Teledyne TIENet 310 Ex Operating instructions

TIENet® 310 Ex

Ultrasonic Level Sensor

Installation and Operation Guide

Ultrasonic Level Sensor

Manual Body #69-4313-010

Copyright © 2012. All rights reserved, Teledyne Isco

Revision E, March 2019

Foreword

This instruction manual is designed to help you gain a thorough understanding of the operation of

the equipment. Teledyne ISCO recommends that you read this manual completely before placing

the equipment in service.

Although Teledyne ISCO designs reliability into all equipment, there is always the possibility of a

malfunction. This manual may help in diagnosing and repairing the malfunction.

If a problem persists, call or e-mail Teledyne ISCO technical support for assistance. Simple

difficulties can often be diagnosed over the phone. For faster service, please have your serial

number ready.

If it is necessary to return the equipment to the factory for service, please follow the shipping

instructions provided by technical support, including the use of the Return Material

Authorization (RMA) specified. Be sure to include a note describing the malfunction. This will

aid in the prompt repair and return of the equipment.

Teledyne ISCO welcomes suggestions that would improve the information presented in this

manual or enhance the operation of the equipment itself.

Teledyne ISCO is continually improving its products and reserves the right to change

product specifications, replacement parts, schematics, and instructions without notice.

Contact Information

Customer Service

Phone: (800) 228-4373 (USA, Canada, Mexico)

(402) 464-0231 (Outside North America)

Fax: (402) 465-3022

Email: [email protected]

Technical Support

Phone: Toll Free (866) 298-6174 (Samplers and flowmeters)

Email: [email protected]

Return equipment to: 4700 Superior Street, Lincoln, NE 68504-1398

Other Correspondence

Mail to: P.O. Box 82531, Lincoln, NE 68501-2531

Email: [email protected]

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

TIENet™ Model 310 Ex Ultrasonic Level Sensor

Safety

v

TIENet™ Model 310 Ex Ultrasonic Level Sensor

Safety

General Warnings Before installing, operating, or maintaining this equipment, it is

imperative that all hazards and preventive measures are fully

understood. While specific hazards may vary according to

location and application, take heed of the following general

warnings:

WARNING

Avoid hazardous practices! If you use this instrument in

any way not specified in this manual, the protection

provided by the instrument may be impaired.

AVERTISSEMENT

Éviter les usages périlleux! Si vous utilisez cet instrument

d’une manière autre que celles qui sont specifiées dans ce

manuel, la protection fournie de l’instrument peut être

affaiblie; cela augmentera votre risque de blessure.

Hazard Severity Levels This manual applies Hazard Severity Levels to the safety alerts,

These three levels are described in the sample alerts below.

CAUTION

Cautions identify a potential hazard, which if not avoided, may

result in minor or moderate injury. This category can also warn

you of unsafe practices, or conditions that may cause property

damage.

WARNING

Warnings identify a potentially hazardous condition, which

if not avoided, could result in death or serious injury.

DANGER

DANGER – limited to the most extreme situations

to identify an imminent hazard, which if not

avoided, will result in death or serious injury.

TIENet™ Model 310 Ex Ultrasonic Level Sensor

Safety

vi

Hazard Symbols The equipment and this manual use symbols used to warn of

hazards. The symbols are explained below.

Hazard Symbols

Warnings and Cautions

The exclamation point within the triangle is a warning sign alerting you of

important instructions in the instrument’s technical reference manual.

The lightning flash and arrowhead within the triangle is a warning sign alert-

ing you of “dangerous voltage” inside the product.

Symboles de sécurité

Ce symbole signale l’existence d’instructions importantes relatives au pro-

duit dans ce manuel.

Ce symbole signale la présence d’un danger d’électocution.

Warnungen und Vorsichtshinweise

Das Ausrufezeichen in Dreieck ist ein Warnzeichen, das Sie darauf

aufmerksam macht, daß wichtige Anleitungen zu diesem Handbuch

gehören.

Der gepfeilte Blitz im Dreieck ist ein Warnzeichen, das Sei vor “gefährlichen

Spannungen” im Inneren des Produkts warnt.

Advertencias y Precauciones

Esta señal le advierte sobre la importancia de las instrucciones del manual

que acompañan a este producto.

Esta señal alerta sobre la presencia de alto voltaje en el interior del

producto.

vii

TIENet™ Model 310 Ex

Ultrasonic Level Sensor

Table of Contents

Section 1 Introduction

1.1 Description.........................................................1-1

1.2 310 Ex Sensor Design ................................................1-2

1.3 Operation ..........................................................1-2

1.4 Technical Specifications ..............................................1-3

1.5 Accessories .........................................................1-4

1.5.1 Ordering Information ..........................................1-4

1.5.2 TIENet 310 Ex Ultrasonic Level Sensor ...........................1-5

Section 2 Installation and Setup for Signature

2.1 Sensor Installation Considerations .....................................2-1

2.1.1 Beam Angle ..................................................2-1

2.1.2 Humidity ....................................................2-1

2.1.3 Surface ......................................................2-1

2.1.4 Temperature ..................................................2-1

2.1.5 Waves .......................................................2-2

2.1.6 Wind ........................................................2-2

2.1.7 Hazardous Locations ...........................................2-2

2.2 Connecting the Cable ................................................2-2

2.2.1 Permanent Meters .............................................2-2

2.2.2 Connecting to Signature Portable via a TIENet Receptacle ............2-5

2.3 Sensor Installation ..................................................2-6

2.3.1 Dead Band ...................................................2-7

2.3.2 Submersion and Fouling ........................................2-7

2.3.3 Mounting Options .............................................2-7

2.4 Installation in Hazardous Locations ....................................2-8

2.4.1 Important Information Regarding “X” Marking .....................2-9

2.4.2 Electrical Requirements .......................................2-10

2.4.3 Ambient Environment .........................................2-10

2.5 Configuring the System .............................................2-14

2.5.1 Updating the Device List .......................................2-14

2.5.2 Measurement Setup ...........................................2-16

2.6 Level Calibration...................................................2-17

2.7 Firmware Updates .................................................2-18

2.8 Troubleshooting TIENet 310 Ex USLS .................................2-18

2.9 Contact Teledyne Isco ...............................................2-18

A.1 Replacement Parts ..................................................A-1

A.1.1 TIENet 310 Ex Ultrasonic Level Sensor Replacement Parts ...........A-2

TIENet™ Model 310 Ex Ultrasonic Level Sensor

Table of Contents

viii

List of Figures

1-1 Basic Signature monitoring system with 310

(mounting hardware not shown) .......................................1-1

1-2 310 Ultrasonic TIENet Sensor with unterminated leads (l) or TIENet plug (r) . . 1-2

2-1 TIENet Device terminal strips ........................................2-3

2-2 Installing cable with a cord-grip fitting .................................2-3

2-3 TIENet Device terminal connections ...................................2-4

2-4 Attach wired terminal strip to case board socket ..........................2-4

2-5 Position and secure the cable ..........................................2-5

2-6 How to connect a TIENet plug to the Signature Portable ...................2-6

2-7 Sensor mounting options .............................................2-8

2-8 Sensor labeling regarding hazloc installations ...........................2-11

2-9 Hazardous Location Installation Control Drawing-Atex ...................2-12

2-10 Hazardous Location Installation Control Drawing-CSA ..................2-13

2-11 Character grid ...................................................2-14

2-12 Menu Tree: 310 Configuration .......................................2-15

2-13 Configuring ultrasonic level measurement .............................2-16

2-14 Ultrasonic level adjustment and calibration ...........................2-17

1-1

TIENet® Model 310 Ex

Ultrasonic Level Sensor

Section 1 Introduction

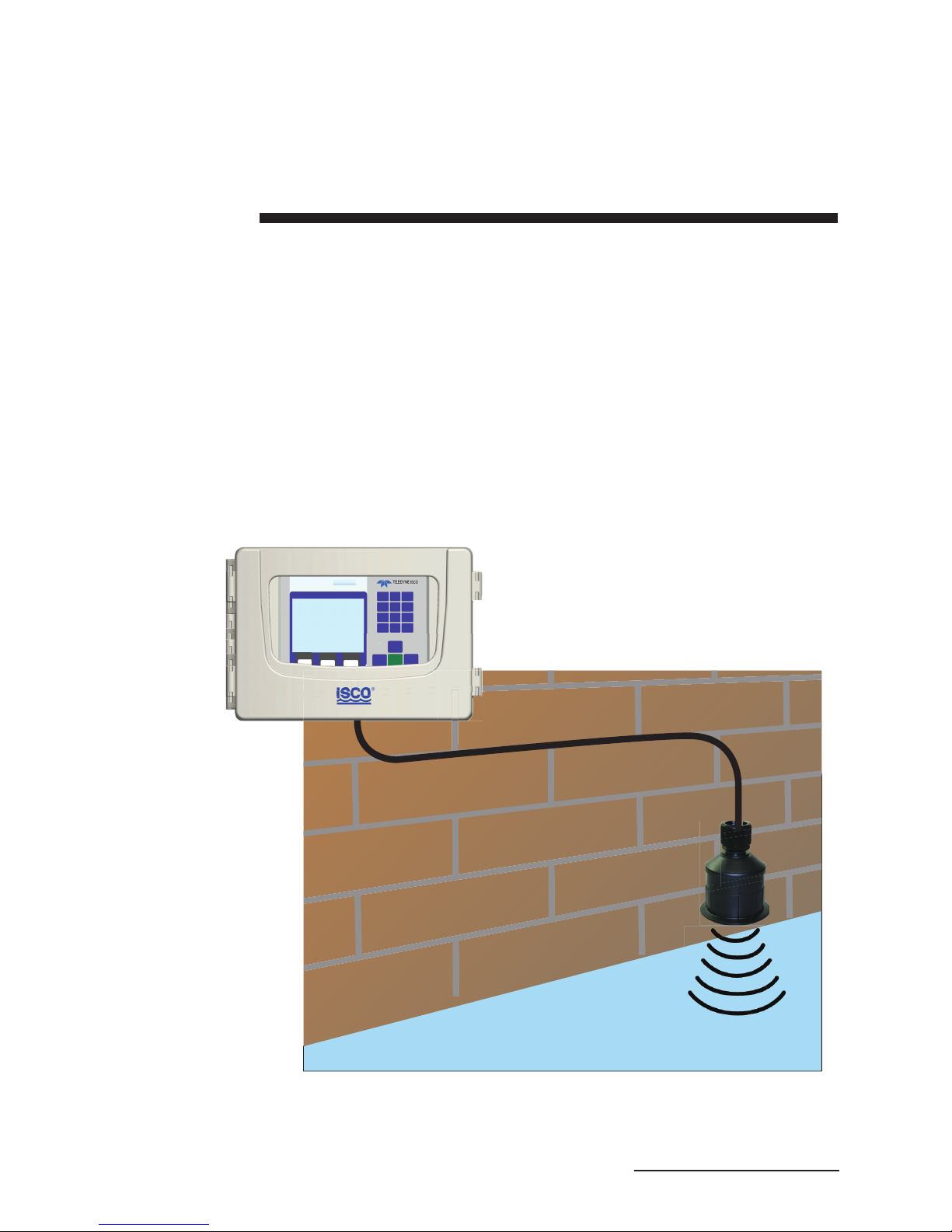

The Signature® Flow Meter uses the TIENet 310 Ex Device to

provide non-contact liquid level measurement. The flow meter

has built-in level-to-flow conversions that cover the majority of

open channel flow measurement situations.

1.1 Description The ultrasonic sensor is mounted over the flow stream. The flow

meter measures the time interval between transmission of a

sound pulse from the sensor, and receiving its echo off the surface

of the liquid, to determine the level of the stream.

Figure 1-1 Basic Signature monitoring system with

310 Ex (mounting hardware not shown)

Signature Flow Meter

310 Ex TIENet Sensor

TIENet® Model 310 Ex Ultrasonic Level Sensor

Section 1 Introduction

1-2

This non-contact measurement method reduces the frequency of

maintenance, and is ideal for applications where the flow may

contain chemicals, grease, silt, or suspended solids.

1.2 310 Ex Sensor Design The ultrasonic level sensor consists of a housing with a single

transducer that is both pulse transmitter and echo receiver. A

temperature sensor within the housing measures the ambient

temperature, and a microprocessor automatically compensates

for speed-of-sound changes due to any changes in air temper-

ature.

The 310 Ex is available with a 10m, 23m, and special order to

150m or less cable lengths with or without connectors. For

greater distances, external connection via conduit, and con-

nection of additional TIENet devices, the TIENet Expansion Box

is available. Bulk TIENet cable may also be used for greater dis-

tances.

Figure 1-2 310 Ex Ultrasonic TIENet Sensor with

unterminated leads (l) or TIENet plug (r)

1.3 Operation The sensor emits multiple ultrasonic pulses per second. Between

pulses, the transducer switches from transmitter to receiver.

When the transducer receives the echo from the water’s surface,

the sound energy is converted into an electrical signal. The

signal is then amplified and processed by the Signature flow

meter into an “echo-received” signal. The time between the trans-

mitted pulse and the echo-received signal is proportional to the

distance between the transducer and the liquid surface. This dis-

tance in turn determines the liquid level used to calculate flow.

Table of contents

Other Teledyne Accessories manuals

Teledyne

Teledyne TIENet 360 LaserFlow Ex Operating instructions

Teledyne

Teledyne 2150 Operating instructions

Teledyne

Teledyne Citadel CTD-ES User manual

Teledyne

Teledyne HVD3000 User manual

Teledyne

Teledyne 452 User manual

Teledyne

Teledyne UFO-130 User manual

Teledyne

Teledyne TIENet 350 Operating instructions

Teledyne

Teledyne PP007 User manual

Teledyne

Teledyne BOA Spot ID Series User manual

Teledyne

Teledyne Everywhereyoulook CCD261-04 User manual