificata e dichiarata conforme alla direttiva

2006/42/CE.

As specified in the directive 2006/42/CE use of the product specified above is not admitted

until the machine on which it is mounted has been identified and declared as

conforming to the directive 2006/42/CE.

',5(C7,9(SANDSTANDARDS

DAL 1965

10

NOTES

DAL 1965

11

WARRANTY CONDITIONS

The company reserves the right to make any modification without prior notice. The conventional SERAI product warranty is valid 24 months following the issuance of the fiscal

document attesting to its purchase. Services covered by the warranty are provided at the company's facilities in Legnaro (PD - ITALY) or at any one of the company's

authorized Service Centres. The relative shipping and transport costs are at the Customer's expense. ForTechnicalAssistance call: +39.049.790.858, Monday to Friday 8:30

to 12:30 and 14:00 to 18:00. The warranty shall be retained void in the event of any tampering with the product or in the event that the label specifying the product's production

batch has been broken or removed.

2011/65/UE DIRECTIVE ABOUT THE RESTRICTION OF THE USE OF CERTAIN HAZARDOUS SUBSTANCES IN ELECTRICAL AND

ELECTRONICEQUIPMENT(RoHS)-2012/19/UEDIRECTIVEABOUT THE WASTEOF ELECTRICALAND ELECTRONIC EQUIPMENT (WEEE)

This device was manufactured according to the restrictions set by the RoHS directive. To protect the environment: when no longer needed, the device

must not be disposed of as mixed municipal waste. Take it to an appropriate WEEE (Waste of Electric and Electronic Equipment) waste collection facility.

CEDECLARATIONOFCONFORMITY

SERAI srl hereby declares that the product MT/BZERO was designed and manufactured in full compliance with the above mentioned directives and standards.

ELETTRONICA PADOVA

DAL 1965

www.serai.com

+39 049 79 08 58

+39 049 88 30 529

+39 049 79 02 95

MADE IN ITALY

VIA ENRICO FERMI, 22

35020 LEGNARO - PADOVA

ITALIA

STAMP

REGION:

PHONE:

CONTACT PERSON:

INSTALLATOR DATA

COMPANY:

LOCATION:

Table of contents

Other Serai Gate Opener manuals