TeeJet 814-FM User manual

814-FM

Monitor

Programming and Operating Manual

(2.00)

98-70014-R0

MI814-FM Programming and Operating Manual, 03/2000 1 of 17

Table Of Contents

TABLE OF CONTENTS ........................................................................................................................................................................ 2

INSTALLATION..................................................................................................................................................................................... 3

PUMP CUT-OFF INSTRUCTIONS ...............................................................................................................................................................4

POWERING CONSOLE ON/OFF ........................................................................................................................................................ 5

POWER ON.............................................................................................................................................................................................5

POWER OFF............................................................................................................................................................................................5

OVERVIEW OF MONITOR DISPLAYS............................................................................................................................................. 6

DISPLAYS................................................................................................................................................................................................ 7

JOB VOLUME.......................................................................................................................................................................................... 7

JOB FLOW RATE.....................................................................................................................................................................................7

PRESSURE /FLOW RATE......................................................................................................................................................................... 8

TOTAL VOLUME.....................................................................................................................................................................................8

AUTOMATIC FILLING .............................................................................................................................................................................9

PROGRAMMING GUIDELINES ....................................................................................................................................................... 10

IMPORTANT PRELIMINARY INFORMATION ...........................................................................................................................................10

PROGRAMMING THE 814-FM SPRAYER CONTROL SYSTEM ............................................................................................... 11

UNITS...................................................................................................................................................................................................11

FLOW METER PULSES ..........................................................................................................................................................................11

Manual Entry..................................................................................................................................................................................11

Automatic Calibration....................................................................................................................................................................12

PRESSURE TRANSDUCER LOW PRESSURE CALIBRATION......................................................................................................................13

PRESSURE TRANSDUCER MAXIMUM RATING (P HI) ............................................................................................................................. 14

FILL VALVE .........................................................................................................................................................................................14

DATE/TIME ..........................................................................................................................................................................................15

PRINTING ............................................................................................................................................................................................. 16

JOB REPORT .........................................................................................................................................................................................16

TOTAL REPORT ....................................................................................................................................................................................16

HIDDEN TOTAL VOLUME COUNTER........................................................................................................................................... 17

OEM REPORT ......................................................................................................................................................................................17

MI814-FM Programming and Operating Manual, 03/2000 2 of 17

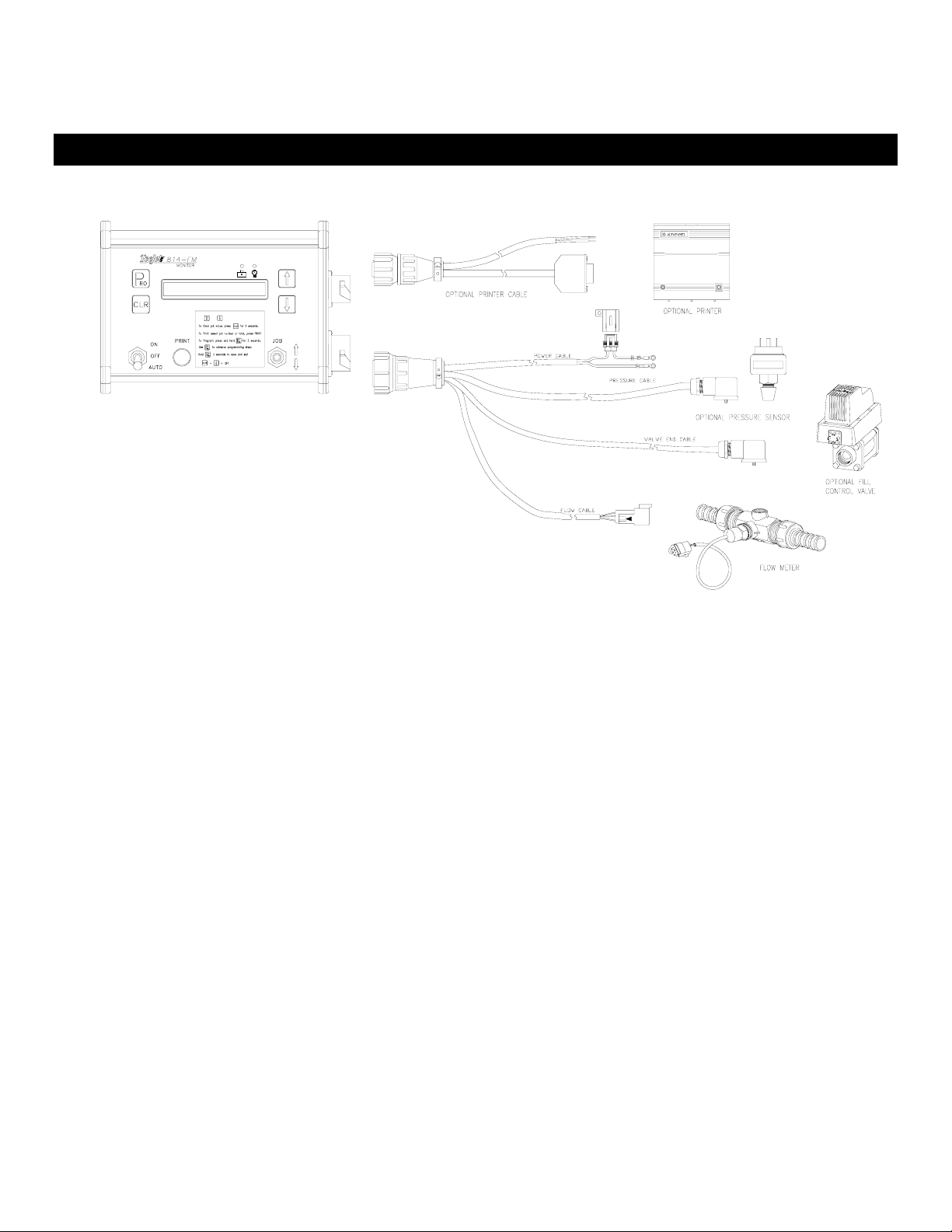

Installation

☛The TeeJet 814-FM monitor is powered by +12VDC. The fused power lead (brown wire) should

go to the positive terminal of the battery. The blue or white wire to the negative or ground

terminal of the battery.

☛The flow meter should be plumbed so that all liquid passing through it is intended to be

measured.

☛The flow meter cable lead should be extended and connected to the the flow meter.

☛The pressure sensor (if used) can be installed at any point in the plumbing system. It should be

mounted in a verticle position on a short stand pipe to help prevent damage from freezing

temperatures.

☛The pressure sensor lead should be extended and connected to the pressure transducer, if

used. If no pressure transducer is used, this cable lead can be tied back for possible future use.

☛The valve lead should be extended and connected to the optional auto fill valve. If an auto fill

valve is not used, this cable can be tied back for possible future use.

☛The auto fill valve used with this system must be a negatively switched valve. This system can

also be used to disengage a pump if desired. Refer to the Pump Cut-off instructions in the

following section.

☛If an optional printer will be used with the system, it requires a separate cable connection to the

console. The printer has two connections, one is the data connection and the other is power for

the printer.

MI814-FM Programming and Operating Manual, 03/2000 3 of 17

PUMP CUT-OFF INSTRUCTIONS

While the 814-FM is capable of switching an auto fill valve, it can also switch an electric transfer

pump. The 814-FM is limited to switching 1.8 amps directly. If the pump requires a higher current to

activate, a relay must be used to isolate/protect the 814-FM. When using a relay for switching higher

currents, it is important that the power supply for the relay and load come through a correctly sized

fuse and directly from the pump power source, not the 814-FM. Keep in mind that the 814-FM is

negatively switched and the relay will need to be wired accordingly.

MI814-FM Programming and Operating Manual, 03/2000 4 of 17

Powering Console On/Off

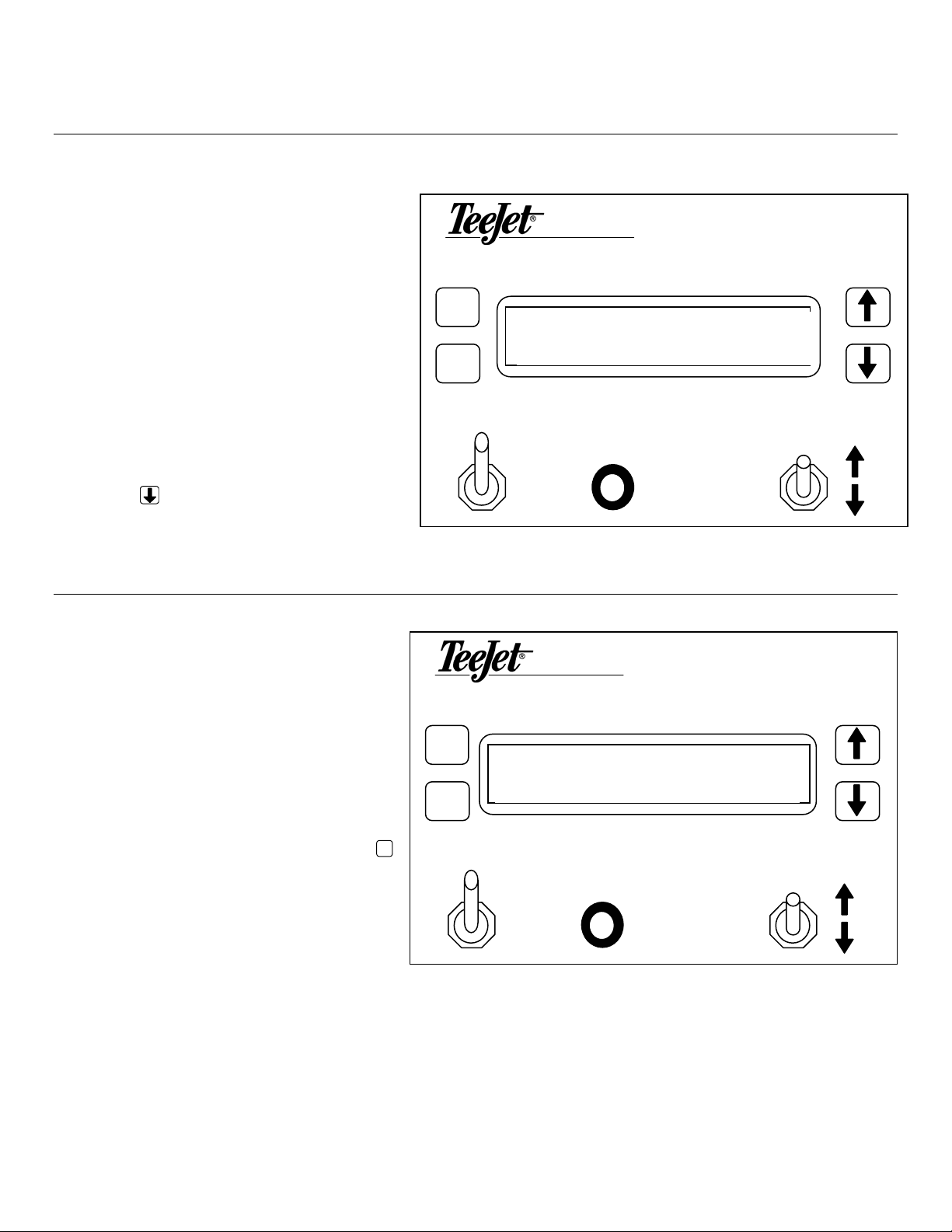

POWER ON

After all the necessary electrical

connections have been made

the console is ready to be

powered on. To power the 814-

FM on press the P

RO key once.

Initially the console will display

the software version of the

console in the display for

approximately 2 seconds. This

information will be needed

when calling for support. After

2 seconds the display will show

the normal operating view.

814-FM

MONITOR

P814-FM V 2.00A

RO

CLR

JOB

PRINT

ON

OFF

AU

T

O

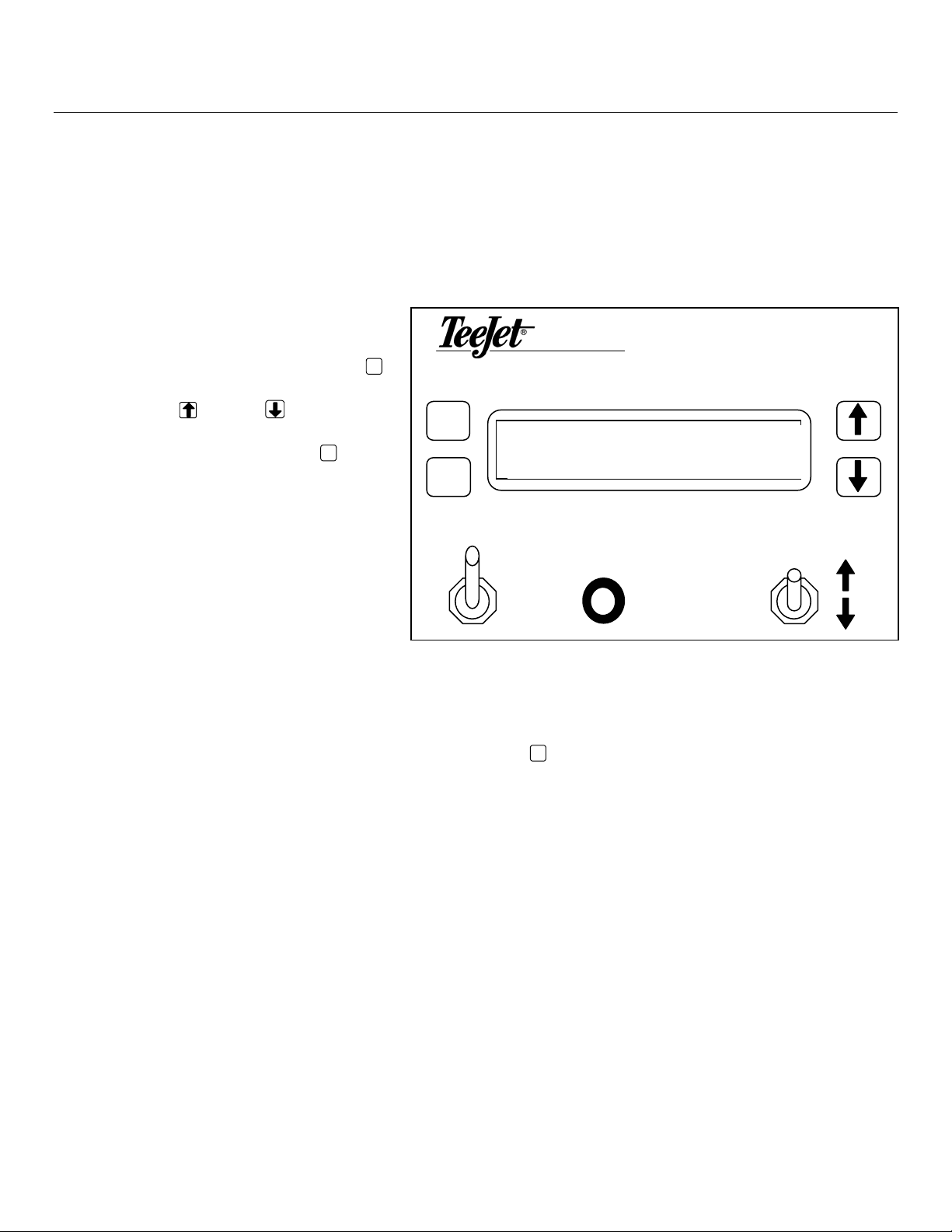

POWER OFF

814-FM

To manually power the console

off, press the and CLR keys

simultaneously. The console

will then save any new

information (volume counters)

to memory and will power off.

MONITOR

P

RO

CLR

Note: The console also has

an Auto Power Down feature.

The console will power itself

off after 10 minutes if not

receiving any inputs.

JOB

PRINT

ON

OFF

AU

T

O

MI814-FM Programming and Operating Manual, 03/2000 5 of 17

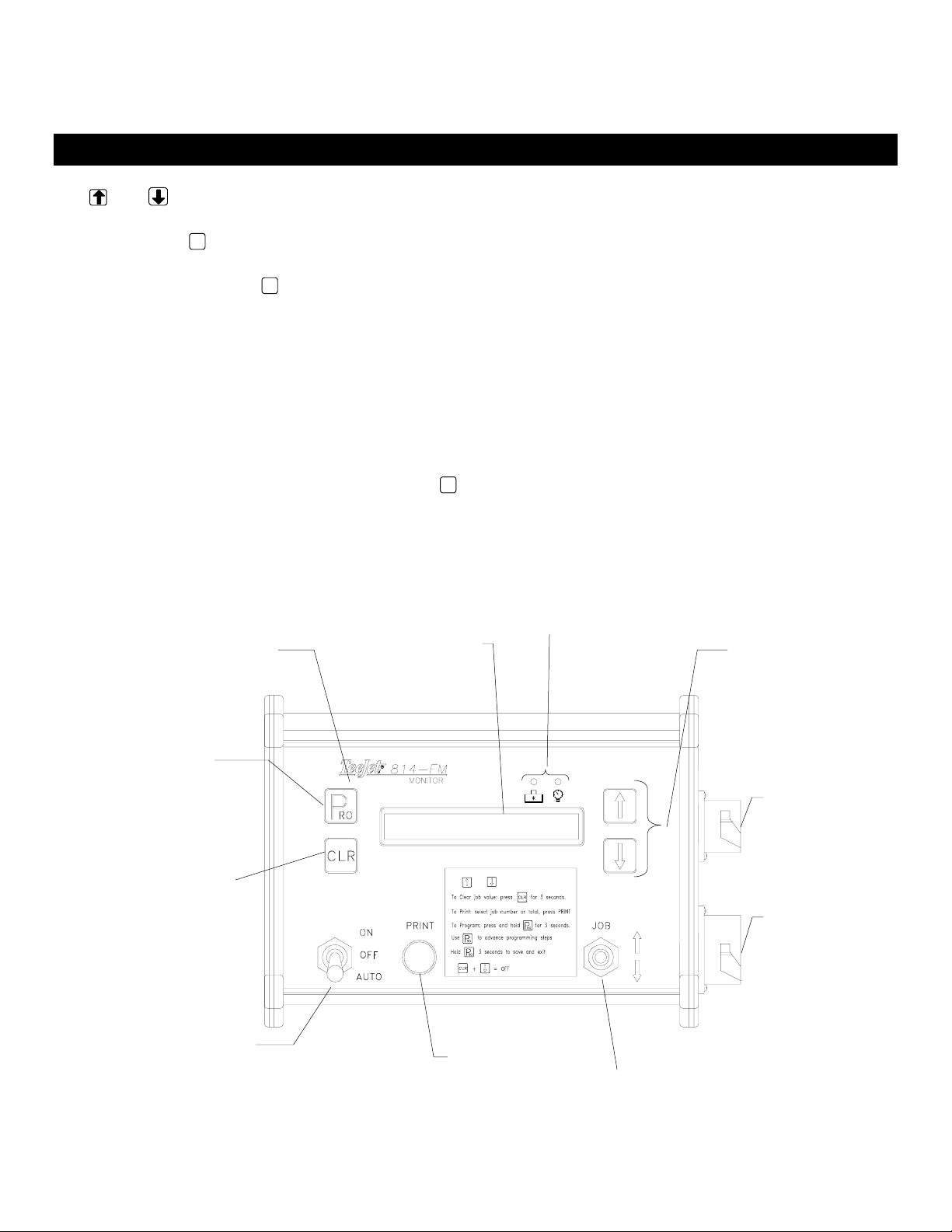

Overview of Monitor Displays

•and keys are used for scrolling through the list of display information or for changing values

when a value is flashing.

•Holding the

CLR key for 3 seconds is used to clear a job volume memory (only one job or all job

memories when the total counter is displayed).

•A short press on the P

RO key allows you to enter amount to be filled if the Fill Valve option has been

activated. You can only enter this step when the job number is visible.

•The fill valve is always switched ON when the switch is in the ON position.

•The fill valve will be automatically controlled when the switch is in the AUTO position.

•The Job selection switch is used to scroll through the possible job settings. You can only change

jobs when the job number is visible.

•The print button is used to print the volume of the selected job or to print the list of all non zero

jobs and the total value.

•GAL (L) or GPM (LPM) is flashing on the screen when automatic filling is busy. Automatic filling

can be stopped by pressing shortly on the CLR key.

Very Important: Whenever you are working around a sprayer or chemicals, be sure to wear

protective clothing and eyewear.

MI814-FM Programming and Operating Manual, 03/2000 6 of 17

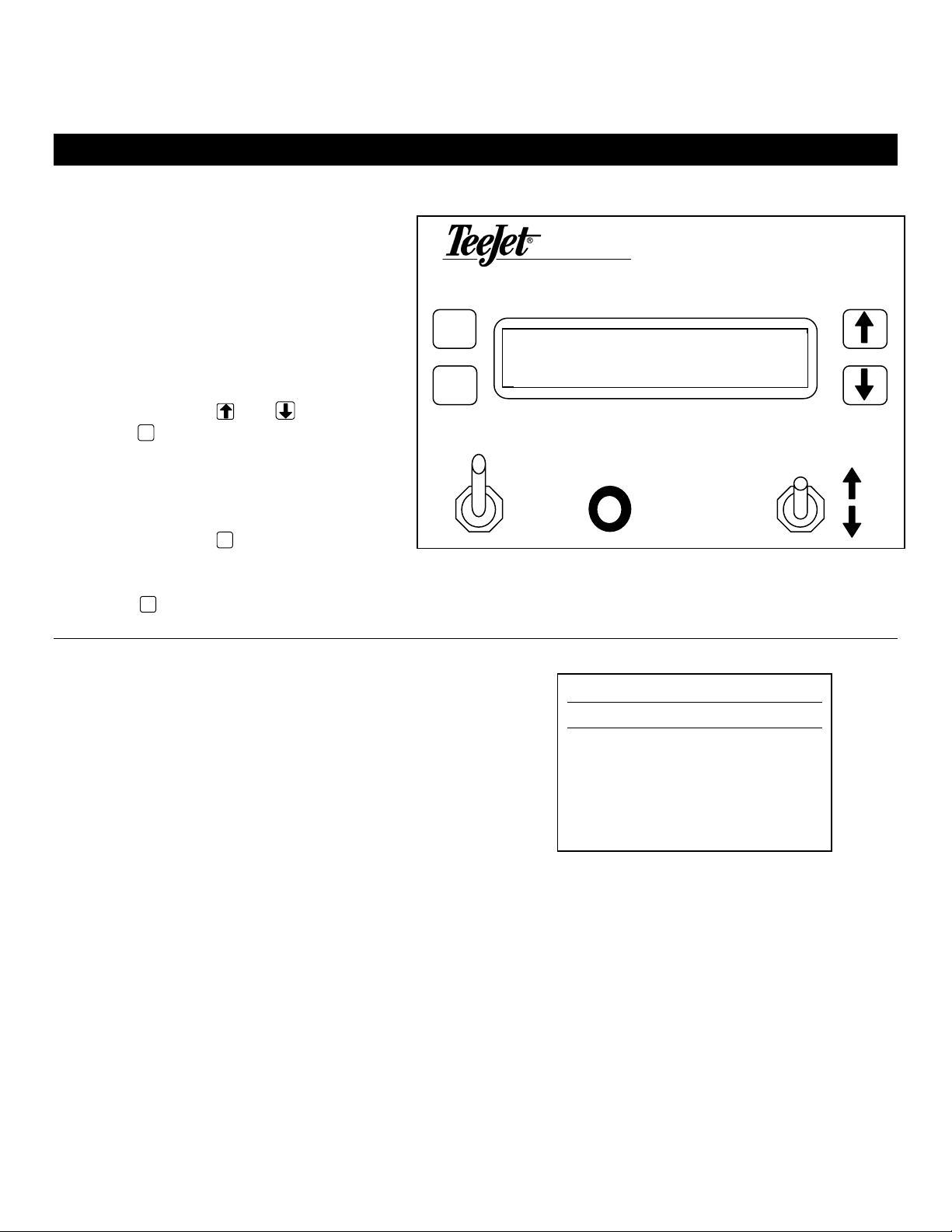

Display

Backlit LCD display for

24 hour operations.

Sensor Monitors

LED’s light when

sensor is sending

signals to console

ON/OFF/AUTO Switch

Used to activate the fill valve/pump.

Auto selection controls shut-of

automatically

Main Connection

Connection for main

cable with leads to

power, sensors and

vales if used.

Data Connection

Used for connection

of optional printer.

Power

Press 1 time to power the

console on.

Easily Accessible Program Mode

Press for 3 seconds to enter/exit program

mode.

Print Button

Used with optional printer

to print individual job

reports or a total report of

all jobs.

Display Selection

Use these keys to chose which

display to view. Chose Job

Volume, Job Flow Rate,

Pressure/Flow Rate or Total

Volume

Clear Function

Used to clear individual job

memories or the total volume

memory. Press and hold to

clear

Job Selection Switch

Use to change the display

from one job to the next.

Displays

JOB VOLUME

814-FMIn this display the console will show the

total accumulated volume for the job

number selected.

MONITOR

P

To change to a new job selection use

the job selection switch. Pushing up on

the job switch will increase the job

number, down will decrease the job

number.

JOB 3 150.0 GAL

RO

CLR

JOB

This volume will be counted any time

that the master boom switch is in the

ON or AUTO position and flow is going

through the flow meter.

PRINT

ON

OFF

AU

T

O

Maximum amount 6500 Gallons

(6500 Liters)

To clear this value, press and hold the CLR key for 3 seconds.

Press the key to advance to the next display.

JOB FLOW RATE

814-FM

In this display the console will show the

current flow rate in GPM (LPM) that is

going through the flow meter.

MONITOR

P

The flow rate will be displayed any time

flow is going through the flow meter

regardless of the position of the master

boom switch. In this example, the total

volume is still being accumulated in Job

JOB 3 75.0 GPM

RO

CLR

JOB

Press the key to advance to the next

display. PRINT

ON

OFF

AU

T

O

MI814-FM Programming and Operating Manual, 03/2000 7 of 17

PRESSURE /FLOW RATE

This display shows the current pressure

and flow rate in GPM (LPM). 814-FM

MONITOR

The flow rate and pressure will be

displayed any time flow is going through

the flow meter and pressure is acting on

the pressure transducer, regardless of the

position of the master boom switch.

P45 PSI 75.0 GPM

RO

CLR

Note: This display is only available

when a pressure transducer has been

installed, connected and properly

programmed into the console. JOB

PRINT

ON

OFF

Press the key to advance to the next

display.

AU

T

O

TOTAL VOLUME

814-FM

This display shows the total

accumulated volume for all jobs.

MONITOR

P

This volume will be counted any time

that the master boom switch is in the ON

or AUTO position and flow is going

through the flow meter.

TOTAL:2500.0 GAL

RO

CLR

To clear this value, press and hold the CLR

key for 3 seconds. JOB

PRINT

ON

Note: Clearing this value also clears

all individual job totals. Insure all

individual job information has been

OFF

AU

T

O

printed and/or recorded before clearing

the Total Volume.

MI814-FM Programming and Operating Manual, 03/2000 8 of 17

AUTOMATIC FILLING

Automatic filling is used to deliver a predefined volume of liquid by opening a filling valve (switching

on a pump) until the desired volume has been measured. The electric fill valve is driven by the

console.

To use the automatic filling feature the console must first be programmed for this function. Refer to

the “Fill Valve” step in the programming section of this manual. This step should be set to “YES”.

To begin auto filling, first select the job

number you would like to use with the

Job Selection switch. Next press the P

RO

key once to access the amount to be

filled. Use the and/or keys to

adjust the volume to be filled. After the

volume has been set, press the P

RO again.

This will advance back to the job

selection display. The GAL (L) or GPM

(LPM) text will be flashing to indicate that

the console is waiting for further action.

Next move the master switch to the

AUTO position. This will activate the fill

valve (transfer pump) to begin the filling

process.

814-FM

MONITOR

PFILL: 0.0 GAL

RO

CLR

JOB

PRINT

ON

OFF

AU

T

O

During the filling process you can temporarily close the filling valve by turning the master switch back

to the OFF position. The filling is continued after switching back to the AUTO position. When the

desired volume is reached the console will automatically close the filling valve (disengage the pump).

If you want to stop the automatic filling you can press the CLR key and the GAL (L) or GPM (LPM) text

will stop flashing and the fill valve will be closed.

The filling valve can be driven manually by switching the master switch to the ON or OFF positions.

MI814-FM Programming and Operating Manual, 03/2000 9 of 17

Programming Guidelines

Make sure that all hardware components are properly installed and tested. Before you start the

programming process you should first be sure that the console and all sensors are working properly.

IMPORTANT PRELIMINARY INFORMATION

Before you begin, it is recommended that you review the following Programming Guidelines that

control the programming process:

☛To enter the program mode press and hold the P

RO key for 3 seconds. The master switch must be

in the off position.

☛To exit the program mode press and hold the P

RO key for 3 seconds, your inputs will be stored and

the computer will exit the program mode. This action can be done at any time but will not be

necessary until the last programming step has been completed.

☛To increase the value of a programmable digit, press the key. To decrease the value, press the

key. These keys are located directly to the right of the display. For some programming steps,

pressing and holding the or key will change the programmable value rapidly. Pressing the

or key once will change the value by one increment.

☛Pressing the and keys simultaneously in some programming steps will will start an

automatic calibration.

☛A short press of the CLR key in program mode will reset the value to its default value.

☛Holding the CLR key for 2 seconds will clear the value to zero.

☛Pressing the P

RO key will advance you to the next programming step. After the last programming

step, the console will return to the first programming step.

☛Note: Due to differences in fonts, some letters on the displays shown in this manual are

not identical with the corresponding letters on the display of the controller. We tried to

match them as close as possible.

MI814-FM Programming and Operating Manual, 03/2000 10 of 17

Programming the 814-FM Sprayer Control System

To enter the Program Mode, press and hold the P

RO key for 3 seconds. The first programming step

should appear on the display.

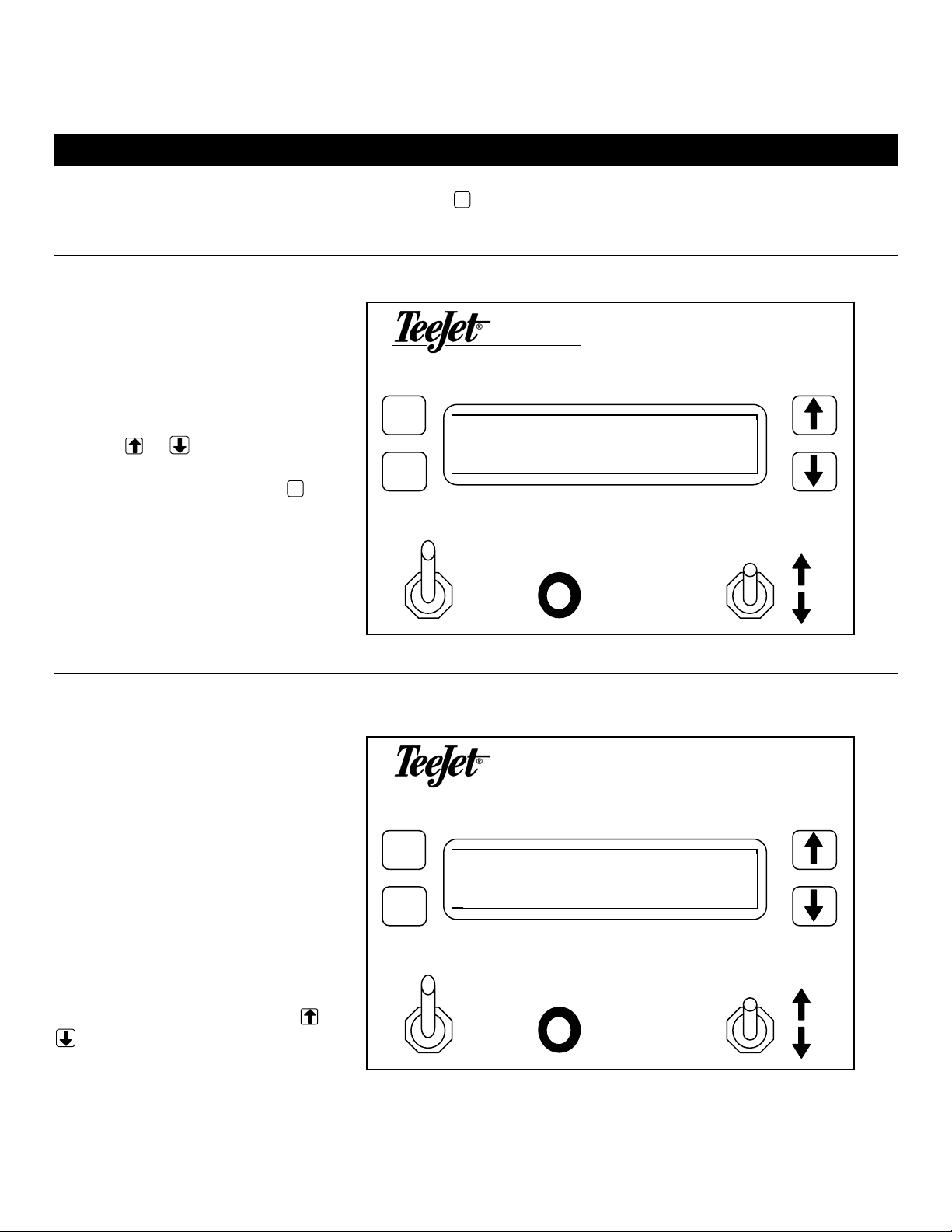

UNITS

814-FM

In this step you indicate if you will

be using US units (GPM, GAL, PSI)

or SI Standard International units

(l/min, L, bar).

MONITOR

P

>Units: US

RO

Use the or keys to adjust the

value. Once you have selected the

appropriate units, press the P

RO key

to advance to the next

programming step.

CLR

JOB

PRINT

ON

OFF

AU

T

O

FLOW METER PULSES

In this step the flow meter

calibration number can be entered

manually from the factory flow

meter tag or an auto calibration

procedure can be activated to

determine the flow meter pulses

based on a known volume of fluid.

814-FM

MONITOR

P> 650 puls/l

RO

Manual Entry CLR

First locate the factory flow meter

tag on the flow meter. If this varies

from the default value (it usually

does) of the console, use the or

keys to modify the value.

JOB

PRINT

ON

OFF

AU

T

O

MI814-FM Programming and Operating Manual, 03/2000 11 of 17

Automatic Calibration

To complete an automatic calibration

of the flow meter, press the and

keys simultaneously. This will clear

the existing value and initiate the

calibration procedure.

814-FM

MONITOR

P

Start auto cal

RO

“Start auto cal” will be displayed in

the screen. This indicates that the

controller is ready to begin the

calibration process.

CLR

JOB

PRINT

ON

OFF

AU

T

O

814-FM

Engage the sprayer pump. Now turn

the Master switch to “ON” and begin

spraying or pumping a known volume

of fluid (e.g. 100 gallons or 100

liters). As you spray the known

amount, the console will count the

pulses.

MONITOR

PAuto cal. 132657

RO

CLR

After the known volume has been

pumped out, turn the Master switch

off to stop counting pulses.

JOB

PRINT

ON

OFF

AU

T

O

MI814-FM Programming and Operating Manual, 03/2000 12 of 17

Now press the P

RO key. The console

will now ask what volume was

pumped (max 9999). 814-FM

MONITOR

Use the or keys to adjust the

value to match the volume

transferred/pumped (in gallons or

liters).

PVolume: 100 GAL

RO

CLR

Now press the P

RO key to return to

the programming mode. Your new

flow meter calibration number will

be displayed. To accept this value

press the P

RO to advance to the next

step. If you wish to repeat the

calibration procedure refer to the

steps above.

JOB

PRINT

ON

OFF

AU

T

O

Note: To achieve an accurate flow meter calibration, a volume of at least 50 gallons should be

pumped during calibration. The more volume used for calibration the more accurate the flow

meter will be.

PRESSURE TRANSDUCER LOW PRESSURE CALIBRATION

This step is used to determine

the “0” pressure setting of the

pressure transducer installed in

your system (if used). The

pressure transducer used with

the 814-FM is a current type

transducer and uses a 4-20 mA

reading. 4.0 mA represents 0

pressure.

814-FM

MONITOR

P>4.0 mA 0 Psi

RO

CLR

If a different pressure transducer

will be used with the system

check the specifications of that

transducer in the manufacturers

literature.

JOB

PRINT

ON

OFF

AU

T

O

Press the P

RO key to advance to the

next step.

If a pressure transducer is NOT being used, press the P

RO key to skip this step and advance to the next

programming step.

MI814-FM Programming and Operating Manual, 03/2000 13 of 17

PRESSURE TRANSDUCER MAXIMUM RATING (P HI)

This step is used to set the

maximum rating of the pressure

transducer in your system. This

number can be found stamped on

the pressure transducer itself.

814-FM

MONITOR

P

If your transducer has a maximum

rating of 145 psi (10 bar) and that

number is shown in the display,

then advance to the next step by

pressing the P

RO key. If however,

the maximum rating is 363 psi (25

bar), use the or keys to

change the value. Press the P

RO

key to advance to the next step.

>145 Psi 20 mA

RO

CLR

JOB

PRINT

ON

OFF

AU

T

O

If a pressure transducer is NOT

being used, set this value to zero

(there will be no pressure monitor

screen) and press the P

RO key to skip

this step and advance to the next

programming step.

FILL VALVE

The 814-FM is capable of

automatically shutting off an electric

valve or a pump motor. An optional

valve is available with the kit.

814-FM

MONITOR

P

In this step you must let the console

know if an auto fill valve or automatic

shut off will be used.

>Fill Valve: YES

RO

CLR

If a fill valve or auto shut off will be

used, use the or keys to select

YES for this step. If no fill valve or

auto shut off will be used select NO.

JOB

PRINT

ON

OFF

Press the P

RO key to accept the value

and advance to the next

AU

T

O

programming step.

MI814-FM Programming and Operating Manual, 03/2000 14 of 17

DATE/TIME

The 814-FM has a date/time function

so that the printed reports can reflect

MONITOR

JOB

RO

CLR

PRINT

814-FM

when the filling/application occurred.

The month will be flashing first. Use

the or keys to adjus the mon

if necessary. Press the P

RO

t th

key to

vance to the date. Use thead or

keys to adjust the date. Press the

P

RO

key to advance to the year. On

the las

MONTH / DATE / YEAR TIME

P05/11/00 10:45

ON

OFF

AU

T

O

Continue the above procedure to

program the time if necessary. Most

ly

t 2 digits of the year will be

sed.

e a real time clock and will not need to have the

ate/time adjusted.

u

814-FM models hav

d

After you have completed the adjustments to the date and time, press the P

RO key to advance to the

beginning of the programming steps. The 814-FM has now been program ed. To save all the steps

and exit the program mode, press and hold the

m

P

RO key for 3 seconds.

MI814-FM Programming and Operating Manual, 03/2000 15 of 17

Printing

The 814-FM is capable of printing two reports, an individual Job Report and a Total Report.

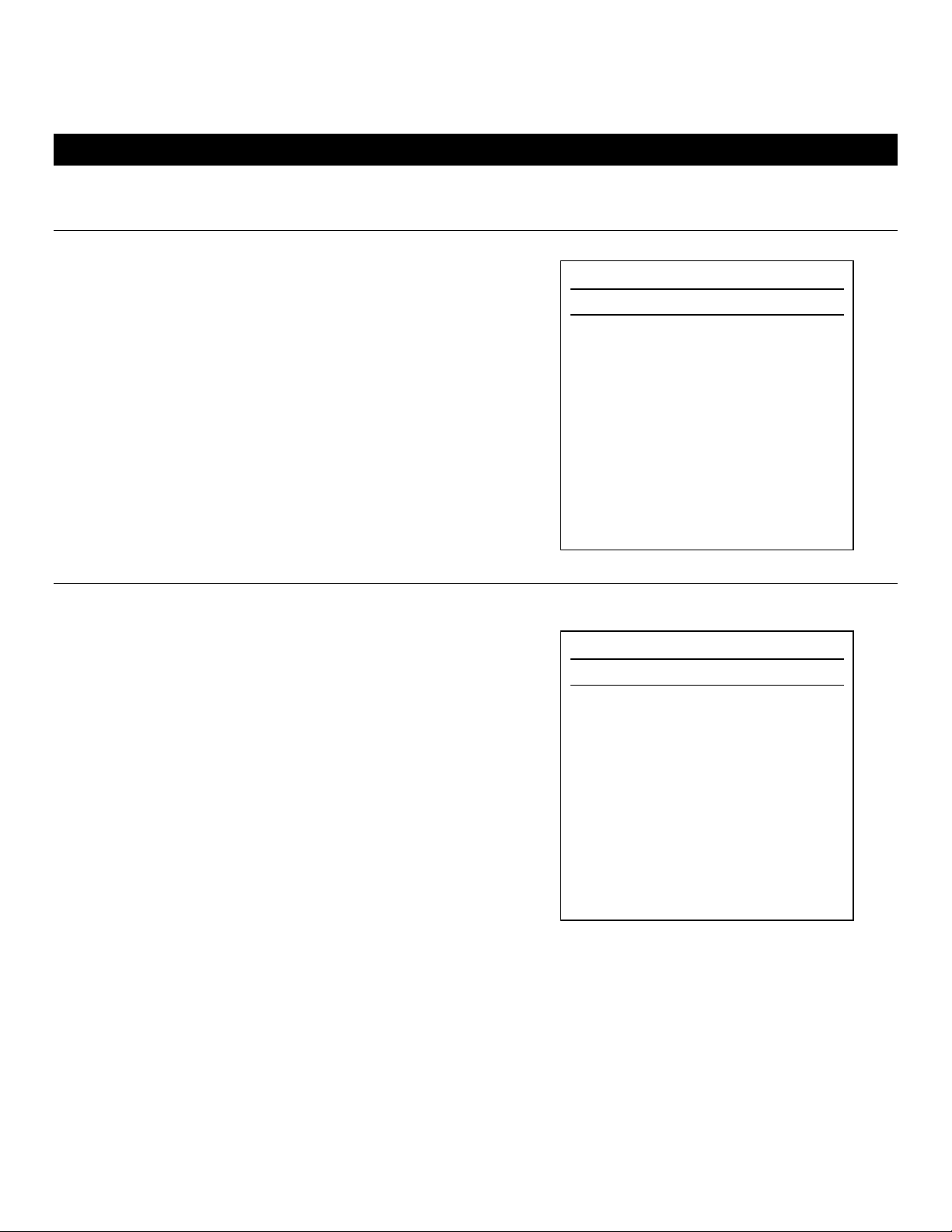

JOB REPORT

Job Report

JOB 2: 50.3 GAL

DATE: 06/07/00 10:14

JOB NAME________________

MATERIAL 1______________

MATERIAL 2______________

MATERIAL 3______________

REM:_____________________

_________________________

_________________________

_________________________

To print an individual job report as shown on the right,

simply press the PRINT key while viewing the appropriate

job number in the Job Volume display. This report will

show the volume that has accumulated for the job

selected.

TOTAL REPORT

Total Report

JOB 1: 50.7 GAL

JOB 2: 50.3 GAL

JOB 3: 25.4 GAL

JOB 4:100.7 GAL

JOB 5: 10.4 GAL

TOTAL: 237.5 GAL

DATE: 06/07/00 10:14

REM:_____________________

_________________________

To print a total report as shown on the right, simply press

the PRINT key while viewing the Total Volume display.

This report will show the volume accumulated for each of

the individual jobs as well as a total volume.

MI814-FM Programming and Operating Manual, 03/2000 16 of 17

Hidden Total Volume Counter

The 814-FM has an additional volume

counter. This counter will continue to

accumulate volume even if the Total

Volume counter has been cleared or

reset to 0. To access the Hidden Total

Volume Counter the console must first be

powered OFF (see Power On/Off section

of this manual).

814-FM

MONITOR

PVtot: 45653.7 GAL

RO

CLR

Press and hold the and keys, then

press the P

RO key to power the console on.

After the initial software version display

the Hidden Total Volume display will

appear.

JOB

PRINT

ON

OFF

AU

T

O

Press and hold the CLR key to reset the

value to 0.

Press the P

RO key to return to the normal mode.

OEM REPORT

OEM REPORT

Vtot: 45653.7 GAL

DATE: 06/07/00 10:14

REM:___________________

________________________

To print an OEM report as shown on the right, simply

press the PRINT key while viewing the Hidden Total

Volume display. This report will show the total volume

accumulated since the last clearing of this value.

MI814-FM Programming and Operating Manual, 03/2000 17 of 17

Table of contents

Other TeeJet Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions