Teikoku USA | Chempump Instruction Manual NC-Series 022020

24. Remove the rear shaft sleeve by removing the shaft sleeve

retainer in the rear with a spanner wrench (Do not use a pipe

wrench). Note: This is a left hand thread.

Pull the shaft sleeve off the shaft. Sleeves are centered with "o"

rings which may present some resistance. Remove the shaft key

and “o” rings from the shaft.

4.3 Periodic Inspection

The TRG meter should be checked periodically during operation.

If the initial reading (TRG) was not recorded, then the color coding

system discussed in Table 2-1 may be used to determine bearing

changing intervals.

4.3.1 Bearings

Since the bearings in this pump are lubricated by the process fluid,

it is essential that bearing inspection and replacement periods be

based on experience in each particular installation. Bearing life will

depend, to some extent, on variable factors including lubrication

quality, temperature, number of starts and stops, viscosity, and

suspension content of the fluid being pumped, as well as ambient

temperature and atmospheric conditions of the operational area.

Each time one of these factors is changed, compensation must be

applied in bearing inspection periods.

As noted above, the TRG meter should be checked periodically

during operation. If the initial reading (TRG) was not recorded,

then the color-coding system in Table 2-1 may be used to

determine bearing changing intervals. This inspection is necessary

to determine the rate of bearing wear, thereby enabling setup of

a proper inspection and replacement schedule. See Table 4-3 for

the maximum wear allowable.

If the inspection indicates that bearings are not wearing or are

wearing very slightly, the next inspection may be put off for an

additional 1,500 running hours, or three months of operation,

whichever occurs first. If inspection indicates only slight wear, the

interval may be lengthened.

If bearings must be changed at the initial inspection, they will

need to be changed again in the time period which necessitated

a change at the initial inspection, i.e., 1,500 running hours.

Frequency of periodic bearing inspection can best be determined

by experience, and from these inspections, the time for

replacement can best be indicated.

Bearings can be inspected and replaced without removing the

pump casing from the line. No main piping connections need to

be broken. Refer to Section 4.2 for Disassembly and Section 4.5

for Reassembly.

In the event the TRG bearing wear monitor indicates bearing wear

on the wear indicator:

1. Measure the inside diameters of the front and rear bearings

and compare to the diameter of the rotor shaft journal. If the

difference in diameters is greater than that indicated in Table

4-3, replace the bearings.

2. Inspect the thrust faces of the front and rear bearings. If any

scoring wear is visualized, measure the length of the bearings.

Replace the bearing if the measured length is less than that

indicated in Table 4-3.

3. Examine the bearings for any grooving or scoring, particularly

on the inside diameter and thrust faces. The existence of

grooving or scoring indicates the presence of solids or foreign

matter in the system which should be eliminated prior to

beginning operation again.

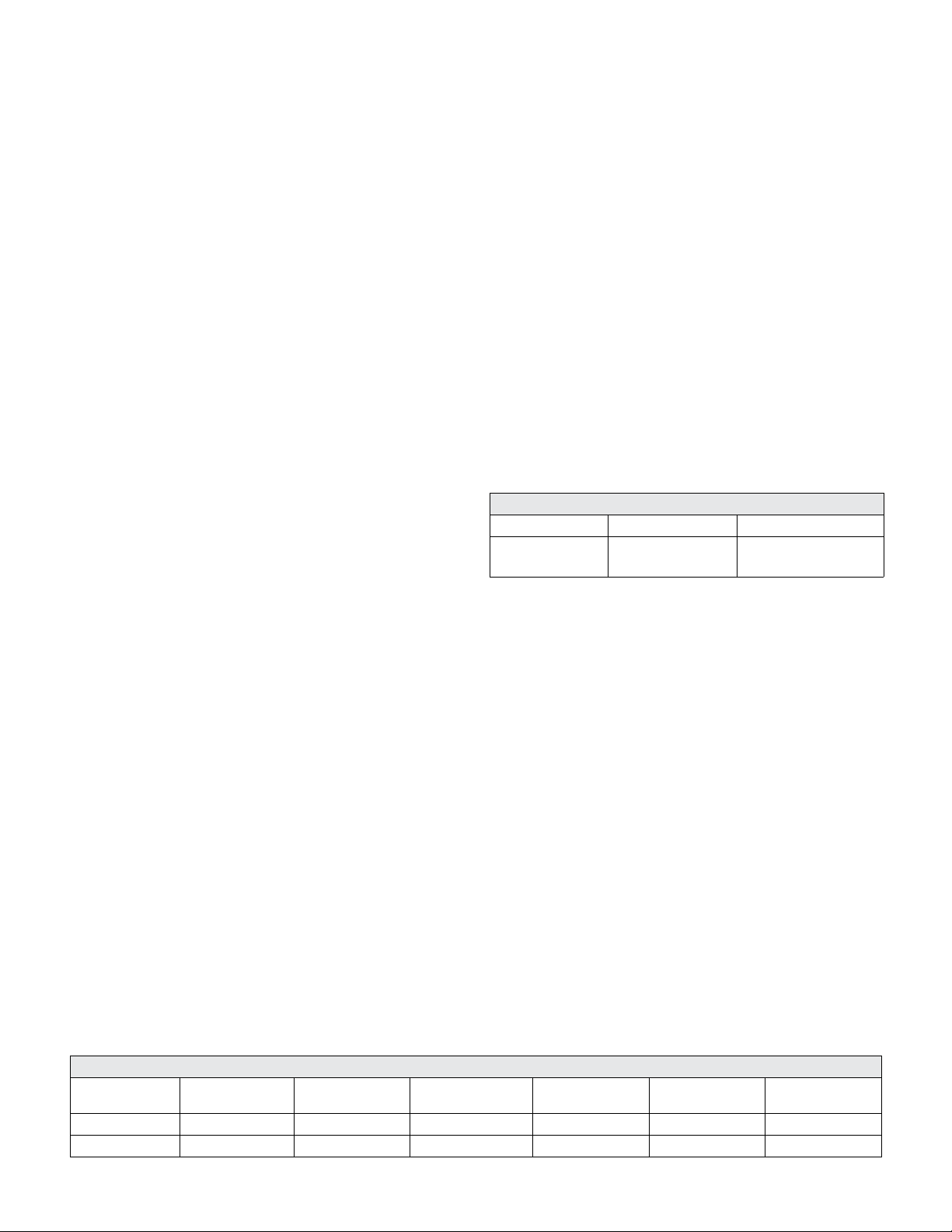

4.3.2 Automatic Thrust Balance and End Play

Inspection

The provision of automatic thrust balance design in the NC-Series,

with its close running seal faces and wearing rings to insure

proper balance chamber pressures, requires that a detailed visual

inspection be made of the impeller, adapter/bearing housing,

front and rear thrust washer and the pump casing, at the time

of bearing inspection. During disassembly for bearing inspection,

measure the unit end play and compare with the following value:

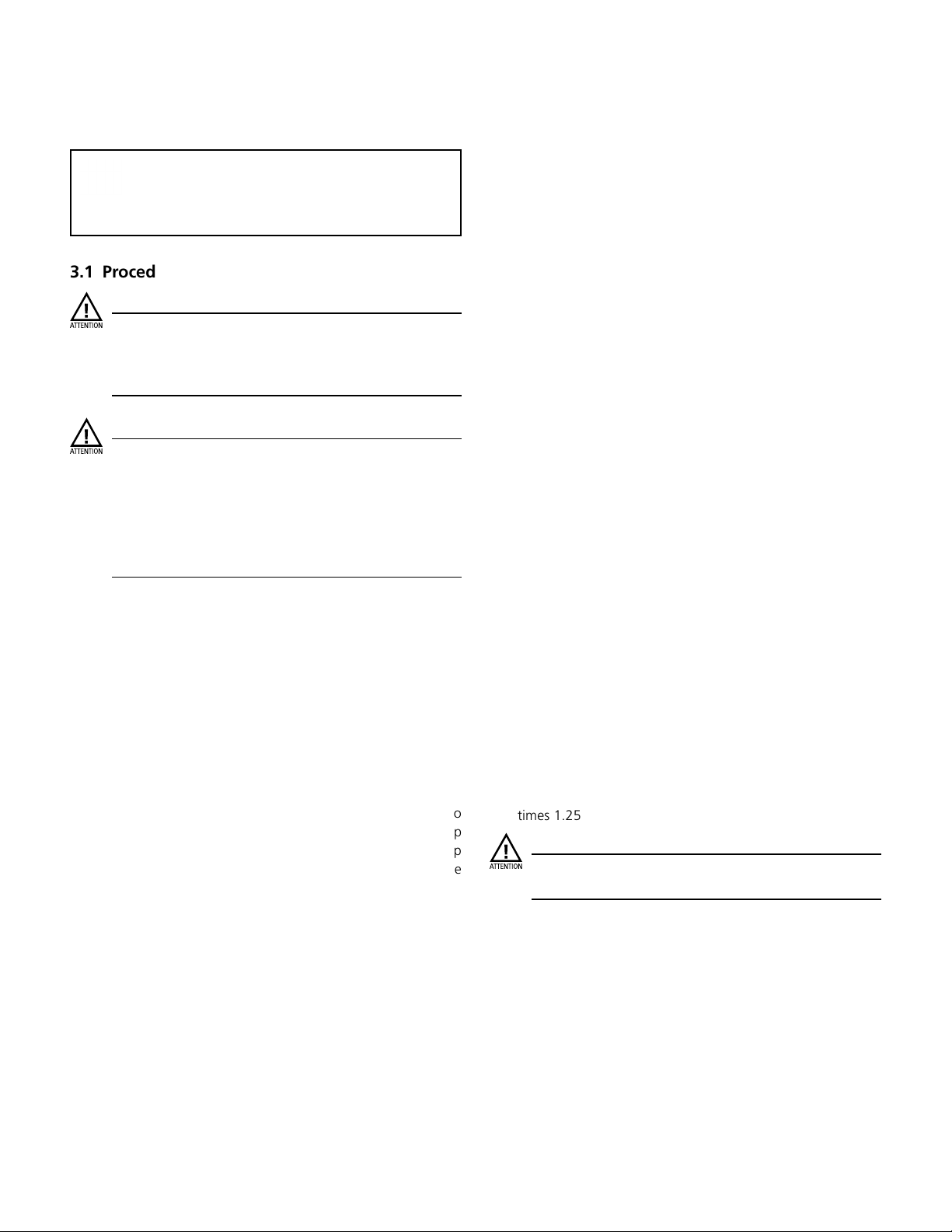

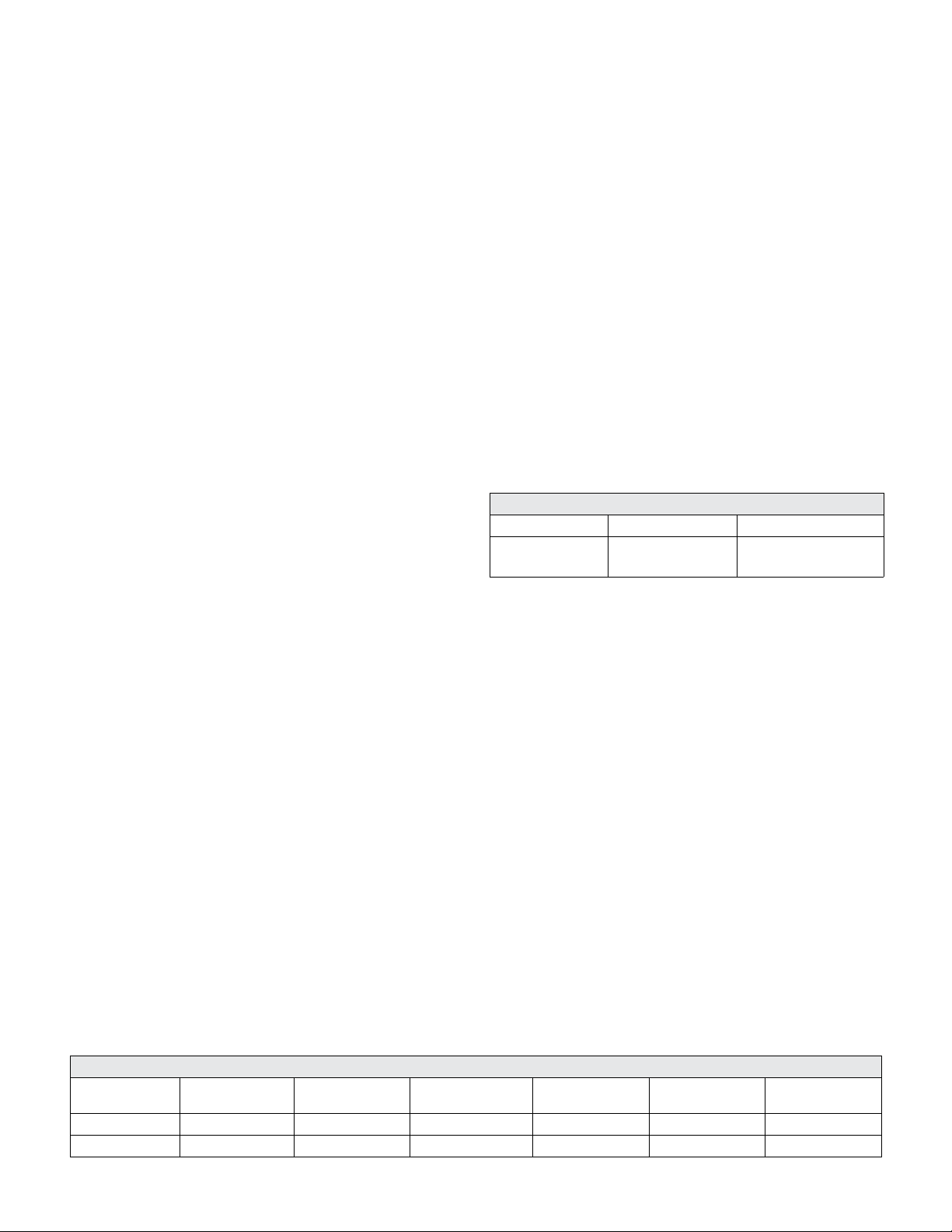

Table 4-4. End Play

Model Motor Size End Play (inches)

ALL ALL 0.072 to 0.096

(0.18 to 0.24 CM)

If the end play exceeds the maximum allowable movement, then

the bearings and/or thrust washers are worn and must be replaced.

(It should be noted that under proper operating conditions, wear

on these parts due to axial thrust forces will be negligible). It is

not necessary to check the end play with the pump casing

mounted on the pump.

4.3.3 Rotor Assembly Inspection

The complete rotor assembly should be visually inspected for

cracks, breaks, pitting, or corrosion which might destroy the

effectiveness of the hermetically sealed rotor end covers and

sleeve.

Check the rotor assembly for straightness of the shaft. The shaft

should be running true and the sleeved rotor core within .003"

(.08 mm) of the shaft.

The rotor assembly shaft sleeves and thrust surfaces should also

be visually inspected at the bearing contact area for general

appearance and uniform wear. Excessive undercutting, pitting, or

scoring is cause for replacement.

4.3.4 Stator Assembly Inspection

The complete stator assembly should be visually inspected for

cracks, breaks, pitting, or corrosion in the stator liner which might

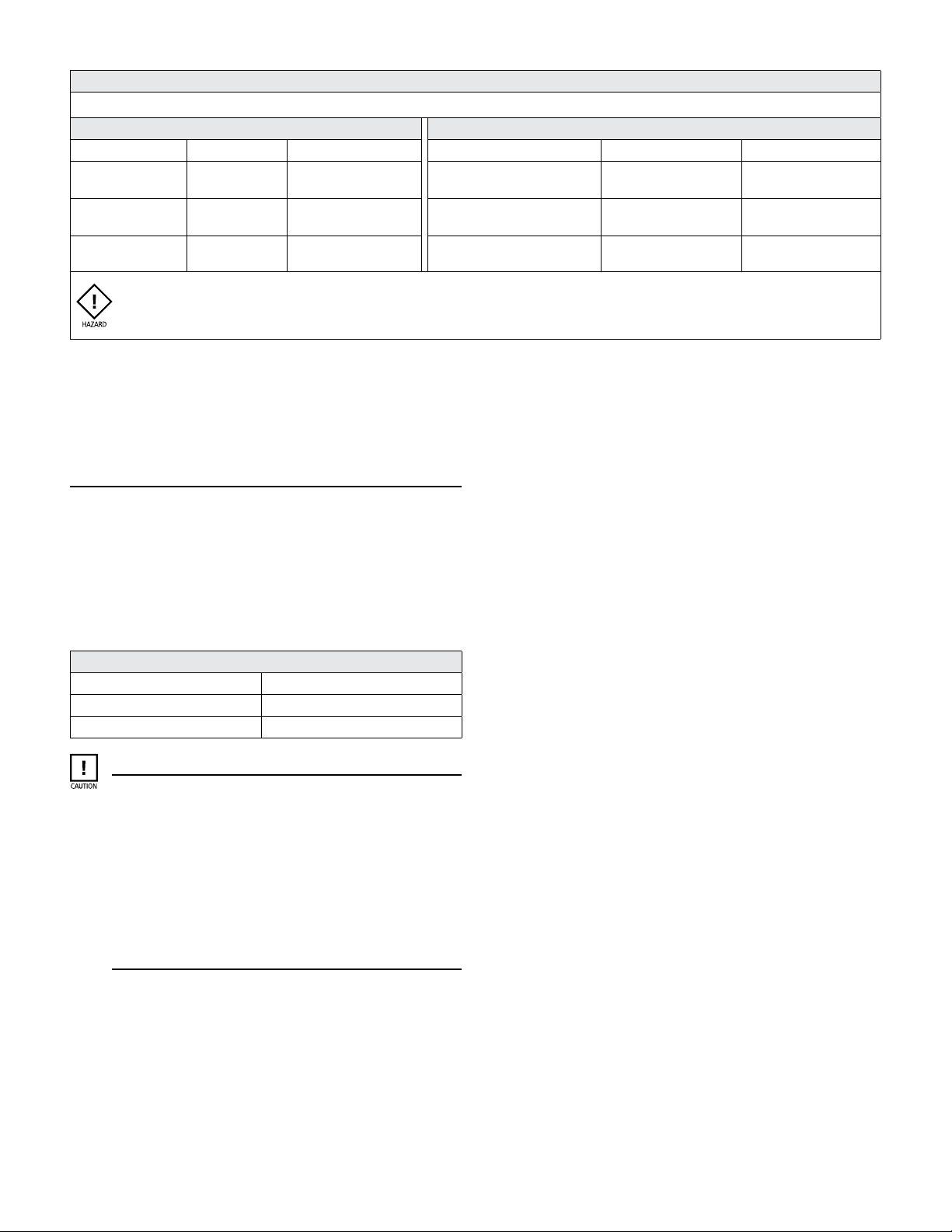

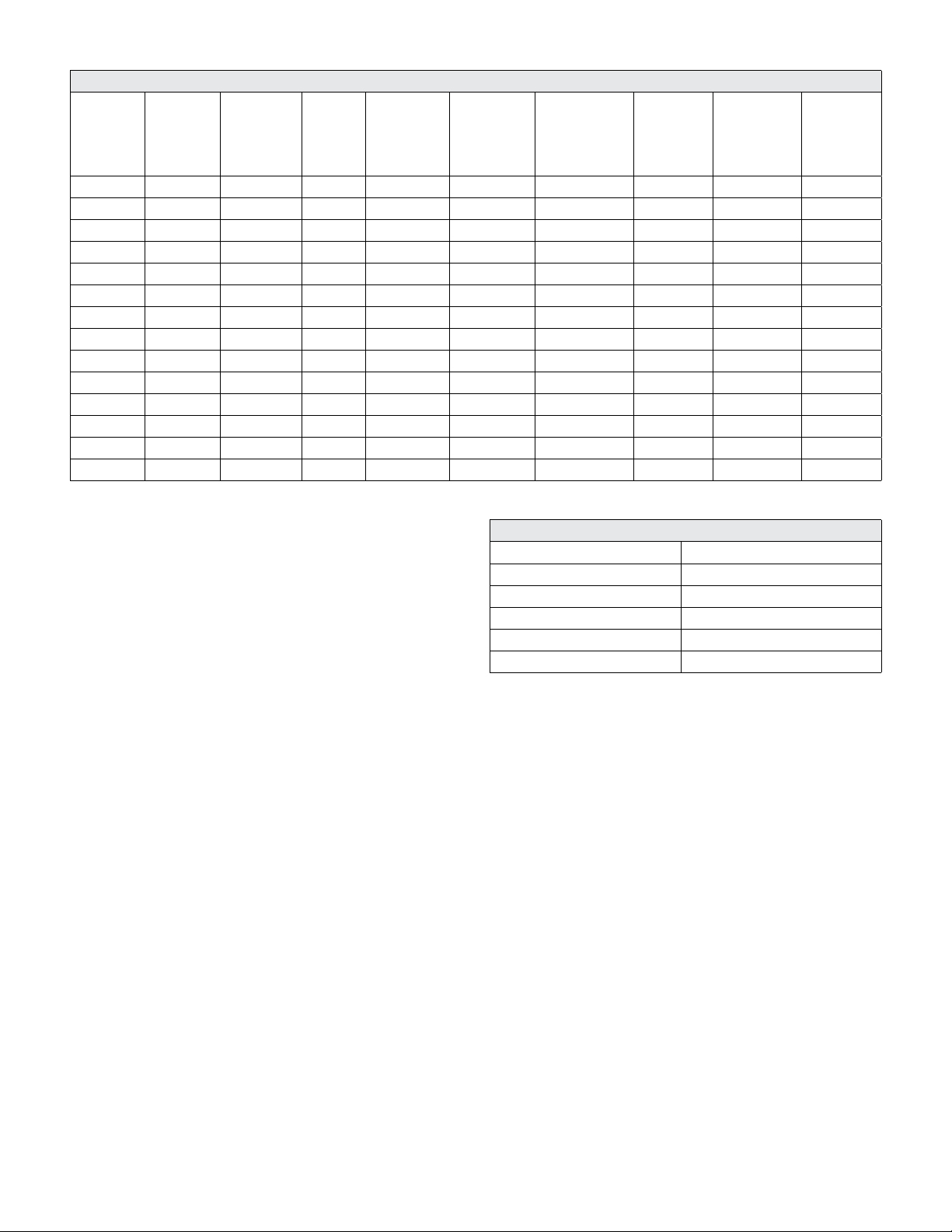

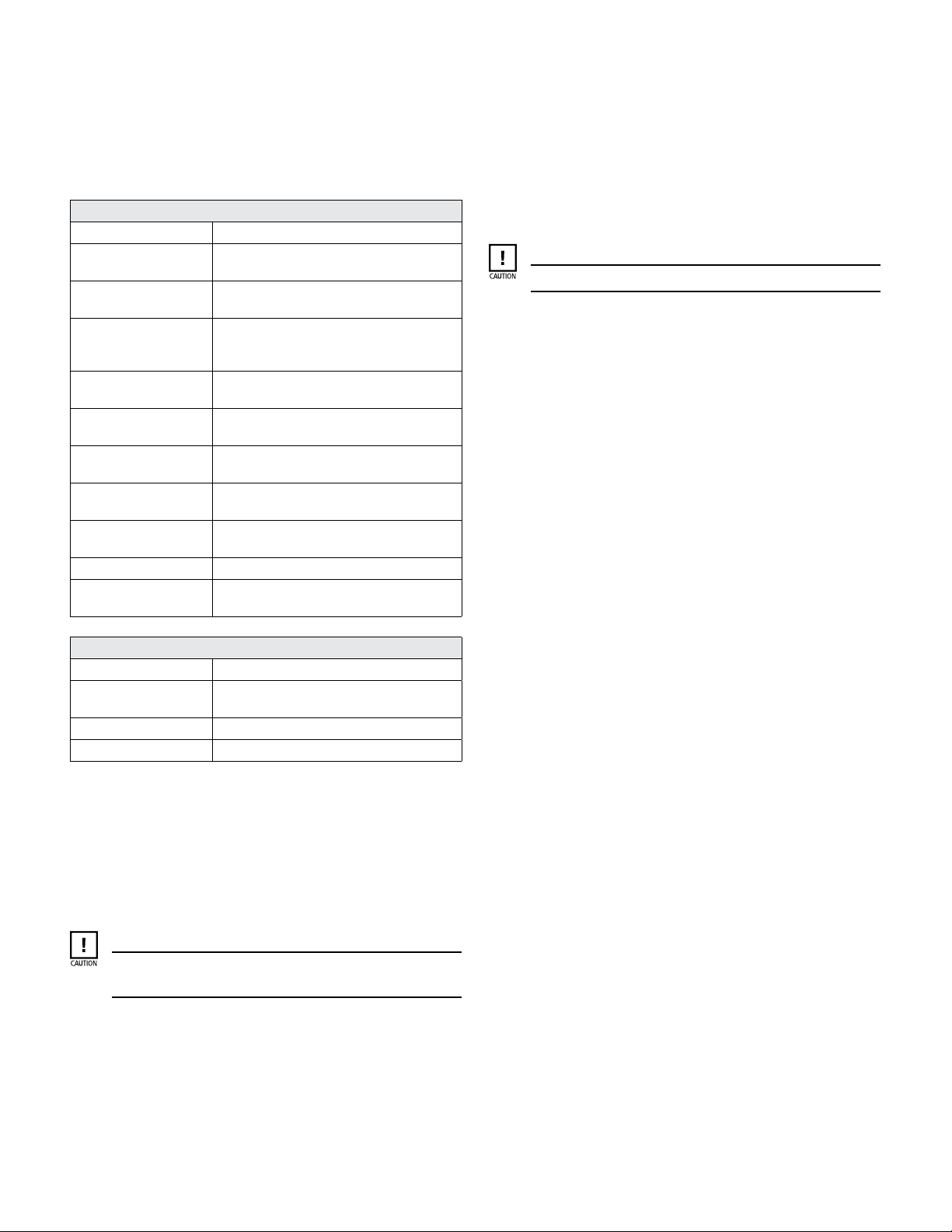

Table 4-3. NCT- Series Bearing and Journal Dimensions

Model Unit Shaft Sleeve

Bearing

Inside DIA

Diametrical

Clearance Max Allowable Length

ALL INCHES 1.6220 - 1.6213 1.626 - 1.627 0.004 - 0.0057 .014 3.0

ALL CM 6.38 6.4 0.02 0.005 11.8