Tecnologic TRH 12 User manual

TRH 12

RELATIVE HUMIDITY AND

TEMPERATURE PROBE

OPERATING INSTRUCTIONS

Vr. 01 (ENG) - cod.: ISTR 05833

TECNOLOGIC S.p.A.

VIA INDIPENDENZA 56

27029 VIGEVANO (PV) ITALY

TEL.: +39 0381 69871

FAX: +39 0381 698730

internet : http:\\www.tecnologic.it

e-mail: [email protected]

PREVIOUS STATEMENT

In this manual are contained all the necessary information for a

correct installation and the instructions for the use and the

maintenance of the product; we recommend, therefore, to read

carefully the following instructions.

The maximum care has been used in the realisation of this

document, anyway TECNOLOGIC S.p.A. does not assume any

responsibility deriving from the use of itself.

The same consideration has to be done for each person or

Company involved in the creation of this manual.

The herewith issue is an exclusive property of TECNOLOGIC

S.p.A. which forbids any reproduction and divulgation, although

partial, if not expressly authorised.

TECNOLOGIC S.p.A. reserves the right to execute aesthetically and

functional modifications, at any moment and without any notice.

INDEX

FUNCTIONAL DATA5.4

MECHANICA

L

DIMENSIONS AND FIXING DEVICE5.3

MECHANICAL DATA5.2

ELECTRICA

L

DAT

A

5.1

TECHNICA

L

DAT

A

5

WARRANTY AND REPAIRS4.3

CLEANING4.2

ERRORS4.1

TROUBLES, MAINTENANCE, WARRANTY4

OPERATING MODE3

ELECTRICA

L

CONNECTION DRAWINGS2.4

ELECTRICAL CONNECTIONS2.3

MECHANICA

L

MOUNTING2.2

USE ALLOWED2.1

INSTALLATION AND USE ADVICES2

PROBE DESCRIPTION1.2

GENERAL DESCRIPTION1.1

DESCRIPTION1

1 - DESCRIPTION

1.1 - GENERAL DESCRIPTION

TRH 12 is a relative humidity (capacitive type) and temperature

(RTD Pt100 type) probe with normalized outputs current signal 0 ..

20 mA.

1.2 - PROBE DESCRIPTION

1 - Sensors protective cap

2 - Terminal block

3 - Cable gland M20x1,5

2 - INSTALLATION AND USE ADVICES

2.1 – USE ALLOWED

The instrument has been projected as measure

transductor.

It has to be reminded that the user has to take care

that the electromagnetic rules are being respected

also after the instrument installing, eventually using

proper filters.

Whenever a failure or a bad functioning of the instrument may

cause dangerous situations or damage to people, things or animals

it has to be reminded that the plant has to be equipped with

additional electromechanical devices in order to grant the safety.

2.2 – MECHANICAL MOUNTING

The instrument, into case 80 x 80 mm , is designed for wall

mounting.

Install the instrument as far as possible from electromagnetic

sources as motors, power relay, relays, electrovalves, etc.

Avoid to place the probe into places where are present corrosive

and polluting gases (see Concentration Maximum Pollutant in the

Technical Data) and to do so that the probe are installed in

ventilated position.

Should be necessary to remove the protective cap, do not cause

any mechanical stress to the sensors and absolutely avoid touching

the umidity sensor.

TECNOLOGIC - TRH 12 - OPERATING INSTRUCTIONS - Vr. 01 - ISTR 05833 - PAG. 1

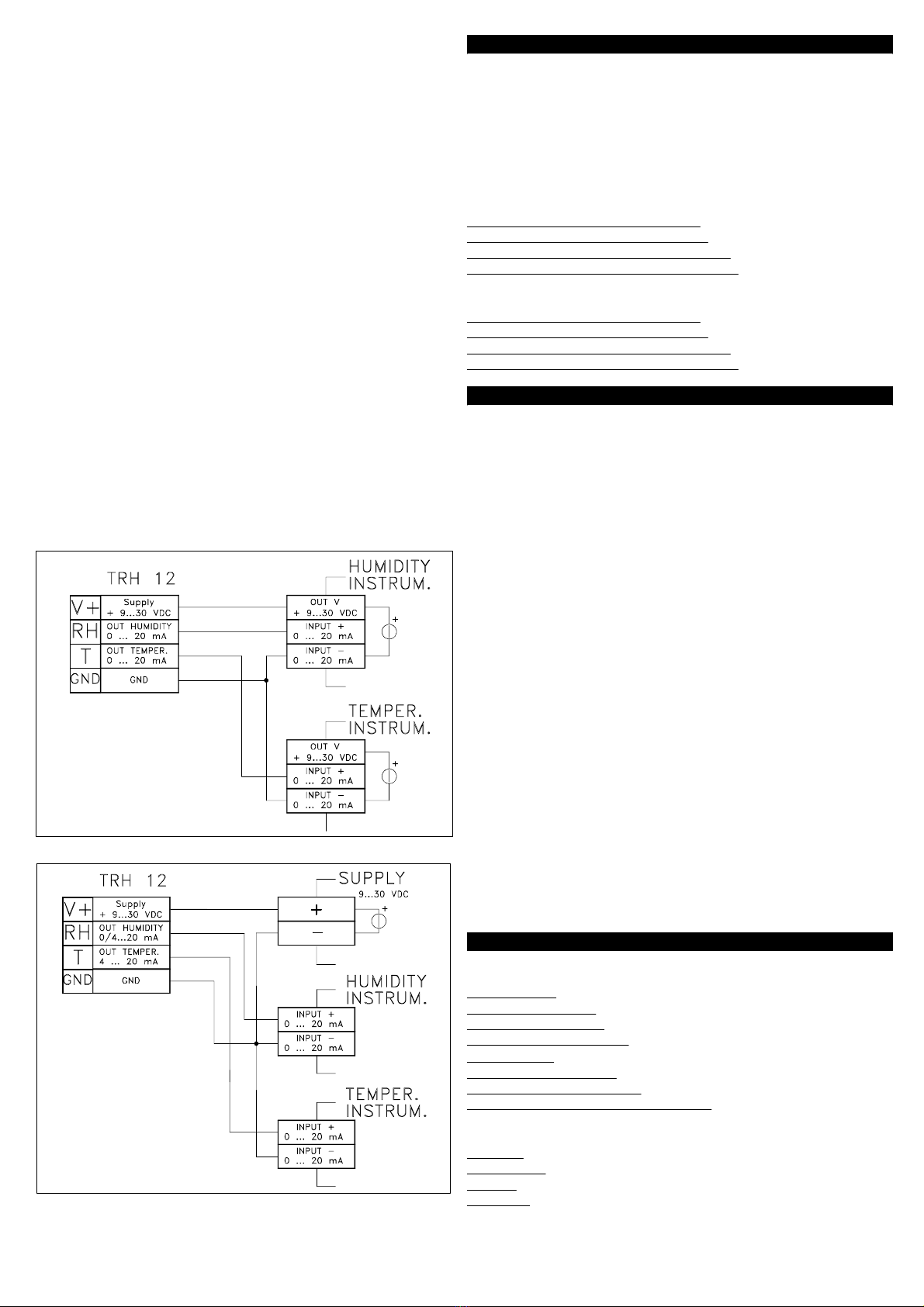

2.3 - ELECTRICAL CONNECTIONS

To access the terminal block remove the cover by unsrewing the

two screws on it.

Avoid touching any electronic components and carry out the

electrical wiring connecting one wire only for each terminal,

according to the following diagrams, checking that the power supply

is the same as indicated on the instrument.

Use the cable gland to make the cable exit and check the correct

grip of the same and of the cover box to obtain the declared

protection degree.

Check then if the measure instrument is equipped with a voltage

output 9...30 VDC able to supply at least 50 mA, otherwise

connecting the probe with an external voltage supply 9...30 VDC

able to supply the necessary current as previously described and

connecting it following the wiring diagrams.

It's strongly recommended to use cables with proper insulation,

according to the working voltages and temperatures.

Furthermore, the cable of the probe has to be kept separate from

line voltage wiring in order to avoid electromagnetic noises

infiltration.

If the input cable of the probe is screened, it advisable to connect it

on the ground with one side only.

Tecnologic S.p.A. and its legal representatives are not

responsible for any eventual damages to people, things or

animals deriving from the instrument violation, not proper or

wrong use or in any case not in accordance with the instrument

features.

2.4 - ELECTRICAL CONNECTION DRAWING

Wiring diagram with instrument supply :

Wiring diagram with external supply :

3 - OPERATING MODE

The instruments to which the probe has to be connected has to be

provided with a current input 0 ... 20 mA type.

To have a correct measure indication is necessary to set the lower

and upper input limits.

These limits are the corrisponding value to 0 mA (lower limit or

beginning of scale) and 20 mA (upper limit or ending of scale) which

have to be displayed.

See on the operating instructions of the measure instrument the

setting mode of these limits.

The set values for TRH 12 probe are:

Lower limit umidity measure (0 mA) : 0

Upper limit umidity measure (20 mA) : 100

Lower limit temperature measure (0 mA) : -30 (°C) or -22 (°F)

Upper limit temperature measure (20 mA) : 70 (°C) or 158 (°F)

It's possible to use instruments with input 4 ..20 mA, in this case the

limits to set will be:

Lower limit umidity measure (4 mA) : 20

Upper limit umidity measure (20 mA) : 100

Lower limit temperature measure (4 mA) : -10 (°C) or 14 (°F)

Upper limit temperature measure (20 mA) : 70 (°C) or 158 (°F)

4 - PROBLEMS, MAINTENANCE AND WARRANT

Y

4.1 - MEASURE ERRORS

Umidity reading errors can occur if settling time is too short, or be

caused by steam, sprayed water, air drafts, direct exposure to

sunlight, or presence of condesate on the sensor.

To obtain accurate measurements the sensor should be left to settle

in the existing atmosphere for some time.

To reduced the possibility of condesation on the humidity sensor

place the probe in ventilated position and where there is not a quick

and elevation variation of temperature (from cold to warm)

4.2 - CLEANING

It’s raccomanded to clean the box only with a cloth welted with water

or with a detergent neither abrasive nor containing solvents.

Should be necessary to remove the protective cap, do not cause

any mechanical stress to the sensors and absolutely avoid touching

the umidity sensor.

4.3 - WARRANTY AND REPAIRS

The instrument is under warranty against construction vices or

defected material, noticed within 12 months from delivery date.

The warranty is limited to the repairs or to the substitution of the

instrument.

The eventual violation of the instrument or the wrong use and

installation of the product means the automatic decay of the

warranty.

In case of defected instrument, noticed in warranty period or out of

warranty, do contact our sales department to obtain the shipment

authorisation.

The defected product must be shipped to TECNOLOGIC with the

detailed description of the failures found and without any fees or

charge for Tecnologic, safe different agreements.

5 - TECHNICAL DATA

5.1 - ELECTRICAL DATA

Power supply: 9 ... 30 VDC

Power consumption:50 mA MAX

Humidity sensor type: Capacitive

Temperature sensor type: RTD Pt100 (class B)

External load: 250 ΩMAX

Humidity output signal : 0...20 mA (0 ...100 %RH)

Temperature output signal : 0...20 mA (-30 ...70 °C )

Protection class against electric shock: Class III

5.2 - MECHANICAL DATA

Housing: plastic

Dimensions: 80 x 80 mm, depth 52 mm

Weight: 130 g approx.

Mounting: Wall mounting

TECNOLOGIC - TRH 12 - OPERATING INSTRUCTIONS - Vr. 01 - ISTR 05833 - PAG. 2

Connections: 2,5 mm

2

screw terminal block

Recommended connection cable: 4x0,5 or 4x 75 mm

2

Box protection : IP 65

Air filter: Polyethylene

Operating temperature : -30 ... 70 °C

Operating humidity: 0 ... 100 RH%

Storage temperature: -30 ... 80 °C

Maximum workplace pollutant concentration:

380 mg/m

3

100 ppmToluene/Xylen

e

(C6H5CH3)

9 mg/m

3

5 ppmNitrogen Oxides (NOx)

15 mg/m

3

10 ppmHydrogen Sulphide (H2S)

13 mg/m

3

5 ppmSulphur Dioxide (SO2)

7 mg/m

3

5 ppmHydrochloric

A

cid (HCl)

590 mg/m

3

200 ppm2-Butanone (C2H5COCH3)

980 mg/m

3

400 ppmIsopropanol ((CH3)2CHOH)

1,2 mg/m

3

1 ppmFormaldehyde (HCHO)

260 mg/m

3

100 ppmEthylen

e

Glycol ( HOCH2CH2OH

)

1900 mg/m

3

1000 ppmEthanol (C2H5OH)

1400 mg/m

3

400 ppmEthyl

A

cetat

e

(CH3COOC2H5)

25 mg/m

3

10 ppmAcetic Acid (CH3COOH)

1,5 mg/m

3

1 ppmChlorine (Cl2)

1200 mg/m

3

300 ppmPetrol

18 mg/m

3

25 ppm

A

mmonia (NH3)

2400 mg/m

3

1000 ppmAcetone (CH3COCH3)

5.3 - MECHANICAL DIMENSIONS AND FIXING DEVICE [mm]

5.4 - FUNCTIONAL DATA

Humidity measurement range: 0 ... 100 %RH (0...20 mA)

Temperature measurement range: -30 ... 70 °C (0...20 mA)

Humidity overall accuracy : +/- 1,5 % (10...95%RH), +/- 2 % (0...10

/ 95...100 %RH) ; (without pollutant presence, at 23 °C and with an

air speed of 3 m/s)

Additional error with pollutant presence: +/- 2 %RH

Temperature overall accuracy : +/- 0,9 %

Response time : 30 sec. to reach a 63 % of an humidity change (at

23 °C and with an air speed of 3 m/s)

Recovery time after saturation: 90 sec. approx.

Maximum air speed: 20 m/s

Temperature compensation: By Pt100 probe

Compliance: ECC directive EMC 2004/108/CE (EN 61326), ECC

directive LV 2006/95/CE (Instrument operating under 50 VAC and

75 VDC)

TECNOLOGIC - TRH 12 - OPERATING INSTRUCTIONS - Vr. 01 - ISTR 05833 - PAG. 3

Table of contents

Other Tecnologic Measuring Instrument manuals