v

Figure index

Figure 3-1 Panel and enclosure arrangement for drives............................................... 3-1

Figure 3-2 Mounting and clearance requirements........................................................ 3-1

Figure 3-3 Din rail mounting of the JNEV Drive ......................................................... 3-2

Figure 3-4 Side-by-side mounting of the JNEV Drive................................................... 3-2

Figure 3-5 NEMA 4 mounting instructions.................................................................. 3-4

Figure 3-6 NEMA 4 wiring diagram............................................................................ 3-4

Figure 3-7 M/N XX-YYY-N4S (115,230V model) connection diagram.......................... 3-5

Figure 3-8 M/N XX-YYY-N4 (115,230V model) connection diagram............................ 3-6

Figure 3-9 Typical installation schematic....................................................................3-10

Figure 3-10a Installation examples.............................................................................3-11

Figure 3-10b Installation examples using a filter.........................................................3-11

Figure 3-10c Installation examples with adjacent signal conductors............................3-11

Figure 3-11 Grounding filtered units..........................................................................3-12

Figure 3-12 Processing the ends of twisted pair tables.................................................3-12

Figure 3-13 Grounding example, multiple drives........................................................3-12

Figure 3-14 EV wiring diagram..................................................................................3-17

Figure 3-15 Power terminal locations.........................................................................3-18

Figure 3-16 Signal terminal locations .........................................................................3-19

Figure 3-17 EV drive frame 1 dimensions...................................................................3-21

Figure 3-18 EV drive frame 2 dimensions...................................................................3-22

Figure 3-19 EV drive IP65 (switch) frame 1 dimensions..............................................3-23

Figure 3-20 EV drive IP65 (no switch) frame 1 dimensions.........................................3-23

Figure 3-21 Common bus configurations....................................................................3-24

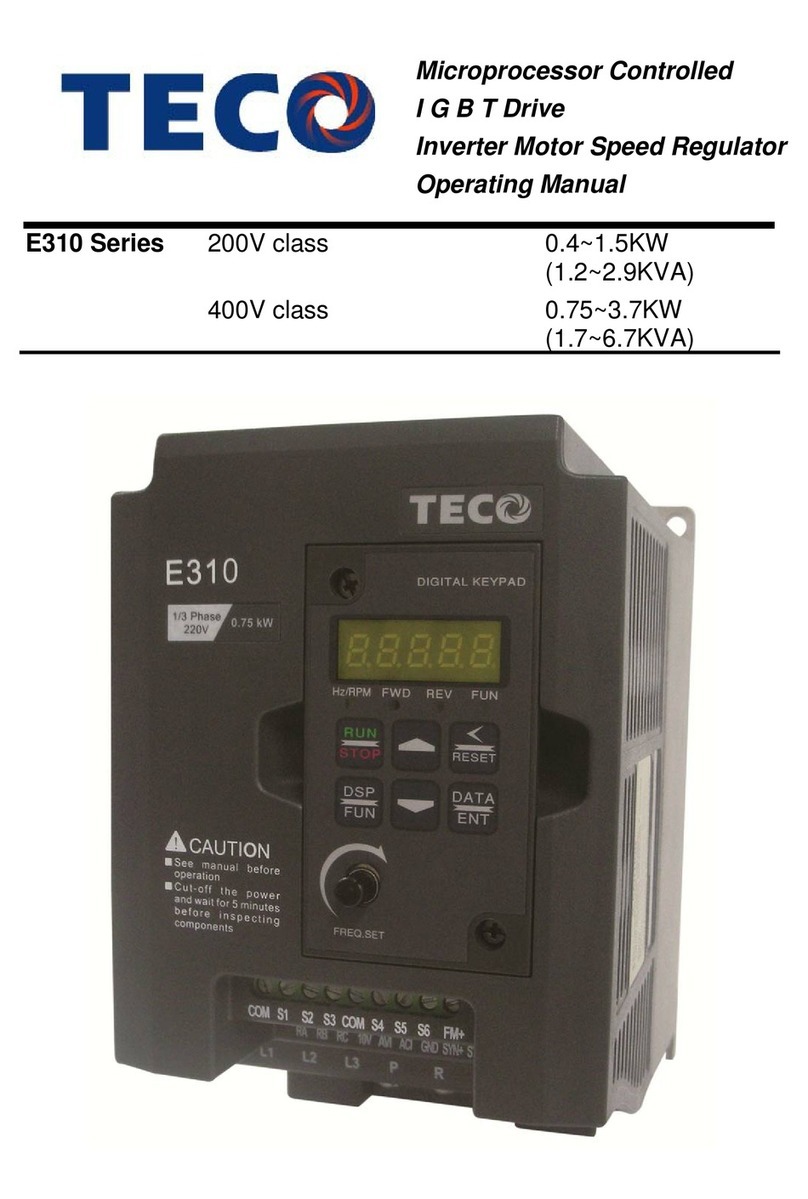

Figure 4-1 Keypad layout............................................................................................ 4-1

Figure 4-2 Keypad operations sequence....................................................................... 4-1

Figure 4-3 Wiring details

a. Fwd/stop-reverse/stop wiring detail ....................................................4-11

b. Run/stop-forward/reverse wiring detail...............................................4-11

c. 3-wire run/stop detail .........................................................................4-11

Figure 4-4 Control method sequences.........................................................................4-12

Figure 4-5 Frequency limits .......................................................................................4-12

Figure 4-6 Acceleration/deceleration prohibit.............................................................4-15

Figure 4-7 AIN gain & bias setting examples..............................................................4-16

Figure 4-8 Frequency detection

a. Frequency Reached (F21/C46=1) .........................................................4-17

b. Frequency Reached (F21/C46=2) .........................................................4-18

c. Frequency Reached (F21/C46=3) .........................................................4-18

d. Frequency Reached (F21/C46=4) .........................................................4-19