Tegam 1805B User manual

MODEL 1805B

RF Control Unit

Instruction Manual

P/N IM200-CD

Rev. J

This owner’s manual was as current as possible when this product was manufactured. However,

products are constantly being updated and improved. Because of this, some differences may occur

between the description in this manual and the product you received.

TEGAM, INC.

TEN TEGAM WAY

GENEVA, OH 44041

TEL: (440) 466-6100

FAX: (440) 466-6110

www.tegam.com

Publication Date: January 2014

SAFETY SUMMARY

DEFINITIONS

The following definitions apply to WARNINGS, CAUTIONS, and NOTES found

throughout this manual.

Highlights an operating or maintenance procedure, practice, statement, condition, etc.,

which, if not strictly observed, could result in injury and/or death of personnel. Do not

proceed beyond a WARNING symbol until all the indicated conditions have been fully

understood and/or met.

CAUTION

Highlights an operating or maintenance procedure, practice, statement, condi-

tion, etc., which, if not strictly observed, could result in damage or destruction of

the equipment. Do not proceed beyond a CAUTION symbol until all the indicat-

ed conditions have been fully understood and/or met.

NOTE

Highlights an essential operating or maintenance procedure, condition, or

statement that must be highlighted.

GENERAL PRECAUTIONS

The following are general precautions that are not related to any specific pro-

cedure and, therefore, do not appear elsewhere in this publication. These are

precautions that personnel must understand and apply during various phases

of instrument operation or service.

Potentially lethal voltages are present in this instrument. Serious shock haz-

ards from voltages above 70 volts may exist in any connector, chassis, or cir-

cuit board. Observe the following precautions:

• Use the buddy system any time work involving active high voltage components is

required. Turn OFF the power before making/breaking any electrical connection.

Regard any exposed connector, terminal board, or circuit board as a possible shock

hazard. DO NOT replace any component or module with power applied.

• If test conditions to live equipment are required, ground the test equipment

before probing the voltage or signal to be tested.

• Personnel working with or near high voltage should be familiar with modem

methods ofresuscitation.

• DO NOT wear jewelry (rings, bracelets, metal watches, and/or neck chains)

while working on exposed equipment. Be very cautious about using hand tools

near exposed backplanes, bus bars, and/or power supply terminals. Use properly

insulated tools. When making test connections to the power supply terminals and

bus bars; use only insulated probe tips.

• Verify that the instrument is set to match the available line voltage and the correct

fuse is installed.

• DO NOT install substitute parts or perform any unauthorized modification to this

i

WARNING

WARNING

!

!

!

instrument. Contact TEGAM to acquire any information on replacement parts or

returning the instrument for repair. Unauthorized modification can cause injury to

personnel and/or destruction of the instrument.

• Operating personnel must not remove instrument covers. Component replacement

or adjustments MUST BE performed by qualified service personnel.

• DO NOT operate the instrument near or in the presence of flammable gases or

fumes.

DETAILED PRECAUTIONS

The following WARNING, CAUTIONS and NOTES appear throughout the text of this

manual and are repeated here for emphasis.

!CAUTION

• All procedures and steps identified as be followed exactly as written

and according to ESDS device handling procedures. Failure to comply WILL

RESULT IN ESDS damage.

• DO NOT use a nylon bristle brush in the solvent as the bristles may dissolve and

cause damage to the circuit card or component.

• DO NOT use ultrasonic cleaning on parts or assemblies containing electrical or

electronic components.

• Compressed air used for cleaning and/or drying can create airborne particles that

may enter the eye. Goggles/faceshields should be worn. DO NOT direct air stream

towards self or other personnel. Pressure should be restricted to a maximum of

15 psi to avoid personal injury.

• Under no circumstances should a wire brush, steel wool, or abrasive compound

be used on any surface. Using these items will cause extensive damage to the

instrument surface.

NOTE

DO NOT return any instrument or component to TEGAM without receiving prior

factory authorization.

SAFETY SYMBOLS

The following symbols are used to identify safety hazards found throughout this

publication and/or located on the instrument.

ii

CAUTION

HIGH VOLTAGE

Protective Conductor

Terminal

Caution,

Risk of Electrical Shcok

Table of Contents

SAFETY SUMMARY

Definitions............................................................................................................................. i

General Prcautions.............................................................................................................. i

Detailed Precautions........................................................................................................... ii

Safety Symbols................................................................................................................... ii

LIST OF ILLUSTRATIONS...............................................................................................................v

LIST OF TABLES............................................................................................................................ vi

SECTION I

INTRODUCTION AND GENERAL DESCRIPTION

INTRODUCTION.......................................................................................................................... 1-1

Purpose.......................................................................................................................... . 1-1

Scope ............................................................................................................................. 1-1

Arrangement.................................................................................................................... 1-1

Related Manuals...............................................................................................................1-1

Contacting TEGAM.......................................................................................................... 1-2

Electrostatic Discharge Sensitive.....................................................................................1-2

Abbreviations and Acronyms.............................................................................................1-3

Safety Considerations.......................................................................................................1-3

GENERAL DESCRIPTION............................................................................................................1-3

Description of Equipment..................................................................................................1-3

Functional Description................................................................................................ 1-3

Physical Description....................................................................................................1-3

Specifications................................................................................................................... 1-4

Recommended Materials................................................................................................. 1-5

Special Tools and Test Equipment................................................................................... 1-5

APPLICATIONS.............................................................................................................................1-5

SECTION II

INSTALLATION AND SHIPMENT

GENERAL .................................................................................................................. .............2-1

Initial Inspection.................................................................... ........................................... 2-1

Inspection.................................................................................................................... 2-1

Damage....................................................................................................................... 2-1

Power Requirements .......................................................................................................2-1

Environmental Requirements........................................................................................... 2-1

Recommended Operating Environment........................................................................... 2-1

PREPARATION FOR USE ............................................................................................................2-2

Mounting Instructions....................................................................................................... 2-2

Initial Setup ..................................................................................................................... 2-2

Input/Output Options........................................................................................................ 2-2

MOUNT BIAS (+/-) Terminals (E1 and E2)..........................................................2-3

TEMPERATURE CONTROL Connector (J1).......................................................2-3

+ AM MODULATION Connector (J2).................................................................. 2-3

IEEE-488 INTERFACE BUS (J3)........................................................................ 2-4

REMOTE PROGRAM—INPUT Connector (J4).................................................. 2-4

-AM MODULATION Connector (J6).....................................................................2-5

Power Input Assembly (XF1).............................................................................. 2-5

iii

Line Voltage and Fuse Selection..................................................................................... 2-5

PREPARATION FOR RESHIPMENT OR STORAGE ..................................................................2-8

Reshipment...................................................................................................................... 2-8

Storage............................................................................................................................. 2-9

SECTION III

THEORY AND OPERATION

GENERAL ..............................................................................................................................3-1

OPERATION ...............................................................................................................................3-1

GENERAL OPERATING CONSIDERATIONS.............................................................................. 3-2

CONTROLS AND INDICATORS ...................................................................................................3-2

LISTEN Indicator.............................................................................................................. 3-3

REMOTE Indicator............................................................................................................3-3

STANDBY Indicator.......................................................................................................... 3-3

POWER Switch................................................................................................................ 3-3

ON Indicator..................................................................................................................... 3-3

DC SUBSTITUTED POWER Switch............................................................................... 3-3

RF ON Indicator............................................................................................................... 3-3

BRIDGE BALANCE Meter............................................................................................... 3-3

RF OFF Indicator.................................................................................................. ............3-4

FINE NULL ADJUST Control........................................................................................... 3-4

COARSE NULL ADJUST Control.................................................................................... 3-4

ERROR Indicator............................................................................................................. 3-4

RF ON/OFF Switch...........................................................................................................3-4

TEMPERATURE Meter.....................................................................................................3-4

ADDRESS Switch............................................................................................................ 3-4

OPERATING INSTRUCTIONS..................................................................................................... 3-5

Initial Powerup and Checkout.......................................................................................... 3-5

Manual Operation............................................................................................................ 3-6

REMOTE OPERATION.................................................................................................... 3-7

TERMINATING OPERATION........................................................................................... 3-8

THEORY OF OPERATION ...........................................................................................................3-8

Power Supply/Motherboard Section................................................................................ 3-8

Microprocessor Section................................................................................................... 3-9

RF Amplifier Section...................................................................................................... 3-11

Thermistor Mount Proportional Temperature Controller................................... 3-11

Bridge Offset Sensing Circuit............................................................................ 3-12

RF Switching Circuitry....................................................................................... 3-12

DC Substitution Section................................................................................................. 3-12

CALIBRATION............................................................................................................................. 3-13

DC Substitution.............................................................................................................. 3-13

Calibration Factors......................................................................................................... 3-13

Sources of Calibration Error........................................................................................... 3-14

Calibration Factor in dB................................................................................................. 3-14

SECTION IV

TESTING

GENERAL ..............................................................................................................................4-1

MAINTENANCE ............................................................................................................................4-1

Inspection................................................................ ........................................................ 4-1

Preventive Maintenance.................................................................................................. 4-1

Connectors................................................................................................................. 4-1

Calibration Data Record .............................................................................................4-1

Special Cleaning Instructions........................................................................................... 4-1

iv

Microwave Coaxial Cable Assemblies..............................................................................4-1

Circuit Cards and Modules ...............................................................................................4-1

Machined Surfaces and Hardware ...................................................................................4-2

Chassis Cleaning..............................................................................................................4-3

Connector Cleaning......................................................................................................... 4-3

PERFORMANCE TESTING...........................................................................................................4-4

Initial Test Setup............................................................................................................... 4-4

DC Substitution Accuracy Test......................................................................................... 4-4

BIAS Power Range Test................................................................................................... 4-5

Temperature Control Circuit Verification........................................................................... 4-6

System IIA Closed Loop Stability Test.............................................................................. 4-6

CONTACTING TEGAM..................................................................................................................4-9

WARRANTY...................................................................................................................................4-9

List of Illustrations

RF Control Unit, Model 1805B ..................................................................................................... 1-1

Model 1805B Assembly Location.................................................................................................. 1-4

Typical Configuration..................................................................................................................... 1-6

10 mW Configuration Using Model 1727A.................................................................................... 1-8

SWR Measurement Configuration ................................................................................................ 1-8

75 Ohm Sensor Calibration Setup................................................................................................. 1-9

Typical Higher Power Calibration Setup........................................................................................ 1-9

Spectrum Analyzer Calibration Setup.......................................................................................... 1-10

Physical Dimensions.................................................................................................................... 1-11

Model 1805B/1807A Bench Configuration.................................................................................... 2-2

Model 1805B Connector Location (FRONT)................................................................................. 2-3

Model 1805B Connector Location (REAR)................................................................................... 2-4

IEEE-488 INTERFACE BUS Pin Location.................................................................................... 2-4

Voltage Selector/Fuse Assembly................................................................................................... 2-6

Precision Power Source Setup..................................................................................................... 2-7

Precision Power Source Setup..................................................................................................... 2-8

Controls and Indicators (FRONT)................................................................................................. 3-2

Controls and Indicators (REAR).................................................................................................... 3-5

Important Interface Dimensions Type 7mm...................................................................................A-2

Important Interface Dimensions Type 2mm...................................................................................A-3

Important Interface Dimensions Type BNC...................................................................................A-3

Important Interface Dimensions Type BNC...................................................................................A-4

Important Interface Dimensions Type BNC...................................................................................A-4

v

Address Switch ................................................................................................................3-5

Simplified Microprocessor Block Diagram....................................................................... 3- 9

Precision Power Source Schematic................................................................................ 3-10

RF Amplifier Functional Diagram.................................................................................... 3-11

Temperature Control Circuitry......................................................................................... 3 -11

Simplified dc Substitution Circuitry................................................................................. 3-13

Closed Loop Stability Test................................................................................................ 4-6

Removal and Installation ...................................................................................................4-7

LIST OF TABLES

Specifications ................................................................................................................ 1-1

Recommended Consumable Materials ........................................................................... 1-2

Special Tools and Test Equipment .................................................................................. 1-3

IEEE-488 INTERFACE BUS Signal Designators .............................................................2-1

Line Voltage Fuse Requirements......................................................................................2-2

Mnemonics for Remote Control ...................................................................................... 3-1

Inspection ...............................................................................................................4-1

Dc Substituted Power Settings..........................................................................................4-2

Pin Height Specification.....................................................................................................A-1

Connector Torque Recommendations...............................................................................A-2

APPENDIX A

CARE and HANDLING of Microwave Coaxial Cable Assemblies

Care and Handling of Assemblies.....................................................................................A-1

Cable Inspection................................................................................................................A-1

Making Initial Connections.................................................................................................A-2

Aligning Connectors......................................................................................................A-2

Mating Connectors........................................................................................................A-4

Ensuring Proper Connector Torque..................................................................................A-5

Overtorquing.................................................................................................................A-5

Hex-Nut Types..............................................................................................................A-5

Knurled Nuts.................................................................................................................A-5

Proper Cable Handling......................................................................................................A-5

Securing Cables.......................................................................................................... .A-6

Storing Cables.............................................................................................................. A-6

Cleaning Connector Interfaces..........................................................................................A-6

vi

Operation & Service Manual Section I

Model 1805B RF Control Unit Introduction and General Description

SECTION INTRODUCTION AND GENERAL DESCRIPTION

INTRODUCTION

PURPOSE

This manual provides Operation and Service instructions necessary to install, service,

test, and operate the TEGAM Model 1805B RF Control Unit (P/N 138-415-1).

SCOPE

This manual is to be used in conjunction with the operation and maintenance of the

RF Control Unit. The manual also provides a description of each assembly; testing of

the unit; maintenance procedures to maintain the instrument.

ARRANGEMENT

The information contained in this manual is tabulated in the Table of Contents, List

of Illustrations, and List of Tables. The manual is divided into four sections, listed as

follows:

SECTION I Introduction and General Description

SECTION II Installation and Shipment

SECTION III Theory and Operation

SECTION IV Testing

Figure 1-1 RF Control Unit, Model 1805B

RELATED MANUALS

The following manuals contain information that may be used in conjunction with

this manual to operate, or calibrate the RF Transfer Standard.

1-1

Operation & Service Manual Section I

Model 1805B RF Control Unit Introduction and General Description

Manual Title

IM128 Models 1109, 1109H and 1110 Coaxial Power Standards, Operation

and Service Manual

IM198 System IIA, Automatic Power Meter/Sensor Calibration System,

Opertion and Service Manual

IM199 Model 1807A RF Transfer Standard, Operation and Service Manual

IM205 Models 1111 and 1116 Coaxial Power Standards, Operation

and Service Manual

IM241 Models 1119, 1119H and 1120 Coaxial Power Standards, Operation

and Service Manual

IM245 Models 1117A, 1117A and 1118 Coaxial Power Standards, Operation

and Service Manual

IM249 Operation Manual, SWR Measurement Kit (P/N 187-4003)

IM255 Operation Manual, 50-75 W Minimum Loss Matching Pad (P/N 138-

650)

IM267 Model 1727A, Amplifier, Operation and Service Manual

CONTACTING TEGAM

In the event of an instrument malfunction, contact TEGAM. An apparent malfunction of

an instrument or component may be corrected over the phone by contacting TEGAM.

DO NOT send the instrument or component back to the factory without prior authoriza-

tion. When it is necessary to return an item, state the symptoms or problems, catalog

and type number of the instrument or component, serial number of the item, and date of

original purchase. Also write the company name, your name, and phone number on an

index card. Then attach the card to the instrument or component to be returned. Or

contact TEGAM using the following:

TEGAM, INC. 800-666-1010 toll-free

TEN TEGAM WAY 440-466-6100 phone

GENEVA, OH 44041 USA 440-466-6110 fax

ELECTROSTATIC DISCHARGE SENSITIVE

The equipment documented in this manual contains certain Electrostatic Discharge

Sensitive (ESDS) components or parts. Therefore, certain procedures/steps are

identified by the use of the symbol . This symbol is used in two ways:

!CAUTION

All procedures and/or steps identified as must be followed exactly as written and

according to ESDS device handling procedures. Failure to comply WILL RESULT IN

ESDS damage.

a. When the ESDS symbo l is placed between a paragraph number and

title, all of that paragraph, including all subparagraphs, is considered an

ESDS device handling procedure.

b. When the ESDS symbol is placed between a procedure/step number

and the text, all of that procedure is considered an ESDS device handling

procedure.

1-2

Operation & Service Manual Section I

Model 1805B RF Control Unit Introduction and General Description

ABBREVIATIONS AND ACRONYMS

The following list contains all abbreviations used throughout this manual. Abbreviations and

acronyms that are not listed conform with MIL-STD-12D.

DUT Device Under Test

ESDS Electrostatic Discharge Sensitive

SAFETY CONSIDERATIONS

The RF Control Unit and all related documentation must be reviewed for familiarization with

safety markings and procedures before performing any operation and/or service. Refer to the

SAFETY SUMMARY located at the beginning of this manual for a summary of safety

information and procedures. Following these simple safety precautions will ensure safe

operation and service of the RF Control Unit.

GENERAL DESCRIPTION

DESCRIPTION OF EQUIPMENT

The following paragraphs provide a general description of the RF Control Unit (shown in

Figure 1-1).

Functional Description

The Model 1805B RF Control Unit is a solid state, microprocessor-controlled RF control unit

designed for precise control ofdc substituted power. When used with thermistor mounts such

as the TEGAM Model 1109,1109H, 1116,1117A, 1119 and 1119H Feedthrough Thermistor

Mounts and a stable RF generator, a system is obtained which allows rapid and accurate

calibration of power meter/sensors and other thermistor mounts from 100 KHz to 26.5 GHz.

Model 1805B also provides:

• IEEE-488 Bus or front panel selection of precise dc power levels. These levels are 0.5

mW and 1-10 mW in 1 mW steps.

• IEEE-488 Bus or front panel RF ON/OFF switching.

• Elimination ofac/dc error by using dc for both bias and substituted power.

• Automatic control of dc level to within ±0.1% +1 mW.

• Constant dc level over an ambient temperature range of from +10° to +40°C.

• Capability to correct RF source level variations of ±3 dB.

• Internal temperature controller for controlling internal temperature of thermistor mount.

Physical Description

Refer to Table 1 -1 for all the physical dimensions for the RF Control Unit, Model 1805B. The

RF Control Unit features a POWER ON/OFF/STANDBY switch/indicators, a

TEMPERATURE control meter, a RF ON/OFF switch/indicator, DC SUBSTITUTED

POWER (mW) control, BRIDGE BALANCE meter, MOUNT BIAS connectors,

REMOTE/LISTEN/ERROR indicators, and FINE/COARSE NULL ADJUST controls, which

are all located on the front panel. The rear panel contains the input power connector and fuse

selector assembly, INPUT/OUTPUT REMOTE PROGRAM connectors, ADDRESS selector

switch, IEEE 488 INTERFACE BUS connector, and+/- AM MODULATION connectors. The

RF Control Unit can be easily stacked with other TEGAM instruments or mounted in any

cabinet or rack designed according to EIA RS-310 and M1L-STD-189 using the appropriate

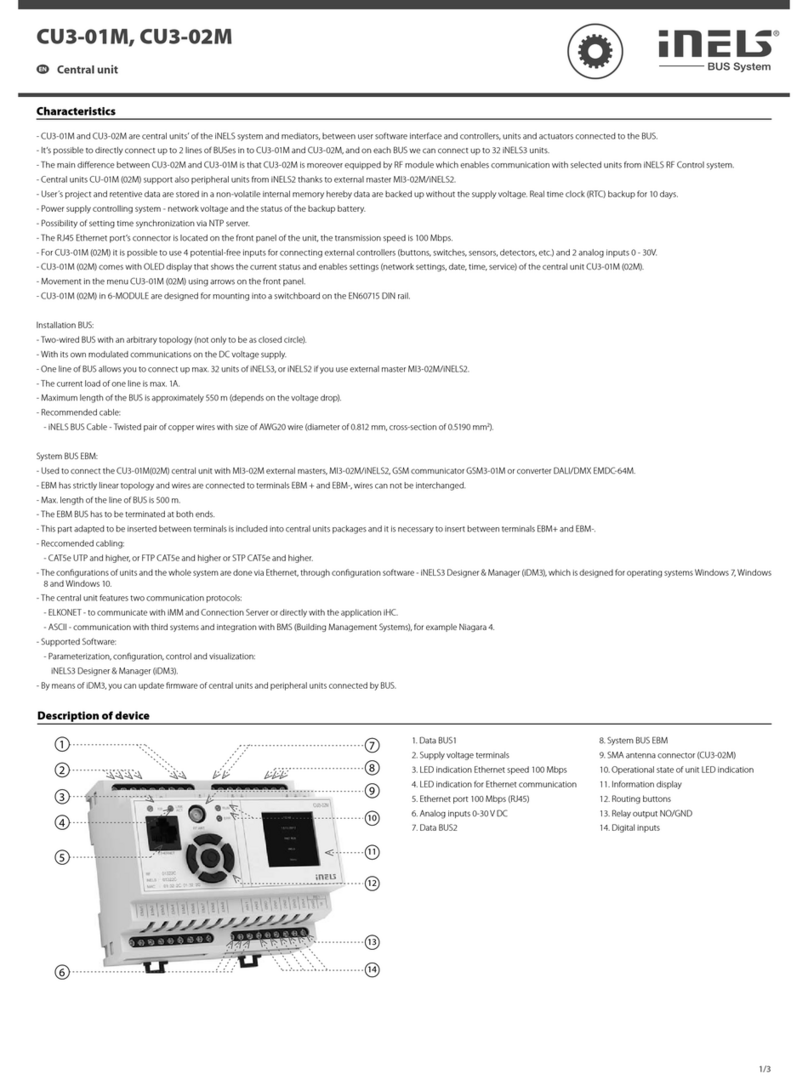

hardware. Figure 1-2 and the following list are provided as an aid in identifying and locating

modules and assemblies within the Models 1805B RF Control Unit.

A1 MICROPROCESSOR PC BD ASSEMBLY

A2 DC SUBSTITUTION PC BD ASSEMBLY

A3 RF POWER BD ASSEMBLY

A4 (NOT USED)

A5 (NOT USED)

A6 POWER SUPPLY/MOTHER BD ASSEMBLY

1-3

Operation & Service Manual Section I

Model 1805B RF Control Unit Introduction and General Description

A7 +30 V POWER SUPPLY ASSEMBLY

A8 FRONT PANEL ASSEMBLY

A9 REAR PANEL ASSEMBLY

W1 RF CABLE ASSEMBLY

W2 RF CABLE ASSEMBLY

W3 ADDRESS SWITCH CABLE ASSEMBLY

W4 CABLE BAND SELECT ASSEMBLY

XF1 INPUT POWER ASSEMBLY

Specifications

Table 1-1 lists specifications to be considered when using the RF Control Unit.

Figure 1-2 Model 1805B Assembly Location

1-4

Operation & Service Manual Section I

Model 1805B RF Control Unit Introduction and General Description

Table 1-1 Specifications

Specification Description

Temperature Range Operating: +10 to +40°C (+ 50 to + 104°F)

Storage: -40 to +75°C (- 40 to + 167°F)

Power Requirements 100/120/220/240 Vac +5%/-10%, 48-66 Hz 40 Watts nominal

Physical Dimensions Depth: 17.5” (44.45 cm)

(Figure 1-9) Width: 8.4” (21.33 cm)

Height: 7” (17.78 cm)

Weight: 13 lbs. (5.9 kg net)

Construction Cabinet or Standard Rack (1/2-Rack) Mount

Operating Modes Remote: IEEE-488-1978 full function Bus Control of RF ON/OFF and

Substituted dc Power Levels (0.5mW and 1-10 mW in 1 mW

steps)

Local: Manual front panel control of all function such as RF ON/OFF

and Substituted dc Power Levels (0.5mW and 1-10 mW

in 1 mW steps)

DC Substitution DC Substituted Power Level Range: 0.5,1,2,3,4,5,6,7,8,9,and 10 mW.

DC Substituted Power Accuracy (at 30±0.7 mW bias power):±0.1%

+5μW

Bias Power Range: 29-31 mW, automatic with error indication for out-of-

range balance condition

Power Level Control Range: Approximately 3-23 dB minimum

(dependent upon specific signal source)

Leveled RF Power Dynamic Range: ±3 dB

(Referenced to DC Substituted Power)

Unbalanced Detector: Sensitivity: 2 mW/division

Resolution: 0.2 mW

Level Control Loop Gain: 80dB minimum

Temperature Ambient Temperature Range: (50° to 104°F)

Controller Loop Gain: 80 dB minimum

Open Loop Frequency Response: 0.1 Hz

Warm-Up Drive (saturated): 8 ~ 10 V at 200 mA min.

Indicator: Voltmeter with marked operating point

*Bias Power Temperature Sensitivity: 2 mW/C°/hr

*Mount Warm-Up Time: 2 hours nominal

*Internal Temperature: +46°C nominal

*Related thermistor mount specifications

Connectors Mount Bias: Binding Post, standard 0.75” spacing for Banana plugs

+AM MODULATION: BNC female

-AM MODULATION: BNC female

CONTROL (Temperature): four pin threaded

IEEE-488 INTERFACE BUS: 24 pin connector per IEEE-488-1978

Recommended Materials

Table 1-2 provides a list of recommended consumables to be used when cleaning or servicing

the RF Control Unit.

Special Tools and Test Equipment

All recommended special tools and test equipment to be used with the RF Control Unit are

listed in Table 1-3.

APPLICATIONS

The primary function of the Model 1805B is to function as part of the TEGAM System IIA

Precision Power Source for the transfer of calibration factors to power meter sensors. Figure

1-5

Operation & Service Manual Section I

Model 1805B RF Control Unit Introduction and General Description

1-3 shows a typical configuration for calibrating coaxial power sensors. Using other TEGAM

Coaxial Feedthrough mounts and the appropriate generator, an operator can easily calibrate

other power sensors with frequency ranges as follows:

Model 1109 0.01-18 GHz

Model 1116 100kHz-100MHz

Model 1117A 0.05 GHz-26.5 Ghz

Model 1119 100 kHz-4.2 GHz

However, the Model 1805B can be used in many other System IIA applications such as

comparing power standards; spectrum analyzer calibration, and to measure effects of noise on

linearity at low signal levels. Virtually any application requiring a precision leveled power

source is a prime candidate for the Model 1805B and the System IIA. The following

paragraphs outline several applications for System IIA.

Figure 1-4 shows a calibration setup using a TEGAM Model 1727A RF Amplifier and a +10

dBm RF Signal source to increase the output power so that the Model 1805B and System IIA

Precision Power Source can perform calibrations from 1 mW to 10 mW in the 100 kHz to 26.5

GHz frequency range. Refer to the Model 1727A Operation and Service Manual for more

information.

Figure 1-5 shows a setup to using the Model 1805B as part of the System IIA Precision Power

source and the TEGAM SWR Measurement Kit to measure Return Loss/SWR. The SWR

Measurement Kit includes a return loss bridge with an "open" and "short". Using the System

IIA Precision Power Source, the DUT's impedance to 50 ohms can be checked by measuring

return loss through the return loss bridge. The actual measured return loss can be readily

converted into SWR by the system software. Refer to the SWR Measurement Kit manual for

more information.

Figure 1-3 Typical Coaxial Power Sensor Configuration

1-6

Operation & Service Manual Section I

Model 1805B RF Control Unit Introduction and General Description

Table 1-2 Recommended Consumable Materials

Table 1-3 Special Tools and Test Equipment

1-7

1 Acid Brush (Fiber Bristle) H-B-643 Type II CLASS I

2 Aluminum Wool MIL-A-4864A

3 Brush, Soft Bristle H-B-420 Type II

4 Cleaner/Solvent Isopropyl Alcohol TT-1-735A (3)

5 Cloth,Lint Free MIL-C-85043 Type IIA

6 Filter Coat Adhesive

7 Permanent Polymer Coating IPC-SM-840 Class III

(Solder Mask)

TOOL/EQUIPMENT/ NOMENCLATURE USE AND APPLICATION

MODEL NUMBER

Gigatronics GT9000 or Synthesized Signal Generator, 0.01-18 Operational Checkout/Calibration

equivalent GHz+10 dBm

HP3458 or equivalent Digital Voltmeter, 8 1/2 digits Operational Checkout/Calibration

HP436/437/438 or Power Meter Operational Checkout/Calibration

equivalent

HP8481 or equivalent Power Sensor, Type N, 0.01-18 GHz Operational Checkout/Calibration

Weinschel 44-10 or 10 dB Fixed Attenuator, Type N, dc- Operational Checkout/Calibration

equivalent 18 GHz

Weinschel 56-10 or 10 dB Fixed Attenuator, 3.5mm, dc- Operational Checkout/Calibration

equivalent 26.5 GHz

SYSIIA-SureCal System IIA Windows Software Operational Checkout/Calibration

(SureCAL)

Any WindowsTM Compatible Printer Operational Checkout/Calibration

with GPIB interface card and

WindowsTM 3.1 Operating System

Any WindowsTM 3.1 Compatible Printer Calibration Report/Graph/Test

Report Printout

Weinschel 1915 or Torque Wrench, 14±1 inch pounds Connector Coupling Torque Type

equivalent (Type N) N Connectors

Weinschel 080-502 or Torque Wrench, 7±1 inch pounds Connector Coupling Torque

equivalent (SMA, 3.5mm) SMA. 3.5 mm Connectors

TEGAM 138-417 AC Extender Board Calibration Adjustment

TEGAM 138-417 AC Extender Board Calibration Adjustment

Operation & Service Manual Section I

Model 1805B RF Control Unit Introduction and General Description

Figure 1-5 SWR Measurement Configuration

1-8

Figure 1-4 10 mW Configuration Using Model 1727A

Operation & Service Manual Section I

Model 1805B RF Control Unit Introduction and General Description

Figure 1-6 shows a setup to using the Model 1805B as part of the System IIA Precision Power

source and the TEGAM 50-75 Ohm Minimum Loss Matching Pad (PN 138-650) to calibrate

75 ohm power sensors over the 0.1 MHz-2.7 GHz frequency range.

Figure 1-7 shows the Model 1805B using a 1109H or 1119H to perform calibrations on higher

power terminating sensors from 1 W to 5 W.

Figure 1-8 shows how a System IIA Precision Power Source using the Model 1805B can be

configured with a Weinschel Model 8300-2 Programmable Attenuator to perform reference

verification over the 0.01-18 GHz frequency range.

Figure 1-7 Typical Higher Power Calibration Setup

1-9

Operation & Service Manual Section I

Model 1805B RF Control Unit Introduction and General Description

Figure 1-8 Spectrum Analyzer Calibration Setup

1-10

Operation & Service Manual Section I

Model 1805B RF Control Unit Introduction and General Description

Figure 1-9 Model 1805B Physical Dimensions

1-11

I

0

Operation & Service Manual Section I

Model 1805B RF Control Unit Introduction and General Description

1-12

Operation & Service Manual Section I I

Model 1805B RF Control Unit Installation and Shipment

SECTION II, INSTALLATION AND SHIPMENT

GENERAL

This section contains information and instructions necessary to install and interface the

Model 1805B RF Control Unit. Included in this section are initial inspection; power

requirements; preparation for use; and shipping instructions.

INITIAL INSPECTION

The instrument was carefully inspected both mechanically and electrically before shipment. It

should be free of mars or scratches and in perfect electrical order upon receipt. After

unpacking the instrument, do not discard the shipping and packing material until the

instrument has been visually inspected and it is determined that reshipment is not necessary.

Perform initial inspection in accordance with the following paragraphs.

Inspection

Perform the following procedures before removing any item from the shipping container:

a. Visually inspect the shipping container for any discoloration; stains; charring; or any

other signs of exposure to heat, moisture, or liquid chemicals.

b. Check for any physical damage to the shipping container such as dents, large snags or

rips, crushed sections or areas, and/or similar signs of excessive shock caused by careless

handling.

c. Carefully remove the instrument and all other items from the shipping container.

d. Inventory all items against the packing list to ensure all items have been received.

e. Inspect the instrument for any dents, cracks, deep scratches, damaged or loose switches

and/or knobs, and any other signs of careless handling.

Damage

If it has been determined that shipping damage has occurred, immediately contact the

delivering carrier to perform an inspection and prepare a concealed damage report. Do not

destroy any shipping or packing material until it has been examined by an agent of the carrier.

Also notify TEGAM to report the nature and extent of damage to the instrument. When

contacting TEGAM, please provide model and serial number of instrument received, so that

the necessary actions can be taken. DO NOT return the instrument until a claim for the

damages has been established. If there is mechanical damage (not from shipping), the contents

are incomplete, and/or the instrument does not function properly, refer to Section I and notify

TEGAM.

POWER REQUIREMENTS

TEGAM supplies a detachable power cable (P/N 068-21) to connect a 100, 120,220, or 240

Vac (+5%/-10%) power source with a frequency between 48 to 66 Hz to the Model 1805 B. To

minimize shock hazard, the instrument chassis must be connected to an electrical ground.

Using the supplied three-conductor power cable ensures that the instrument can be firmly

connected to the ac power source and electrical ground (safety ground) at a grounded power

outlet. Refer to Initial Setup (below) before applying any power to the instrument.

ENVIRONMENTAL REQUIREMENTS

The Model 1805B operates best within its specifications at an ambient temperature of +10° to

+40°C. Operating beyond these limits can affect the accuracy of the instrument and damage

internal circuitry.

RECOMMENDED OPERATING ENVIRONMENT

Normal Calibration Laboratory best practice dictates that the environment should be closely

controlled. This will minimize errors introduced by temperature and humidity changes, A

nominal temperature of+23°C (+73.4°F) provides a good working condition. A tolerance of

2-1

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

LEGRAND

LEGRAND 0 746 85 manual

Bardiani Valvole

Bardiani Valvole B925 Instruction, use and maintenance manual

Armstrong

Armstrong 3750 Installation and operating instructions

Keithley

Keithley DDA-08 user guide

ASCO Numatics

ASCO Numatics 651 Series Installation and maintenance instructions

Hirschmann

Hirschmann PTN-7-SERIAL user manual