Tectronix Systems Genius User manual

1TecTronix-GENIUS-BA-CU-EN-3006.doc

Operating Instructions

GENIUS Control Unit

9 - 18812 96th Avenue

Surrey, BC Canada, V4N 3R1

Tel: (001) 604 607-6028 Fax: (001) 604 607-6026

2TecTronix-GENIUS-BA-CU-EN-3006.doc

Customer Name:

Location:

Date in Service d/m/y:

We would like to take this opportunity to thank you for purchasing your

Metal Detector from TecTronix. The confidence you have placed in our product

is sincerely appreciated and we will endeavour to provide the best service and

support possible.

Please take the time to read the User Manual completely as this provides

you with the expertise necessary to install and adjust the system according to

your requirements. In addition to this, you will learn about the sophisticated

options provided by the Genius electronics.

If you have any problems in the set up and operation of your system, the

TecTronix team are available to assist you.

TecTronix Systems inc.

26688 56th Avenue

Langley, British Columbia

Canada, V4W 3X5

Telephone: (001) 604 607-6028

Fax: (001) 604 607-6026

E-mail: service@tectronixsystems.com

3TecTronix-GENIUS-BA-CU-EN-3006.doc

Installation Do´s and Don´ts

Electrical

- Do Not cut the connector or the power cables

These cables are equipped with special double shields and connectors and must not be cut. If you require

longer or shorter cables please order them from our parts department. The electrical cables are approxi-

mately 10 feet (3m) in length and the connector cables are 26 feet (8m). It is therefore recommended that

consideration be given to where the connection boxes are located and that all cables be installed in conduit.

- Do Not weld in reasonable proximity to the metal detector

Welding in the vicinity of the metal detector will trigger faults.

- Run a clean, constant voltage power supply from the main to the control panel

Voltage fluctuations can cause false tripping therefore a constant voltage transformer is highly recom-

mended.

- Do Not install the metal detector near MCC's or control panels

Stray fields can trigger faults

- Run the connector cables to the metal detector separately

Connector cables are part of the metal detector and have to be protected against noise. It is highly recom-

mended to run them in a dedicated conduit. Both cables can be run in the same conduit. The conduit should

be metal but, must be grounded. If the conduit is to be connected at the transmit/receive boxes on the coil

and/or the control panel, all fittings must be plastic.

- Do Not install the detection coil inside an electromagnetic field (strong power supply fluctuations)

Interferences can trigger faults. For example; Where units are installed in close proximity to chipper motors,

when under high amperage draw, can cause nuisance or false tripping and this may require the fabrication of

a shield.

- Do Not disconnect the metal detector from the power supply main

A constant, uninterrupted power supply enables more sensitive adjustments. Powering the unit on and off

causes it to recalibrate during which time metal will not be detected.

- When welding, do not use the control panel mounting surface as a ground

Mechanical

- Do Not use conductive (Anti-Static) belt material

Non-conductive belt material is preferred. When splicing belts, use a "Finger over Finger" splice for best

results. Ensure all surfaces are clean and free of debris at the splice.

- Vibration less installation of the detector coil (except "VT")

Higher sensitivities can be attained and maintained if the operating conditions are optimal. Ensure the coil is

mounted to a structure that is stationery at all times.

- Eliminate loose metal to metal connections near or within the detection field

Intermittent metal to metal contacts from such things as roller axis, loose bolted connections, or broken welds

can cause the metal detector to false trip especially on the higher sensitivity settings.

- Vibration less installation of the Control Panel

Mount the control panel on a vibration free surface. Vibration can cause premature electronic component

failure.

- Avoid cable whiplash……….

On "VT" Vibratory Conveyor installations, use the supplied cable clamps and tie wraps to secure the cables

to the metal detector housing. Doing so will avoid whip lash at the transmit/receive box strain relief connec-

tions. In addition to this we recommend that you loop the cables as they exit the conduit. These loops will

then flexas the conveyor cycles. It is also advisable to follow this procedure on belt conveyor installations.

- Do Not touch the sensor/coil surface of the detector

Mechanical contacts may cause detection errors. Keep the sensing surface free of debris.

- Mount the FLAT PLATE type coils as close as possible to the underside of the vibrating conveyor or

belt conveyor

The closer the coil to the product being conveyed, the greater the sensitivity. Do not allow material to build up

on the sensing face so that it touches the conveyor pan. Doing so creates a closed conductive loop and the

metal detector will false trip.

- Isolate rollers on belt and driven roll conveyors

On belt and roller conveyor applications where a roller is less than 24" (610mm) from the centerline of the

detector, the roller must be isolated on one side to avoid the possible effect of errant static charges. Use a

UHMW shim beneath the bearing and nylon washers or some other non conductive material beneath the bolt

head and nut/flat washer. The bolts should also be sleeved with a non conductive material. It may be neces-

sary to isolate more than one roller in either direction to achieve the desired results.

Contents

4TecTronix-GENIUS-BA-CU-EN-3006.doc

Contents

1General information 6

1.1 Reasons for using the Control Unit GENIUS 6

1.2 Symbols used 6

1.3 Legal basis 6

1.4 Overall view 6

2Technical data 7

2.1 Performance data 7

2.2 Dimensions 8

3Design and method of operation 9

3.1 Functional principle 9

3.2 Functional and control elements 10

3.2.1 GENIUS - Housing 10

3.2.2 GENIUS - Controller board STE 11

3.2.3 GENIUS - Evaluation electronics board AWE 12

4Safety 13

4.1 Use to the intended purpose 13

4.2 Notification of risk 13

4.3 Risks in case of non-observance of the safety notes 13

4.4 Safety notes for the operator 13

4.5 Safety notes for operation and maintenance 13

4.6 Notes on residual risk 13

4.7 Consequences of unauthorized modification 13

4.8 Inadmissible operation 13

5Commissioning 14

5.1 Mechanical Mounting 14

5.2 Connection of the equipment 14

5.2.1 Connector assignments on the controller board 14

5.2.2 Electrical connection 15

5.2.3 Electrical Performance 16

5.2.4 Electrical Connection of the equipment 17

6Operation / Menu structure 19

6.1 Quick start 19

6.1.1 Setting of the most important parameters 19

6.1.2 Teach-in procedure for new product 19

6.2 Operating mask and Adjustment menu 20

6.3 Set up menu 21

6.3.1 Check of detector adjustment and software version 21

6.3.2 Event recording by the GENIUS Log book 22

6.3.3 Activation of Access Codes 22

6.3.4 Time setting 22

6.3.5 Date setting 23

6.3.6 Language setting 23

6.3.7 Serial Interface configuration (option) 23

6.3.8 Setting of Device and Line name 23

6.3.9 Setting of the unit for conveying speed 24

6.3.10 Adjustment of the Air pressure monitor (option) 24

6.3.11 Conveying speed setting with distance measurement (option belt conveyor) 24

6.3.12 Adjustment of Reject and Level monitor (option belt conveyor) 25

6.3.13 Adjustment of the Diverter position monitor (option pipe conveyor) 25

6.3.14 Adjustment of the Diverter Controller (option pipe conveyor) 26

Contents

5TecTronix-GENIUS-BA-CU-EN-3006.doc

6.4 Product teach-in menu 27

6.4.1 Selection of a product memory 27

6.4.2 Product parameter setting 27

6.4.2.1 Conveying speed 28

6.4.2.2 Automatic product teach-in 29

6.4.2.3 Manual setting of product parameters 30

6.4.2.4 Options for product effect equalization 30

6.4.2.5 Input / change of product name 31

6.4.2.6 Setting of the outputs 31

6.4.2.7 Activation of performance validation and scheduled testing 34

6.5 Menu Product change 34

7The use of the GENIUS metal detector for quality insurance 35

7.1 Instruction for setting the performance test intervals 35

7.2 Carrying out a performance validation 35

8Errors and error remedying 36

8.1 Error messages 36

8.1.1 Interface to evaluation unit interrupted 36

8.1.2 Transmitter or receiver faulty 36

8.1.3 Receiver voltage too high 36

8.1.4 Battery voltage too low 36

8.1.5 24V switching output overload 36

8.1.6 Datememory not existing 37

8.1.7 Compressed Air 37

8.1.8 Not rejected 37

8.1.9 Reject box full 37

8.1.10 Diverter Position 37

8.2 Undefinable activation of the switching outputs 38

8.3 Replacement of electronic boards 39

8.3.1 Replacing the control electronics board 40

8.3.2 Replacing the evaluation electronics board 40

8.3.3 Replacing the display board 40

9Spare parts, service 41

9.1 Spare parts view 41

9.2 Spare parts list 41

9.3 Accessories 41

9.4 Service address 42

10 Shipping, transport, storing, preservation 43

11 Index 44

1. General information

6TecTronix-GENIUS-BA-CU-EN-3006.doc

1 General information

1.1 Reasons for using the Control Unit GENIUS

•Product liability

•ISO 9000

•TQM (Total Quality Management)

•Protection of consumers and of machines

1.2 Symbols used

= Important notes

= Danger notes

= Safety notes

1.3 Legal basis

This equipment complies

•with EMC guideline 89/336/EC and 92/31/EC

•low-voltage guideline 73/23/EC

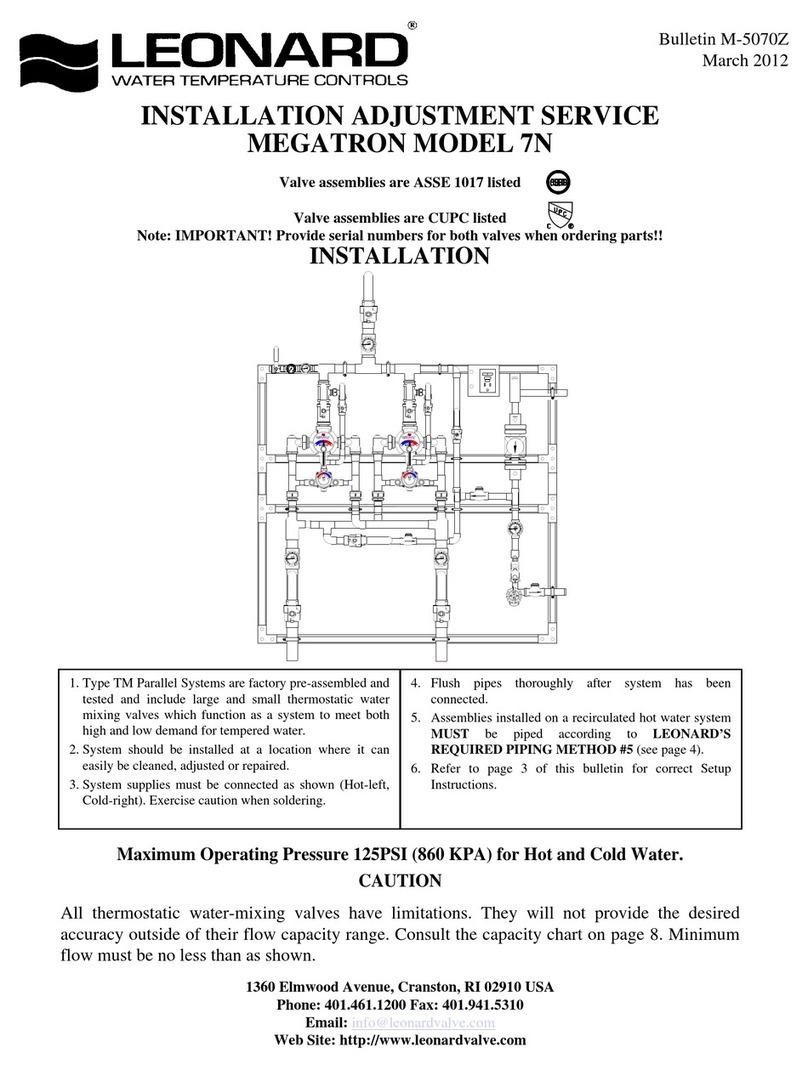

1.4 Overall view

2. Technical data

7TecTronix-GENIUS-BA-CU-EN-3006.doc

2 Technical data

2.1 Performance data

Type: Control Unit GENIUS

Housing: Sheet metal, painted, pure-orange (RAL 2004) or

FDA white, food grade (RAL 9010) or

stainless steel, glass lead blasted or polished.

Dimensions: see page 6

Weight: 6 kg

Connecting cable: (to the detection coil) standard up to 5m (up to 50 m max.)

Mains cable: 1,8 m with plug

Ambient temperature:

on request

Type of protection: IP 65

Operating voltage: 230V / 115V (+10%, -15%), selectable, 50Hz / 60Hz

Current input: approx. 120 mA

Fuse: 630 mA, slow-blowing

Switching inputs: 2 switching inputs for initiators

1 switching input for light barrier

1 switching input RESET

8 switching inputs for special functions and options

Switching outputs: 1 switching output 24V DC, 200mA for metal detection

2 relay switching outputs for metal detection

1 relay switching output error message

Interface: Serial interface RS232 or. RS485 (option)

Operation: Graphic display with 4-key operation

Conveying speed: depends on type and size of the detection coil used

Can be combined: Detection coils of GLS, GLS-R, DLS and ELS

Subject to changes due to technical innovation!

2. Technical data

8TecTronix-GENIUS-BA-CU-EN-3006.doc

2.2 Dimensions

240mm

240 mm

260 mm

315mm

145 mm

3. Design and method of operation

9TecTronix-GENIUS-BA-CU-EN-3006.doc

3 Design and method of operation

3.1 Functional principle

A metal impurity within the aperture of the detector causes an unbalanced condition of the high fre-

quency electromagnetic field, which is recognized by the evaluation electronics.

The product to be inspected can also cause an unbalanced condition. The evaluation electronics is

able to neutralize and store this effect and detect despite of that metal impurities within that product.

The controller acts as the central processing unit and controls the evaluation electronics, display unit,

serial interface for external control units (SPS, PC) and printers. The PC can run also the Data Man-

agement System INSIGHT GENIUS.

Evaluation electronic

Serial

Interface

Signal ampl.

Transmitte

r

Receive

r

Controller

Power supply

LCD-Display

key pad

Relay,24VDC output

Ausgang

24VDC input

Eingänge

Microcontroller

Memory

1000 events

100 products

Serial

Interface

RS232 / RS485

Data

Quartz oscillator

Receive

r

Detector coil

Analog / Digital

Converter

Data Digital

Signal-

processing

SPS

PC

Printer

Data

3. Design and method of operation

10 TecTronix-GENIUS-BA-CU-EN-3006.doc

3.2 Functional and control elements

3.2.1 GENIUS - Housing

Display and key pad:

(1) LCD display

(2) Function keys F1 - F4

(3) „Operation lamp“: lights

up when mains supply is

ON

(4) „Fault“ lamp: blinks in

case of fault or error

(5) „Metal“ lamp: lights up in

case of metal detection

(6) Resetting of the metal

and alarm

At the bottom of the housing:

(7) Cable gland for the mains cable

(8) Cable gland for free use

(9) Cable gland for free use

(10) „Receiver“ cable gland for connecting the detector

coil

(11) „Transmitter“ cable gland for connecting the detector

coil

(12) Cable gland for free use

(13) Cable gland for free use (or connection of the serial

interface (option)

10987 131211

F2F1 F4

F3

G E N I U S

METAL DETECTOR

operation

opération

fault

défalt

metal

métal

1

2

3

4

5

Reset

6

funcionamiento

error

metal

3. Design and method of operation

11 TecTronix-GENIUS-BA-CU-EN-3006.doc

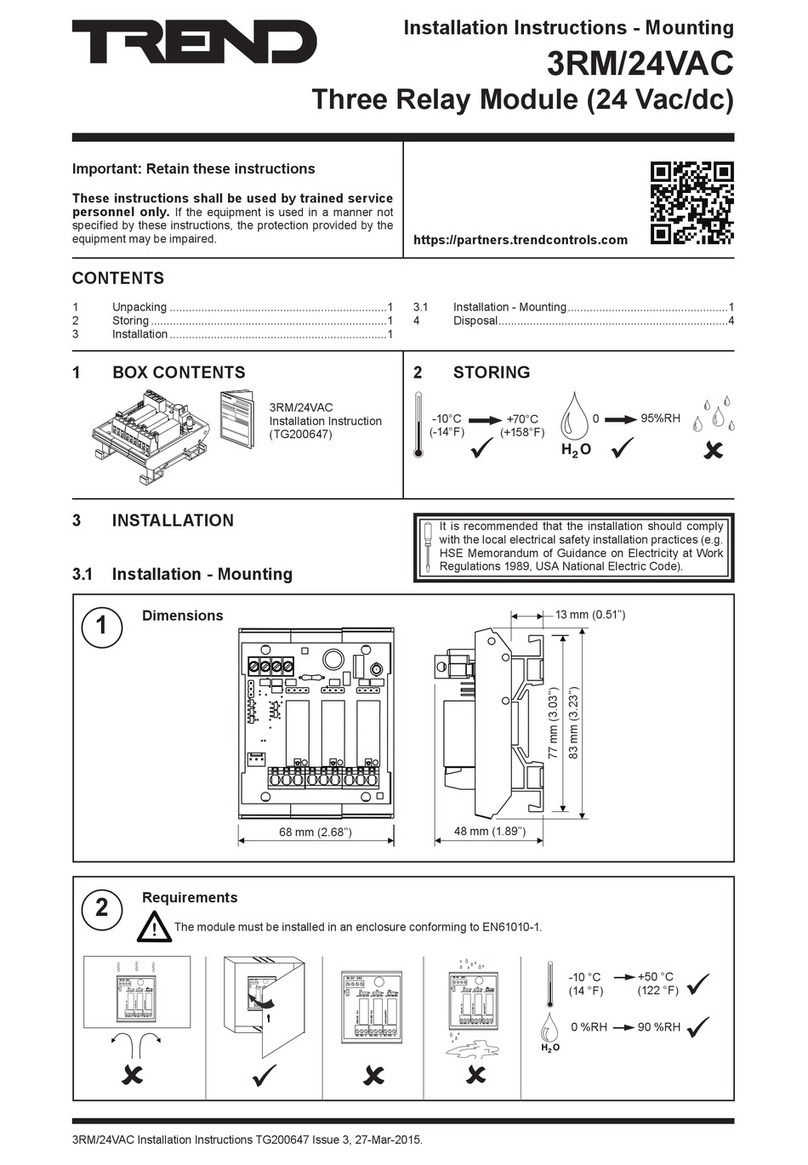

3.2.2 GENIUS - Controller board STE

1 2 3 4 5

6b

6a

14

11

10

10

12

13

15

16

9

8

7b

7a

red

Connectors: (1) „Mains“: Mains supply

(2) „Fault“: Potential-free change-over contact

(3) „Metal 1“: Potential-free change-over contact

(4) „Metal 2“: Potential-free change-over contact

(5) „24V Output“: 24V switching output

(6) a) 24 Inputs and outputs.

b) Connection detection coil/sensor electr.

(7) a) 24 Inputs

b) Serial interface RS485/RS232

(8) Ribbon cable connector for control panel

(9) Ribbon cable connector Option

Elements connected to mains volt-

age: ( 1) „Mains“ connector

(10) Mains fuse

(11) Mains voltage selector switch

Elements connected to external

voltage: (2) „Fault“ connector

(3) „Metal“ connector

(4) „Metal“ connector

Memory devices: (14) Data battery for Logbook

(15) Program memory

(16) Device and product data memory

3. Design and method of operation

12 TecTronix-GENIUS-BA-CU-EN-3006.doc

3. Design and method of operation

13 TecTronix-GENIUS-BA-CU-EN-3006.doc

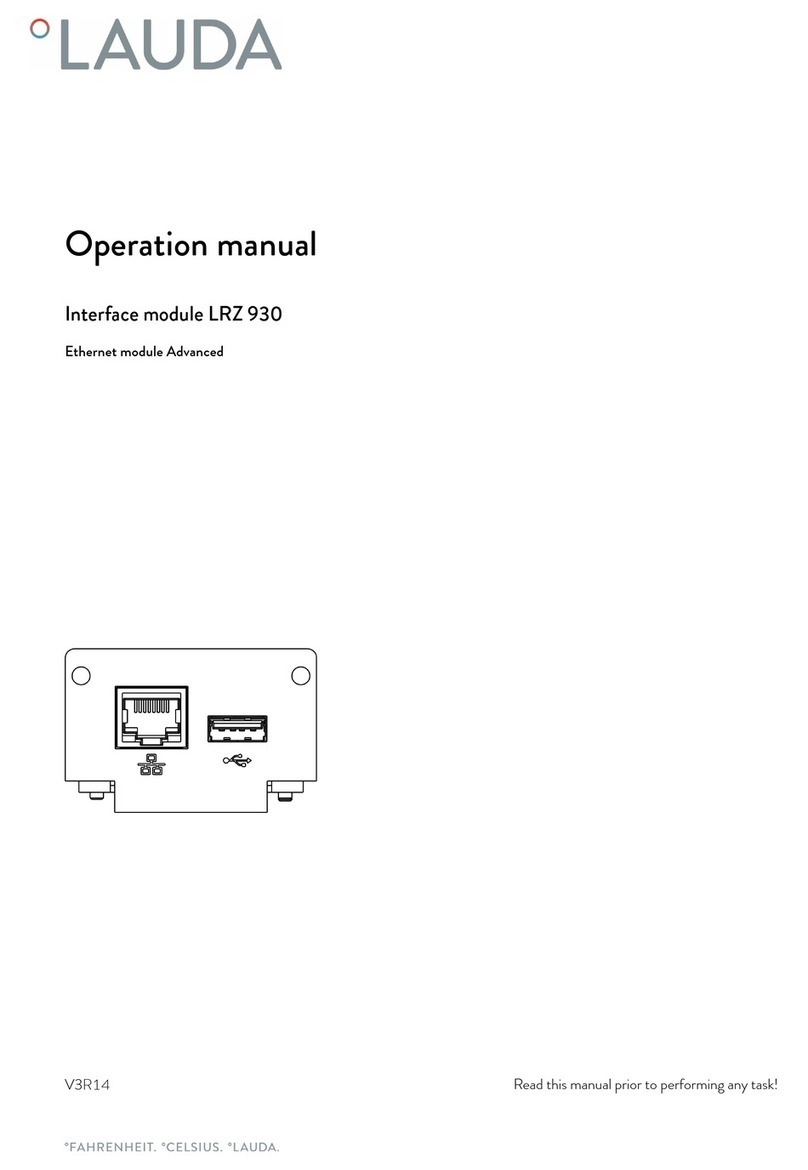

3.2.3 GENIUS - Evaluation electronics board AWE

+

1

5

-

1

5

R

T

GND

GND

1

2

3

5

6

7

8

9

+9V

xx

GND

GND

+22V

- 22V

- 30V

+30V

Connectors: (1) STE RS485: Interface RS485 to the controller board

(2) Power Supply: Power supply from the controller board

(3) Transmitter: Output signal to the detector coil

(4) Cable Check: Control signal to the detector coil

(5) Receiver: Input signal from the receiver

Test points: GND Common ground for all signals

(6) Transmitter Sine wave signal (45..50Vss) feeding the

transmitter coil

(7) Receiver Sine wave signal from the receiver coils

(8) Metal signal branch S

(9) Metal signal branch A

4. Safety

14 TecTronix-GENIUS-BA-CU-EN-3006.doc

4 Safety

4.1 Use to the intended purpose

The equipment is intended to be used in the following fields of application only in

combination with a corresponding detector coil: SF-DF, free-fall applications, and

conveyor belt applications.

4.2 Notification of risk

People with cardiac pacemaker should not stay in the area of the detection coil

permanently.

4.3 Risks in case of non-observance of the safety notes

There are no known risks or side effects emanating from the electronic unit, if the

equipment is not used to the intended purpose.

4.4 Safety notes for the operator

If potentially explosive materials are examined, the pertinent regulations have to

be observed.

4.5 Safety notes for operation and maintenance

During operation the covers for the electronic unit and/or electronic controllers

must always be kept closed.

For maintenance work at the electric/electronic unit or at the pneumatic unit the

power supply and external circuits and compressed air must always be discon-

nected.

Maintenance work may only be performed by qualified personnel.

4.6 Notes on residual risk

Disconnect external control circuits.

4.7 Consequences of unauthorized modification

In case of unauthorized modification or repair work all the declarations and guar-

antees given by the manufacturer will become void.

4.8 Inadmissible operation

Operation out of the specifications given in the technical data.

Operation under high mechanical static and dynamic loads (e.g. heavy system

parts or strong vibrations).

5. Commissioning

15 TecTronix-GENIUS-BA-CU-EN-3006.doc

5 Commissioning

5.1 Mechanical Mounting

•Ensure stable and non-vibrating installation!

•Do not install the detection coil and the electronic unit in the vicinity of interference fields (large

electric motors and frequency converters!) The distance depends on the power consumption of the

motor or of the frequency converter (value for orientation: 5 m).

•Never install the electronic unit in other switchgear cabinets, because this may lead to interference

effects.(e.g. from contactor controls)!

•Cable lengths may only be modified after consultation with „TecTronix Systems“. Use only original

cables. Lay the connecting cable in fixed installation apart from other cables (e.g. fix it with nailing

clips or lay it in a cable duct).

•If several metal detector systems are used, the distance of the detection coils must not be less

than 2m, if these coils stand side by side. If the coils are arranged opposite to each other, the dis-

tance must not be less than 10 m. These values apply to large systems; for smaller systems the

distances may be reduced to 50 cm. If, for reasons of space, these distances cannot be observed,

please contact TecTronix Systems service!

5.2 Connection of the equipment

In order to meet CSP, UL and CE standards all cable outside of

the housing have to be shielded. The shields must be grounded

immediately after the cable gland.

HousingShield

Cable

The terminals „Mains“ and „Evaluation Unit“ are already factory reconnected.

According to the delivered option several connectors may be used.

5.2.1 Connector assignments on the controller board

Outputs

Metal 2

L1NPE

Mains 22 21 24 12

Fault

LF

11 3414 32 31

Metal 1 0 1

PE

24V Output

10 9

T

e

x

_

B

C

k

2

4

V

L

B

L

M

I

N

1

I

N

2

L

S

R

S

T

i

7

I

n

p

u

t

s

E

v

a

l

u

a

t

i

o

n

U

n

i

t

8

7

6

5

4

3

2

1

D

t

i

4

i

5

i

6

i

0

i

1

i

2

i

3

I

n

p

u

t

s

R

S

4

8

5

b

a

R

S

2

3

2

R

x

D

T

x

D

5. Commissioning

16 TecTronix-GENIUS-BA-CU-EN-3006.doc

5.2.2 Electrical connection

Signal Connection Function

„Fault “ Potential-free relay

contact Normal operation: Contact 21 and 24 closed

In case of a fault: Contact 21 and 22 closed

“Metal 1“ Potential-free relay

contact Normal operation: Contact 31 and 32 closed

In case of metal detection: Contact 31 and 34 closed

Special functions at mode Rapid (for Alarm devices) and

CONSENSE-D (Belt conv. Start/Stop)

„Metal 2“ Potential-free relay

contact Normal operation: Contact 11 and 12 closed

In case of metal detection: Contact 11 and 14 closed

„24V Output” 24VDC switching

output Low-activ = yes (see 6.4.2.6):

Normal operation: 0V DC to ⊥

In case of metal detection: 24V DC to ⊥

Low-activ = no (see 6.4.2.6):

Normal operation: 24V DC to ⊥

In case of metal detection: 0V DC to ⊥

Special functions for bidirectinal pusher and for diverter

controller (Option)

„⊥

⊥⊥

⊥“ Ground (GND) Power supply for proximity switches and light barriers

Ground reference for the inputs IN1, IN2, LS and RST

„Outputs“ 24VDC switching

outputs wired to

+24VDC

LM: Metal lamp lights on metal detection

LB: Operation lamp lights on test request (see also

chapter 7.2)

LF: Fault lamp lights in case of errors

„24V“ 24VDC Power

supply Power supply for light barriers and proximity switches

Signal reference for outputs LF, LB and LM

Signal reference for inputs i0 .. i7

„Inputs“ 24V switching inputs

to ⊥

wired to +24VDC

Inputs to 24V

IN1 1. Proximity switch input for distance measurement /

diverter flap (NPN)

IN2 2. Proximity switch input for distance measurement /

diverter flap (NPN)

LS Start Autotest (see chapter 6.4.2.7)

RST External Reset input

I0 identically to IN1 but PNP

I1 identically to IN2 but PNP

I2 Pressure monitor

I5 identically to LS but PNP

I7 Free fall mode (Rapid XXXX): connection ot test push

button to activate the diverter unit.

I3,I4,I6, for special applications.

21

Fault

PE 22L1N

Mains Metal 1

3224 12 11 14

Metal 2 31 34 24V Output. i6

24V 24V 24V 24V

24VLF LB LM

Outputs IN1IN2LSRST i7

Inputs i0i1i2i3i4i5 Inputs

5. Commissioning

17 TecTronix-GENIUS-BA-CU-EN-3006.doc

5.2.3 Electrical Performance

Potential-free relay contact 250VAC/ 3A

120VDC/ 3A

24VDC outputs Max current load: 300mA

Inputs: In1 / In2 / LS / RST Connection of make contacts

against ⊥, resp. NPN outputs

Inputs: i0 .. i7 Connection of make contacts

against+24 V, resp. PNP outputs

5. Commissioning

18 TecTronix-GENIUS-BA-CU-EN-3006.doc

5.2.4 Electrical Connection of the equipment

Only qualified persons are authorized for the following procedure!

Before opening the housing make sure that no mains voltage or any external voltage is

connected!

1. After unloosing 4 screws fold the cover down-

ward.

2. Do the wiring according to your needs.

3. Check the mains voltage selector switch for

correct position.

4. Connect mains power supply.

4.1. The power cord and skintop gland may not be

removed - it is a essential part of the EMC-

concept. If the mains plug cannot be used a

conduit box should be used.

Mains supply by using the

outlet

Mains supply using alter-

natively a mains connec-

tion box

Controller board GENIUS

1

2

3

4.2. If necessary, connect plug ST1 "Mains"

Mains

bl bn

Yel/gr

Shield

Control unit

Cable gland

Skintop PG9

GNLM 3G 0,75

Strip of vanish for

cable gland

Mains cable

1

2

3

4

5

Cable Plug / connection cable

Shield

Shield PE Conductor

Conductor L (brown, bn) L PVC - insulation

Conductor N (blue, bl) N Shield

Conductor PE (yellow, yel / green, gr) PE Sheath

5. After 5 sec the unit is ready for work

230

115

230

115

6. Operation / Menu structure

19 TecTronix-GENIUS-BA-CU-EN-3006.doc

Setting menu

Change product

Teach in product

Operat

ing mask

Setup

Serial setup

Options

Line name

Device name

Setup page 2

Interface

Interface

Device name

Line name

Options

enter alarm time

ent

er alarm time

Receiver adjustment / software

Print protocol

Setup page 1

Datum

Device data

Logbook

GENIUS Logbook

Code

setting

Code change Prod.

Clock

Setting clock

Setting date

Language

Language

Testintervall

Previous menu

Controlintervall

Operating mask

Every hour

Every day

Every week

no alarm

Code Setup

Code teach in Prod.

I

D no. test piece

Hand setting

Handadjustment / Auto.

Configuration

Auto. Reset

Manu. Reset

Output adjust

Reset-

mode auto / manu

Configuration

Manu. teach in

Options

Next

Conveyance speed

Menu options

Teach in product 2

Product name

Freefall

Reject duration

Change product name

Automatic time

measurement

Convey metal piece...

repeat

previous menu

fine adjustment

Fine adjustment

Setting by hand

Hand adjustment

Product effect too high

Convey product

Prod.comp.activated, State: #

Operating mask

Select product

Select produ

ct

Teach in product 1

Auto. teach in

Conveyance speed

Frequency

6. Operation / Menu structure

20 TecTronix-GENIUS-BA-CU-EN-3006.doc

6 Operation / Menu structure

This section starts with a short form instruction for the most important settings including cross refer-

ences for the comprehensive instructions.

Afterward all menus are described. To ease the handling the menu structure can be fold out.

6.1 Quick start

6.1.1 Setting of the most important parameters

Language (if necessary):

1. The operation mask appears after power on (see 6.2).

2. Press F1 „Adjustments“ followed by F3 „Setup“ .

3. Press five times key ↓until „Language“ is marked and press „O.K.“.

4. Select language and confirm with „O.K.“ (see 6.3.6)

5. Return by pressing key „END“ .

6.1.2 Teach-in procedure for new product

1. Press F1 „Adjustments“ followed by F2 „Product teach-in“.

2. If a list of preprogrammed products is displayed press key ↓until „**NEW**“ appears and confirm

with „O.K.“ (see 6.4.1)

3. Set the conveying speed of the product or speed of belt conveyor and confirm with „O.K.“.

4. Follow the instruction on the display. Pay also attention to the -window described in chapter

6.4.2.2!

5. Press F4 (“continue”), then F2 (“output adjust”) in menu „Product teach-in“.

6. Select F1 or F2 for automatic or manual Reset of the metal outputs (see 6.4.2.6).

7. Press F1 „Manual Adjustment“ and set the requested „Delay time“ after metal detection and acti-

vation of the outputs.

8. Confirm the inputs by pressing key „O.K.“, then press F4 to get to the previous menu.

9. To get to the „Operating mask“ press F4.

10. The GENIUS is now adapted to the surrounded conditions and the product.

11. Check the proper operation by putting a metal particle through the detector and watch if it works

correctly.

Table of contents