Teleflex Marine CH2200ENC User manual

09/2006 Page 1 of 6 ISCH2200ENC_Rev_0

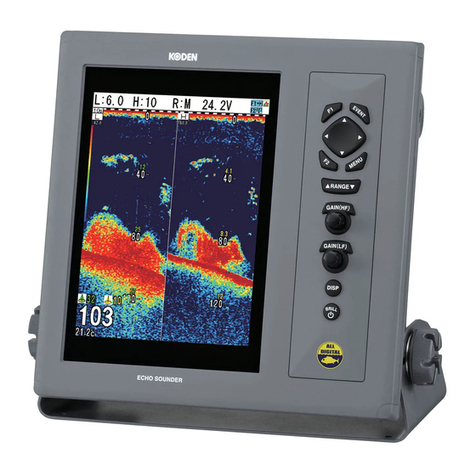

1. Select a location for the control ensuring that the handle does not

interfere with dashboard, steering wheel, seat, switches, or other

equipment at any point in its travel. NOTE: THICKNESS OF

MOUNTING SURFACE MUST NOT BE GREATER THAN ½”.

Also ensure that the shift cable will have at least 36 inches of

unrestricted space for movement (see INSTALLATION OF

SHIFT CABLE). Refer to Figure 1 for dimensions and

clearances. NOTE: CONTROL CAN BE MOUNTED

HORIZONTALLY OR VERTICALLY TO FACILITATE CABLE

CLEARANCE.

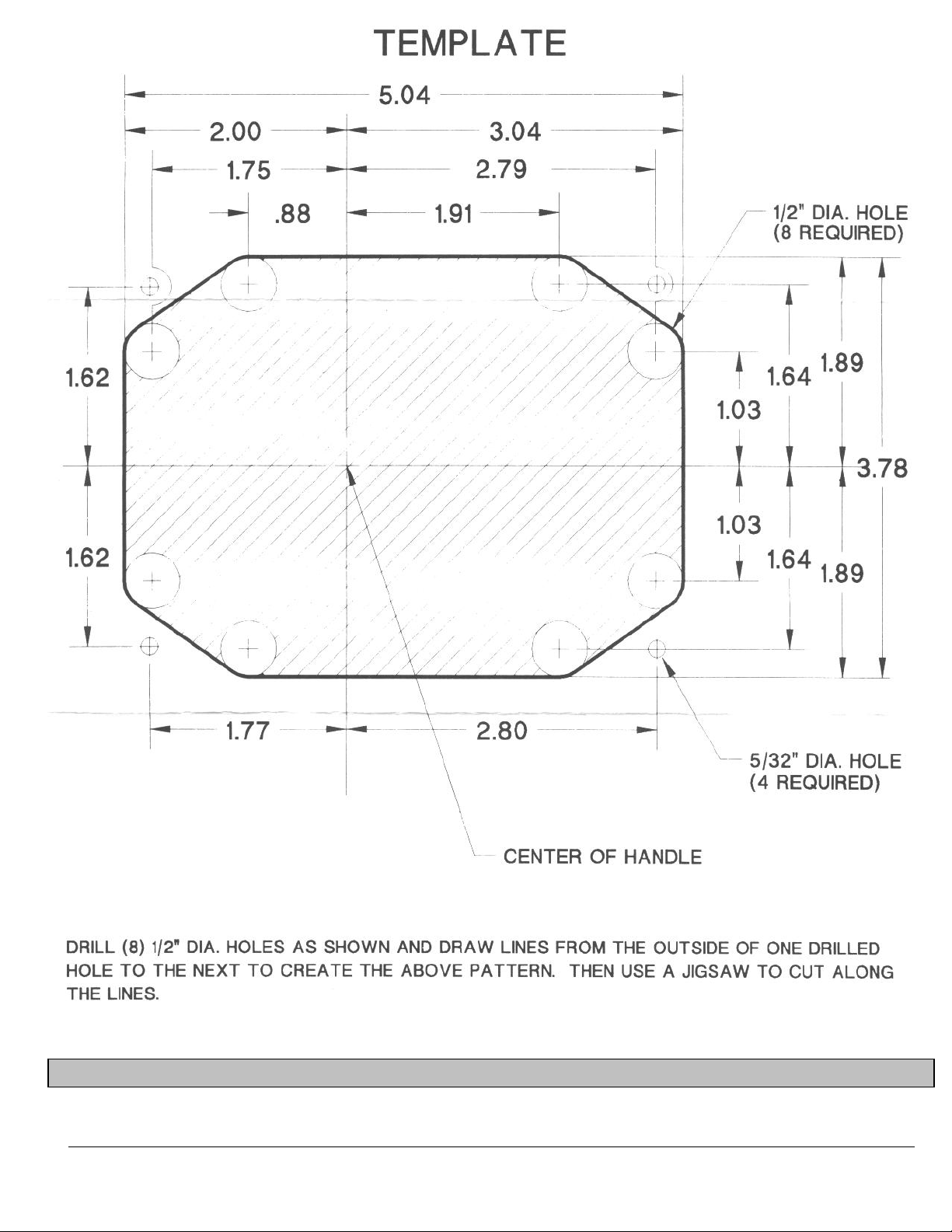

2. Cut mounting holes in selected location, using template provided.

3. If not already routed, route the shift cable and engine harness

to the cutout, allowing the cable and harness to protrude from

the cutout enough to allow connection to the control mechanism.

INSTALLATION OF SHIFT CABLE

1. BEND RADIUS

Minimum bend radius is 8”. If installed with sharper bends, cable

wear will increase rapidly.

2. SUPPORTING THE CABLE

DO NOT TIE OR CLAMP THE CABLE WITHIN 36 INCHES OF THE

CONTROL. WHEN SUPPORTING THE CABLE BEYOND 36

INCHES OF THE CONTROL, DO NOT TIE OR CLAMP TIGHTLY.

THESE INSTRUCTIONS DESCRIBE HOW TO

INSTALL THE CH2200ENC SERIES SIDE MOUNT

CONTROL.

A

DDITIONAL EQUIPMENT REQUIRED:

One Cable - P/Ns CC172XX and CC633XX (CC172 is a 3300-type

cable used for shift in all applications.)

Note: This control does NOT provide “Start in Gear” protection, which must

be provided by the engine manufacturer.

READ THESE INSTRUCTIONS THOROUGHLY BEFORE

STARTING INSTALLATION. FAILURE TO FOLLOW THESE

INSTRUCTIONS AS WELL AS THE INSTRUCTIONS PROVIDED

BY THE ENGINE MANUFACTURER MAY RESULT IN LOSS OF

ENGINE CONTROL WITH SUBSEQUENT PROPERTY DAMAGE

AND PERSONAL INJURY. DO NOT SUBSTITUTE PARTS FROM

OTHER CONTROL MAKERS, AS THEY MAY CAUSE A SAFETY

HAZARD FOR WHICH TELEFLEX, INC. CANNOT ACCEPT

RESPONSIBILITY.

PREPARATION FOR MOUNTING CONTROL

Figure 1

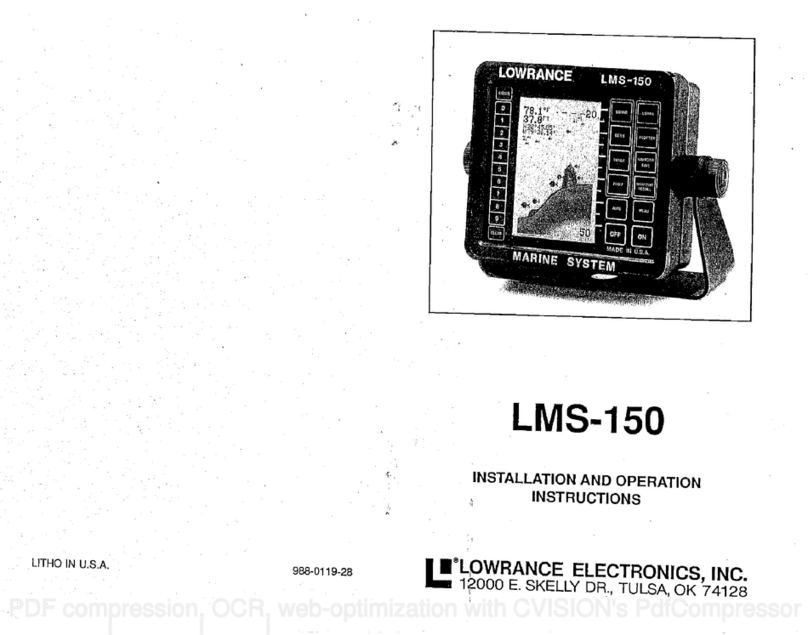

3. CONNECTION OF THE SHIFT CABLE

NOTE: ALWAYS CONNECT THE CABLE TO THE

MECHANISM BEFORE CONNECTING IT TO THE

ENGINE AND GEAR.

1. Push the shift cable through the appropriate retainer,

making sure the cable seats securely into the

retainer (Figure 3, item A).

2. Thread the pivot (Figure 2, item A) onto the cable

terminal until the threaded portion of the terminal

protrudes 5/32” (5 threads). Secure the pivot by

tightening the nut (Figure 2, item B).

3. Connect the pivot to the shifting lever (Figure 3, item

B) and secure with a cotter pin (Figure 3, item C).

Figure 2

A

CH2200ENC

SERIES SIDE MOUNT

SINGLE LEVER CONTROL

Copyright 2006 Teleflex Incorporated (USA) INSTRUCTIONS

Manufactured by

Teleflex Inc. U.S.A.

640 N. Lewis Road

Limerick, PA 19468 (USA)

610/495-7011

Figure 3

INSTALLER: THESE INSTRUCTIONS CONTAIN IMPORTANT SAFETY INFORMATION AND MUST BE FORWARDED TO THE BOAT OWNER.

WARNING

09/2006 Page 2 of 6 ISCH2200ENC_Rev_0

INSTALLATION OF WIRING HARNESS

A wire harness must be prepared for connection of the

CH2200ENC control head to the engine TAC module. Every

boat is different and there may be several ways to route the

harness. Inside the boat there is often a channel or conduit used

for wiring. This can also be used to route the wire harness for

the CH2200ENC control.

When routing the wiring harness, care must be taken not to

damage the cable insulation. If a harness is short, replace it with

a correct length harness. Don't add a short harness to make up

the required length. Run the harness over the shortest and

straightest possible path. Secure the harness every 2 feet (0.6

m) with stainless steel screws and mounting head ties or

clamps. Excess harness length should be neatly coiled and

secured with nylon ties. The mounted harness should be as far

as practical from high current wires or wiring runs and should

not be subjected to water, fuel, lubricants, or excess heat.

PREPARATION OF CONTROL HEAD WIRE HARNESS

Measure from the control head mounting location along

unobstructed wire runs to the engine module.

Round measurement to the next whole foot and add additional

length if uncertain.

Prepare harness as shown in Figure 5 [on page 3]. It is

recommended that conductors be stranded tinned copper (UL

1426 or equivalent), 18 AWG min. Colors shown are optional.

CONNECTION OF THE WIRING HARNESS

NOTE: ALWAYS CONNECT THE WIRING HARNESS TO THE

CONTROL HEAD BEFORE CONNECTING TO THE ENGINE.

ENGINE CONNECTION SHOULD NOT BE MADE UNTIL THE

CONTROL HAS BEEN COMPLETELY INSTALLED.

Ensure that the watertight seal is in place and connect the 6-pin

connector from the completed harness assembly into the rear of

the potentiometer mounted on the control head mechanism. The

connector should be fully seated and latched for proper

operation.

THROTTLE BRAKE ADJUSTMENT

The control mechanism is equipped with an adjustable friction

device (brake) for the throttle to prevent throttle creep. I

f

needed, the friction device can be adjusted by turning the

adjustment screw (Figure 4, item A) clockwise to increase

braking and counterclockwise to decrease or remove braking.

A

ny adjustments should be made with the control set at 1/2

throttle and the gear engaged. Gear shifting is not influenced

by the brake.

Figure 4

INSTALLATION OF CONTROL

A. INSTALLING THE MECHANISM

1. Make sure the control is in gear and at the half throttle

position. This will allow the control to fit in the cutout

shown in the template. If not already in half throttle

position, use the handle to move in gear and at half

throttle position by temporarily placing the handle on the

splined shaft of the control. Push the mechanism until it

seats flush against the mounting surface of the boat.

2. Secure the control mechanism to the boat with the four

screws provided.

A

09/2006 Page 3 of 6 ISCH2200ENC_Rev_0

PREPARATION OF CONTROL HEAD WIRE HARNESS

Figure 5

Del

p

hi Packard Website: www.del

p

hiconnect.com

09/2006 Page 4 of 6 ISCH2200ENC_Rev_0

B. INSTALLING THE COVER (IF SUPPLIED)

Once the mechanism has been securely mounted, the

handle assembly may be attached to the control. The

handle assembly contains two (2) sets of internal splines;

one (1) on the chrome locking ring, and one (1) on the black

handle. There are two (2) sets of mating external splines on

the mechanism; one (1) on the cast housing and one (1) on

the steel shaft. Each set of splines contains forty-eight (48)

teeth and both sets of the 1 3/8” splines and ¾” splines are

consistently oriented to the other (See Figure 6).

CONNECTION OF WIRING HARNESS AND SHIFT

CABLE CABLES TO ENGINE

1. Read engine maker’s manual and use the recommended

attachment kits to connect shift cable to the engine.

2. Connect the 10-pin connector from the wiring harness into

the engine TAC module. The watertight seal should be in

place and connector should be fully seated and latched

for proper operation.

KEEP THESE INSTRUCTIONS WITH YOUR BOAT FOR FUTURE REFERENCE.

4. Once the handle has been attached with the set screw,

insert the black button onto the push pin in the shaft and

press firmly. Insert the #6-32 x 7/8” long machine screw

through the center of the button and tighten until the screw

is flush with the button. Overtightening can result in

damaging the button and/or screw.

3. While applying pressure firmly against the assembly and

leaving the handle in the locked position, install the set

screw into the bottom of the handle and tighten.

1. Place the cover over the shaft and spline and snap into

place on the control mechanism.

C. INSTALLING THE HANDLE

1. Make sure the pinned rocker in the handle is situated in the

slot in the locking ring; this is referred to as the locked

position.

2. Firmly install the handle assembly onto the control so that

both sets of splines are fully engaged and the steel shaft

'bottoms-out' against the internal shoulder of the handle.

Since the splines on the shaft and handle wiII engage

before the splines on the locking plate and diecast housing,

make sure the locking ring rests securely on the 1 3/8”

splines and cannot rotate.

2. If the handle develops lost motion, check that it is firmly

attached the control body, that the control body is firmly

attached to the boat and that the cables are firmly

attached to the control, engine, and gear.

3. If stiffness of operation develops, disconnect cable from

the engine and check operation. If stiffness is due to

shift cable, it must be replaced.

1. Ensure that the control is firmly mounted.

A

lthough very little maintenance is required for this control

system, periodically check the following:

MAINTENANCE

IMPORTANT: ONCE THE ASSEMBLY HAS BEEN FULLY

A

TTACHED AND THE ENGINE TURNED OFF, LIFT THE

'UMBRELLA' OF THE HANDLE AND CYCLE THE HANDLE

THROUGH FULL FORWARD AND FULL REVERSE TO

ENSURE THAT BOTH SETS OF SPLINES ARE FULLY

ENGAGED. IF THE LOCKING PLATE IS CAPABLE OF

ROTATING WITH THE HANDLE, REMOVE THE HANDLE

A

SSEMBLY AND REPEAT THE HANDLE INSTALLATION

PROCEDURE. ALSO, CYCLE THE CONTROL USING THE

PUSH BUTTON/NEUTRAL WARM-UP TO ENSURE THAT

THE BLACK BUTTON HAS BEEN PROPERLY INSTALLED.

NOTE: Since the sets of splines are oriented and have the

same number of teeth, the control allows for the handle

assembly to be indexed every 7.5○. The centerline of the

handle is aligned with the centerline of the control, so if the

control is mounted horizontally, the handle can be attached

perpendicularly to the control.

PARTS LIST

ITEM DESCRIPTION QUANTITY

1 Handle 1

2 Locking Ring 1

3 Neutral Detent Warm-up Button 1

4 Button Mounting Screw 1

5 Control Mechanism 1

6 Control Mounting Screw 4

7 Knob 1

8 Handle Mounting Set Screw 1

9* Pivot, Small (3/16”) Dia. Thread 2

10 Cotter Pin (Figure 3, Item C) 1

*See Figure 2, item A

7

09/2006 Page 5 of 6 ISCH2200ENC_Rev_0

09/2006 Page 6 of 6 ISCH2200ENC_Rev_0

KNOB

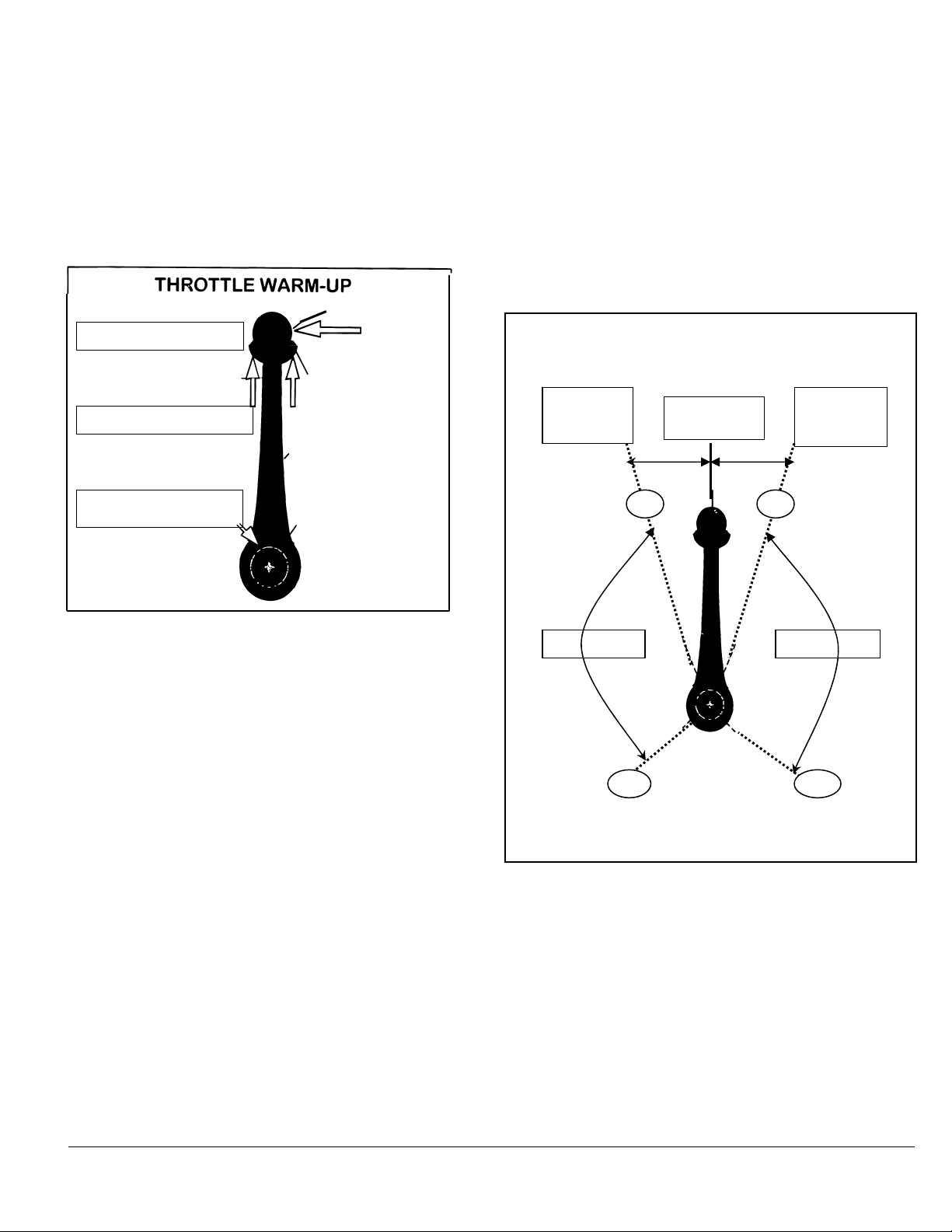

SHIFTING THE CONTROL

To shift the control into forward or reverse, pull the umbrella up

toward the knob and advance the handle forward (for forward

travel) or rearward (for reverse travel) until the handle settles

into a detent at approximately 30○of travel (see Figure 8). At

this point, the control has engaged the gear and automatically

entered the throttle mode where further advancement of the

handle will increase the throttle. Once in the throttle mode, it is

no longer necessary to pull on the umbrella. Increase or

decrease throttle by simply moving the handle.

1. PUSH (AND HOLD)

BUTTON IN

2. PULL UMBRELLA UP

3. ADVANCE HANDLE

UMBRELLA

STEM

BUTTON

SHIFTING

FORWARD

SHIFT

POSITION

FIGURE 8

REVERSE

SHIFT

POSITION

NEUTRAL

POSITION

OPERATION OF CONTROL

THROTTLE WARM-UP IN NEUTRAL POSITION

To start the boat's engine and to activate the throttle for engine

warm-up, the handle must be in the neutral position. Neutral

can be found by rotating the handle (by grasping the knob or

stem) until the handle locks in position and can not be rotated

in either direction. Usually the handle is vertical as shown in

Figure 7 when in the neutral position.

FIGURE 7

Push in the button with your left hand while grasping the

umbrella and knob with your right hand and pull the umbrella

up toward the knob (see Figure 7). While still holding the

button and umbrella, advance the handle forward to put the

control in warm-up throttle mode. Once in this mode, the

button and umbrella can be released and throttle can be

adjusted by simply moving the control handle away from the

neutral position to increase throttle and towards the neutral

position to decrease throttle. Returning the handle to the

neutral position will disengage throttle warm-up.

THROTTLE THROTTLE

300

300

Table of contents

Other Teleflex Marine Marine Equipment manuals