EN

8

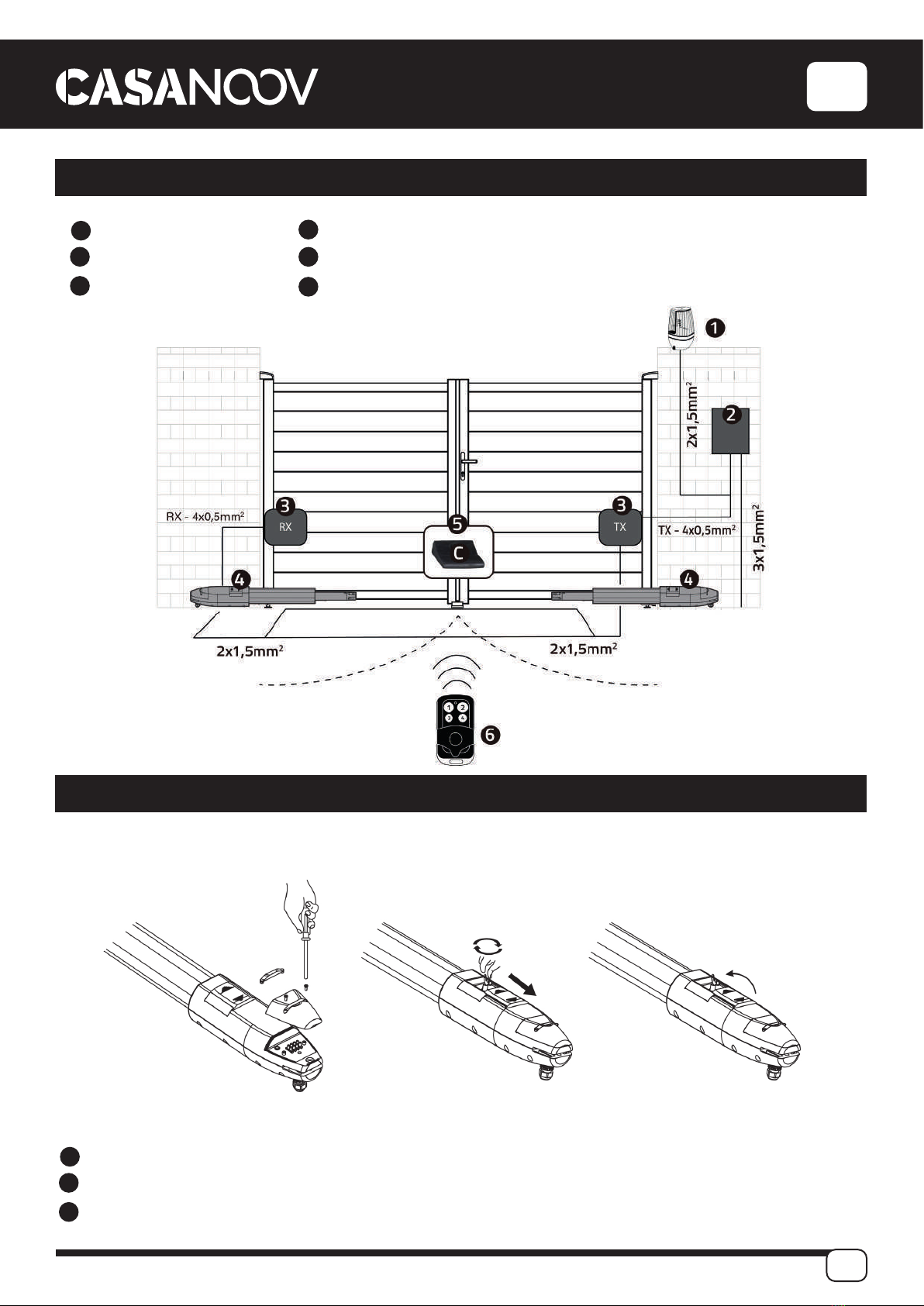

•When Gate is Obstructed : Gate stops.

•Optional : The Gate Opener Controller can be connected to a solar system, a Flash light warning, a

photocell, back up battery, keypad and other access control devices.

•Speed Control : Gate opening and closing speed can be adjusted.

•Gentle Start : The Gate Opener is equipped with a soft start function.

•Auto Close : The Gate Opener System is equipped with Auto close function with adjustable closing

time delay.

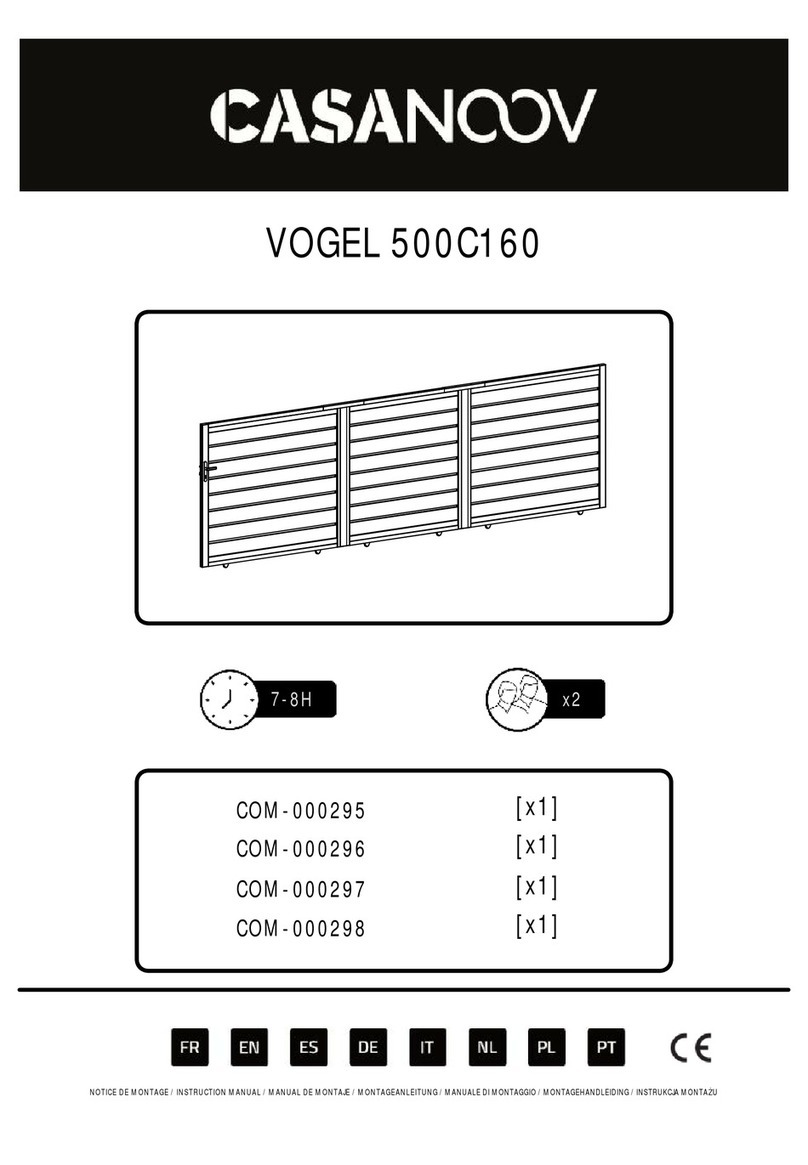

•Single or Dual Gate : Either Single or Dual Swing Gate can be opened.

•Multiple Remote Transmitters : The Controller can easily accommodate several unique extra remotes

to control the swing gate opener.

•Battery Back Up : DC 24V back up battery can be incorporated

•Optional Devices : DC 24V Gate Lock, photocell ,keypad , photocell, push button, large size or small

size control box.

The Gate Opener can be configured to allow smooth noiseless operation.

The Gate Opener can be configured to enable open condition as default, or close condition as default

depending on the placement of the provided hardware brackets.

General options and accessories

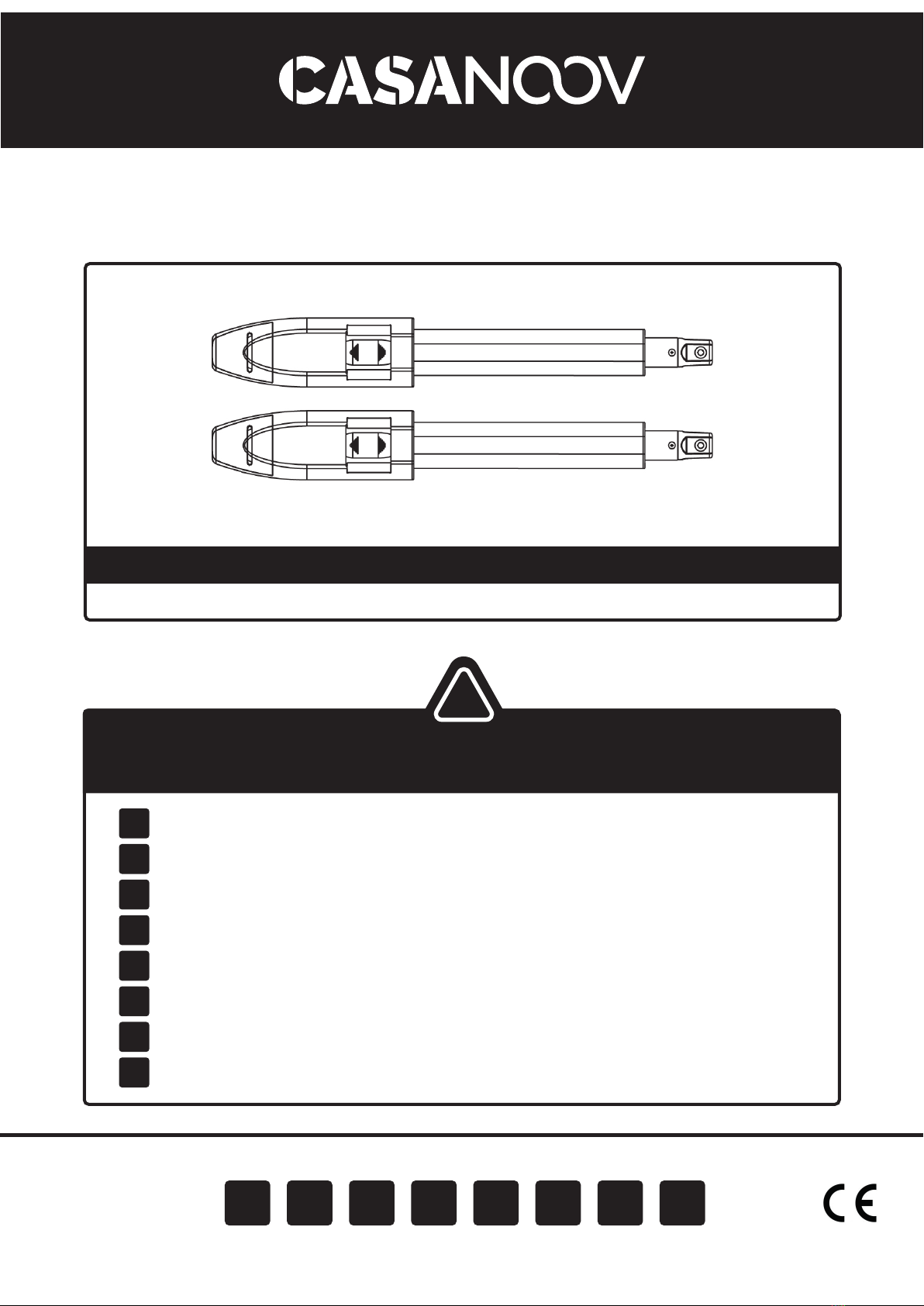

Primary Post Bracket

Secondary Post Bracket Clutch Key

Gate Bracket

Motor

Actuator Arm