PAGE

LIST OF ILLUSTRATIONS ............................................................... ii

LIST OF TABLES ............................................................................ iii

SAFETY INFORMATION ................................................................. iv

SECTION 1 GENERAL INFORMATION

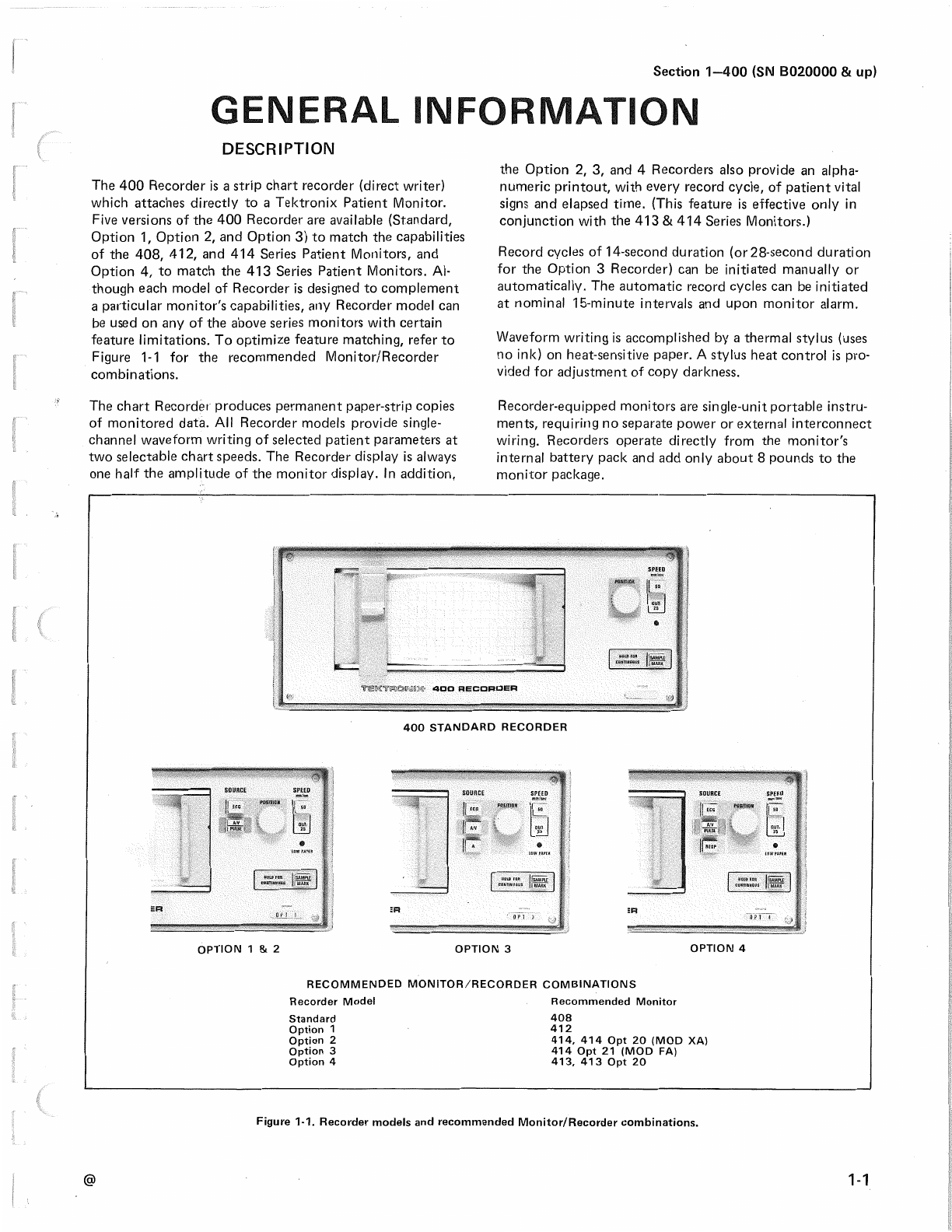

DESCRIPTION................................................................... 1-1

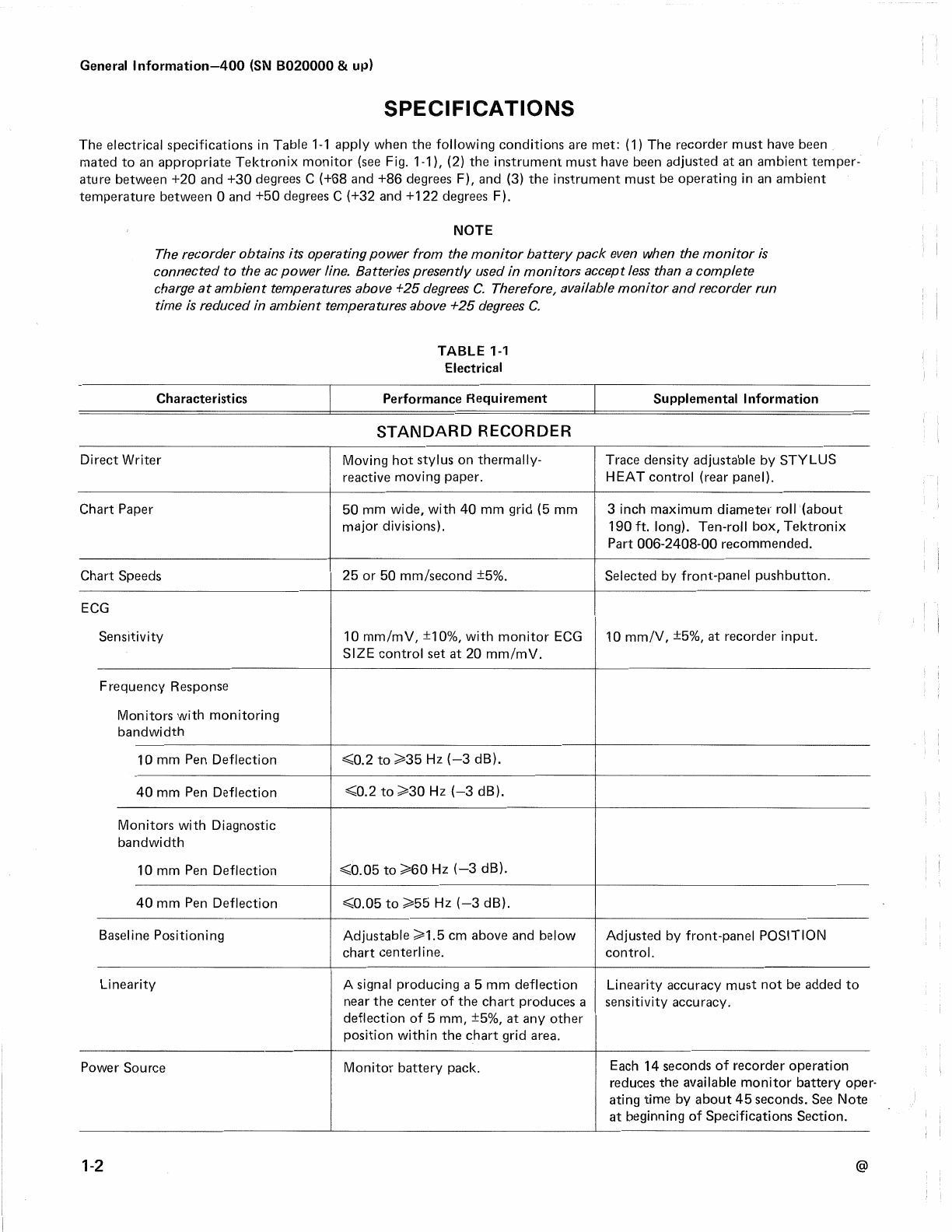

SPECIFICATIONS................................................................... 1-2

MOUNTING INFORMATION .................................................. 1-6

MOUNTING KIT ................................................................ 1-7

MOUNTING BRACKET ..................................................... 1-7

MOUNTING ADAPTER ..................................................... 1-7

RECORDERSUPPORT BLOCK ........................................ 1-7

SUPPLEMENTAL INFORMATION ......................................... 1-8

RUN CONTROL PROGRAMMABLE FUNCTIONS...........1-8

BATTERY DRAIN............................................................... 1-8

408/412/414 MONITOR/RECORDER ADAPTER

KIT INSTALLATION .............................................................. 1-10

INTRODUCTION.............................................................. 1-10

Battery-Pack Ordering lnformation .......................... 1-1O

INSTALLATION INSTRUCTIONS.................................... 1-10

A. Monitor Preparation ............................................. 1-1O

B. 408 Monitors ....................................................... 1-15

C. 412 Mod 735C Monitors ..................................... 1-15

D. 412 Monitors ....................................................... 1-15

E. 414 Monitors ........................................................ 1-17

F. 414 Option 21 (Mod FA) Monitors .....................1-19

G. 414 Option 20 (MOD XA) Monitors ...................1-21

H. Recorder Mounting and Checkout .....................1-22

413 MONITOR/RECORDER ADAPTER

KIT INSTALLATION .............................................................. 1-24

INTRODUCTION.............................................................. 1-24

Battery-Pack Ordering lnformation ..........................1-24

INSTALLATION INSTRUCTIONS.................................... 1-24

A. Monitor Preparation ............................................ 1-24

B. Recorder Mounting and Checkout ......................1-27

SECTION 2 OPERATING INFORMATION

HOW TO LOAD PAPER.................................................... 2-1

PAPER GRID FORMAT ..................................................... 2-1

PAPER USAGE RATE....................................................... 2-1

HOW TO ORDER PAPER................................................. 2-1

REMOTE AND AUTOMATIC STARTING (FIG. 2-4) .....,..2-3

Automatic .................................................................... 2-3

Remote ......................................................................... 2-3

HOW TO READ PRESSURERECORDINGS....................2-3

Alpha-Numeric Printing .............................................. 2-3

FUNCTIONS OF CONTROLS, CONNECTORS

& INDICATORS ................................................................. 2-5

Front Panel (Fig. 2-6) .................................................. 2-5

Rear Panel (Fig. 2-7) ................................................... 2-6

POWER.............................................................................. 2-6

Note About Battery Fuse: ........................................... 2-7

SECTION 3 THEORY OF OPERATION

RUN CONTROL BOARD ................................................... 3-1

PEN AMPLIFIER BOARD .................................................. 3-8

A CONDITIONER BOARD (OPTION 3 ONLY)................3-12

A/V BUFFER BOARD (OPTION 2 ONLY)......................3-14

A/V CONDITIONER BOARD (OPTION 3 ONLY) ...........3-15

DVM ANALOG AND DVM DIGITAL ..............................3-16

PRINT CONTROL 1 BOARD, PRINT CONTROL 2

BOARD, PRINT DRIVE BOARD...................................... 3-19

POWER SUPPLY BOARD............................................... 3-30

@

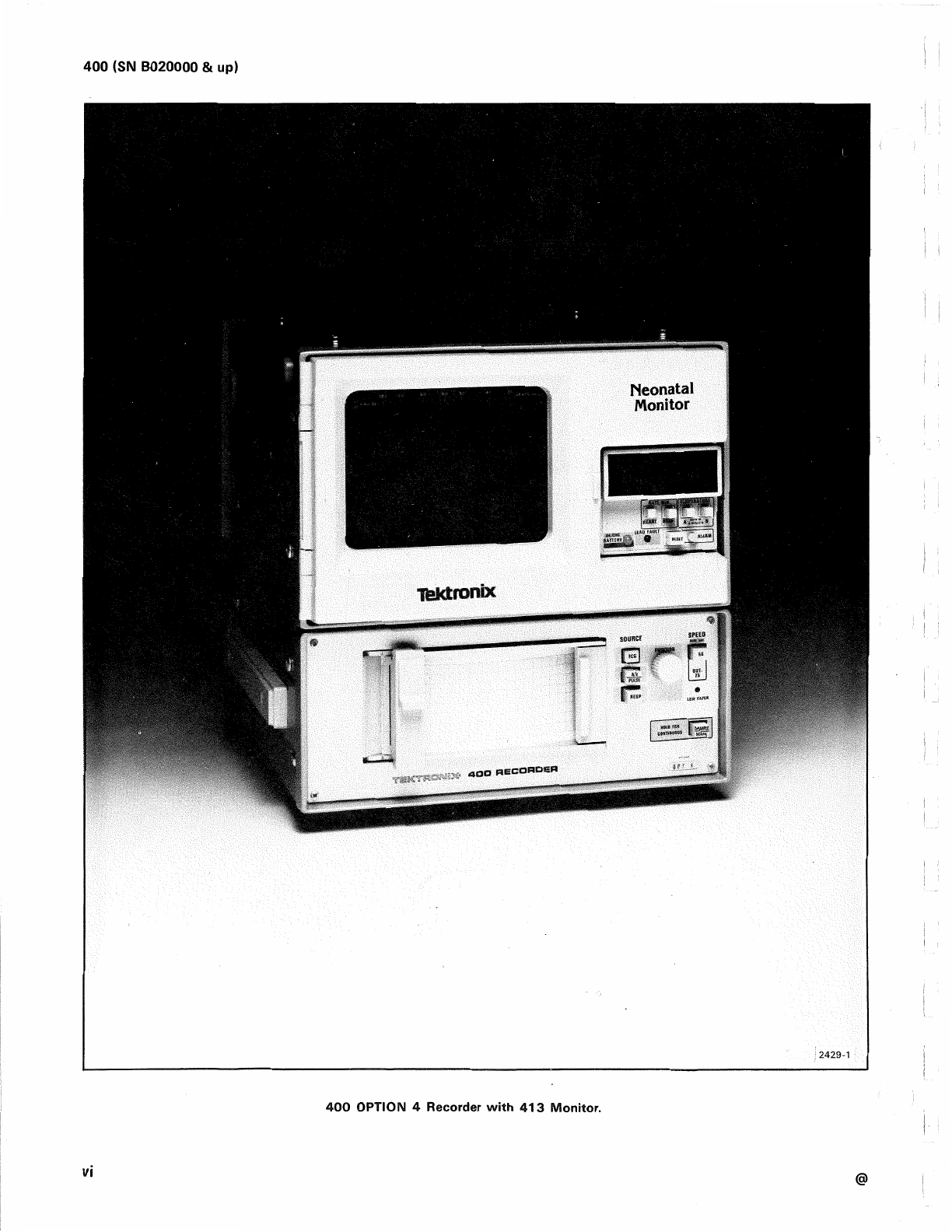

400 (SN 8020000 & up)

PAGE

SECTION 4 MAINTENANCE

PREVENTIVEMAINTENANCE ............................................... 4-1

CABINET REMOVAL. ....................................................... .4-1

CLEANING......................................................................... 4-1

Exterior ........................................................................ 4-1

Interior ......................................................................... 4-1

VISUAL INSPECTION...................................................... .4-2

SEMICONDUCTOR CHECKS........................................... .4-2

TROUBLESHOOTING ............................................................ .4-3

TROUBLESHOOTING AIDS .............................................. 4-3

Diagrams ..................................................................... 4-3

Circuit Board Illustrations ......................................... .4-3

Adjustment And Test Point Locations ....................... 4-3

Component Value Identification ................................ 4-3

Semiconductor Lead Configurations .........................4-3

Signal Routing Diagrams .......................................... .4-3

Truth Tables ................................................................ 4-3

Servicing Extender Set .............................................. .4-3

CORRECTIVE MAINTENANCE ................................. 4-5

SERVICE RECORD........................................................... .4-5

OBTAINING REPLACEMENT PARTS.............................. .4-5

Standard Parts ............................................................ 4-5

Special Parts ............................................................... 4-5

Ordering Parts ............................................................. 4-5

SOLDERING TECHNIQUES .............................................. 4-5

COMPONENT REMOVAL AND REPLACEMENT............4-5

Instrument Disassembly ............................................. 4-5

Pushbuttons ................................................................ 4-6

Interconnecting Cables and Terminal

Connectors .................................................................. 4-6

Semiconductors .......................................................... 4-6

Interconnecting Circuit-Board Pins ...........................4-6

Circuit Boards.............................................................. 4-9

Strip Chart Recorder Module ...................................4-14

PRINT HEAD ASSEMBLY (A16) ....................................4-16

RECOMMENDED PRINT HEAD ADJUSTMENT

PROCEDURE................................................................... 4-17

ALTERNATE PRINT HEAD ADJUSTMENT

PROCEDURE................................................................... 4-18

PEN MOTOR ................................................................... 4-18

Adjusting Stylus Tension Using A

Dynamometer ............................................................ 4-20

Adjusting Stylus Tension Without A

Dynamometer ............................................................ 4-20

Chart Drive Motor .................................................... .4-21

ADJUSTMENT AFTER REPAIR......................................4-22

SECTION 5 CALIBRATION

INTRODUCTION................................................................ 5-1

Purpose ........................................................................ 5-1

Calibration Interval ..................................................... 5-1

Partial Adjustment ...................................................... 5-1

Test Equipment Required ........................................... 5-1

FUNCTIONAL CHECK....................................................... 5-1

PRELIMINARY PROCEDURE FOR ADJUSTMENT.. ........5-2

OPTION 2, 3 AND 4 RECORDERADJUSTMENTS .........5-5

SECTION 6 REPLACEABLE ELECTRICAL PARTS

SECTION 7 DIAGRAMS AND CIRCUIT BOARD

ILLUSTRATIONS

SECTION 8 REPLACEABLE MECHANICAL PARTS

CHANGE INFORMATION