TECO-Westinghouse Motor GA7200 User manual

4H358D0030007

–

M O T O R C O M P A N Y

Operation Manual

GA7200

AC Inverter

380 to 460V 1HP~450HP

200 to 230V 1HP~100HP

The GA7200 is a high-performance/low noise general-purpose inverter. This manual describes

the operation procedures for the digital operator (JNEP--12) provided with the GA7200.

A thorough understanding of this operation manual and the GA7200 installation manual is

recommended before using the GA7200.

─2─

CONTENTS

Page

1. OUTLINE............................................................................................... 5

1.1 MAIN FUNCTIONS............................................................................................................................. 5

1.2 DIGITAL OPERATOR KEYPAD.......................................................................................................... 6

2. DRIVE MODE AND PROGRAM MODE................................................ 8

2.1 DISPLAY CONTENTS........................................................................................................................ 9

2.2 CONSTANT GROUPS ....................................................................................................................... 10

3. CONSTANTS SETTING AND CHANGE ............................................... 11

3.1 STANDARD FACTORY SETTING ..................................................................................................... 11

3.2 FREQUENCY REFERENCE SETTING AND CHANGE .................................................................. 11

3.3 CONSTANTS CHANGE AND FUNCTION SELECTION ................................................................... 12

3.4 OPERATION ERRORS “ ”................................................................................................. 13

4. WIRING................................................................................................. 14

4.1 CONNECTION DIAGRAMS ............................................................................................................... 14

4.2 TERMINAL FUNCTIONS (MAIN CIRCUIT)……………………………………………………………….16

5. DIGITAL OPERATOR PROGRAMMING ............................................... 18

6. PROGRAM MODE SETTING AND CHANGE....................................... 20

6.1 V/f PATTERN SETTING ....................................................Sn-02....................................................... 23

6.2 ACCEL/DECEL TIME SETTING .......................................bn-0 I to-04 (Sn-06, Sn-15 to -18)........... 24

6.3 INPUT SIGNAL SELECTION ............................................Sn-04....................................................... 27

6.4 PROTECTIVE CHARACTERISTICS SELECTION...........Sn-10 to-14 ............................................. 28

6.5 MULTI-FUNCTION INPUT SELECTION...........................Sn-04, Sn-15 to 19, bn-09....................... 31

6.6 CONTACT OUTPUT SELECTION ....................................Sn-20....................................................... 37

6.7 FREQUENCY REFERENCE CHANGE ............................bn-05, -06................................................ 40

6.8 DC INJECTION BRAKING (DC) .......................................Cn-10 to -13 ............................................ 41

6.9 FULL-RANGE DC INJECTION BRAKING STOP

(DCB STOP).....................................................................Sn-04=10 XX, Cn-12............................... 42

6.10 UPPER/LOWER LIMIT OF

FREQUENCY REFERENCE ..........................................Cn-14, -15 ............................................... 43

6.11 PROHIBITED (SKIP) FREQUENCY ...............................Cn-16 to -19 ............................................ 44

6.12 DISPLAY MODE CHANGE .............................................Cn-20 ...................................................... 45

6.13 STALL PREVENTION LEVEL WHILE RUNNING...........Cn-30 (Sn-10) ......................................... 46

6.14 AUTO RESET/RESTART OPERATION AT FAULT.........Cn-36 ...................................................... 47

6.15 INITIALIZING CONSTANTS............................................Sn-03....................................................... 48

─3─

7. CONSTANTS/FUNCTION LIST ............................................................ 50

7.1 FREQUENCY REFERENCE ..........................................An- .................................................. 50

7.2 CONSTANT CHANGE WHILE RUNNING ......................bn- .................................................. 51

7.3 SYSTEM CONSTANTS...................................................Sn- .................................................. 55

Inverter Capacity Selection ...............................................Sn-01....................................................... 62

V/f Pattern Selection .........................................................Sn-02....................................................... 66

Operation Mode Selection 1 .............................................Sn-04....................................................... 69

Operation Mode Selection 2 .............................................Sn-05....................................................... 72

Operation Mode Selection 3 .............................................Sn-06....................................................... 73

Operation Mode Selection 4 .............................................Sn-07....................................................... 76

Operation Mode Selection 5 .............................................Sn-08....................................................... 77

Operation Mode Selection 6 .............................................Sn-09....................................................... 78

Protective Characteristic Selection 1 ................................Sn-10....................................................... 89

Protective Characteristic Selection 2 ................................Sn-11....................................................... 81

Protective Characteristic Selection 3 ................................Sn-12....................................................... 82

Protective Characteristic Selection 4 ................................Sn-13…………………………………Not Used

Protective Characteristic Selection 5 ................................Sn-14....................................................... 83

7.4 MULTI-FUNCTION CONTACT INPUT SELECTION ......Sn-15 to -18 ............................................ 84

7.5 MULTI-FUNCTION ANALOG INPUT SELECTION ........Sn-19....................................................... 96

7.6 MULTI-FUNCTION CONTACT OUTPUT SELECTION ..Sn-20 to -22 ............................................ 97

7.7 CONTROL CONSTANTS................................................Cn- ................................................. 101

7.8 MONITOR DISPLAY .......................................................Un- ................................................. 117

8. FAULT DISPLAY AND TROUBLESHOOTING ...................................... 119

9. GA7200 TERMINAL FUNCTIONS ........................................................ 123

10. APPENDIX (OPTIONS AND PERIPHERALS) .................................... 124

10.1 OPTION CARDS .............................................................................................................................. 124

10.2 ANALOG OPERATOR...................................................................................................................... 125

10.3 BRAKING RESISTOR AND BRAKING UNIT................................................................................... 126

10.4 AC REACTOR .................................................................................................................................. 127

10.5 NOISE FILTER ................................................................................................................................. 128

─4─

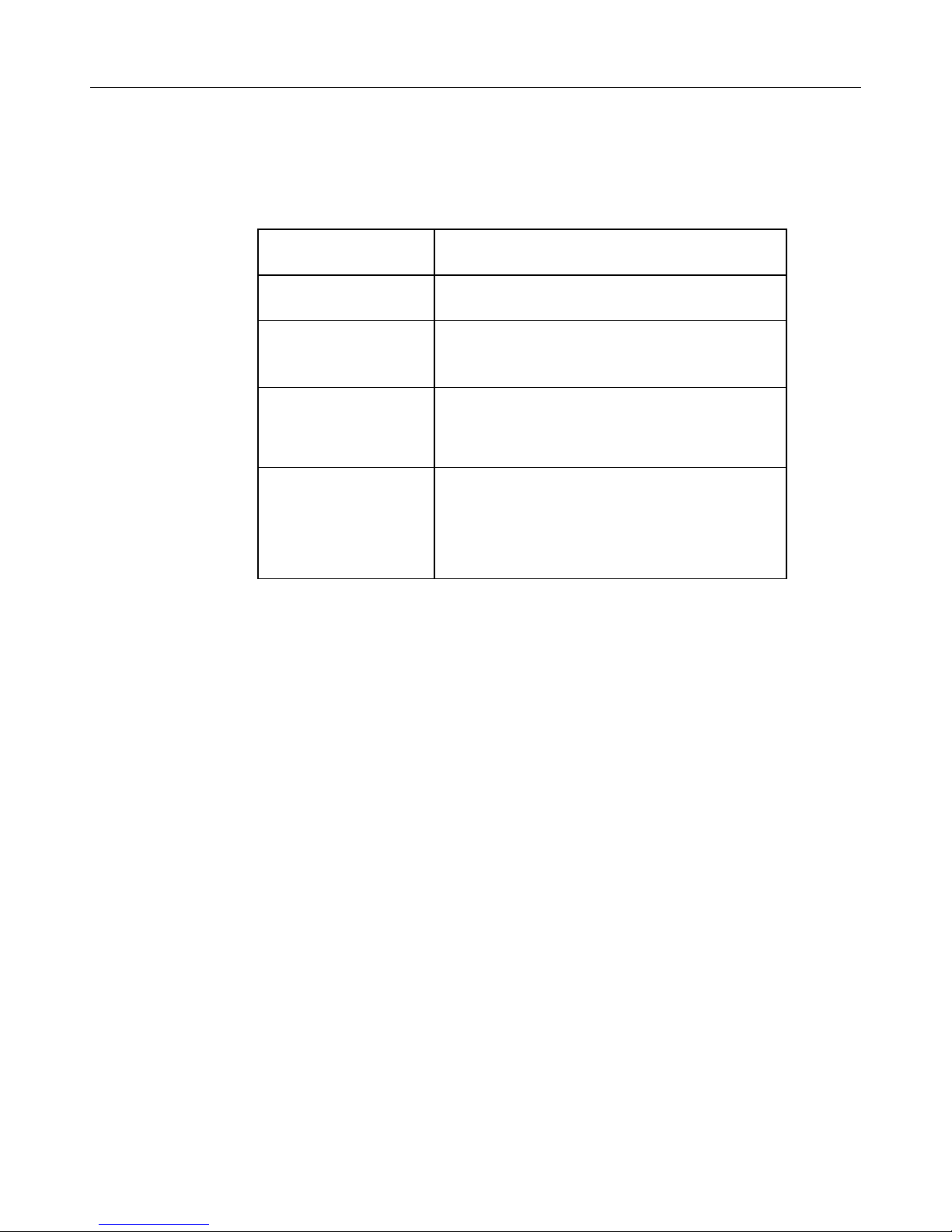

1. OUTLINE

1.1 MAIN FUNCTIONS

Function Description

Drive Mode GA7200 can be operated easily with the

digital operator.

Program Mode

Function selection and constant setting for

GA7200 can be performed with the digital

operator.

Monitor Function

Monitoring of output frequency, output

current, output voltage or status of run / stop

commands can be performed with the digital

operator.

Fault Contents Display

If a fault occurs, its contents order of

occurrence is displayed. When the power

supply is turned ON, maintenance

inspection or troubleshooting can be

performed since fault is recorded.

─5─

Table of contents

Other TECO-Westinghouse Motor Inverter manuals

Popular Inverter manuals by other brands

BARRON

BARRON EXITRONIX Tucson Micro Series installation instructions

Baumer

Baumer HUBNER TDP 0,2 Series Mounting and operating instructions

electroil

electroil ITTPD11W-RS-BC Operation and Maintenance Handbook

Silicon Solar

Silicon Solar TPS555-1230 instruction manual

Mission Critical

Mission Critical Xantrex Freedom SW-RVC owner's guide

HP

HP 3312A Operating and service manual