2

Overview

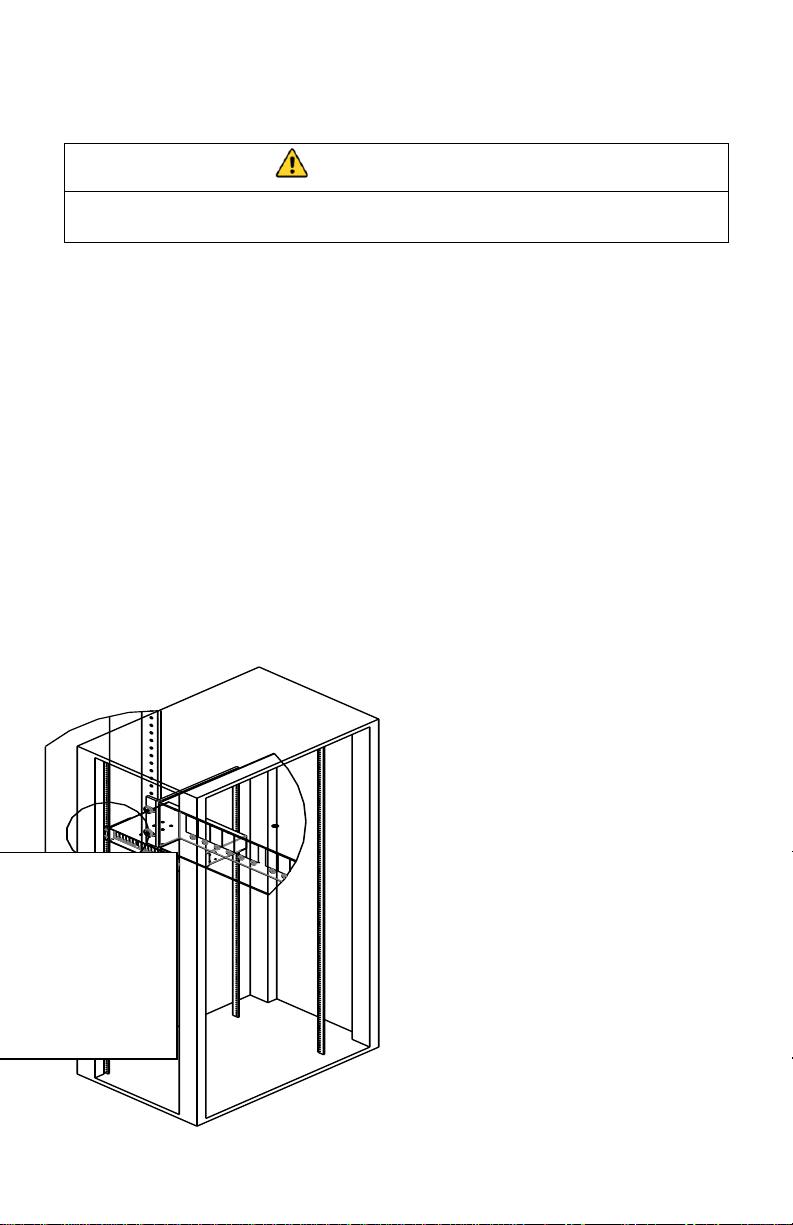

The Zonit Power Distribution System (Z-PDS™) is an extremely

versatile and reliable power delivery solution for data centers and

tele-communication closets with many innovative patented and

patent pending features. It delivers 208V or 480V three phase A-B

redundant power directly at the rack and outputs a wide variety of

power configurations. Depending on the power density needed in

each rack a single Z-PDS can feed multiple plug strips or power IT

equipment such as blade servers. A typical deployment uses a Z-PDS

to provide A+B redundant power to multiple racks.

The Z-PDS has patented phase load balancing technology which

statistically distributes power loads evenly across all phases to

eliminate manual balancing of the per phase power loads on UPS

units and generators. It also has individual circuit breaker

protection for each hot phase of each output to minimize the

impact of any fault. While plug strips are typically attached to the

outputs of the Z-PDS it is possible to connect either plug strips or IT

equipment directly. All output connections are made via standard

plugs and receptacles so no electricians are needed to make

changes. A wide variety of standard and custom plug adapters for

the Z-PDS system are available from Zonit.

The Z-PDS system is the logical evolution of power distribution in

the data center. By moving three phase power to the rack and

tapping it via inexpensive plug adapters, the same result as running

a new whip from a three phase power panel or putting a new tap

box in an overhead busway can be achieved, easier, quicker and

cheaper.