TeeJet 844-RA User manual

MI844-RA Programming and Operating Manual, 01/2000 1 of 28

Sprayer Control

Programming and Operating Manual

(1.03)

98-70011-R0

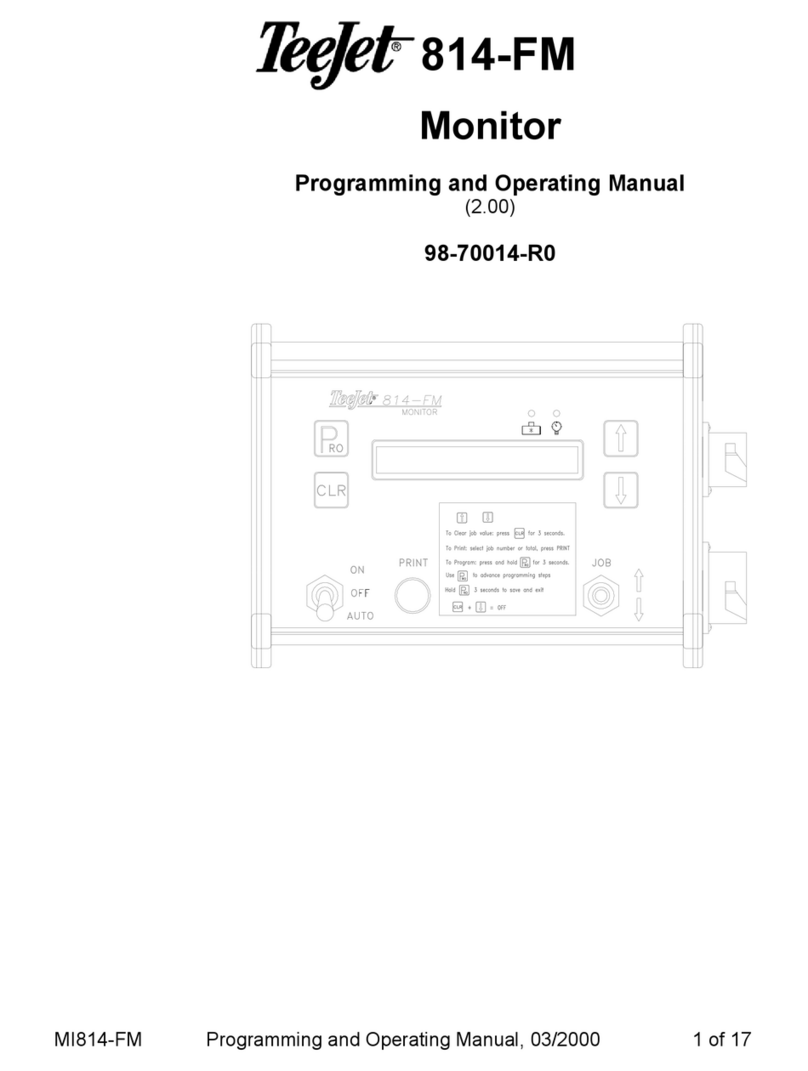

844-RA

844-R

A

Auto Man

Sprayer Control

1 2 3 4 5

P

RO

ROAD APPLICATION CONTROLLER

MI844-RA Programming and Operating Manual, 01/2000 2 of 28

Table Of Contents

TABLE OF CONTENTS ............................................................................................................................. 2

PROGRAMMING GUIDELINES.............................................................................................................. 4

IMPORTANT PRELIMINARY INFORMATION .................................................................................................. 4

POWERING CONSOLE ON/OFF ............................................................................................................. 5

POWER ON.................................................................................................................................................. 5

POWER OFF ................................................................................................................................................ 5

PROGRAMMING THE 844-RA SPRAYER CONTROL SYSTEM ...................................................... 6

SELECTION OF WORKING UNITS ................................................................................................................ 6

Reset To Defaults .................................................................................................................................. 6

SPEED SENSOR CALIBRATION..................................................................................................................... 7

Proximity/Magnetic Pulses ................................................................................................................... 7

Radar Speed Pulses............................................................................................................................... 8

DISTANCE COUNTER .................................................................................................................................. 9

FLOW METER SENSOR INSTALLED?............................................................................................................ 9

FLOW METER PULSES............................................................................................................................... 10

Manual Entry ...................................................................................................................................... 10

Automatic Calibration ........................................................................................................................ 10

PRESSURE SENSOR INSTALLED? ............................................................................................................... 11

PRESSURE TRANSDUCER LOW PRESSURE CALIBRATION (P REF) .............................................................. 12

PRESSURE TRANSDUCER MAXIMUM RATING (P HI) ................................................................................. 13

SENSOR SELECTION .................................................................................................................................. 13

SECTION WIDTH ....................................................................................................................................... 14

REFERENCE PRESSURE ............................................................................................................................. 14

REFERENCE SECTION FLOW ..................................................................................................................... 15

PRESSURE REGULATING MODE ................................................................................................................ 16

REGULATING VALVE CAPACITY............................................................................................................... 17

REGULATING VALVE SPEED FACTOR ....................................................................................................... 17

Coarse Adjustment.............................................................................................................................. 17

Fine Adjustment .................................................................................................................................. 18

COMMUNICATIONS ................................................................................................................................... 18

SIMULATED GROUND SPEED .................................................................................................................... 19

Low Speed........................................................................................................................................... 19

High Speed.......................................................................................................................................... 19

MEMORY LOAD FUNCTION....................................................................................................................... 20

TARGET APPLICATION RATE ............................................................................................................ 21

OPERATING INSTRUCTIONS............................................................................................................... 22

SPRAYER CHECKOUT................................................................................................................................ 22

THE SPRAYING OPERATION ...................................................................................................................... 24

FEATURES................................................................................................................................................. 25

AREA/VOLUME DISPLAY .......................................................................................................................... 25

APPLICATION ALARM............................................................................................................................... 26

NO FLOW ALARM..................................................................................................................................... 26

BOOST MODE ........................................................................................................................................... 27

Boost Up ............................................................................................................................................. 27

Boost Down......................................................................................................................................... 27

AUTO POWER DOWN ................................................................................................................................ 28

MI844-RA Programming and Operating Manual, 01/2000 3 of 28

PRINTING.................................................................................................................................................. 28

MI844-RA Programming and Operating Manual, 01/2000 4 of 28

Programming Guidelines

Make sure that all hardware components are properly installed and tested.

Before you start the programming process you should first check if the console

and all sensors are working properly. Refer to the plumbing and installation

manual supplied with this console.

IMPORTANT PRELIMINARY INFORMATION

Before you begin, we recommend that you review the following Programming

Guidelines that control the programming process:

☛To enter the program mode press and hold the P

RO key for 3 seconds. The

master switch must be in the off position.

☛To exit the program mode press and hold the P

RO key for 3 seconds, your

inputs will be stored and the computer will exit the program mode. This action

will not be necessary until the last programming step has been completed.

☛To increase the value of a programmable digit, press the +key. To decrease

the value, press the key. These keys are located directly to the right of the

display. For some programming steps, pressing and holding the +or key

will change the programmable value rapidly. Pressing the +or key once

will change the value by one increment.

☛Pressing the +and keys simultaneously in some programming steps will

set the value to “0” or will start an automatic calibration.

☛Pressing the key in some steps will reset the value to the factory default

value.

☛Pressing the P

RO key will advance you to the next programming step. After the

last programming step, the console will return to the first programming step.

☛Note: Due to differences in fonts, some letters on the displays shown in

this manual are not identical with the corresponding letters on the

display of the controller. We tried to match them as close as possible.

MI844-RA Programming and Operating Manual, 01/2000 5 of 28

G5 1

0 0 2 5

1.0 3

s f t

ROAD

A

PPLICATION CONTROLLER

ROAD APPLICATION CONTROLLER

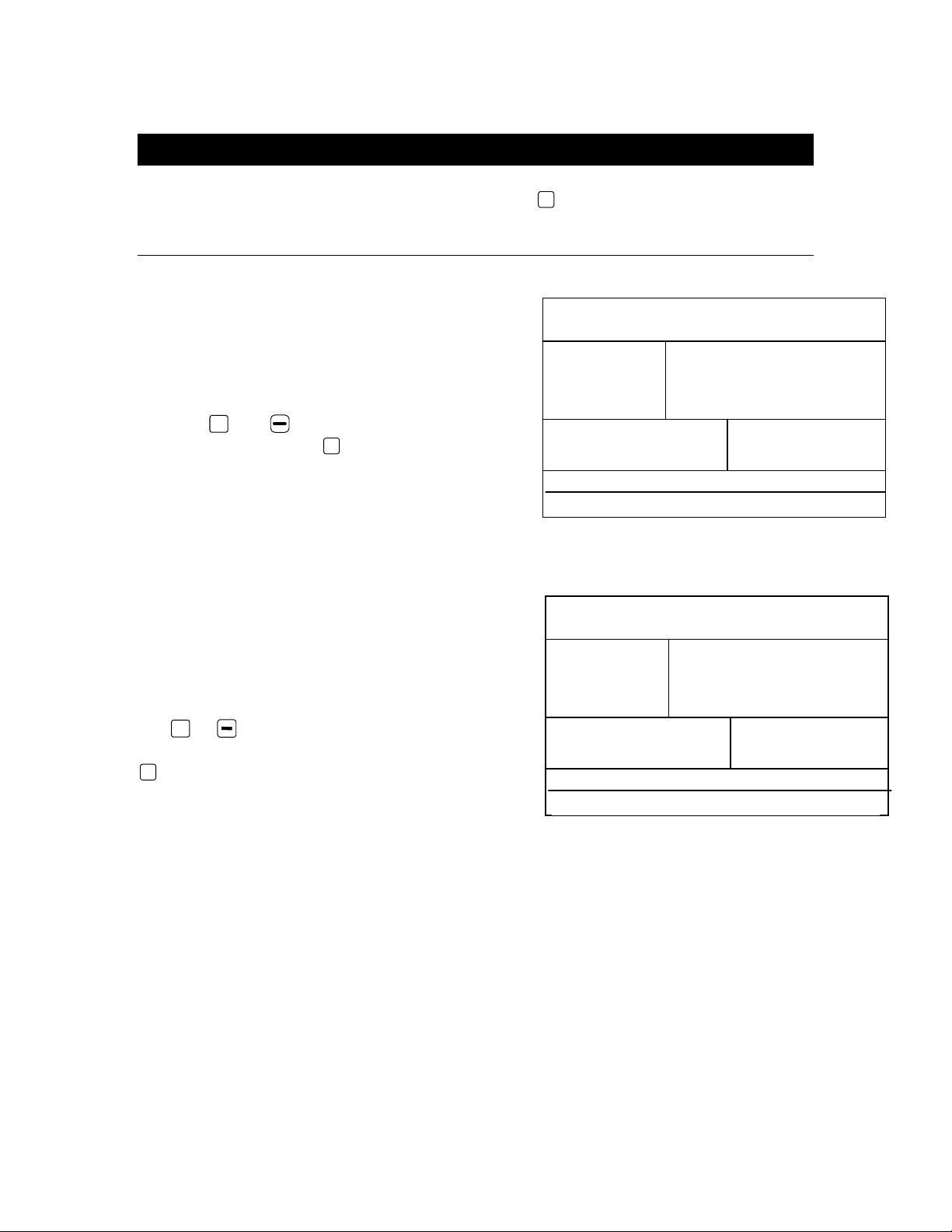

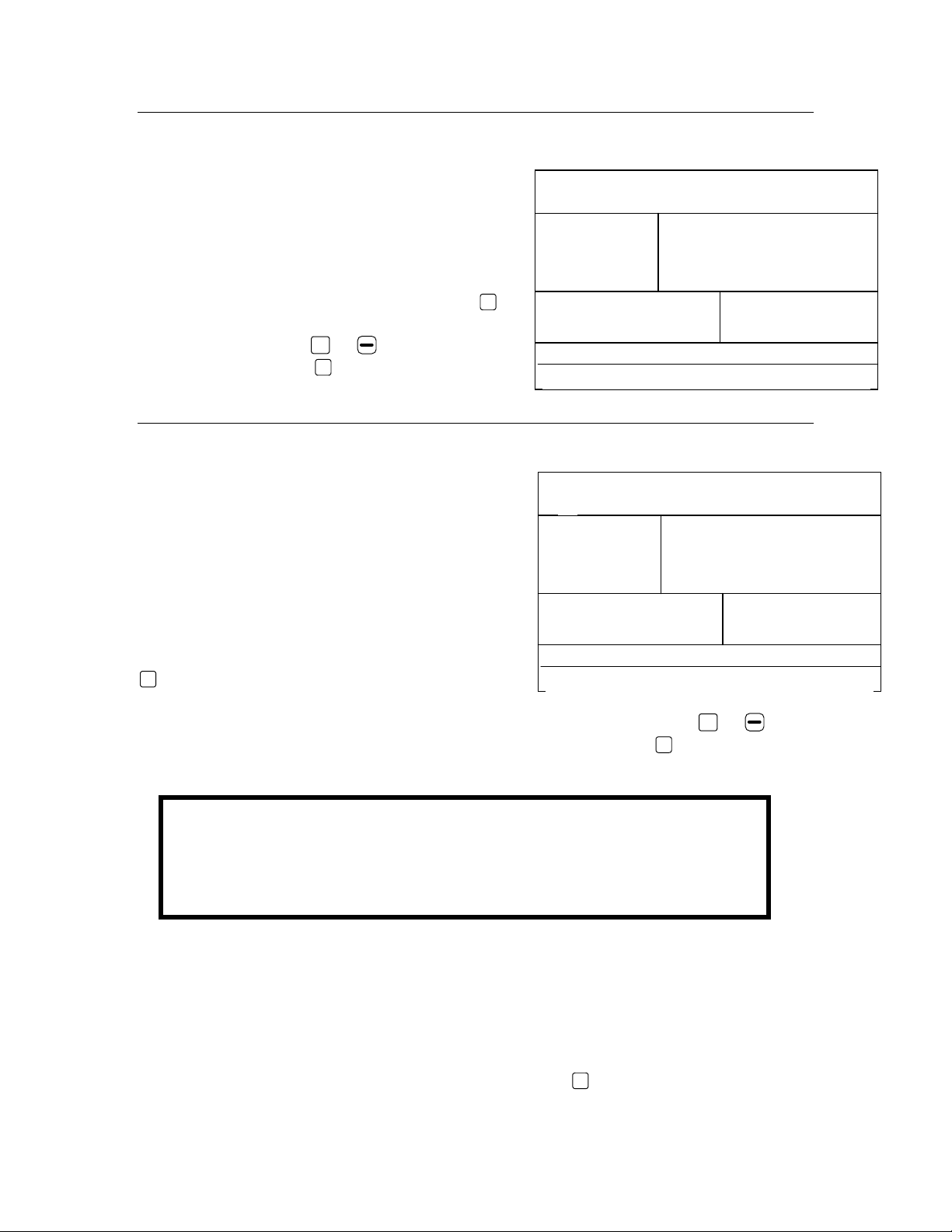

Powering Console On/Off

POWER ON

After all the necessary electrical connections

have been made (refer to the Plumbing and

Installation manual included with this kit) the

console is ready to be powered on. To power

the 844-RA on press the P

RO key once. Initially

the console will display the software version

of the console in the top display and the serial

number of the console in the bottom of the

display for approximately 5 seconds. This

information will be needed when calling for

support. After 5 seconds the display will show

the normal operating view.

POWER OFF

To manually power the console off, press

the and P

RO keys simultaneously. The

console will then save any new information

(area and volume counters) to memory and

will power off.

Note: The console also has an Auto Power Down feature. Refer to this in

the features section of this manual.

MI844-RA Programming and Operating Manual, 01/2000 6 of 28

u n i t

g l n

P

RO

ROAD APPLICATION CONTROLLER

g p a

d f l t

y e s

r e s

P

RO

ROAD APPLICATION CONTROLLER

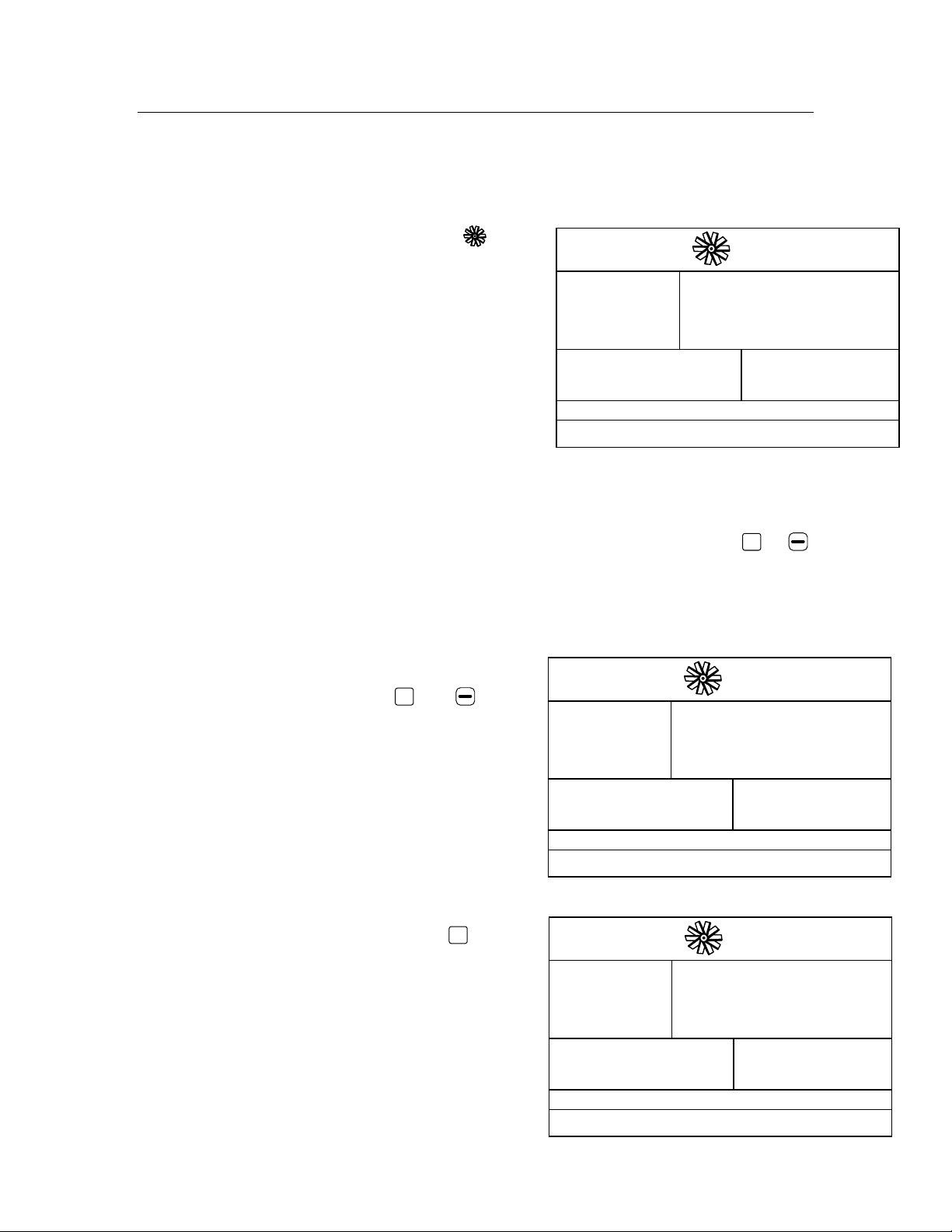

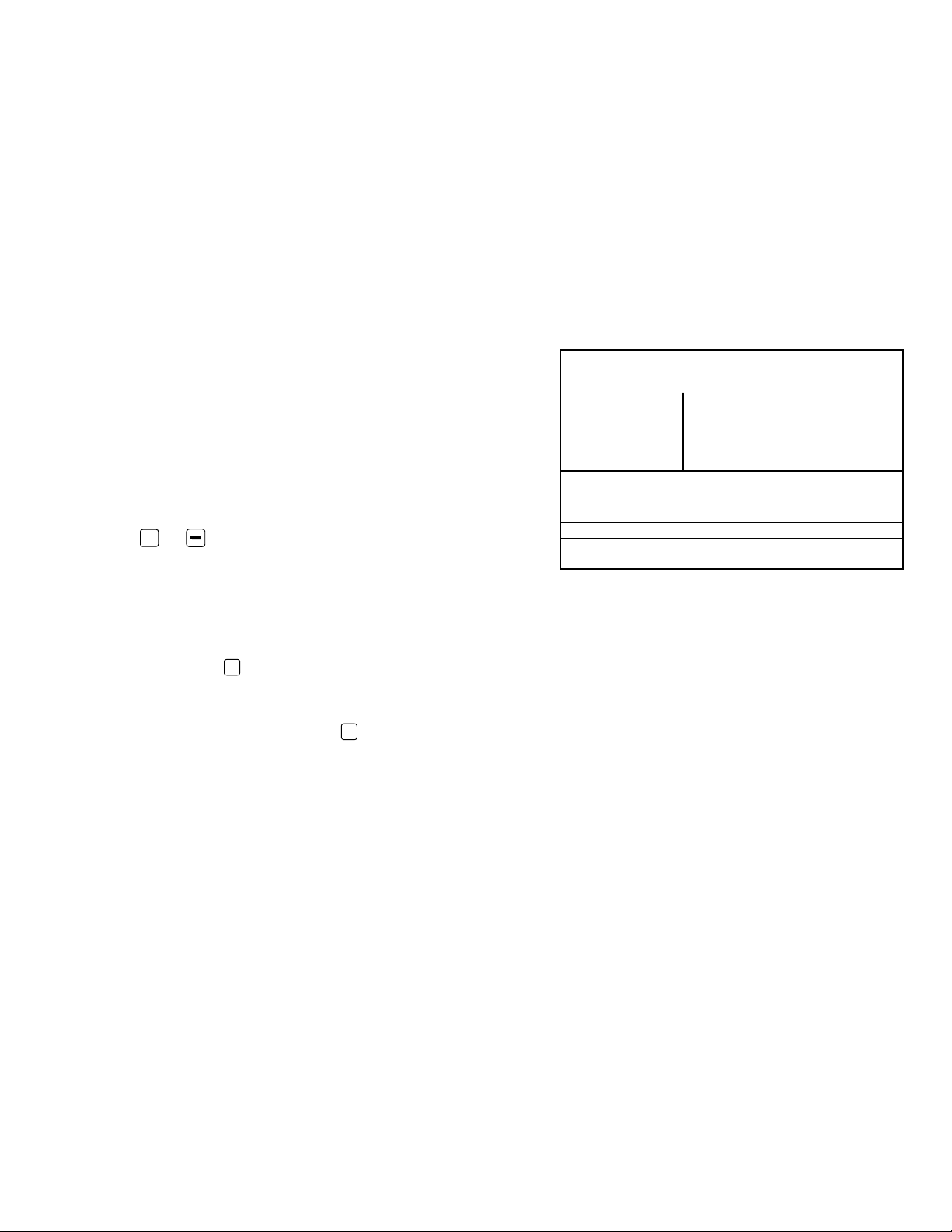

Programming the 844-RA Sprayer Control System

To enter the Program Mode, press and hold the P

RO key for 3 seconds. The first

programming step should appear on the display.

SELECTION OF WORKING UNITS

The 844-RA is capable of working in either

GLM (Gallons Per Lane Mile) or GPA (Gallons

Per Acre) units. In this step you select which

units you will be using.

Use the +and keys to switch from GLM to

GPA units. Press the P

RO key to accept the

value and advance to the next program step.

Reset To Defaults

If you made a change to the units in the first

programming step, before advancing to the

next step the console will ask if you would like

to reset all the program parameters to defaults

specified for the units you have chosen. Use

the +or key to select either yes or no.

After you have made your selection, press the

P

RO key to begin resetting or advance to the next

step.

Note: If you did not make any changes to the units, this step will be

skipped and you will automatically be advanced to Speed Sensor

Calibration Step.

MI844-RA Programming and Operating Manual, 01/2000 7 of 28

2 5 0

c a l

s p d

P

RO

ROAD APPLICATION CONTROLLER

c a l

P

RO

ROAD APPLICATION CONTROLLER

15 7

c a l

s p d

P

RO

ROAD APPLICATION CONTROLLER

SPEED SENSOR CALIBRATION

Note: During Speed Calibration, the 844-RA will automatically sense

whether a Wheel Speed or Radar Speed Sensor is being used.

Proximity/Magnetic Pulses

The speed sensor needs to be calibrated in

order to provide the proper speed and area

readings. The value for this step is the

number of pulses generated by the speed

sensor in 300 ft., or by entering the number

manually.

Automatic Calibration:

To automatically calibrate the speed sensor,

first mark off a distance of exactly 300 ft.

Next press and hold the +and keys

simultaneously for 3 seconds to clear the

contents of the display and to activate the

auto calibration mode. When the auto

calibration mode has been activated, “CA L ”

will be displayed at the lower right of the

display.

Now start driving toward the start point of the

of 300 ft. (100 meter) course. As you cross

the start point press the +key once to begin

the calibration process. Continue across the

course and the 844-RA will count the pulses

as the sprayer moves. The speed at which

you drive over the course is not important. As

you cross the end point, press the +key

once. The number displayed is your speed

calibration number.

Note: The auto speed calibration process should take place with the

sprayer tank ½ full.

Note: It is best to repeat the automatic speed calibration process at least

twice and use and average of the speed calibration numbers.

MI844-RA Programming and Operating Manual, 01/2000 8 of 28

r a d

118

c a l

s p d

P

RO

ROAD APPLICATION CONTROLLER

During the automatic calibration step, the 844-RA automatically senses whether

a proximity/magnetic or radar ground speed sensor is installed

Radar Speed Pulses

Automatic Calibration

The automatic calibration of a Radar speed

sensor is similar to the automatic calibration of a

proximity/magnetic wheel speed sensor. Refer

to the directions above. When the console has

determined that a Radar Speed Sensor is being

used, “RAD” will be displayed in the lower left of

the console display.

When the correct value has been entered, press the P

RO key to validate this value

and advance to the next step.

Note: If the auto calibration mode has been activated, no other functions

are possible until the console receives speed pulses for calibration. To

deactivate the auto calibration mode, press the +key twice.

Note: To manually enter the radar calibration value, first press the P

RO and +

keys simultaneously to put the console into radar mode. When the control

console is in the radar mode, “RA D” will be displayed in the lower left of the

console display. Now use the +or keys to adjust the value. Pressing the

Auto/Man key will reset the speed calibration to the default value.

MI844-RA Programming and Operating Manual, 01/2000 9 of 28

c t r

0

f t

d s t

P

RO

ROAD APPLICATION CONTROLLER

f l o

s e n s

y e s

P

RO

ROAD APPLICATION CONTROLLER

DISTANCE COUNTER

This step is a feature, not a calibration step. No

specific value needs to be entered here for the

controller to operate correctly.

This feature will measure distance in feet. This

can be used to confirm Automatic Speed

Calibration (see note below). To activate the

counter, turn the Master Boom Switch on. To

avoid actually spraying during this task, toggle

the individual boom sections off.

Anytime that the Master Boom Switch is on during this step to console will

measure distance. If the Master switch is toggled off, the console will stop

counting distance.

To clear an existing distance, press and hold the +and keys simultaneously

for 3 seconds.

Note: To confirm Automatic Speed Calibration, first complete the

calibration procedure. Advance to Distance Counter step. Drive across the

same 300 feet course turning the Master Switch ON at the start point and

OFF at the finish point. Distance measured should be 300 feet (+/- 6 feet).

FLOW METER SENSOR INSTALLED?

This step indicates if a flow meter has been

installed on the sprayer. Use the +or

keys to adjust the value. Either select YES if a

flow meter is installed or NO if a flow meter will

not be used.

When the correct value has been entered,

press the P

RO key to validate this value and

advance to the next step.

Note: If you select NO in this step, the next step in the manual will not

appear in the console programming selection.

MI844-RA Programming and Operating Manual, 01/2000 10 of 28

p l s

6 5 0 .0

c a l

f l o

P

RO

ROAD APPLICATION CONTROLLER

c a l

P

RO

ROAD APPLICATION CONTROLLER

2 3

2 7 7 7

c a l

P

RO

ROAD APPLICATION CONTROLLER

FLOW METER PULSES

Note: This step may not appear in the console programming. It only

appears if the Flow Meter Installed step is set to YES.

During the Flow Meter Pulses step, the

symbol (flow meter turbine) will be flashing at

the top of the console display.

In this step the flow meter calibration number

can be entered manually from the factory

calibrated flow meter pulse rate tag or an Auto

calibration procedure can be activated to

determine the flow meter pulses based on a

know volume of fluid.

Manual Entry

First locate the factory calibrated flow meter pulse rate tag on the flow meter. If

this varies from the default value (it usually does) of the console, use the +or

keys to modify the value.

Automatic Calibration

To complete an automatic calibration of the

flow meter, press and hold the +and keys

simultaneously for 3 seconds. This will clear

the existing value and initiate the calibration

procedure.

“CA L ” will be displayed in the screen. This

indicates that the controller is ready to begin

the calibration process.

Engage the sprayer pump. Push the +key to

activate the calibration. Now turn the boom

sections on and begin spraying a known

volume of fluid (e.g. 100 gallons). As you spray

the known amount, the console will count the

pulses.

MI844-RA Programming and Operating Manual, 01/2000 11 of 28

g a l

V

ol

10 0

P

RO

ROAD APPLICATION CONTROLLER

p l s

6 2 5

c a l

f l o

P

RO

ROAD APPLICATION CONTROLLER

PRS

s e n s

n o

P

RO

ROAD APPLICATION CONTROLLER

After the known volume has been sprayed out,

turn the Master switch off to stop counting

pulses.

Now press the P

RO key. The console will now

ask what volume was sprayed.

Use the +and/or keys to adjust the value to

match the volume sprayed (in gallons).

Now press the P

RO key to return to the

programming mode. Your new flow meter

calibration number will be displayed. To accept

this value press the P

RO to advance to the next

step. If you wish to repeat the calibration

procedure refer to the steps above.

Note: To achieve an accurate flow meter

calibration, a volume of at least 50 gallons

should be sprayed during calibration. The

more volume used for calibration the more

accurate the flow meter will be.

PRESSURE SENSOR INSTALLED?

This step indicates if a pressure sensor has

been installed on the sprayer. Use the +or

keys to adjust the value. Either select YES if a

pressure transducer is installed or NO if no

pressure transducer will be used.

When the correct value has been entered,

press the P

RO key to validate this value and

advance to the next step.

Note: If you select NO in this step, the next

2 steps in the manual will not appear in the

console programming selection.

MI844-RA Programming and Operating Manual, 01/2000 12 of 28

r e f

n a

4 .0 8

0

P

RO

ROAD APPLICATION CONTROLLER

r e f

s e n s

4 .0 0

PSI

0

P

RO

ROAD APPLICATION CONTROLLER

10

5 2

4 .0 0

0

P

RO

ROAD APPLICATION CONTROLLER

PRESSURE TRANSDUCER LOW PRESSURE CALIBRATION (P REF)

This step is used to calibrate the “0” pressure

setting of the pressure transducer installed in

your system. The pressure transducer used with

the 844-RA is a current type transducer and uses

a 4-20 mA reading. 4.0 mA represents 0

pressure.

This step uses an auto-calibration feature to

calibrate the transducer. Make sure that the

sprayer pump is turned off and there is

absolutely no pressure in the system (release

pressure held by boom control valves and nozzle

body check valves). In some cases it may be

best to remove the sensor from the plumbing

system to complete the calibration. Press and

hold the +and keys simultaneously for 3

seconds to activate the auto-calibration feature.

The lower left portion of the display will count 1-

10 during the calibration.

When the display finishes counting, a number

close to 4.0 (+/- 0.2) should be displayed. The

low

pressure value of the transducer is now

calibrated.

Press the P

RO key to advance to the next step.

MI844-RA Programming and Operating Manual, 01/2000 13 of 28

p r s

s e n s

p h i

PSI

14 5

P

RO

ROAD APPLICATION CONTROLLER

f l o

r e g

P

RO

ROAD APPLICATION CONTROLLER

PRESSURE TRANSDUCER MAXIMUM RATING (P HI)

This step is used to set the maximum rating

of the pressure transducer in your system.

This number can be found stamped on the

pressure transducer itself. If your transducer

has a maximum rating of 145 psi (10 bar) and

that number is shown in the display, then

advance to the next step by pressing the P

RO

key. If however, the maximum rating is 363

psi (25 bar), use the +or keys to change

the value. Press the P

RO key to advance to the

next step.

SENSOR SELECTION

The 844-RA system can be used with either a

flow meter, pressure transducer or both. This

step tells the computer which sensor you will

be using on your sprayer to control the

regulation.

The default value is set for a “F L O” based

system using a flow meter. If this is what you

have installed on your sprayer, then press the

P

RO key to advance to the next step.

If however you have installed a pressure transducer instead, us the +or key

to select “PRS” for a pressure based system. Then press the P

RO key to advance

to the next step.

If both sensors have been installed on the sprayer, this step will determine which

sensor will be used by the 844-RA to determine regulation. If “F L O” is selected,

the flow meter will be used to control flow and the pressure transducer will be

used only to display the actual pressure. If “PRS” is selected, the pressure

transducer will be used to control the flow and display the actual pressure.

Select the appropriate sensor setting then press the P

RO key to accept the value

and advance to the next programming step.

Warning

The pressure based regulation may only be used when you are

using linear tips. For non-linear tips you should always use flow

based regulation. Most tips are linear and may be used with

Pressure Based re

g

ulation

,

but ConeJet ti

p

s are non-linear.

MI844-RA Programming and Operating Manual, 01/2000 14 of 28

ROAD APPLICATION CONTROLLER

5

i n c h

12 0

s e c

P

RO

ROAD APPLICATION CONTROLLER

PRS

4 0 .0

REF

P

RO

ROAD APPLICATION CONTROLLER

1

i n c h

12 0

s e c

P

RO

SECTION WIDTH

The 844-RA can control up to 5 boom sections

individually. The next 5 programming steps

indicate the width of each individual section.

Use the +or keys to adjust the value so

that it matches the width of boom section 1 in

inches. Then press the P

RO key to advance to

section 2.

Repeat this procedure until all 5 boom

sections have been programmed. Any

individual boom switches not being used for a

boom section must be programmed to a “0”

value.

After programming the boom section width for

section switch 5, press the P

RO key to advance

to the next step.

REFERENCE PRESSURE

In the following programming steps, reference

flow rates must be entered for each boom

section. Those flows must be referenced at a

specific reference pressure. Select a pressure

that you will use to reference the flow rates

and enter that pressure here.

Use the +and keys to adjust the value.

Press the P

RO key to advance to the next step.

MI844-RA Programming and Operating Manual, 01/2000 15 of 28

ROAD APPLICATION CONTROLLER

1

2 .4 0

g p n

s e c

P

RO

ROAD APPLICATION CONTROLLER

5

2 .4 0

g p n

s e c

P

RO

REFERENCE SECTION FLOW

In this step you must enter the reference flow

for boom section 1 in GPM. This is the total

flow rate for the boom section if it were

spraying at the reference pressure indicated in

the previous step.

To find the total flow rate for a boom section,

add all of the individual tip flow rates at the

referenced pressure.

Use the +or key to adjust the value to

match the actual flow rate.

After you have entered the flow rate for section

1 press the P

RO key to advance to section 2 flow

rate. Repeat the procedure above until all 5

boom section reference flow rates have been

entered.

Note: Any individual boom section not

being used must be programmed to a “0”

value.

When you have programmed and validated the

last Reference Section Flow press the P

RO key to

advance to the next programming step.

BOOM SECTION 1 BOOM SECTION 3BOOM SECTION 2

1 2 3 11

24 3

32 4

Boom Section 1

4 Tips – XR8006VS

(1) XR8006VS = 0.60 GPM

@40 PSI

4 X 0.60 = 2.40 GPM @40PSI

Boom Section 2

3 Tips – XR8006VS

(1) XR8006VS = 0.60 GPM

@40 PSI

3 X 0.60 = 1.80 GPM @40PSI

Reference Section Flow Exam

p

le

MI844-RA Programming and Operating Manual, 01/2000 16 of 28

ROAD APPLICATION CONTROLLER

b y p

r e g

P

RO

ROAD APPLICATION CONTROLLER

t h r

r e g

P

RO

PRESSURE REGULATING MODE

This step tells the 844-RA where the regulating

valve has been plumbed. Once set correctly,

this value should not change unless the

regulating valve is physically moved to a new

point in the plumbing. For more information

about plumbing refer to the Plumbing and

Installation manual supplied with this kit.

The default value “BYP” indicates that the

pressure regulating valve is plumbed in a

bypass line. If this is correct press the P

RO key to

accept the value and advance to the next step.

If you have plumbed the pressure regulating

valve in a supply line to the booms, this is

considered a throttling position. If you have

located your regulating valve in this position,

use the +or key to change the value to

“thr” (throttling mode). By doing this, you have

reversed the polarity that the console uses to

control the regulating valve.

Press the P

RO key to advance to the next step.

Note: When programmed in the bypass

mode, with the controller in “MAN” mode,

the pressure regulating valve should close

when the +key is pressed and open

when the key is pressed.

Note: When programmed in the throttling

mode with the controller in “MAN” mode,

the valve should open when the +key is

pressed and close when the is pressed.

MI844-RA Programming and Operating Manual, 01/2000 17 of 28

ROAD APPLICATION CONTROLLER

c a p

3 2

g p n

r e g

P

RO

ROAD APPLICATION CONTROLLER

s p d

r e g

P

RO

1o .2

Common TeeJet Regulating Valves

344AE-2RL .................... 27 GPM

344AE-2RB .................... 30 GPM

344AE-2PR .................... 12 GPM

AA346ZR ....................... 85 GPM

AA346ZRB..................... 85 GPM

REGULATING VALVE CAPACITY

Enter the maximum flow capacity of the

regulating valve you are using in Gallons Per

Minute (GPM). The regulating parameters

needed to drive the regulating valve smoothly

are different depending on the size of the

valve. This step optimizes these parameters of

the 844-RA for the size of valve you are using.

Use the +or keys to adjust the value so

that it matches the maximum flow capacity

(GPM) of the regulating valve you are using.

Note: Reference the valve manufacturer’s

literature to determine the flow capacity of

the regulating valve.

Press the P

RO key to advance to the next step.

REGULATING VALVE SPEED FACTOR

This step allows you to adjust the speed of the pressure regulating valve to

accommodate different application needs. Operating conditions may necessitate

a higher or lower response speed for the regulating valve. This is accomplished

by adjusting both the coarse and fine adjustment values.

Coarse Adjustment

The coarse adjustment controls the speed of

the valve when large adjustments in flow are

required by the controller. To change the

response time number, simply use the +or

keys to increase or decrease the number. Any

number between 0 and 19 may be selected.

0 = Slow : 19 = Fast

If your regulating valve is plumbed in a by-pass

line, the valve speed coarse adjustment number

of 15 works very well in most applications.

MI844-RA Programming and Operating Manual, 01/2000 18 of 28

ROAD APPLICATION CONTROLLER

s p d

r e g

P

RO

1o .2

ROAD APPLICATION CONTROLLER

c o n

n o

P

RO

If your regulating valve is plumbed in the throttling position (supply line), start with

a valve coarse adjustment speed number of 5 and adjust the number according

to your application requirements.

Press the P

RO key to accept the value and advance to the Fine Adjustment setting.

Fine Adjustment

The fine adjustment controls the speed of the

valve when small adjustments in flow are

required by the controller. To change the

response time number, simply use the +or

keys to increase or decrease the number. Any

number between 0 and 9 may be selected.

0 = Slow : 9 = Fast

It is recommended that you start with a fine

adjustment speed of 2. This works well in most

situations. This number may need to be

optimized during the spraying operation.

Note: Adjusting agitation volumes can often assist the regulating valve

operation.

To accept your Regulating Valve Actuating Factor and advance to the next step,

press the P

RO key.

Note: This speed value can be adjusted to optimize system performance.

If you notice that the valve seems to “search” for the programmed

application rate by cycling the pressure up and down continuously, reduce

the number until the “searching” is minimized or eliminated. Conversely, a

higher number will increase the valve response speed and speed up the

rate of adjustment.

COMMUNICATIONS

If your 844-RA has been upgraded to be

communications compatible, this step lets

you select what type of communication you

will be using. The choices available are

the default of “n o c o n ” (no

communications), ”c n t p r t ”

(Contractor printing), “u s r p r t ” (User

printing), “g p s ” (Global Positioning

System communication capability), “l o g ”

MI844-RA Programming and Operating Manual, 01/2000 19 of 28

MPH

2 0 .0

l o

s p d

s i n

P

RO

ROAD APPLICATION CONTROLLER

MPH

3 0 .0

h i g h

s p d

s i n

P

RO

ROAD APPLICATION CONTROLLER

(Downloading to a PC on the go capability), or “p c ” ( PC link – not used).

If, however, your 844-RA has been upgraded with the communications package,

use the +and keys to select the type of communication you will be using.

After selecting the communication you will be using, press the P

RO key to advance

to the next step.

SIMULATED GROUND SPEED

Simulated ground speed allows you to check out the functions and operations of

the console and of the sprayer, spraying water, without actually moving the

sprayer. This can and should be done prior to any spraying activity.

The 844-RA has a low and high simulated ground speed. This allows you to

switch between the two to simulate a speed change to ensure the console is

regulating properly during the Sprayer Checkout.

Low Speed

To set the Low simulated speed use the +

and keys to adjust the value.

When the low value has been set, press the P

RO

key to advance to the High Simulated speed

step.

High Speed

To set the High simulated speed use the +

and keys to adjust the value.

When the high value has been set, press the P

RO

key to advance to the next programming step.

To activate the simulated speed, while in the normal operating mode with the

master switch ON, press the P

RO and keys for low simulated speed; press the P

RO

and +keys for high simulated speed. The simulated speed will remain in the

normal operating mode display until the console receives actual speed pulses.

MI844-RA Programming and Operating Manual, 01/2000 20 of 28

ROAD APPLICATION CONTROLLER

l o a d

n o

n e n

P

RO

Note: Once the sprayer begins moving and the 844-RA receives actual

speed pulses, the simulated speed feature is deactivated. If you are using

a Radar Speed Sensor, disconnect the Radar connection from the main

console. Because of the sensitivity of this speed sensor, any movement

can disable simulated speed.

MEMORY LOAD FUNCTION

The memory load function is used to restore all

programming values to previously set values. A

sprayer manufacturer may pre-program this

console for specific parameters on a sprayer and

save those values internally. If for some reason

you need to get back to those pre-programmed

values this step allows you to do that. Use the

+or keys to select either YES or NO.

The default NO means that your programming values will be saved as you have

entered them. The YES selection will likely change the program values. It is

recommended that you leave this setting at NO unless otherwise instructed.

Press the P

RO key to advance to the next step. This should take you to the

beginning of the program mode.

Now press and hold the P

RO key for three seconds to exit the program mode and

save the programming information to the computer’s memory.

Note: For your protection, the 844-RA console will not automatically power

down while in the Program Mode. You must exit properly as described

above to enable the console’s auto power down feature.

Note: Cutting the power to the controller while in the Program Mode will

not save any changes into the computers memory.

Table of contents

Other TeeJet Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions