TECO-Westinghouse Motor MA7200 User manual

4H358D0180009

Installation Manual

MA7200

AC Inverter

208 to 230V 1 / 3 Phase 1 ~ 3HP

3 Phase 5 ~ 40HP

380 to 460V 3 Phase 1 ~ 75HP

SAFE OPERATION NOTES

Read this instruction manual thoroughly before installation, operation, maintenance

or inspection of the inverter. Only authorized personnel should be permitted to perform

maintenance, inspections or parts replacement.

In this manual, notes for safe operation are classified as:

“WARNING” or “CAUTION”.

WARNING : Indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury to personnel.

CAUTION : Indicates a potentially hazardous situation that, if not avoided,

may result in minor or moderate injury to personnel and damage

to the equipment.

“WARNING” and “CAUTION”

WARNING

yAlways turn off the input power supply before wiring terminals.

yAfter turning OFF the main circuit power supply, do not touch the circuit

components until the “CHARGE” LED is extinguished.

yNever connect power circuit output U/T1, V/T2, W/T3 to AC power supply.

CAUTION

yWhen mounting the MA7200 in a separate enclosure, install a fan or other cooling

device to keep the intake air temperature below 113oF (45oC).

yDo not perform a withstand voltage test to the inverter.

yAll the parameters of the inverter have been preset at the factory. Do not change

the settings unnecessarily.

This inverter has been placed through demanding tests at the factory before shipment.

After unpacking, check for the following:

1. Verify that part numbers on shipping carton and unit match the purchase order

sheet and/or packing list.

2. Do not install or operate any inverter that is damaged or missing parts.

3. Do not install or operate any inverter that has no QC marking.

Contact your local TECO authorized distributor or TECO representative if any of

the above irregularities have been found.

Contents Page

1. MA7200 Handling Description ------------------------------------- 1-1

1.1 Inspection Procedure upon Receiving ---------------------------------------- 1-1

1.2 Installation------------------------------------------------------------------------ 1-2

1.3 Removing/Attaching of LCD Digital Operator and Front Cover---------- 1-4

1.4 Wiring between Inverter and Peripheral Devices --------------------------- 1-7

1.5 Description of Terminal Function --------------------------------------------1-11

1.6 Main Circuit Wiring Diagram -------------------------------------------------1-13

1.7 Wiring Main Circuit------------------------------------------------------------1-14

1.8 Inverter Specifications ---------------------------------------------------------1-17

1.9 Dimensions ----------------------------------------------------------------------1-19

1.10 Peripheral Units-----------------------------------------------------------------1-22

2. Using LCD Digital Operator----------------------------------------- 2-1

3. Parameter Setting------------------------------------------------------ 3-1

3.1 Frequency Command An- ----------------------------------------------- 3-1

3.2 Parameters That Can be Changed during Running Bn- -------------- 3-2

3.3 Control Parameters Cn- -------------------------------------------------3-12

3.4 System Parameters Sn- --------------------------------------------------3-30

3.5 Monitoring Parameters Un- ---------------------------------------------3-75

4. Fault Display and Troubleshooting ------------------------------ 4-1

4.1 General---------------------------------------------------------------------------- 4-1

4.2 Error Message and Troubleshooting ------------------------------------------ 4-2

Appendix

A. PID Parameter Setting -------------------------------------------------------App-1

B. Supplementary on PID Control Block Diagram--------------------------App-3

C. Wiring for PG Feedback Use------------------------------------------------App-4

D. RS-485 Communication Interface------------------------------------------App-5

E. SINK/SOURCE Typical Connection Diagram ---------------------------App-7

F. RS-232C Serial Communication Connection Diagram------------------App-8

G. Set-up Using the Sensorless Vector Control ------------------------------App-9

H. Notes for Circuit Protection and Environmental Ratings-------------- App-11

I. Spare Parts------------------------------------------------------------------- App-15

J. Electrical Ratings For Contstant Torque and Quadratic Torque------ App-25

K. Inverter Heat Loss ---------------------------------------------------------- App-26

No. Figure Contents Page No. Figure Contents Page

1 Air clearance for MA7200 wall mounting 1-2 27 S curve 3-27

2 Standard connection diagram 1-9 28 ASR Integral Gain 2 3-28

3 Processing the ends of twisted-pair cables 1-15 29 Deceleration to stop 3-44

4The optical-couplers connect to external

inductive load 1-15 30 Coast to Stop 3-44

5 MA7200 ground winding 1-16 31 Whole range DC Injecting Braking Stop 3-44

6 LCD digital operator dimension 1-27 32 Coast to Stop with Timer 3-45

7 Analog operator 1-28 33 Output voltage limit 3-48

8 LCD digital operator 2-1 34 Stall prevention function during deceleration 3-48

9 Acceleration and Deceleration time 3-4 35 Zero speed braking operation selection 3-49

10 Analog input gain and bias 3-5 36 Motor overload protection curve 3-51

11 Adjust the auto torque boost gain Bn-11 to

increase the output torque 3-5 37 3-wire mode connection diagram 3-53

12 Block diagram for PID control in inverter 3-7 38 Operation sequence in 3-wire mode 3-53

13 Response of PID control for step-shape

(deviation) input 3-8 39 2-wire mode connection diagram 3-53

14 PID Control Block diagram (After Version

30.18) 3-9 40 Time chart for multi-step speed and jog

command 3-54

15 An operation example of timer function 3-9 41 Acceleration and deceleration ramp hold 3-55

16 Time chart for energy-saving operation 3-10 42 Time chart for DC injection braking command 3-57

17 User-defined V/F curve 3-15 43 PG speed control block diagram 3-58

18 Output frequency with slip compensation. 3-16 44 Time chart of output frequency with the

UP/DOWN function 3-59

19 Slip compensation limit 3-16 45 Pulse signal output 3-65

20 DC injection braking time chart 3-17 46 The input/output signal in ‘Timer’ function

application 3-66

21 Upper and lower bounds of the frequency

command 3-18 47 PID control block diagram App-3

22 Setting jump frequencies 3-18 48 PID wiring diagram App-3

23 Acceleration stall prevention function 3-20 49 Wiring of PG feedback App-4

24 Run stall prevention function 3-20 50 Wiring for MODBUS Protocol communication App-5

25 Time chart for overtorque detection 3-23 51 Wiring for PROFIBUS protocol communication App-6

26 Speed search timing chart 3-25 52 RS232-C Typical Connection Diagram App-8

No. Table Contents Page

1 Main circuit terminals 1-11

2 Control circuit terminals 1-12

3230V/460V class applicable wire size and connector 1-14

4 Brake resistor list 1-22

5 AC reactor list 1-23

6 Noise filter on the input side 1-24

7 Key's functions 2-2

8 Setting of monitoring contents 3-6

9 LCD Digital Operator Display Unit 3-21

10 230V Class Inverter Capacity Selection 3-39

11 460V Class Inverter Capacity Selection 3-40

12 V/F curve of 1~2 HP compact size, 230V Class MA inverter 3-41

13 V/F curve of 3~20 HP, 230V Class MA inverter 3-42

14 Multi-Function Input Setting 3-52

15 Multi-function analog input function list 3-60

16 Multi-function output terminal function 3-63

1-1

1. MA7200 Handling Description

1.1 Inspection Procedure upon Receiving

Before delivery, Every MA7200 inverter has been properly adjusted and passed the

demanding function test. After receiving the inverter, the customer should take it out and

follow the below procedure:

•Verify that the Type No. of the inverter you’ve received is the same as the Type No.

listed on your purchase order. (Please read the Nameplate)

•Observe the condition of the shipping container and report any damage immediately to

the commercial carrier that has delivered your inverter.

■Inverter nameplate:

■Inverter model number :

INPUT SPECIFICATION

OUTPUT SPECIFICATION

Model:MA7200-2002-N1 HP:2 KVA:2.7 INVERTER MODEL

AC Input: 1PH/3PH 200-230V 50/60Hz

AC Output: 3PH 0-230V Amps: 6.4A

MOTOR COMPANY LISTED

(IND. CONT. EQ.)

848F

MA7200-2002-N1

N1: NEMA1

N4: NEMA4

0001 : 1HP

∫∫

0075 : 75HP

NEMA4 for 1~20HP only

Max. Applicable Motor

Capacity (HP)

Rated Voltage

2: 200~230V

4: 380~460V

MA7200

Series

1-2

1.2 Installation

When installing the inverter, always provide the following space to allow normal

heat dissipation.

50 mm min.

30 mm

min. 30 mm

min.

50 mm

min.

ambient

temperature

-10 ~ + 40 ℃

AIR

AIR

120 mm

min.

120 mm

min.

(a) Space in Side (b) Space in Top/bottom

Fig. 1-a. Air clearance for MA7200 wall mounting

1-3

220-240V

380-480V

Single/ThreePhases

L1(L)

3Phases IM

L2(N) L3 T3T2

T1 Single/ThreePhases

380-480V

220-240V

L2(N)L1(L) L3

3Phases IM

T1 T2 T3

(a) NEMA4 Frame1 (b) NEMA4 Frame2

Fig. 1-b. MA7200 NEMA4 Installation

CAUTION

Location of equipment is important to achieve proper performance and normal

operating life. The MA7200 inverter should be installed in area where the following

conditions exist.

yAmbient temperature: +14 to 104oF, (-10 to 40oC).

yInstall the MA7200 in a location protected from rain, moisture and direct sunlight.

yInstall the MA7200 in a location free from harmful mists, gases, liquids, airborne

dusts and metallic particles.

yInstall the MA7200 in a location free from vibration and electromagnetic noise. (i.e.

welding machines, power units, etc…)

yWhen mounting multiple units in a common enclosure, install a cooling fan or some

other means to cool the air entering the inverter to at least 113oF (+45oC) or below.

1-4

1.3 Removing/Attaching the Digital Operator and Front cover

CAUTION

Please disassemble Front Cover before you connect wires to terminals on MA7200

models.

• 230V 1~25HP & 460V 1~30HP models: Plastic instructions, so please disconnect

LCD Digital Operator before you disassemble Front Cover. After you finished the

wiring connection, assemble Front Cover first then reinstall LCD Digital Operator.

• 230V 30HP、40HP & 460V 40~75HP: Iron instructions, you can disassemble Front

Cover for wiring connection without disconnect LCD Digital Operator. Then

reinstall Front Cover back after you finished wiring connection.

MA7200 disassembly / Assembly procedures will be depended on different model as

follows:

(A)For 230V : 1-2HP, 460V : 1-2HP

yMA7200-2001-N1 yMA7200-4001-N1

yMA7200-2002-N1 yMA7200-4002-N1

■Removing the digital operator :

Take off the two screws on the front cover in the

place a and b. Remove the front cover and take

off the screws in the place c and d. Disconnect

the RS-232 cable connector on the backside of

the LCD digital operator. Lift and remove digital

operator.

■Attaching the front cover and digital operator:

Connect the RS-232 cable connector on the back

of the LCD digital operator.

LCD Digital

Operator

Front Cover

a

b

d

c

RS-232

Cable

Connector

Attach the

d

i

g

i

t

al o

p

erator and ti

g

hten the screws in the

p

lace c and d. Insert the tabs of

the u

pp

er

p

art of front cover into the

g

roove of the inverter and ti

g

hten the screws in the

place a and b.

1-5

(B) For 230V : 3-10HP, 460V : 3-10HP

yMA7200-2003-N1 yMA7200-4003-N1

yMA7200-2005-N1 yMA7200-4005-N1

yMA7200-2007-N1 yMA7200-4007-N1

yMA7200-2010-N1 yMA7200-4010-N1

■Removing the digital operator

Take off the screws in the place a. and b.

Press the lever on the side of the di

g

ital o

p

erato

r

in the direction of arrow 1 to unlock the di

g

ital

operator.

Disconnect the RS-232 cable connector on the

b

ack side of the LCD di

g

ital o

p

erator. Lift the

di

g

ital o

p

erator in the direction of arrow 2 to

remove the digital operator.

1

2a

b

Front Cover

LCD Digital Operator

■Removing the front cover

Press the left and right sides of the front cover in

the directions of arrow 1 and lift the bottom of the

cover in the direction of arrow 2 to remove the

front cover.

1

2

1

Front

Cover

c

RS-232

Cable

Connector

■Mounting the front cover and digital operator

Insert the tab of the upper part of front cover into

the groove of the inverter and press the lower part

of the front cover onto the inverter until the front

cover snaps shut.

Connecting the RS-232 cable connector on the

back side of the LCD digital operator and hook

the digital operator at a on the front cover in the

direction of arrow 1.

Press the digital operator in the direction of arrow

2 until it snaps in the place b and then tighten the

screws in the place c and d. (on the front cover)

12

Front

Cover

c

b

a

d

e

Digital

Operator

RS-232

Cable

Connector

1-6

(C) For 230V 15,20HP and 460V 15,20HP Series

yMA7200-2015-N1 yMA7200-4015-N1

yMA7200-2020-N1 yMA7200-4020-N1

■Removing the digital operator :

Take off the screws in the place a. and b.

Disconnect the RS-232 cable connector on the

back side of the LCD digital operator and then lift

the digital operator upwards.

■Removing the front cover :

Loosen the two screws of the front cover in the

place c and d. And lift the bottom of the front

cover to remove the front cover.

■Mounting the front cover and digital operator :

Insert the tab of the upper part of front cover into

the groove of the inverter and tighten the screws

in the place c and d.

Connect the RS-232 cable connector on the back

of the LCD digital operator.

Attach the digital operator and tighten the screws

in the place a and b.

Front

Cover

LCD Digital

Operator

a

b

c

d

RS-232 Cable

Connector

(D)For 230V 30~40HP and 460V 40~75HP Series

■Removing the front cover: Loosen the two screws

of the front cover in the place a. and b. Then

loosen the two screws c and d, lift the front cover

upwards. (Don’t removing the digital operator.)

■Mounting the front cover: Press the front cover

and then tighten the screws in the place a, b, c and

d.

Front cover

1-7

1.4 Wiring between Inverter and Peripheral devices and notice

CAUTION

1. After turning OFF the main circuit power supply, do not touch the circuit

components or change any circuit components before the “CHARGE” lamps

extinguished. (It indicates that there is still some charge in the capacitor).

2. Never do wiring work or take apart the connectors in the inverter while the power

is still on.

3. Never connect the inverter output U/T1, V/T2, W/T3 to the AC source.

4. Always connect the ground lead E to ground.

5. Never apply high voltage test directly to the components within the inverter. (The

semiconductor devices are vulnerable to high voltage shock.)

6. The CMOS IC on the control board is vulnerable to ESD. Do not try to touch the

control board.

7. If Sn-03 is 7,9,11 (2-wire mode) or is 8, 10, 12 (3-wire mode), except parameter

settings of Sn-01 and Sn-02, the other parameter settings will return to their initial

settings at factory. If the inverter is initially operated in 3-wire mode (Sn-03= 8,

10, 12), the motor will rotate in CCW sense after setting changed to 2-wire mode.

(Sn-03= 7, 9, 11). Be sure that the terminals 1 and 2 are OPEN so as not to

harmful to personal or cause any potential damage to machines.

CAUTION

1. Determine the wire size for the main circuit so that the line voltage drop is within

2% of the rated voltage. If there is the possibility of excessive voltage drop due to

wire length, use a larger wire (larger diameter) suitable to the required length

-3

10current(A)length(m)wire/km)(resistancewire3drop(V)voltageLine ×××Ω×=

2. If the length of the cable wire between the inverter and the motor exceeds 30m,

use a lower carrier frequency for PWM (adjust the parameter Cn-34). Refer to

Page 3-21

1-8

Example of connection between the MA7200 and typical peripheral devices are shown as below.

MCCB (Molded-Case Circuit Breaker)

yChoose the Molded Case Circuit Breaker (MCCB) o

f

proper current rating. Please refer to the selection guide

“1.10 Peripheral Units” on Page 1-22.

yDo not use a circuit breaker for start/stop operation.

yWhen a ground fault interrupter is used, select the one with

no influence for high frequency. Setting current should be

200mA or above and the operating time at 0.1 second or

longer to avoid false triggering.

MC (Magnetic Contactor)

yIt is not always necessary to have a Magnetic Contactor on

the input side. However, an input Magnetic Contactor can

be used to prevent an automatic restart after recovery from

an external power loss during remote control operation.

yDo not use the Magnetic Contactor for start/stop operation.

AC Reactor

yTo improve power factor or to reduce surge current, install

an AC Reactor on the input side of the MA7200.

Input Noise Filter

yWhen used with TECO specified Input Noise Filter, the

MA7200 will comply with EN55011 class A regulation.

yPlease refer to the selection guide “1.10 Peripheral Units”

on page 1-22.

MA7200 Inverter

yThe input power supply can be connected to any terminal

R/L1, S/L2, T/L3 on the terminal block.

yPlease connect the ground terminal E to the site ground

securely.

Output Noise Filter (Zero Phase Core)

yInstall an Output Noise Filter between the MA7200 and the

Induction Motor to eliminate noise transmitted between the

power line and the inverter.

yPlease refer to the selection guide “1.10 Peripheral

Devices” on page 1-22.

Induction Motor

yWhen multiple motors are driven in parallel with an

inverter, the inverter rated current should be at least 1.1

times the total motor rated current.

yThe inverter and the motor must be separately grounded.

Induction

moto

r

Power supply

Power supply

switch(NFB)

and earth

leakage

breake

r

Electromagnetic

contacto

r

A

C reacto

r

Input noise

filte

r

MA 7200

inverte

r

Zero phase

core

1-9

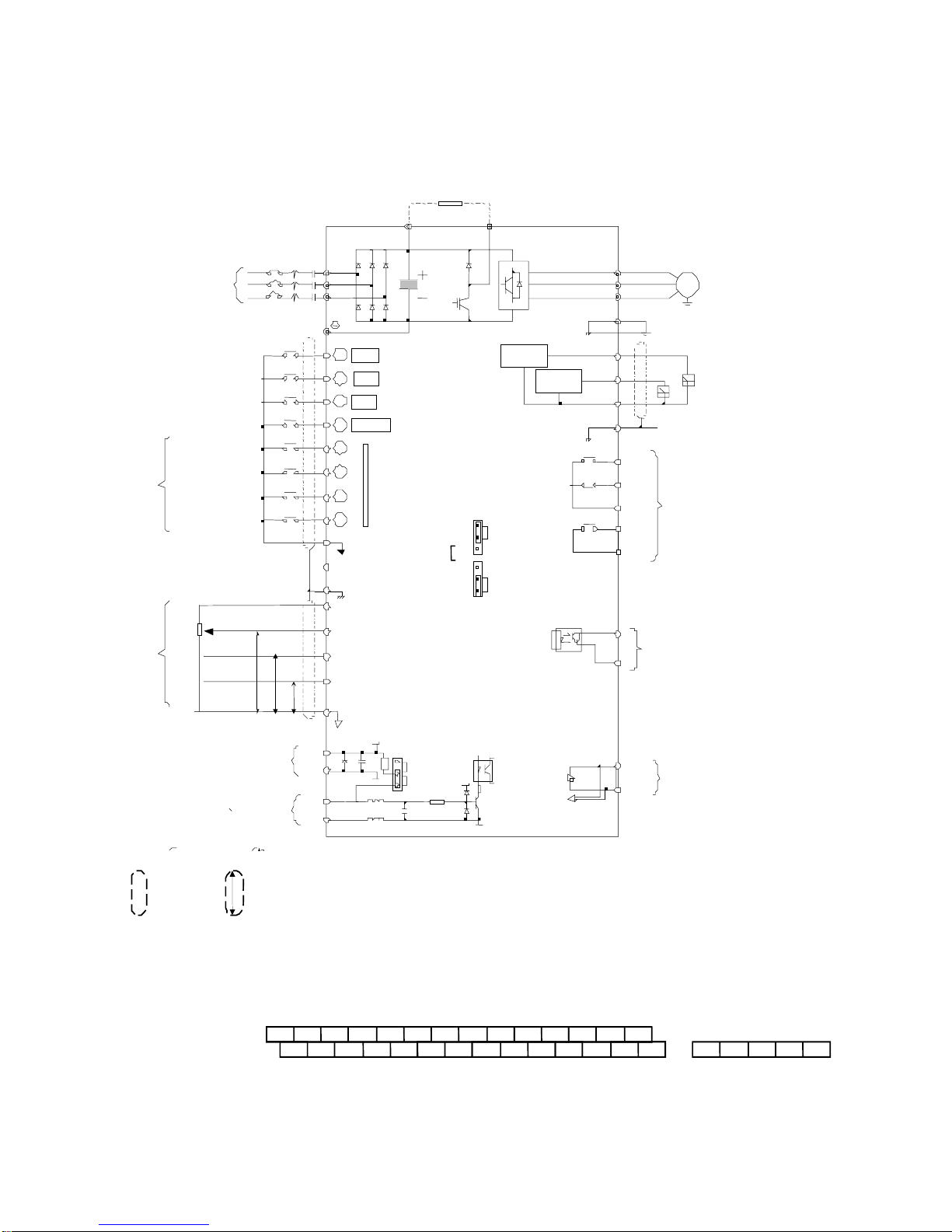

■Standard Connection Diagram

The standard connection diagram of MA7200 is shown in Fig. 2. The sign ◎

indicates the main circuit terminal and the sign ○indicates control circuit terminal. The

terminal function and arrangement are summarized in Table 1 and Table 2. There are

three types of control board, the terminal arrangement is shown as below.

(A) For Compact Size Type 230V : 1-2HP, 460V : 1-2HP (NEMA4 are the same)

•MA7200-2001/2-N1 •MA7200-4001/2-N1

IP12

OPEN

PULL UP

B1/P B2

Braking Resistor

MC

NFB

SC (DG)

Shield Sheath

E

GND Analog signal Common

Digital signal Common

+12V Power Supply for

Speed Ref.

(+12V, 20 mA)

AIN Master Speed Ref.

VIN Master Speed Ref. 0 ~ 10V, (20k

Ω

)

AUX Multi-Funtion

Analog Input

0 ~ 10V, (20k

Ω

)

2k

Ω

1/2W

FWD/STOP

REV/STOP

External Fault

Multi-Step

Speed Ref.1

Jogging

Acc. & Dec.

Switch

Factory Preset

P

P

P

0 ~ +10V

4 ~ 20 mA

0 ~ +10V

0V

4 ~ 20 mA, (250

Ω

)

AO1

V/T2

W/T3

IM

Grounding Lead

(<100

Ω

)

GND

AO2

Analog

Output 1

RA

RB

RC

Multi-Function Contact Output

250V AC, <1A

30V DC, <1A

DO1

DOG

DO2 Multi-Function Output 1, 2

(Open Collector 48V, 50mA)

RS-485 Port

S(+)

S(-)

Analog Monitor 1, 2

(DC 0 ~ 10 V)

U/T1

Main Ckt

Power Supply

R/L1

S/L2

T/L3

Multi-Step

Speed Red.2

Analog

Output 2

E

EXTERNAL FREQUENCY

COMMAND

Fault RESET

(*1)

(*2) The terminal arrangement

(*3) The control board code No. : 4P101C0040001

(*4) The CN2 wire code No. : 4H339D0250001

P

Shield

Wire

Shielded

Twisted Wire

SC 1357

VIN AIN AUX DO1 DO2 DOG

E2468

+12V

GND AO1 AO2

ES(+)

S(-)

GND

RA RB RC

A(+)

A(-)

PG INPUT

(A PHASE)

IP12

IG12

EXTERNAL PG

DC VOLTAGE

1

2

3

4

CN2

FWD ("Close":FWD)

REV ("Close":REV)

Eb

RESET

Multi-Function

Contact Input

2

3

4

5

6

7

8

1

(*1)

TP1

(*4)

Fig. 2-a Standard connection diagram

(*4)Pulse Input Frequency Command

1-10

(B) 230V : 3-40HP, 460V : 3-75HP (NEMA4 to 20HP)

yMA7200-2003-N1 yMA7200-4003-N1

through through

MA7200-2040-N1 MA7200-4075-N1

IP12

OPEN

PULL UP

B1/P B2

Braking Resistor

MCNFB

24VG

Shield Sheath

E

(Sink Common)

FW D/STOP

REV/STOP

External Fault

Multi-Step

Speed Ref.1

Jogging

Acc. & Dec.

Switch

Factory Preset

V/T2

W/T3 IM

U/T1

Main Ckt

Power Supply R/L1

S/L2

T/L3

Multi-Step

Speed Red.2

Fault RESET

GND Analog signal Common

+12V or -12V Power Supply

for

Speed Ref.

(±12V, 20 mA)

AIN Master Speed Ref.

VIN Master Speed Ref. 0 ~ 10V & -10V~10V

, (20kΩ)

AUX Multi-Function

Analog Input

0 ~ 10V, (20k

Ω

)

2k

Ω

1/2W

PP

P

-10V ~ +10V

4 ~ 20 mA

0 ~ +10V

0V

4 ~ 20 mA, (250

Ω

)

EXTERNAL FREQUENCY

COMMAND

24V

(Source Common)

AO1

Grounding Lead

(<100

Ω

)

GND

AO2

Analog

Output 1

Analog Monitor 1, 2

(DC 0 ~ 10 V)

Analog

Output 2

E

Multi-Function Contact Output

250V AC, <1A

30V DC, <1A

R1A

R1B

R1C

R2A

R2C

RS-485 Port

S(+)

S(-)

Multi-Function Output 1

(

Open Collector 48V, 50mA

)

DO1

DOG

FW D ("Close":FWD)

REV ("Close":REV)

Eb

RESET

Multi-Function

Contact Input

2

3

4

5

6

7

8

1

(*1)

(

*2

)

The terminal can be set as SINK or SOURCE t

yp

e in

p

ut interface, when settin

g

as sink t

yp

e

input, the short jumper of TP2 must be set to SINK position, and set to SOURCE position for source type input.

(*3) The terminal arrangement

(*4) The control board code No. : 4P101C0060002

P

Shield

Wire Shielded

Twisted Wire

24VG 135 7 AUXVIN AIN24V DO1 DOG IP12 A(+) A(-)

E24 6 8 +12VGND AO1 AO2 EIG12 S(+) S(-)GND R2A R2C R1A R1B R1C

18

~1 8

~

(*1)

A(+)

A(-)

PG INPUT

(A PHASE)

IP12

IG12

EXTERNAL PG

DC VOLTAGE

(* 2)

TP2 :

TP2 : SINK

SOURCE

TP1

Fig. 2-b Standard connection diagram

Fig. 2-b Standard connection diagram

TP2

SINK

(

20

K

Ω

)

(*4)Pulse Input Frequency Command

(*1)

(*2) The term inal

c

and

j

can be set

as SINK or

S OURCE

type input interface, when settingc

~j

as sink type input, the short jum per of TP2

must be set to SIN K posit

ion, and set to SOURCE position fo r source type input.

P

Shield Wire Shield e Twisted

Wire

( * 5) The term inal arrangem ent

( * 6) The contro l board code No.

:

4P101C 0130001

24VG 1357VIN AIN AUX DO1

24V DOG IP12 A(+) A(-)

E2468+12V -

12V AO1 AO2 EIG12 S(+) S(-)

GND R2A R2C R1A R1B R1C

(

*3)

(*4)

VIN Ref. can be set in two input methods as 0~10V or -10~+10V

The term inal A(+), A (-) can be the output term inal of Pulse Input Frequency Command, and the jum per of TP1 must be set to OPEN position.

Pulse Input Frequency Command: 0~32K H z, 3~12V High torsion, input resistor 2.7K Ω

1-11

1.5 Description of terminal function

Table 1 Main circuit terminals

Terminal 230V:1~20HP, 460V:1~20HP 230V:25~40HP, 460V:25~75HP

R/L1

S/L2

T/L3

Main circuit input power supply

(For single phase power supply, please use R/L1, S/L2 as input terminal)

B1/P

B2 -

Θ

B1/P, B2: External braking resistor

B1/P, Θ: DC power supply input

⊕-

• ⊕ - \: DC power supply or

braking unit

B2/R Unused -

U/T1

V/T2

W/T3

Inverter output

EGrounding lead (3rd type grounding)

■Terminal block configuration

․230V : 1 ~ 2HP ․ 460V : 1 ~ 2HP

R/L1 S/L2 T/L3

B1/P

U/T1 V/T2

W

/

T3

B2

R/L1 S/L2 T/L3

B1/P

U/T1 V/T2

W

/

T3

B2

J2

J4

․230V : 3~5HP

R

/L1

S

/L2

T

/L3

E

B1/P

B1/R

B2

U

/T1

V

/T2

Power In Dynamic Brake

To Moto r

W

/T3

CHARGE

․460V : 3~5HP

R

/L1

S

/L2

T

/L3

E

B1/P

B2

U

/T1

V

/T2

Power In Dynamic Brake

To Moto r

W

/T3

CHARGE

․230V/460V : 7.5~10HP

R

/L1

S

/L2

T

/L3

E

B1/P

B1/R

B2

Power In Dynamic Brake

CHARGE

U

/T1

V

/T2

W

/T3

E

To Motor

․230V/460V : 15~20HP ․ 230V : 25~40HP, 460V : 25~75HP

R/L1 S/L2 T/L3 U/T1 V/T2

W

/

T3B1/P B2

R/L1 S/L2 T/L3 U/T1 V/T2

W

/T3

1-12

Table 2 Control circuit terminals

Terminal Functions

1(DI1) Forward Operation – Stop Signal

2(DI2) Reverse Operation – Stop Signal

3(DI3) External Fault Input

4(DI4) Fault Reset

5(DI5)

6(DI6)

7(DI7)

8(DI8)

Multifunction Input Terminal: 3-Wire Operation, Load/Remote Control, Multi-Speed Select,

FWD/REV Select, ACC/DEC Choice, ACC/DEC Halting, Base Block, Overheat Warn, PID

Control, DC Braking, Speed Search, Up/Down Function, PG Feedback Control, External Fault,

Timer function, Multifunction Analog Input Setting

SC(DG)

(24VG)

Digital Signal Ground

Sink Common Point (Locate the short jumper of TP2 in SINK position)

24V Source Common Point (Locate the short jumper of TP2 in SOURCE position)

E Connection to Shield Signal Lead (Frame Ground)

+15V(+12V) DC voltage for External Device

-12V Only support by the board 4P101C01301

VIN Master speed Voltage Reference (0~10V) (4P101C01301 support –10V~10V input)

AIN Master speed Current Reference (4~20mA)

AUX

Auxiliary Analog Input:

Auxiliary frequency Command, Frequency Gain, Frequency Bias, Overtorque Detection, Output

Voltage Bias, ACC/DEC Ramp, DC-Brake Current, Stall Prevention Current Level during

Running Mode, PID Control, Lower-Bound of Frequency Command, Frequency-Jump-4, etc

GND Analog Signal Common

IP12

IG12 External Power Source For PG Feedback Use

A(+)

A(-) Signal Input of PG (also can be the input terminal of Pulse Input Frequency Command)

AO1

AO2

Analog Multifunction Output Port:

Frequency Commend, Output Frequency, Output Current, Output Voltage, DC Voltage, PID

Controlled Value, Analog Command Input of VIN, AIN or AUX.(Below 2mA)

GND Common Lead for Analog Port

RA(R1A) Relay Contact Output A

RB(R1B) Relay Contact Output B

RC(R1C) Relay Contact Common

Same function as terminal DO1,

DO2

DO1

DO2

(

R2A

R2B

)

Digital Multi-Function (Open Collector) Output “1”, “2” Terminals:

During-Running, Zero-speed, Agreed-frequency, Agree-frequency-setting, Frequency-Output,

Inverter-Operation-Ready, Undervoltage-Detection, Base-Block Output, Run Source, Frequency

command, Overtorque Detection, Frequency Command Invalid, Fault, Undervoltage, Overheat,

Motor Overload, Inverter Overload, During-Retry, Communication-Fault, Timer-Function-Output

DOG Common Terminal (of Open Collector Transistor)

S(+)

S(-) RS-485 Port

Caution

• Use the control circuit terminals VIN, AIN according the setting of Sn-24.

• The MAX. Output current at terminal (+15V or +12V) is 20mA.

• The multi-function analog output terminals AO1, AO2 is a dedicated output for a frequency meter, ammeter,

etc. Do not use these 2 analog outputs for feedback control or any other control purpose.

1-13

1.6 Main Circuit Wiring Diagram

Main Circuit Wiring Diagram of MA7200:

1. 230V/460V : 1~20HP

2. 230V : 25HP 460V : 25~30HP

3. 230V : 30~40HP 460V : 40~75HP

1-14

1.7 Wiring main circuit and notice

■Main circuit wiring

The non-fusible-breaker (NFB) should be installed between the AC source and the

R/L1-S/L2-T/L3 input terminal of MA7200 inverter. The user can make his own decision

of installing electromagnetic contactor block (MCB) or not. To protect against the false

triggering of leakage-current, the user should install a leakage current breaker with

amperage sensitivity≧200mA and operation time≧0.1 sec.

Table 3 230V and 460V class applicable wire size and connector

MA7200 model Wire size (mm2)

Power

supply

Applicable

Power Rating

(HP)*1

Rated

KVA

Rated

current

(A)

Main

circuit*2

Ground

connection

wire E (G)

Control

wire*3

NFB*4 MCB*4

1HP 2 4.8 2~5.5 2~5.5 0.5~2TO-50EC(15A) CN-11

2HP 2.7 6.4 2~5.5 3.5~5.5 0.5~2TO-50EC(20A) CN-11

230V

1Φ/3Φ3HP 4 9.6 3.5~5.5 3.5~5.5 0.5~2TO-50EC(20A) CN-11

5.4HP 7.5 17.5 5.5 5.5 0.5~2TO-50EC(30A) CN-16

7.5HP 10.1 24 8 5.5~80.5~2TO-100S(50A) CN-18

10HP 13.7 32 8 5.5~80.5~2TO-100S(60A) CN-25

15HP 20.6 48 14 8 0.5~2TO-100S(100A) CN-50

20HP 27.4 64 22 8 0.5~2TO-100S(100A) CN-65

25HP 34 80 22 14 0.5~2TO-225S(150A) CN-80

30HP 41 96 38 14 0.5~2TO-225S(175A) CN-100

230V

3 Φ

40HP 54 130 60 22 0.5~2TO-225S(175A) CN-125

1HP 2.2 2.6 2~5.5 2~5.5 0.5~2TO-50EC(15A) CN-11

2HP 3.4 4 2~5.5 3.5~5.5 0.5~2TO-50EC(15A) CN-11

3HP 4.1 4.8 2~5.5 3.5~5.5 0.5~2TO-50EC(15A) CN-11

5.4HP 7.5 8.7 2~5.5 3.5~5.5 0.5~2TO-50EC(15A) CN-18

7.5HP 10.3 12 3~5.5 3.5~5.5 0.5~2TO-50EC(20A) CN-18

10HP 12.3 15 5.5 5.5 0.5~2TO-50EC(30A) CN-25

15HP 20.6 24 8 8 0.5~2TO-50EC(30A) CN-25

20HP 27.4 32 8 8 0.5~2TO-100S(50A) CN-35

25HP 34 40 8 8 0.5~2TO-100S(75A) CN-50

30HP 41 48 14 8 0.5~2TO-100S(100A) CN-50

40HP 54 64 22 8 0.5~2TO-100S(100A) CN-65

50HP 68 80 22 14 0.5~2TO-125S(125A) CN-80

60HP 82 96 38 14 0.5~2TO-225S(175A) CN-100

460V

3Φ

75HP 110 128 60 22 0.5~2TO-225S(175A) CN-125

*1 : It is assumed constant torque load.

*2 : The main circuit has terminals of R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, B1/P, B2/R, B2,Θ.

*3 : The control wire is the wire led to the pin terminals of control board.

*4 : In Table 3, the specified Part No. of NFB and MC are the item No. of the products of TECO. The

customer can use the same rating of similar products from other sources. To decrease the noise

interference, be sure to add R-C surge suppressor (R: 10Ω/5W, C: 0.1µF/1000VDC) at the 2

terminals of coils of electromagnetic contactor.

1-15

■External circuit wiring precaution:

(A) Control circuit wiring:

(1) Separate the control circuit wiring from main circuit wiring (R/L1, S/L2, T/L3, U/T1,

V/T2, W/T3) and other high-power lines to avoid noise interruption.

(2) Separate the wiring for control circuit terminals RA-RB-RC (R1A-R2B-R2C) (contact

output) from wiring for terminals c~j, A01, A02, GND, DO1, DO2 , DOG 15V(or

+12V, -12V), VIN, AIN, AUX, GND, IP12, IG12, A (+), A (-), S(+) and S(-).

(3) Use the twisted-pair or shielded twisted-pair cables for control circuits to prevent

operating faults. Process the cable ends as shown in Fig. 3. The max. wiring distance

should not exceed 50 meter.

Connect to shield

sheath terminal E

Shield sheath Armor

Do not

connect here

Insulated with tape

Fig. 3. Processing the ends of twisted-pair cables

When the digital multi-function output terminals connect serially to an external relay, an

anti-parallel freewheeling diode should be applied at both ends of relay, as shown below.

free-wheeling diode

(100V, >100mA)

48V max.

50 mA max.

7200MA external wiring circuit

Fig. 4. The Optical-couplers connect to external inductive load

(B) Wiring the main circuit terminals:

(1) Input power supply can be connected to any terminal R/L1, S/L2 or T/L3 on the

terminal block. The phase sequence of input power supply is irrelevant to the phase

sequence.

(2) Never connect the AC power source to the output terminals U/T1, V/T2 and. W/T3.

(3) Connect the output terminals U/T1, V/T2, W/T3 to motor lead wires U/T1, V/T2, and

W/T3, respectively.

(4) Check that the motor rotates forward with the forward run source. Switch over any 2

of the output terminals to each other and reconnect if the motor rotates in reverse with

the forward run source.

(5) Never connect a phase advancing capacitor or LC/RC noise filter to an output circuit.

MA7200

1-16

(C) GROUNDING :

(1) Always use the ground terminal (E) with a ground resistance of less than 100Ω.

(2) Do not share the ground wire with other devices, such as welding machines or

power tools.

(3) Always use a ground wire that complies with the technical standards on electrical

equipment and minimize the length of ground wire.

(4) When using more than one inverter, be careful not to loop the ground wire, as

shown below.

(a) OK (b) OK (c) NO

Fig. 5. MA7200 ground winding

•Determine the wire size for the main circuit so that the line voltage drop is within

2% of the rated voltage. (If there is the possibility of excessive voltage drop, use a

larger wire suitable to the required length)

•Installing an AC reactor

If the inverter is connected to a large-capacity power source (600kVA or more),

install an optional AC reactor on the input side of the inverter. This also improves

the power factor on the power supply side.

•If the cable between the inverter and the motor is long, the high-frequency

leakage current will increase, causing the inverter output current to increase as

well. This may affect peripheral devices. To prevent this, adjust the carrier

frequency, as shown below:

Cable length < 100ft. 100-165ft. 166-328ft.

>

329ft.

Carrier frequency

(Cn-34)

15kHz max

(Cn-34=6)

10kHz max

(Cn-34=4)

5kHz max

(Cn-34=2)

2.5kHz

(Cn-34=1)

Table of contents

Other TECO-Westinghouse Motor Inverter manuals

Popular Inverter manuals by other brands

BARRON

BARRON EXITRONIX Tucson Micro Series installation instructions

Baumer

Baumer HUBNER TDP 0,2 Series Mounting and operating instructions

electroil

electroil ITTPD11W-RS-BC Operation and Maintenance Handbook

Silicon Solar

Silicon Solar TPS555-1230 instruction manual

Mission Critical

Mission Critical Xantrex Freedom SW-RVC owner's guide

HP

HP 3312A Operating and service manual